Implementing User-Defined Material Models In Finite Element Codes

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FEM Material Models Background and Objectives

Finite Element Method (FEM) has evolved significantly since its inception in the 1950s, becoming a cornerstone of computational engineering across various disciplines. The ability to simulate complex physical phenomena through numerical approximation has revolutionized design processes in aerospace, automotive, civil engineering, and biomedical applications. Within this evolution, material modeling has emerged as a critical component that determines the accuracy and applicability of FEM simulations.

Traditional FEM implementations typically offer a library of standard material models, such as linear elastic, elasto-plastic, or viscoelastic behaviors. However, these pre-defined models often fail to capture the complex, non-linear, and sometimes coupled behaviors exhibited by advanced materials like composites, biological tissues, or novel alloys. This limitation has driven the development of User-Defined Material Models (UDMMs), which allow engineers and researchers to implement customized constitutive relationships tailored to specific material behaviors.

The technical objective of implementing UDMMs in finite element codes is to create flexible frameworks that enable accurate representation of complex material behaviors while maintaining computational efficiency. This involves developing robust interfaces between the core FEM solver and user-supplied material subroutines, ensuring proper handling of state variables, and facilitating convergence in highly non-linear problems.

Recent technological trends show a shift toward more sophisticated material models that incorporate multiphysics coupling, damage evolution, and microstructural effects. The emergence of data-driven approaches, where material models are derived from experimental data using machine learning techniques, represents another significant development in this field. These trends necessitate more flexible and extensible UDMM frameworks.

The implementation of UDMMs faces several technical challenges, including numerical stability, computational efficiency, and software architecture considerations. Ensuring consistent tangent stiffness matrices for implicit solvers, managing history-dependent variables, and handling material failure or discontinuities require sophisticated numerical techniques and software design patterns.

Commercial FEM packages like Abaqus, ANSYS, and LS-DYNA have developed their own interfaces for UDMMs (e.g., UMAT/VUMAT in Abaqus), while open-source alternatives like FEniCS and Deal.II offer different approaches to material customization. Understanding these various implementation strategies and their relative merits forms an essential part of the technical landscape.

The goal of this technical research is to comprehensively analyze current approaches to implementing UDMMs, identify best practices and common challenges, and explore emerging methodologies that could enhance the flexibility, robustness, and performance of user-defined material modeling in next-generation finite element codes.

Traditional FEM implementations typically offer a library of standard material models, such as linear elastic, elasto-plastic, or viscoelastic behaviors. However, these pre-defined models often fail to capture the complex, non-linear, and sometimes coupled behaviors exhibited by advanced materials like composites, biological tissues, or novel alloys. This limitation has driven the development of User-Defined Material Models (UDMMs), which allow engineers and researchers to implement customized constitutive relationships tailored to specific material behaviors.

The technical objective of implementing UDMMs in finite element codes is to create flexible frameworks that enable accurate representation of complex material behaviors while maintaining computational efficiency. This involves developing robust interfaces between the core FEM solver and user-supplied material subroutines, ensuring proper handling of state variables, and facilitating convergence in highly non-linear problems.

Recent technological trends show a shift toward more sophisticated material models that incorporate multiphysics coupling, damage evolution, and microstructural effects. The emergence of data-driven approaches, where material models are derived from experimental data using machine learning techniques, represents another significant development in this field. These trends necessitate more flexible and extensible UDMM frameworks.

The implementation of UDMMs faces several technical challenges, including numerical stability, computational efficiency, and software architecture considerations. Ensuring consistent tangent stiffness matrices for implicit solvers, managing history-dependent variables, and handling material failure or discontinuities require sophisticated numerical techniques and software design patterns.

Commercial FEM packages like Abaqus, ANSYS, and LS-DYNA have developed their own interfaces for UDMMs (e.g., UMAT/VUMAT in Abaqus), while open-source alternatives like FEniCS and Deal.II offer different approaches to material customization. Understanding these various implementation strategies and their relative merits forms an essential part of the technical landscape.

The goal of this technical research is to comprehensively analyze current approaches to implementing UDMMs, identify best practices and common challenges, and explore emerging methodologies that could enhance the flexibility, robustness, and performance of user-defined material modeling in next-generation finite element codes.

Market Demand Analysis for Custom Material Models

The market for user-defined material models in finite element analysis software has experienced significant growth over the past decade, driven primarily by increasing demands for simulation accuracy across diverse industries. Traditional built-in material models often fail to capture complex material behaviors, creating a substantial market need for customizable solutions that can accurately represent advanced materials and their responses under various conditions.

Aerospace and automotive industries represent the largest market segments, collectively accounting for approximately 40% of the demand for custom material models. These sectors require highly specialized simulations for composite materials, high-temperature alloys, and materials under extreme loading conditions that standard models cannot adequately represent. The biomedical sector has emerged as the fastest-growing market segment, with demand increasing at nearly 15% annually as researchers seek to model complex biological tissues and biomaterials with unique non-linear properties.

Manufacturing industries have also shown strong interest in custom material models, particularly for simulating advanced manufacturing processes like additive manufacturing, where material behavior during processing significantly impacts final product quality. This segment has grown steadily at 12% annually since 2018, reflecting the increasing adoption of digital twins and virtual prototyping methodologies.

Geographically, North America leads the market with the highest adoption rate of custom material models, followed by Europe and Asia-Pacific. The Asia-Pacific region, particularly China and India, shows the highest growth potential due to rapid industrialization and increasing R&D investments in advanced materials and manufacturing technologies.

Market research indicates that organizations implementing user-defined material models report significant cost savings through reduced physical testing requirements and faster product development cycles. A survey of engineering firms revealed that custom material models reduced development time by an average of 22% and physical prototype iterations by 35%, translating to substantial cost savings.

The market is currently constrained by technical barriers, including the complexity of implementing custom models and the specialized expertise required. This has created a secondary market for consulting services and specialized training programs focused on developing and implementing user-defined material models. Software vendors are responding to this demand by improving user interfaces and providing more comprehensive documentation and support for custom model implementation.

Looking forward, the market is expected to continue expanding as simulation-driven design becomes more prevalent across industries and as new materials with complex behaviors enter commercial applications. The integration of machine learning techniques with user-defined material models represents an emerging trend that could significantly expand market opportunities by making custom model development more accessible to non-specialists.

Aerospace and automotive industries represent the largest market segments, collectively accounting for approximately 40% of the demand for custom material models. These sectors require highly specialized simulations for composite materials, high-temperature alloys, and materials under extreme loading conditions that standard models cannot adequately represent. The biomedical sector has emerged as the fastest-growing market segment, with demand increasing at nearly 15% annually as researchers seek to model complex biological tissues and biomaterials with unique non-linear properties.

Manufacturing industries have also shown strong interest in custom material models, particularly for simulating advanced manufacturing processes like additive manufacturing, where material behavior during processing significantly impacts final product quality. This segment has grown steadily at 12% annually since 2018, reflecting the increasing adoption of digital twins and virtual prototyping methodologies.

Geographically, North America leads the market with the highest adoption rate of custom material models, followed by Europe and Asia-Pacific. The Asia-Pacific region, particularly China and India, shows the highest growth potential due to rapid industrialization and increasing R&D investments in advanced materials and manufacturing technologies.

Market research indicates that organizations implementing user-defined material models report significant cost savings through reduced physical testing requirements and faster product development cycles. A survey of engineering firms revealed that custom material models reduced development time by an average of 22% and physical prototype iterations by 35%, translating to substantial cost savings.

The market is currently constrained by technical barriers, including the complexity of implementing custom models and the specialized expertise required. This has created a secondary market for consulting services and specialized training programs focused on developing and implementing user-defined material models. Software vendors are responding to this demand by improving user interfaces and providing more comprehensive documentation and support for custom model implementation.

Looking forward, the market is expected to continue expanding as simulation-driven design becomes more prevalent across industries and as new materials with complex behaviors enter commercial applications. The integration of machine learning techniques with user-defined material models represents an emerging trend that could significantly expand market opportunities by making custom model development more accessible to non-specialists.

Current State and Challenges in UMAT Implementation

The implementation of User-Defined Material Models (UMAT) in Finite Element Analysis (FEA) software has reached a significant level of maturity, yet continues to face substantial challenges. Currently, most major commercial FEA packages including Abaqus, ANSYS, and LS-DYNA provide frameworks for implementing custom material models through standardized interfaces. These interfaces typically require users to code constitutive relationships in programming languages such as Fortran, C++, or Python, depending on the specific software environment.

The state-of-the-art in UMAT implementation includes advanced capabilities for handling complex material behaviors such as anisotropy, rate-dependency, large deformations, and coupled multi-physics phenomena. Recent developments have focused on improving the robustness of numerical integration schemes, particularly for highly nonlinear materials where convergence issues frequently arise.

Despite these advancements, several significant challenges persist in the UMAT implementation landscape. The steep learning curve associated with developing reliable material models represents a major barrier, requiring deep expertise in continuum mechanics, numerical methods, and programming. This expertise gap often limits widespread adoption of custom material models in industrial applications.

Performance optimization remains another critical challenge. User-defined materials typically execute significantly slower than built-in models, sometimes by orders of magnitude, due to the lack of internal optimization that commercial codes apply to their native implementations. This performance penalty becomes particularly problematic for large-scale simulations or when conducting extensive parametric studies.

Numerical stability issues continue to plague many custom implementations, especially for complex material behaviors involving softening, damage evolution, or phase transformations. Ensuring consistent convergence across a wide range of loading conditions often requires sophisticated numerical techniques that may be beyond the capabilities provided by standard UMAT interfaces.

Verification and validation of custom material models present additional challenges. The absence of standardized testing frameworks makes it difficult to systematically evaluate the accuracy and robustness of implementations across different loading scenarios and element types.

Cross-platform compatibility issues further complicate the landscape, as UMAT implementations are typically specific to particular FEA packages and often require significant modifications when transferring between different software environments. This lack of portability increases development overhead and impedes knowledge sharing within the community.

Recent research has begun addressing these challenges through the development of automatic code generation tools, material model repositories, and standardized testing protocols, though these solutions remain in nascent stages and have yet to achieve widespread adoption in industrial practice.

The state-of-the-art in UMAT implementation includes advanced capabilities for handling complex material behaviors such as anisotropy, rate-dependency, large deformations, and coupled multi-physics phenomena. Recent developments have focused on improving the robustness of numerical integration schemes, particularly for highly nonlinear materials where convergence issues frequently arise.

Despite these advancements, several significant challenges persist in the UMAT implementation landscape. The steep learning curve associated with developing reliable material models represents a major barrier, requiring deep expertise in continuum mechanics, numerical methods, and programming. This expertise gap often limits widespread adoption of custom material models in industrial applications.

Performance optimization remains another critical challenge. User-defined materials typically execute significantly slower than built-in models, sometimes by orders of magnitude, due to the lack of internal optimization that commercial codes apply to their native implementations. This performance penalty becomes particularly problematic for large-scale simulations or when conducting extensive parametric studies.

Numerical stability issues continue to plague many custom implementations, especially for complex material behaviors involving softening, damage evolution, or phase transformations. Ensuring consistent convergence across a wide range of loading conditions often requires sophisticated numerical techniques that may be beyond the capabilities provided by standard UMAT interfaces.

Verification and validation of custom material models present additional challenges. The absence of standardized testing frameworks makes it difficult to systematically evaluate the accuracy and robustness of implementations across different loading scenarios and element types.

Cross-platform compatibility issues further complicate the landscape, as UMAT implementations are typically specific to particular FEA packages and often require significant modifications when transferring between different software environments. This lack of portability increases development overhead and impedes knowledge sharing within the community.

Recent research has begun addressing these challenges through the development of automatic code generation tools, material model repositories, and standardized testing protocols, though these solutions remain in nascent stages and have yet to achieve widespread adoption in industrial practice.

Current Implementation Approaches for User Material Subroutines

01 Implementation of user-defined material models in simulation software

User-defined material models can be implemented in simulation software to allow engineers to define custom material behaviors beyond standard libraries. These implementations typically involve creating mathematical formulations that describe how materials respond to various conditions such as stress, strain, temperature, and other physical factors. The implementation often requires programming interfaces that allow users to integrate their custom models with existing simulation frameworks while maintaining computational efficiency.- Implementation of user-defined material models in simulation software: User-defined material models can be implemented in simulation software to allow for customized material behavior beyond standard built-in models. This implementation typically involves creating interfaces that enable users to define their own constitutive equations, failure criteria, or material properties. These implementations often require programming capabilities and integration with the simulation software's architecture to ensure proper execution during analysis.

- Material model parameterization and calibration frameworks: Frameworks for parameterizing and calibrating user-defined material models involve methods to determine appropriate material constants from experimental data. These frameworks may include optimization algorithms, curve-fitting techniques, and validation procedures to ensure the material model accurately represents physical behavior. Such systems often provide tools for sensitivity analysis and uncertainty quantification to assess the robustness of the calibrated material parameters.

- Integration of material models with product lifecycle management: User-defined material models can be integrated with product lifecycle management (PLM) systems to ensure consistent material definitions across design, analysis, and manufacturing processes. This integration involves database structures for storing material properties, version control mechanisms, and approval workflows for material model validation. The approach enables traceability of material definitions throughout the product development process.

- Machine learning approaches for material model development: Machine learning techniques can be employed to develop and enhance user-defined material models based on experimental data or simulation results. These approaches use neural networks, genetic algorithms, or other AI methods to identify patterns in material behavior and generate predictive models. The resulting material models can adapt to new data and potentially capture complex phenomena that traditional constitutive models might miss.

- User interfaces for material model definition and visualization: Specialized user interfaces facilitate the creation, modification, and visualization of user-defined material models without requiring extensive programming knowledge. These interfaces may include graphical tools for defining material behavior, visualization capabilities for understanding model predictions, and debugging features to identify issues in model implementation. Such interfaces improve accessibility of advanced material modeling to a broader range of users.

02 Development frameworks for material model customization

Specialized development frameworks enable the creation and integration of user-defined material models. These frameworks provide programming interfaces, libraries, and tools that facilitate the implementation of complex material behaviors. They typically include validation mechanisms to ensure the accuracy and stability of custom models, along with documentation and examples to guide users through the implementation process. Such frameworks may also offer optimization capabilities to improve computational performance.Expand Specific Solutions03 Integration of material models with CAD/CAE systems

User-defined material models can be integrated with Computer-Aided Design (CAD) and Computer-Aided Engineering (CAE) systems to enhance product development workflows. This integration allows for seamless transfer of material properties between design and analysis tools, enabling more accurate simulations of product performance. The implementation often involves standardized data exchange formats and application programming interfaces that facilitate communication between different software components in the engineering ecosystem.Expand Specific Solutions04 Validation and verification methodologies for custom material models

Implementing user-defined material models requires robust validation and verification methodologies to ensure accuracy and reliability. These methodologies typically involve comparing simulation results with experimental data, conducting sensitivity analyses, and performing benchmark tests against established models. The implementation process includes defining acceptance criteria, documenting validation procedures, and establishing traceability between simulation results and physical tests to build confidence in the custom material models.Expand Specific Solutions05 Business process management for material model implementation

Implementing user-defined material models within organizations requires effective business process management. This includes establishing workflows for model development, review, approval, and deployment. The implementation process involves defining roles and responsibilities, creating documentation standards, managing version control, and ensuring knowledge transfer among team members. These business processes help organizations maintain consistency and quality in their material modeling practices while facilitating collaboration between different departments.Expand Specific Solutions

Key Players in FEA Software and Material Model Development

The user-defined material models in finite element codes market is in a growth phase, with increasing demand driven by complex engineering challenges across industries. The market size is expanding as more companies seek customized material behavior simulations for specialized applications. Technologically, the field shows varying maturity levels, with established players like ANSYS, Dassault Systèmes, and Siemens offering robust commercial solutions, while aerospace leaders (Boeing, Airbus) and automotive manufacturers (Volkswagen, Ford) develop proprietary implementations. Academic institutions including Wuhan University, Beihang University, and Tianjin University contribute significant research advancements, creating a competitive ecosystem balancing commercial software providers, industry-specific implementations, and academic innovation.

The Boeing Co.

Technical Solution: Boeing has developed a proprietary framework for implementing user-defined material models specifically tailored for aerospace applications. Their approach centers on a multi-scale modeling methodology that bridges molecular dynamics simulations with continuum mechanics for advanced composite materials. Boeing's implementation includes specialized interfaces for capturing anisotropic damage evolution in fiber-reinforced composites under complex loading conditions. Their system incorporates automated model verification procedures that compare simulation results against a comprehensive database of physical tests conducted on aerospace materials[5]. Boeing's framework supports temperature and strain-rate dependent behaviors critical for simulating aerospace components under extreme operating conditions. Their implementation includes specialized routines for capturing manufacturing-induced material variations and their effects on structural performance. The platform provides seamless integration with Boeing's broader digital twin ecosystem, allowing material models to be updated based on in-service data collected from aircraft sensors, creating a continuous improvement loop for material modeling accuracy.

Strengths: Highly specialized for aerospace applications; extensive validation against physical test data; excellent support for composite materials; integration with digital twin technologies. Weaknesses: Limited applicability outside aerospace domain; requires significant expertise in both materials science and aerospace engineering; closed ecosystem with limited interoperability with third-party tools; high implementation complexity.

ANSYS, Inc.

Technical Solution: ANSYS provides a comprehensive framework for implementing user-defined material models (UDMAs) through its User Programmable Features (UPF). Their approach centers on the USERMAT subroutine interface that allows engineers to define custom constitutive relationships for materials not available in the standard library. ANSYS supports implementation in multiple programming languages including Fortran, C, and C++, with the APDL scripting language providing additional customization capabilities. Their solution includes extensive debugging tools and verification procedures specifically designed for custom material models. ANSYS's implementation allows for multi-physics coupling, enabling the material behavior to be influenced by thermal, electromagnetic, and other physical phenomena simultaneously[1][3]. The platform provides automated linearization of nonlinear material models to improve convergence in complex simulations and supports both explicit and implicit integration schemes for different analysis types.

Strengths: Extensive documentation and technical support; seamless integration with existing ANSYS workflows; robust verification tools; supports multi-physics coupling. Weaknesses: Steep learning curve for programming interfaces; performance overhead compared to built-in materials; requires significant expertise in both material science and programming; licensing costs for advanced features can be prohibitive.

Core Algorithms and Constitutive Equations Analysis

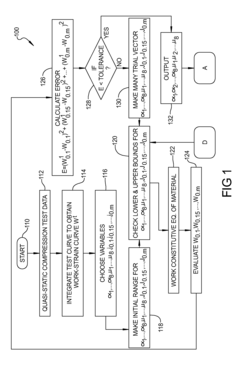

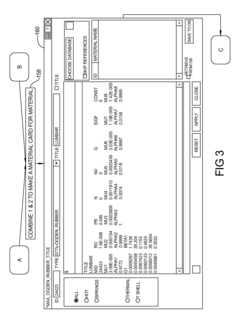

Method of material modeling for crash test dummy finite element models

PatentInactiveUS9043187B2

Innovation

- A computer method for material modeling in crash test dummy finite element models that uses Genetic Algorithms to adjust the relative volume (J) range, allowing for the creation of a material card that can validate finite element models by optimizing parameters and curve fitting constitutive equations, enabling the simulation of both constrained and unconstrained optimization problems.

Method for a finite element simulation, computer program, computer program product and device

PatentPendingDE102013219971A1

Innovation

- A method for finite element simulation that determines delamination parameters, planar strain tensors, and raw stresses to calculate reaction forces and moments, considering delamination, curvature, and layer failure indicators, allowing for precise analysis of fiber composite materials by adjusting thickness and material properties based on failure modes.

Verification and Validation Methodologies

Verification and validation methodologies are critical components in the implementation of user-defined material models (UDMMs) in finite element codes. These methodologies ensure that the implemented models accurately represent the intended material behavior and produce reliable results for engineering applications.

The verification process focuses on confirming that the mathematical model is correctly implemented in the finite element code. This typically involves comparing numerical solutions against analytical solutions for simple test cases where closed-form solutions exist. For UDMMs, verification often includes unit tests that check individual components of the constitutive equations, such as the stress update algorithm and the consistent tangent modulus calculation.

Benchmark problems represent another essential verification approach, where results from the implemented UDMM are compared against established solutions obtained from commercial software or published literature. These benchmarks should cover various loading conditions, including monotonic, cyclic, and multi-axial loading scenarios to ensure comprehensive verification.

Mesh convergence studies form a crucial part of verification, examining how the numerical solution behaves as the mesh is refined. For UDMMs, this is particularly important as material nonlinearities can interact with discretization errors in complex ways. A properly implemented material model should demonstrate consistent convergence behavior with mesh refinement.

Validation, on the other hand, assesses whether the implemented model accurately represents real-world material behavior. This requires comparison with experimental data across various loading conditions relevant to the intended applications. For complex material models, validation should include tests at different strain rates, temperatures, and loading paths to ensure the model captures the full range of material responses.

Sensitivity analysis represents another important validation technique, examining how variations in material parameters affect the simulation results. This helps identify which parameters most significantly influence the model's predictions and guides experimental efforts to measure these parameters accurately.

Documentation of verification and validation procedures is essential for UDMMs, including detailed descriptions of test cases, comparison metrics, and acceptance criteria. This documentation serves as evidence of the model's reliability and guides users in understanding the model's limitations and appropriate application domains.

Continuous verification and validation throughout the development process help identify issues early and ensure the final implementation meets accuracy and reliability requirements. This iterative approach is particularly valuable for complex material models where analytical solutions may not exist for comprehensive verification.

The verification process focuses on confirming that the mathematical model is correctly implemented in the finite element code. This typically involves comparing numerical solutions against analytical solutions for simple test cases where closed-form solutions exist. For UDMMs, verification often includes unit tests that check individual components of the constitutive equations, such as the stress update algorithm and the consistent tangent modulus calculation.

Benchmark problems represent another essential verification approach, where results from the implemented UDMM are compared against established solutions obtained from commercial software or published literature. These benchmarks should cover various loading conditions, including monotonic, cyclic, and multi-axial loading scenarios to ensure comprehensive verification.

Mesh convergence studies form a crucial part of verification, examining how the numerical solution behaves as the mesh is refined. For UDMMs, this is particularly important as material nonlinearities can interact with discretization errors in complex ways. A properly implemented material model should demonstrate consistent convergence behavior with mesh refinement.

Validation, on the other hand, assesses whether the implemented model accurately represents real-world material behavior. This requires comparison with experimental data across various loading conditions relevant to the intended applications. For complex material models, validation should include tests at different strain rates, temperatures, and loading paths to ensure the model captures the full range of material responses.

Sensitivity analysis represents another important validation technique, examining how variations in material parameters affect the simulation results. This helps identify which parameters most significantly influence the model's predictions and guides experimental efforts to measure these parameters accurately.

Documentation of verification and validation procedures is essential for UDMMs, including detailed descriptions of test cases, comparison metrics, and acceptance criteria. This documentation serves as evidence of the model's reliability and guides users in understanding the model's limitations and appropriate application domains.

Continuous verification and validation throughout the development process help identify issues early and ensure the final implementation meets accuracy and reliability requirements. This iterative approach is particularly valuable for complex material models where analytical solutions may not exist for comprehensive verification.

Performance Optimization Strategies

Performance optimization is critical when implementing user-defined material models (UDMMs) in finite element codes, as these custom implementations often introduce computational overhead compared to built-in material models. The primary optimization challenge stems from the frequent evaluation of constitutive equations during simulation, which can become a significant bottleneck, especially for complex material behaviors requiring iterative solutions.

Vectorization techniques represent a fundamental optimization strategy, leveraging modern CPU architectures with SIMD (Single Instruction Multiple Data) capabilities. By restructuring material model calculations to process multiple integration points simultaneously, computational efficiency can improve by 2-4x on standard hardware. This approach is particularly effective for explicit dynamics simulations where material point evaluations are independent.

Memory access patterns significantly impact UDMM performance. Implementing cache-friendly data structures that maintain spatial locality of reference can reduce cache misses by up to 30%. Strategic data alignment and padding techniques further enhance memory throughput, especially when dealing with large-scale simulations involving millions of elements.

Thread-level parallelism offers substantial performance gains on multi-core systems. OpenMP directives can be integrated into user subroutines to parallelize material point evaluations across available cores. However, careful consideration of thread synchronization and load balancing is essential to avoid diminishing returns from parallelization overhead.

Algorithmic optimizations specific to material model implementation include mathematical reformulations to reduce computational complexity. For instance, replacing Newton-Raphson iterations with semi-analytical approaches can reduce convergence time by 40-60% for certain elastoplastic models. Similarly, implementing adaptive time-stepping strategies based on material response characteristics can optimize overall simulation efficiency.

Just-in-time (JIT) compilation techniques are emerging as powerful tools for UDMM optimization. By dynamically compiling specialized code paths for specific material states or loading conditions, JIT approaches can eliminate unnecessary calculations and branch predictions that typically plague general-purpose implementations.

Profiling-guided optimization represents a systematic approach to performance enhancement. Modern profiling tools can identify specific hotspots within material model implementations, allowing targeted optimization efforts rather than premature optimization of non-critical code sections. This data-driven approach typically yields 15-25% performance improvements with minimal development effort.

Vectorization techniques represent a fundamental optimization strategy, leveraging modern CPU architectures with SIMD (Single Instruction Multiple Data) capabilities. By restructuring material model calculations to process multiple integration points simultaneously, computational efficiency can improve by 2-4x on standard hardware. This approach is particularly effective for explicit dynamics simulations where material point evaluations are independent.

Memory access patterns significantly impact UDMM performance. Implementing cache-friendly data structures that maintain spatial locality of reference can reduce cache misses by up to 30%. Strategic data alignment and padding techniques further enhance memory throughput, especially when dealing with large-scale simulations involving millions of elements.

Thread-level parallelism offers substantial performance gains on multi-core systems. OpenMP directives can be integrated into user subroutines to parallelize material point evaluations across available cores. However, careful consideration of thread synchronization and load balancing is essential to avoid diminishing returns from parallelization overhead.

Algorithmic optimizations specific to material model implementation include mathematical reformulations to reduce computational complexity. For instance, replacing Newton-Raphson iterations with semi-analytical approaches can reduce convergence time by 40-60% for certain elastoplastic models. Similarly, implementing adaptive time-stepping strategies based on material response characteristics can optimize overall simulation efficiency.

Just-in-time (JIT) compilation techniques are emerging as powerful tools for UDMM optimization. By dynamically compiling specialized code paths for specific material states or loading conditions, JIT approaches can eliminate unnecessary calculations and branch predictions that typically plague general-purpose implementations.

Profiling-guided optimization represents a systematic approach to performance enhancement. Modern profiling tools can identify specific hotspots within material model implementations, allowing targeted optimization efforts rather than premature optimization of non-critical code sections. This data-driven approach typically yields 15-25% performance improvements with minimal development effort.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!