Finite Element-Based Topology Optimization For Structural Lightweighting

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary approach in structural design, evolving from theoretical concepts in the 1980s to a practical engineering methodology widely adopted across industries today. This mathematical method determines the optimal material distribution within a design space, subject to specified constraints and loading conditions, to achieve maximum performance objectives such as stiffness or minimum weight. The fundamental principle involves removing material from low-stress regions while maintaining structural integrity, resulting in organic, often bionic-inspired structures that would be difficult to conceive through traditional design methods.

The evolution of topology optimization has been closely tied to advancements in computational capabilities and finite element analysis (FEA). Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. The seminal SIMP (Solid Isotropic Material with Penalization) method introduced by Bendsøe and Sigmund revolutionized the field by providing a practical framework for material distribution optimization.

Recent technological developments have significantly expanded the application scope of topology optimization. Integration with additive manufacturing has been particularly transformative, as 3D printing can produce the complex geometries that topology optimization often generates. This synergy has accelerated adoption across aerospace, automotive, and medical device industries, where weight reduction directly translates to performance improvements and cost savings.

The primary objective of topology optimization in structural lightweighting is to achieve maximum performance-to-weight ratios while maintaining or enhancing functional requirements. This includes minimizing material usage, reducing production costs, improving energy efficiency, and extending product lifespan. For transportation industries, weight reduction directly correlates with fuel efficiency and emissions reduction, aligning with global sustainability goals.

Secondary objectives often include optimizing thermal management, vibration characteristics, and manufacturability. Modern topology optimization algorithms increasingly incorporate these multi-objective considerations, allowing designers to balance competing requirements within a single optimization framework.

Looking forward, topology optimization aims to overcome current limitations in computational efficiency, manufacturing constraints interpretation, and material property considerations. The integration of machine learning approaches with traditional optimization algorithms represents a promising direction, potentially enabling real-time optimization of complex structures and more effective navigation of the design space.

The evolution of topology optimization has been closely tied to advancements in computational capabilities and finite element analysis (FEA). Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. The seminal SIMP (Solid Isotropic Material with Penalization) method introduced by Bendsøe and Sigmund revolutionized the field by providing a practical framework for material distribution optimization.

Recent technological developments have significantly expanded the application scope of topology optimization. Integration with additive manufacturing has been particularly transformative, as 3D printing can produce the complex geometries that topology optimization often generates. This synergy has accelerated adoption across aerospace, automotive, and medical device industries, where weight reduction directly translates to performance improvements and cost savings.

The primary objective of topology optimization in structural lightweighting is to achieve maximum performance-to-weight ratios while maintaining or enhancing functional requirements. This includes minimizing material usage, reducing production costs, improving energy efficiency, and extending product lifespan. For transportation industries, weight reduction directly correlates with fuel efficiency and emissions reduction, aligning with global sustainability goals.

Secondary objectives often include optimizing thermal management, vibration characteristics, and manufacturability. Modern topology optimization algorithms increasingly incorporate these multi-objective considerations, allowing designers to balance competing requirements within a single optimization framework.

Looking forward, topology optimization aims to overcome current limitations in computational efficiency, manufacturing constraints interpretation, and material property considerations. The integration of machine learning approaches with traditional optimization algorithms represents a promising direction, potentially enabling real-time optimization of complex structures and more effective navigation of the design space.

Market Demand for Structural Lightweighting Solutions

The global market for structural lightweighting solutions has experienced significant growth in recent years, driven primarily by increasing regulatory pressures on emissions reduction and energy efficiency across multiple industries. The automotive sector represents the largest market segment, with stringent fuel economy standards in Europe, North America, and Asia compelling manufacturers to reduce vehicle weight substantially. According to industry reports, a 10% reduction in vehicle weight can improve fuel efficiency by approximately 6-8%, making lightweight structural optimization a critical competitive advantage.

Aerospace applications form the second-largest market segment, where weight reduction directly translates to fuel savings, increased payload capacity, and extended range. Major aircraft manufacturers have committed to ambitious weight reduction targets for next-generation aircraft designs, creating sustained demand for advanced topology optimization techniques that can deliver maximum structural integrity with minimal material usage.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a rapidly growing market for structural lightweighting. Larger turbine blades require sophisticated optimization to balance structural requirements against weight constraints, with manufacturers seeking solutions that can optimize complex composite structures while maintaining necessary stiffness and fatigue resistance properties.

Consumer electronics and medical device industries represent expanding niche markets, where miniaturization trends drive demand for optimized structural components that maintain functionality while reducing material usage. The growing adoption of additive manufacturing technologies across these sectors has further accelerated interest in topology optimization, as these production methods can realize complex geometries that were previously unfeasible with traditional manufacturing processes.

Market analysis indicates that the global structural optimization software market is growing at a compound annual rate exceeding 15%, with finite element-based topology optimization tools representing the fastest-growing segment. This growth reflects the increasing recognition of topology optimization as an essential capability for competitive product development across industries.

Regional market distribution shows North America and Europe currently leading in adoption rates, though Asia-Pacific markets are experiencing the fastest growth, particularly in China, Japan, and South Korea. This regional growth is closely aligned with government initiatives promoting advanced manufacturing capabilities and sustainability goals in these countries.

Customer requirements are evolving beyond simple weight reduction to encompass multi-objective optimization capabilities that simultaneously address thermal management, vibration characteristics, and manufacturing constraints. This trend is driving demand for more sophisticated topology optimization algorithms that can handle these complex, multi-physics optimization scenarios while remaining accessible to design engineers without specialized optimization expertise.

Aerospace applications form the second-largest market segment, where weight reduction directly translates to fuel savings, increased payload capacity, and extended range. Major aircraft manufacturers have committed to ambitious weight reduction targets for next-generation aircraft designs, creating sustained demand for advanced topology optimization techniques that can deliver maximum structural integrity with minimal material usage.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a rapidly growing market for structural lightweighting. Larger turbine blades require sophisticated optimization to balance structural requirements against weight constraints, with manufacturers seeking solutions that can optimize complex composite structures while maintaining necessary stiffness and fatigue resistance properties.

Consumer electronics and medical device industries represent expanding niche markets, where miniaturization trends drive demand for optimized structural components that maintain functionality while reducing material usage. The growing adoption of additive manufacturing technologies across these sectors has further accelerated interest in topology optimization, as these production methods can realize complex geometries that were previously unfeasible with traditional manufacturing processes.

Market analysis indicates that the global structural optimization software market is growing at a compound annual rate exceeding 15%, with finite element-based topology optimization tools representing the fastest-growing segment. This growth reflects the increasing recognition of topology optimization as an essential capability for competitive product development across industries.

Regional market distribution shows North America and Europe currently leading in adoption rates, though Asia-Pacific markets are experiencing the fastest growth, particularly in China, Japan, and South Korea. This regional growth is closely aligned with government initiatives promoting advanced manufacturing capabilities and sustainability goals in these countries.

Customer requirements are evolving beyond simple weight reduction to encompass multi-objective optimization capabilities that simultaneously address thermal management, vibration characteristics, and manufacturing constraints. This trend is driving demand for more sophisticated topology optimization algorithms that can handle these complex, multi-physics optimization scenarios while remaining accessible to design engineers without specialized optimization expertise.

Current FE-Based Topology Optimization Challenges

Despite significant advancements in Finite Element-Based Topology Optimization (FE-TO) for structural lightweighting, several critical challenges persist that limit its broader industrial application. Computational efficiency remains a primary concern, as high-resolution optimization problems often require substantial computational resources and time, particularly for complex 3D structures with multiple load cases. Many industrial applications demand solutions within hours, yet current methods may require days or weeks for convergence on detailed models.

Manufacturing constraints present another significant hurdle. While topology optimization algorithms can generate theoretically optimal designs, these often include complex geometries that are difficult or impossible to manufacture using conventional methods. The integration of manufacturing constraints (such as minimum feature size, overhang angle limitations for additive manufacturing, or draft angle requirements for casting) into the optimization process remains challenging and often leads to sub-optimal compromises.

Multi-physics considerations further complicate the optimization process. Real-world structures rarely operate under purely mechanical loads; they often experience thermal, fluid, electromagnetic, or coupled multi-physics conditions. Current FE-TO methods struggle to efficiently incorporate these diverse physics domains simultaneously, leading to potentially suboptimal designs when considering the complete operating environment.

Material nonlinearity and anisotropy represent additional technical barriers. Most commercial topology optimization tools assume linear elastic material behavior, yet many lightweight materials exhibit nonlinear responses or directional properties. Incorporating these complex material models into the optimization framework significantly increases computational complexity and may lead to convergence issues.

Uncertainty quantification and robust design optimization remain underdeveloped in the FE-TO domain. Real-world applications involve uncertainties in loading conditions, material properties, and manufacturing processes. Current methods typically optimize for deterministic scenarios, potentially leading to designs that perform poorly under variable conditions.

Verification and validation methodologies for topology-optimized structures are not yet standardized. The complex geometries resulting from topology optimization often make experimental validation challenging, and numerical verification may be complicated by mesh dependencies and numerical artifacts.

Integration with existing CAD/CAM workflows presents practical implementation challenges. The organic, mesh-based geometries produced by topology optimization algorithms often require significant post-processing before they can be incorporated into traditional CAD systems or manufacturing processes, creating a bottleneck in the design-to-manufacturing pipeline.

Manufacturing constraints present another significant hurdle. While topology optimization algorithms can generate theoretically optimal designs, these often include complex geometries that are difficult or impossible to manufacture using conventional methods. The integration of manufacturing constraints (such as minimum feature size, overhang angle limitations for additive manufacturing, or draft angle requirements for casting) into the optimization process remains challenging and often leads to sub-optimal compromises.

Multi-physics considerations further complicate the optimization process. Real-world structures rarely operate under purely mechanical loads; they often experience thermal, fluid, electromagnetic, or coupled multi-physics conditions. Current FE-TO methods struggle to efficiently incorporate these diverse physics domains simultaneously, leading to potentially suboptimal designs when considering the complete operating environment.

Material nonlinearity and anisotropy represent additional technical barriers. Most commercial topology optimization tools assume linear elastic material behavior, yet many lightweight materials exhibit nonlinear responses or directional properties. Incorporating these complex material models into the optimization framework significantly increases computational complexity and may lead to convergence issues.

Uncertainty quantification and robust design optimization remain underdeveloped in the FE-TO domain. Real-world applications involve uncertainties in loading conditions, material properties, and manufacturing processes. Current methods typically optimize for deterministic scenarios, potentially leading to designs that perform poorly under variable conditions.

Verification and validation methodologies for topology-optimized structures are not yet standardized. The complex geometries resulting from topology optimization often make experimental validation challenging, and numerical verification may be complicated by mesh dependencies and numerical artifacts.

Integration with existing CAD/CAM workflows presents practical implementation challenges. The organic, mesh-based geometries produced by topology optimization algorithms often require significant post-processing before they can be incorporated into traditional CAD systems or manufacturing processes, creating a bottleneck in the design-to-manufacturing pipeline.

State-of-the-Art FE-Based Optimization Approaches

01 Topology optimization algorithms for structural lightweighting

Various algorithms are employed in topology optimization to achieve structural lightweighting while maintaining performance requirements. These methods include density-based approaches, level set methods, and evolutionary structural optimization techniques that iteratively remove inefficient material from a design space. The optimization process typically involves defining design variables, constraints, and objective functions to minimize mass while meeting structural performance criteria such as stiffness and strength.- Topology optimization algorithms for structural lightweighting: Various algorithms are employed in topology optimization to achieve structural lightweighting while maintaining mechanical performance. These methods include density-based approaches, level set methods, and evolutionary structural optimization techniques. The algorithms iteratively redistribute material within a design space to minimize weight while satisfying constraints such as stress limits, displacement boundaries, and manufacturing requirements. These computational methods enable engineers to identify optimal material layouts that reduce weight without compromising structural integrity.

- Multi-objective optimization for lightweight structures: Multi-objective optimization frameworks allow engineers to balance competing design goals in structural lightweighting applications. These approaches simultaneously consider multiple performance criteria such as weight reduction, stiffness maximization, stress minimization, and manufacturing constraints. By employing Pareto optimization techniques, designers can evaluate trade-offs between different objectives and select solutions that best meet project requirements. This approach is particularly valuable in industries like automotive and aerospace where both weight reduction and structural performance are critical.

- Integration of manufacturing constraints in topology optimization: Incorporating manufacturing constraints directly into the topology optimization process ensures that lightweight designs can be practically produced. These constraints include minimum feature size, symmetry requirements, extrusion directions, and additive manufacturing considerations. By embedding these constraints within the optimization algorithm, the resulting designs require fewer modifications before production, maintaining the intended weight reduction benefits. This approach bridges the gap between theoretical optimization and practical manufacturing, enabling more efficient implementation of lightweight structures.

- Lattice and cellular structure optimization: Lattice and cellular structures represent an advanced approach to structural lightweighting through topology optimization. These structures feature repeating geometric patterns or cells that provide excellent strength-to-weight ratios. Optimization algorithms can determine the ideal cell type, size, orientation, and density distribution throughout a component. This approach is particularly effective with additive manufacturing technologies, allowing for complex internal geometries that would be impossible with traditional manufacturing methods. The resulting structures can achieve significant weight reduction while maintaining or even improving mechanical performance.

- Industry-specific applications of topology optimization: Topology optimization techniques for structural lightweighting have been adapted to meet the specific requirements of various industries. In aerospace, optimization focuses on minimizing weight while ensuring fatigue resistance and damage tolerance. Automotive applications emphasize crash performance and NVH (noise, vibration, harshness) characteristics alongside weight reduction. Medical device optimization considers biocompatibility and patient-specific geometries. Each industry application requires specialized constraints, loading conditions, and performance metrics to be incorporated into the optimization framework, resulting in lightweight designs tailored to specific operational environments.

02 Multi-objective optimization for lightweight structures

Multi-objective optimization approaches balance competing design goals in structural lightweighting applications. These methods simultaneously consider factors such as weight reduction, structural integrity, manufacturability, and cost. Advanced algorithms enable engineers to explore Pareto-optimal solutions that represent different trade-offs between objectives, allowing for informed decision-making based on specific application requirements and constraints.Expand Specific Solutions03 Integration of manufacturing constraints in topology optimization

Incorporating manufacturing constraints into topology optimization ensures that lightweight designs are actually producible. These constraints may include minimum feature size, symmetry requirements, extrusion directions, and additive manufacturing considerations. By embedding these constraints directly in the optimization process, the resulting lightweight structures can be manufactured without significant modifications that might compromise their performance benefits.Expand Specific Solutions04 Lattice and cellular structure optimization

Lattice and cellular structures offer significant weight reduction potential while maintaining mechanical performance. Finite element-based optimization methods can determine optimal lattice configurations, including cell type, size, orientation, and density distribution. These structures can be tailored to specific loading conditions, creating lightweight components with locally optimized properties that efficiently carry loads while minimizing material usage.Expand Specific Solutions05 Industry-specific applications of topology optimization

Topology optimization techniques are applied across various industries to achieve structural lightweighting. In automotive and aerospace sectors, these methods reduce component weight to improve fuel efficiency and performance. In medical device design, they create lightweight yet strong implants. Each application domain has specific requirements regarding loading conditions, material properties, and manufacturing constraints that influence the optimization approach and resulting lightweight structures.Expand Specific Solutions

Leading Companies and Research Institutions

Finite Element-Based Topology Optimization for structural lightweighting is in a growth phase, with the market expanding due to increasing demands for efficient material usage across automotive, aerospace, and manufacturing sectors. The technology has reached moderate maturity, with academic institutions like Central South University, Zhejiang University, and Northwestern Polytechnical University leading fundamental research, while companies including Dassault Systèmes, Siemens AG, and Boeing are commercializing advanced applications. Industry players are focusing on integrating topology optimization with additive manufacturing and AI to enhance computational efficiency. The competitive landscape features collaboration between academic research centers and industrial implementers, with automotive manufacturers like Volkswagen increasingly adopting these technologies to meet lightweighting requirements for electric vehicles and sustainability goals.

Dassault Systèmes SE

Technical Solution: Dassault Systèmes has integrated advanced topology optimization capabilities into their SIMULIA suite, particularly through Tosca Structure and Abaqus. Their approach combines finite element analysis with sophisticated optimization algorithms to achieve structural lightweighting across diverse industries. The technology employs both density-based and level-set methods, allowing users to select the most appropriate technique for specific applications. Dassault's implementation features multi-disciplinary optimization capabilities, simultaneously addressing structural, thermal, and fluid dynamics considerations. Their platform incorporates manufacturing constraints specific to various production methods, including traditional machining, casting, and additive manufacturing. The system features automated interpretation tools that convert optimized topologies into parametric CAD models ready for detailed design and manufacturing. Dassault has developed specialized algorithms for composite structure optimization, addressing fiber orientation and layup sequence as additional design variables. Their solution includes design space exploration tools that generate multiple optimized designs across the Pareto front, giving engineers options that balance competing objectives like weight, cost, and manufacturability[3][6].

Strengths: Seamless integration with existing CATIA/SOLIDWORKS workflows; comprehensive manufacturing constraint handling; advanced interpretation tools for downstream design; multi-disciplinary optimization capabilities. Weaknesses: Complex implementation requiring significant training; computationally intensive for large models; optimization results may still require substantial engineering interpretation.

Siemens AG

Technical Solution: Siemens has developed a comprehensive topology optimization solution integrated within their NX software suite, specifically through the Simcenter 3D Engineering Desktop. Their approach combines finite element analysis (FEA) with advanced optimization algorithms to achieve structural lightweighting across multiple industries. The technology utilizes density-based methods (SIMP - Solid Isotropic Material with Penalization) where each element's density becomes a design variable, allowing material to be redistributed to optimal locations while maintaining structural integrity. Siemens' implementation includes multi-physics considerations, accounting for thermal loads, fluid-structure interactions, and manufacturing constraints simultaneously. Their solution incorporates design for additive manufacturing (DfAM) principles, enabling the creation of complex geometries that would be impossible with traditional manufacturing methods. The platform also features automated meshing refinement that adaptively concentrates computational resources in critical regions to improve accuracy while maintaining reasonable solution times[1][3].

Strengths: Seamless integration with existing CAD/CAM workflows; comprehensive multi-physics capabilities; advanced manufacturing constraints implementation. Weaknesses: Computationally intensive for large-scale industrial applications; requires significant expertise to fully leverage advanced features; optimization results may still require substantial engineering interpretation.

Key Algorithms and Mathematical Formulations

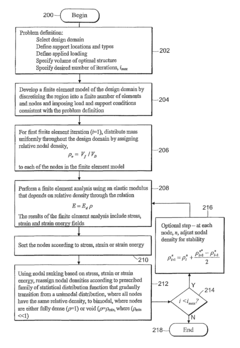

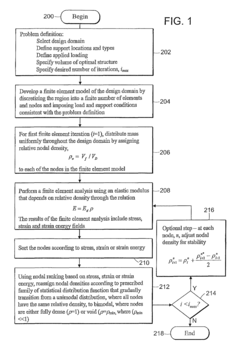

System and method for finite element based topology optimization

PatentWO2007076357A3

Innovation

- Iterative density adjustment based on stress intensity ranking for topology optimization, creating a more efficient structural design process.

- Stress-based node ranking methodology that systematically identifies critical and non-critical regions within the design domain.

- Integration of finite element analysis within an iterative optimization loop until termination criteria is met, ensuring convergence to an optimal structural topology.

Systems and methods for finite element based topology optimization

PatentInactiveUS8335668B2

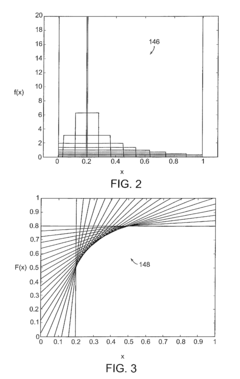

Innovation

- A node-based approach using a family of probability distribution functions to transition from an initial uniform density state to a bimodal state of fully dense and void regions, ensuring constant mass and preventing numerical instabilities by interpolating nodal density values based on stress or strain energy, implemented as supplemental routines to standard finite element software.

Manufacturing Constraints and Additive Technologies

Manufacturing constraints represent a critical consideration in topology optimization for structural lightweighting. Traditional manufacturing methods often impose significant limitations on the geometric complexity achievable in optimized designs. Conventional processes such as casting, forging, and machining typically require considerations for draft angles, tool accessibility, and minimum feature sizes. These constraints can substantially reduce the design freedom and potential weight reduction benefits that topology optimization algorithms might otherwise achieve. When implementing manufacturing constraints in finite element-based topology optimization, engineers must carefully balance theoretical optimization results with practical producibility requirements.

Additive manufacturing technologies have revolutionized the implementation of topology optimization by dramatically expanding manufacturing capabilities. These technologies, including selective laser melting (SLM), electron beam melting (EBM), and fused deposition modeling (FDM), enable the production of complex geometries previously impossible to manufacture. The layer-by-layer building approach allows for internal cavities, lattice structures, and organic shapes that closely match mathematically optimized designs. This synergy between topology optimization and additive manufacturing has created unprecedented opportunities for structural lightweighting across aerospace, automotive, and medical industries.

Despite these advantages, additive manufacturing introduces its own set of constraints that must be incorporated into topology optimization algorithms. Support structure requirements for overhanging features, build orientation considerations, residual stress management, and minimum feature size limitations remain important factors. Advanced topology optimization frameworks now incorporate these additive manufacturing constraints directly into the optimization process, resulting in designs that are both structurally efficient and manufacturable without significant post-processing modifications.

Recent developments in multi-material additive manufacturing have further expanded the potential for structural lightweighting. By strategically combining materials with different mechanical properties within a single component, engineers can achieve even greater performance improvements. Topology optimization algorithms adapted for multi-material applications can determine not only the optimal geometry but also the optimal material distribution throughout the structure, creating functionally graded components with unprecedented strength-to-weight ratios.

The economic considerations of additive manufacturing must also be evaluated when implementing topology-optimized designs. While the technology enables remarkable weight reduction and performance improvements, factors such as build time, material costs, post-processing requirements, and equipment investment can impact the overall viability of additively manufactured lightweight structures. Comprehensive cost-benefit analyses that consider the entire product lifecycle are essential for determining when topology optimization combined with additive manufacturing represents the most appropriate lightweighting strategy.

Additive manufacturing technologies have revolutionized the implementation of topology optimization by dramatically expanding manufacturing capabilities. These technologies, including selective laser melting (SLM), electron beam melting (EBM), and fused deposition modeling (FDM), enable the production of complex geometries previously impossible to manufacture. The layer-by-layer building approach allows for internal cavities, lattice structures, and organic shapes that closely match mathematically optimized designs. This synergy between topology optimization and additive manufacturing has created unprecedented opportunities for structural lightweighting across aerospace, automotive, and medical industries.

Despite these advantages, additive manufacturing introduces its own set of constraints that must be incorporated into topology optimization algorithms. Support structure requirements for overhanging features, build orientation considerations, residual stress management, and minimum feature size limitations remain important factors. Advanced topology optimization frameworks now incorporate these additive manufacturing constraints directly into the optimization process, resulting in designs that are both structurally efficient and manufacturable without significant post-processing modifications.

Recent developments in multi-material additive manufacturing have further expanded the potential for structural lightweighting. By strategically combining materials with different mechanical properties within a single component, engineers can achieve even greater performance improvements. Topology optimization algorithms adapted for multi-material applications can determine not only the optimal geometry but also the optimal material distribution throughout the structure, creating functionally graded components with unprecedented strength-to-weight ratios.

The economic considerations of additive manufacturing must also be evaluated when implementing topology-optimized designs. While the technology enables remarkable weight reduction and performance improvements, factors such as build time, material costs, post-processing requirements, and equipment investment can impact the overall viability of additively manufactured lightweight structures. Comprehensive cost-benefit analyses that consider the entire product lifecycle are essential for determining when topology optimization combined with additive manufacturing represents the most appropriate lightweighting strategy.

Sustainability Impact of Optimized Structures

The implementation of Finite Element-Based Topology Optimization for structural lightweighting delivers significant sustainability benefits across multiple environmental dimensions. By reducing material usage through optimized designs, this approach directly decreases the consumption of raw materials, many of which have substantial environmental footprints associated with their extraction and processing. Studies indicate that topology-optimized structures can achieve material reductions of 30-70% compared to conventional designs while maintaining required performance characteristics.

Energy consumption throughout the product lifecycle represents another critical sustainability factor positively impacted by lightweighted structures. In transportation applications, weight reduction directly correlates with improved fuel efficiency and reduced emissions. For example, in automotive applications, a 10% weight reduction typically yields a 6-8% improvement in fuel economy. When applied to aircraft components, similar optimization techniques have demonstrated potential for reducing fuel consumption by up to 5%, representing substantial emissions reductions over the operational lifetime of the vehicle.

Carbon footprint reduction constitutes a primary environmental benefit of topology-optimized structures. The combined effects of reduced material production and decreased operational energy requirements significantly lower greenhouse gas emissions. Life cycle assessment (LCA) studies of optimized components in various industries show potential carbon footprint reductions ranging from 15% to 40% compared to traditional designs, depending on application and material selection.

Manufacturing processes for topology-optimized components increasingly leverage additive manufacturing technologies, which can further enhance sustainability through reduced waste generation. Unlike traditional subtractive manufacturing methods that may waste up to 90% of raw material as scrap, additive manufacturing approaches can achieve material utilization rates exceeding 95% for certain applications, particularly when combined with optimized designs that minimize support structure requirements.

End-of-life considerations also benefit from topology optimization. Lightweighted structures typically contain less material to process during recycling operations, and the trend toward mono-material designs in optimization projects facilitates more efficient material recovery. Additionally, the extended operational lifetimes often achieved through optimized designs that better distribute stresses and reduce fatigue contribute to overall product longevity, delaying replacement cycles and associated environmental impacts.

Economic sustainability aspects complement these environmental benefits, as material savings translate directly to cost reductions in production. Though initial engineering costs may increase due to the computational requirements of optimization processes, these are typically offset by material savings and improved performance characteristics over the product lifecycle, creating a compelling business case that aligns economic and environmental objectives.

Energy consumption throughout the product lifecycle represents another critical sustainability factor positively impacted by lightweighted structures. In transportation applications, weight reduction directly correlates with improved fuel efficiency and reduced emissions. For example, in automotive applications, a 10% weight reduction typically yields a 6-8% improvement in fuel economy. When applied to aircraft components, similar optimization techniques have demonstrated potential for reducing fuel consumption by up to 5%, representing substantial emissions reductions over the operational lifetime of the vehicle.

Carbon footprint reduction constitutes a primary environmental benefit of topology-optimized structures. The combined effects of reduced material production and decreased operational energy requirements significantly lower greenhouse gas emissions. Life cycle assessment (LCA) studies of optimized components in various industries show potential carbon footprint reductions ranging from 15% to 40% compared to traditional designs, depending on application and material selection.

Manufacturing processes for topology-optimized components increasingly leverage additive manufacturing technologies, which can further enhance sustainability through reduced waste generation. Unlike traditional subtractive manufacturing methods that may waste up to 90% of raw material as scrap, additive manufacturing approaches can achieve material utilization rates exceeding 95% for certain applications, particularly when combined with optimized designs that minimize support structure requirements.

End-of-life considerations also benefit from topology optimization. Lightweighted structures typically contain less material to process during recycling operations, and the trend toward mono-material designs in optimization projects facilitates more efficient material recovery. Additionally, the extended operational lifetimes often achieved through optimized designs that better distribute stresses and reduce fatigue contribute to overall product longevity, delaying replacement cycles and associated environmental impacts.

Economic sustainability aspects complement these environmental benefits, as material savings translate directly to cost reductions in production. Though initial engineering costs may increase due to the computational requirements of optimization processes, these are typically offset by material savings and improved performance characteristics over the product lifecycle, creating a compelling business case that aligns economic and environmental objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!