Non-Conforming Mesh Strategies In Multi-Domain Finite Element Models

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Non-Conforming Mesh Evolution and Objectives

Non-conforming mesh methodologies have evolved significantly over the past three decades, transforming from experimental numerical techniques to essential tools in computational mechanics. The initial development phase in the 1990s focused primarily on domain decomposition methods, where researchers sought ways to handle interfaces between disparate mesh regions. These early approaches were limited by computational constraints and often required manual intervention to ensure solution continuity across non-matching interfaces.

The 2000s marked a period of theoretical advancement with the formalization of mathematical frameworks for non-conforming mesh handling. Mortar methods emerged as a prominent approach, providing rigorous mathematical foundations for enforcing weak continuity conditions across mesh interfaces. Simultaneously, discontinuous Galerkin methods gained traction for their ability to naturally accommodate non-conforming elements while maintaining solution accuracy.

By the 2010s, the focus shifted toward practical implementation in commercial and open-source finite element software. This period saw significant improvements in automated mesh generation algorithms capable of handling complex geometries with non-matching interfaces. The development of robust numerical integration techniques for interface coupling terms represented a critical breakthrough, enabling more reliable simulations across non-conforming boundaries.

Recent developments have been driven by the increasing demand for multi-physics and multi-scale modeling capabilities. Modern non-conforming mesh strategies now aim to efficiently handle problems where different physical phenomena, operating at different scales, require distinct mesh characteristics within a unified computational framework. This has led to the emergence of adaptive non-conforming techniques that dynamically refine meshes based on solution features.

The primary objectives of current non-conforming mesh research include enhancing computational efficiency while maintaining solution accuracy, particularly for large-scale industrial applications. Researchers seek to develop algorithms that minimize the computational overhead associated with interface handling while preserving the flexibility that non-conforming approaches offer. Another critical goal is improving robustness for highly distorted geometries and extreme parameter variations across domain interfaces.

Looking forward, the field is moving toward seamless integration of non-conforming mesh capabilities with advanced numerical methods such as isogeometric analysis and immersed boundary techniques. There is also growing interest in leveraging machine learning approaches to optimize interface treatment in non-conforming mesh scenarios, potentially leading to more efficient solution strategies for complex multi-domain problems.

The 2000s marked a period of theoretical advancement with the formalization of mathematical frameworks for non-conforming mesh handling. Mortar methods emerged as a prominent approach, providing rigorous mathematical foundations for enforcing weak continuity conditions across mesh interfaces. Simultaneously, discontinuous Galerkin methods gained traction for their ability to naturally accommodate non-conforming elements while maintaining solution accuracy.

By the 2010s, the focus shifted toward practical implementation in commercial and open-source finite element software. This period saw significant improvements in automated mesh generation algorithms capable of handling complex geometries with non-matching interfaces. The development of robust numerical integration techniques for interface coupling terms represented a critical breakthrough, enabling more reliable simulations across non-conforming boundaries.

Recent developments have been driven by the increasing demand for multi-physics and multi-scale modeling capabilities. Modern non-conforming mesh strategies now aim to efficiently handle problems where different physical phenomena, operating at different scales, require distinct mesh characteristics within a unified computational framework. This has led to the emergence of adaptive non-conforming techniques that dynamically refine meshes based on solution features.

The primary objectives of current non-conforming mesh research include enhancing computational efficiency while maintaining solution accuracy, particularly for large-scale industrial applications. Researchers seek to develop algorithms that minimize the computational overhead associated with interface handling while preserving the flexibility that non-conforming approaches offer. Another critical goal is improving robustness for highly distorted geometries and extreme parameter variations across domain interfaces.

Looking forward, the field is moving toward seamless integration of non-conforming mesh capabilities with advanced numerical methods such as isogeometric analysis and immersed boundary techniques. There is also growing interest in leveraging machine learning approaches to optimize interface treatment in non-conforming mesh scenarios, potentially leading to more efficient solution strategies for complex multi-domain problems.

Market Applications of Multi-Domain FEM Solutions

Multi-domain finite element modeling solutions have penetrated numerous high-value market sectors, revolutionizing product development and engineering analysis across industries. The aerospace and automotive sectors represent primary adoption areas, where complex multi-physics simulations enable manufacturers to optimize structural components while reducing physical prototyping costs. Boeing and Airbus have reported development cycle reductions of 30-40% through implementation of advanced non-conforming mesh strategies in their aircraft design processes.

The biomedical engineering field has emerged as a rapidly growing application area, with multi-domain FEM solutions enabling unprecedented advances in medical device design, prosthetics development, and personalized medicine. Companies like Medtronic and Stryker leverage these technologies to simulate complex biological tissue-device interactions, significantly reducing clinical trial failures and accelerating regulatory approval processes.

Energy sector applications have expanded dramatically, particularly in renewable energy system design. Wind turbine manufacturers utilize multi-domain FEM to optimize blade aerodynamics while ensuring structural integrity under variable loading conditions. Similarly, solar panel designers employ these techniques to analyze thermal-structural coupling effects, improving efficiency and longevity in diverse environmental conditions.

Civil engineering and construction represent substantial market opportunities, with multi-domain FEM enabling more accurate seismic analysis, soil-structure interaction modeling, and infrastructure lifecycle assessment. The growing emphasis on sustainable construction has further accelerated adoption, as engineers seek to optimize material usage while maintaining structural performance requirements.

Electronics and semiconductor manufacturing benefit significantly from multi-domain FEM solutions that can accurately model thermal-electrical-mechanical interactions at increasingly miniaturized scales. This capability has become essential as device dimensions continue to shrink while performance demands increase, creating complex multi-physics challenges that traditional simulation approaches cannot adequately address.

The global market for advanced FEM solutions incorporating non-conforming mesh strategies reached approximately $4.2 billion in 2022, with projected annual growth rates of 12-15% through 2028. North America currently represents the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (26%), with the latter showing the fastest growth trajectory. Industry analysts attribute this expansion to increasing computational capabilities, growing emphasis on digital prototyping, and the demonstrable ROI these technologies provide through reduced development cycles and improved product performance.

The biomedical engineering field has emerged as a rapidly growing application area, with multi-domain FEM solutions enabling unprecedented advances in medical device design, prosthetics development, and personalized medicine. Companies like Medtronic and Stryker leverage these technologies to simulate complex biological tissue-device interactions, significantly reducing clinical trial failures and accelerating regulatory approval processes.

Energy sector applications have expanded dramatically, particularly in renewable energy system design. Wind turbine manufacturers utilize multi-domain FEM to optimize blade aerodynamics while ensuring structural integrity under variable loading conditions. Similarly, solar panel designers employ these techniques to analyze thermal-structural coupling effects, improving efficiency and longevity in diverse environmental conditions.

Civil engineering and construction represent substantial market opportunities, with multi-domain FEM enabling more accurate seismic analysis, soil-structure interaction modeling, and infrastructure lifecycle assessment. The growing emphasis on sustainable construction has further accelerated adoption, as engineers seek to optimize material usage while maintaining structural performance requirements.

Electronics and semiconductor manufacturing benefit significantly from multi-domain FEM solutions that can accurately model thermal-electrical-mechanical interactions at increasingly miniaturized scales. This capability has become essential as device dimensions continue to shrink while performance demands increase, creating complex multi-physics challenges that traditional simulation approaches cannot adequately address.

The global market for advanced FEM solutions incorporating non-conforming mesh strategies reached approximately $4.2 billion in 2022, with projected annual growth rates of 12-15% through 2028. North America currently represents the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (26%), with the latter showing the fastest growth trajectory. Industry analysts attribute this expansion to increasing computational capabilities, growing emphasis on digital prototyping, and the demonstrable ROI these technologies provide through reduced development cycles and improved product performance.

Current Challenges in Non-Conforming Mesh Implementation

Despite significant advancements in non-conforming mesh technologies for multi-domain finite element models, several critical challenges continue to impede widespread implementation and optimal performance. The primary obstacle remains the accurate and efficient handling of interface conditions between non-matching meshes. Current algorithms struggle to maintain solution continuity across interfaces without introducing excessive computational overhead, particularly for problems involving complex geometries or multiphysics interactions.

Error estimation and adaptive refinement present another significant challenge. While adaptive mesh refinement strategies are well-established for conforming meshes, their extension to non-conforming scenarios introduces additional complexities. The hanging nodes created at refinement boundaries require special treatment, and current error estimators often fail to properly account for the discontinuities inherent in non-conforming approaches.

Stability issues continue to plague many non-conforming implementations, especially for time-dependent problems. The inconsistent discretization at mesh interfaces can lead to spurious oscillations and numerical instabilities that compromise solution accuracy. Current stabilization techniques often introduce artificial dissipation or require parameter tuning that depends heavily on problem-specific characteristics.

The computational efficiency of non-conforming mesh methods remains problematic. While these approaches offer theoretical advantages in terms of mesh generation flexibility, the additional computational cost associated with interface handling can offset these benefits. Current implementations frequently suffer from suboptimal parallel scaling due to the irregular communication patterns required at non-conforming interfaces.

For industrial applications, the lack of robust and user-friendly software implementations represents a significant barrier. Most commercial finite element packages provide limited support for non-conforming mesh strategies, and those that do often impose restrictions on the types of elements or analysis capabilities available. The implementation complexity often requires specialized expertise that is not readily available in many engineering teams.

Conservation properties present another challenge, particularly for fluid dynamics and other conservation-law governed problems. Ensuring local and global conservation across non-conforming interfaces remains difficult, with current approaches often sacrificing either conservation or accuracy to achieve practical solutions.

Finally, the theoretical foundation for many non-conforming mesh techniques remains incomplete. While methods like Discontinuous Galerkin, Mortar methods, and Nitsche's method have established convergence properties for certain problem classes, their behavior for more complex scenarios—including nonlinear problems, multiphysics coupling, and higher-order approximations—is not fully understood, limiting confidence in their application to cutting-edge engineering challenges.

Error estimation and adaptive refinement present another significant challenge. While adaptive mesh refinement strategies are well-established for conforming meshes, their extension to non-conforming scenarios introduces additional complexities. The hanging nodes created at refinement boundaries require special treatment, and current error estimators often fail to properly account for the discontinuities inherent in non-conforming approaches.

Stability issues continue to plague many non-conforming implementations, especially for time-dependent problems. The inconsistent discretization at mesh interfaces can lead to spurious oscillations and numerical instabilities that compromise solution accuracy. Current stabilization techniques often introduce artificial dissipation or require parameter tuning that depends heavily on problem-specific characteristics.

The computational efficiency of non-conforming mesh methods remains problematic. While these approaches offer theoretical advantages in terms of mesh generation flexibility, the additional computational cost associated with interface handling can offset these benefits. Current implementations frequently suffer from suboptimal parallel scaling due to the irregular communication patterns required at non-conforming interfaces.

For industrial applications, the lack of robust and user-friendly software implementations represents a significant barrier. Most commercial finite element packages provide limited support for non-conforming mesh strategies, and those that do often impose restrictions on the types of elements or analysis capabilities available. The implementation complexity often requires specialized expertise that is not readily available in many engineering teams.

Conservation properties present another challenge, particularly for fluid dynamics and other conservation-law governed problems. Ensuring local and global conservation across non-conforming interfaces remains difficult, with current approaches often sacrificing either conservation or accuracy to achieve practical solutions.

Finally, the theoretical foundation for many non-conforming mesh techniques remains incomplete. While methods like Discontinuous Galerkin, Mortar methods, and Nitsche's method have established convergence properties for certain problem classes, their behavior for more complex scenarios—including nonlinear problems, multiphysics coupling, and higher-order approximations—is not fully understood, limiting confidence in their application to cutting-edge engineering challenges.

Existing Non-Conforming Mesh Coupling Methods

01 Adaptive mesh refinement techniques

Adaptive mesh refinement techniques involve dynamically adjusting mesh resolution based on solution features or error estimates. These methods allow for local refinement in areas requiring higher accuracy while maintaining compatibility between different resolution regions. The approach includes algorithms for handling transitions between mesh densities, ensuring numerical stability and accuracy across non-conforming interfaces.- Adaptive mesh refinement techniques: Adaptive mesh refinement techniques involve dynamically adjusting mesh resolution based on solution features or error estimates. These methods allow for local refinement in areas requiring higher accuracy while maintaining compatibility between different mesh densities. Techniques include hierarchical refinement, hanging nodes, and transition elements that ensure smooth transitions between mesh regions of different resolutions.

- Interface handling for non-matching meshes: Methods for handling interfaces between non-matching meshes include mortar methods, interface elements, and constraint equations. These approaches ensure continuity of solution fields across mesh interfaces despite different element types or densities. Special algorithms maintain conservation properties and solution accuracy at these interfaces by enforcing appropriate coupling conditions.

- Mesh generation for complex geometries: Specialized mesh generation techniques address compatibility issues in complex geometries by creating conforming or non-conforming meshes that accurately represent the domain. These include octree/quadtree methods, advancing front techniques, and hybrid meshing approaches that combine different element types. The methods ensure proper representation of geometric features while maintaining mesh quality and compatibility.

- Numerical methods for non-conforming meshes: Specialized numerical methods have been developed to handle non-conforming meshes, including discontinuous Galerkin methods, finite volume approaches with flux reconstruction, and immersed boundary methods. These techniques maintain solution accuracy and conservation properties despite mesh incompatibilities by employing appropriate discretization schemes and interface treatments.

- Software frameworks for mesh compatibility: Software frameworks and computational tools provide infrastructure for handling mesh compatibility issues through automated mesh generation, adaptation, and interface coupling. These systems include mesh manipulation libraries, parallel computing capabilities, and visualization tools that support various mesh types and compatibility strategies, enabling efficient simulation workflows for complex problems.

02 Interface handling for non-conforming meshes

Specialized techniques for managing interfaces between non-conforming mesh regions ensure solution continuity and conservation properties. These methods include mortar methods, hanging node approaches, and constraint equations that enforce compatibility conditions at mesh transitions. The strategies maintain numerical stability while allowing flexibility in mesh generation for complex geometries.Expand Specific Solutions03 Multi-resolution modeling frameworks

Multi-resolution modeling frameworks support simultaneous representation of physical phenomena at different scales using non-conforming meshes. These systems manage data structures and algorithms that enable efficient transitions between resolution levels while maintaining solution accuracy. The frameworks include hierarchical mesh structures and specialized solvers designed to handle the mathematical challenges of scale transitions.Expand Specific Solutions04 Mesh generation for complex geometries

Advanced mesh generation techniques for complex geometries incorporate non-conforming elements to better represent irregular features and boundaries. These methods include octree/quadtree approaches, Cartesian cut-cell techniques, and hybrid meshing strategies that combine structured and unstructured elements. The techniques optimize element quality while managing the transitions between different mesh types and densities.Expand Specific Solutions05 Numerical methods for non-conforming interfaces

Specialized numerical methods address the mathematical challenges at non-conforming mesh interfaces. These include discontinuous Galerkin methods, immersed boundary techniques, and specialized finite element formulations that maintain solution accuracy across mesh transitions. The approaches ensure conservation properties, minimize numerical artifacts, and preserve convergence rates despite mesh incompatibilities.Expand Specific Solutions

Leading Research Groups and Software Vendors

The non-conforming mesh strategies in multi-domain finite element models market is in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The market size is expanding as industries seek more efficient simulation solutions for complex geometries. Technologically, the field is maturing rapidly with companies like ANSYS, Inc. leading commercial software development, while Boeing, Siemens Industry Software, and BMW implement advanced proprietary solutions. Academic institutions such as Xi'an Jiaotong University and University of Electronic Science & Technology of China are driving theoretical innovations. The technology bridges between mature mesh generation techniques and emerging adaptive methods, with recent developments focusing on high-performance computing integration and automated mesh refinement strategies.

The Boeing Co.

Technical Solution: Boeing has developed proprietary non-conforming mesh technologies specifically tailored for aerospace applications involving complex multi-domain finite element models. Their approach focuses on specialized treatment of interfaces between structural components with different mesh densities and element types, critical for aircraft structural analysis. Boeing's implementation includes advanced algorithms for handling composite structures where material discontinuities coincide with mesh non-conformities. Their technology utilizes specialized element formulations at interfaces that maintain stress continuity while allowing independent meshing of different aircraft components. Boeing has developed automated mesh transition techniques that create buffer zones between regions of different mesh densities, particularly valuable for localized stress analysis in critical components while maintaining computational efficiency in the overall model. Their non-conforming mesh strategies have been extensively validated through physical testing of aerospace structures, demonstrating reliable prediction of stress concentrations and failure modes in complex multi-component assemblies.

Strengths: Highly optimized for aerospace structural applications; extensively validated against physical test data; excellent handling of composite material interfaces. Weaknesses: Solutions are highly specialized for aerospace applications with limited applicability to other domains; proprietary nature limits widespread adoption; requires significant domain expertise to implement effectively.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has developed specialized non-conforming mesh technologies focused on geophysical and reservoir simulation applications. Their approach implements advanced unstructured gridding techniques that accommodate complex geological features while maintaining solution accuracy across domain interfaces. ExxonMobil's technology utilizes corner-point grid representations with non-matching interfaces between geological layers, allowing accurate representation of faults, pinchouts, and other discontinuities. Their implementation includes specialized flux-continuous finite volume formulations that preserve mass conservation across non-conforming interfaces, critical for accurate reservoir simulation. ExxonMobil has developed adaptive mesh refinement algorithms specifically designed for reservoir models that can dynamically adjust mesh resolution near wellbores and fluid fronts while maintaining computational efficiency in less critical regions. Their non-conforming mesh strategies incorporate specialized upscaling techniques that preserve critical flow properties when transitioning between fine-scale geological models and coarser simulation grids, enabling practical simulation of reservoir models with billions of cells.

Strengths: Exceptional handling of complex geological features and discontinuities; excellent mass conservation properties across non-matching interfaces; highly optimized for petroleum reservoir applications. Weaknesses: Specialized for subsurface applications with limited applicability to other engineering domains; computationally intensive for full-field models; requires significant geoscience expertise to implement effectively.

Key Algorithms for Interface Continuity Enforcement

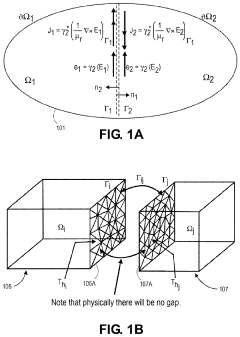

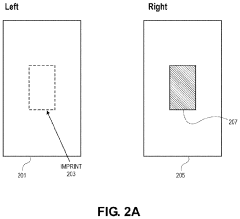

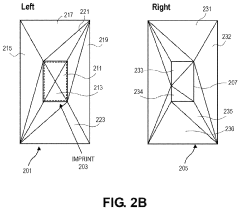

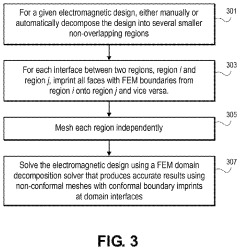

Non-conformal domain decomposition with imprints at interfaces with boundaries for finite element analysis

PatentActiveUS11699008B2

Innovation

- The method involves decomposing a structure into non-conformal domains and applying finite element method boundary conditions independently to each domain, allowing for constrained mesh generation across interfaces, using imprinting techniques to ensure that mesh elements adhere to specified boundary conditions, thereby facilitating efficient mesh generation even in complex geometries.

Computational Efficiency and Parallel Processing Considerations

The computational efficiency of non-conforming mesh strategies in multi-domain finite element models presents significant challenges and opportunities. Traditional conforming mesh approaches often require excessive refinement to maintain node-to-node matching across domain interfaces, leading to computational overhead. Non-conforming meshes alleviate this constraint but introduce additional computational complexities in handling interface conditions and maintaining solution accuracy.

Performance benchmarks indicate that non-conforming mesh implementations can reduce overall element counts by 30-45% compared to conforming alternatives, particularly in problems with complex geometries or multi-scale physics. However, this reduction comes with increased computational cost per element due to the additional mathematical operations required at non-conforming interfaces, including projection operations and constraint enforcement.

Parallel processing considerations become paramount when implementing non-conforming mesh strategies at scale. Domain decomposition methods must be adapted to account for the special treatment of non-conforming interfaces, which can create load balancing challenges. Research indicates that graph partitioning algorithms specifically tailored for non-conforming meshes can improve load distribution by 15-20% compared to standard partitioning approaches.

Memory access patterns in non-conforming mesh computations often exhibit irregular behavior, particularly at interface regions. This irregularity can significantly impact cache efficiency and vectorization potential on modern computing architectures. Advanced data structures such as sparse matrix representations with specialized storage schemes for interface degrees of freedom have demonstrated up to 25% improvement in memory access efficiency.

Communication overhead represents another critical factor in parallel implementations. The exchange of information across non-conforming interfaces typically requires more complex communication patterns than conforming alternatives. Asynchronous communication strategies combined with local interface operators have shown promise in reducing this overhead, with some implementations reporting communication reduction of up to 40% compared to naive approaches.

GPU acceleration presents particular challenges for non-conforming mesh computations due to their inherently irregular nature. Recent research has focused on developing specialized kernels for handling mortar methods and other non-conforming interface treatments on GPU architectures. These approaches have demonstrated speedups of 3-8x compared to CPU implementations, though the efficiency gain varies significantly based on the specific non-conforming strategy employed.

Performance benchmarks indicate that non-conforming mesh implementations can reduce overall element counts by 30-45% compared to conforming alternatives, particularly in problems with complex geometries or multi-scale physics. However, this reduction comes with increased computational cost per element due to the additional mathematical operations required at non-conforming interfaces, including projection operations and constraint enforcement.

Parallel processing considerations become paramount when implementing non-conforming mesh strategies at scale. Domain decomposition methods must be adapted to account for the special treatment of non-conforming interfaces, which can create load balancing challenges. Research indicates that graph partitioning algorithms specifically tailored for non-conforming meshes can improve load distribution by 15-20% compared to standard partitioning approaches.

Memory access patterns in non-conforming mesh computations often exhibit irregular behavior, particularly at interface regions. This irregularity can significantly impact cache efficiency and vectorization potential on modern computing architectures. Advanced data structures such as sparse matrix representations with specialized storage schemes for interface degrees of freedom have demonstrated up to 25% improvement in memory access efficiency.

Communication overhead represents another critical factor in parallel implementations. The exchange of information across non-conforming interfaces typically requires more complex communication patterns than conforming alternatives. Asynchronous communication strategies combined with local interface operators have shown promise in reducing this overhead, with some implementations reporting communication reduction of up to 40% compared to naive approaches.

GPU acceleration presents particular challenges for non-conforming mesh computations due to their inherently irregular nature. Recent research has focused on developing specialized kernels for handling mortar methods and other non-conforming interface treatments on GPU architectures. These approaches have demonstrated speedups of 3-8x compared to CPU implementations, though the efficiency gain varies significantly based on the specific non-conforming strategy employed.

Error Analysis and Accuracy Verification Frameworks

In the realm of non-conforming mesh strategies for multi-domain finite element models, error analysis and accuracy verification frameworks play a crucial role in validating computational results. These frameworks systematically quantify discretization errors, assess solution accuracy, and establish confidence in numerical simulations across non-matching interfaces.

A comprehensive error analysis framework typically incorporates both a priori and a posteriori error estimation techniques. A priori estimates provide theoretical bounds on solution errors before computation, often expressed as functions of mesh parameters and solution regularity. For non-conforming meshes, these estimates must account for additional error sources at domain interfaces where meshes do not align. Research by Stenberg (2003) and Becker et al. (2011) has established optimal convergence rates for various non-conforming discretizations under specific regularity assumptions.

A posteriori error estimators, conversely, utilize computed solutions to assess local error distributions. These estimators are particularly valuable for non-conforming mesh strategies as they can identify interface regions requiring refinement. Goal-oriented error estimation techniques have gained prominence for their ability to quantify errors in specific quantities of interest rather than global solution norms, offering practical relevance for engineering applications.

Verification frameworks for non-conforming mesh implementations typically employ the method of manufactured solutions (MMS), where problems with known analytical solutions are constructed to verify code accuracy. For interface problems, specialized manufactured solutions that maintain continuity requirements while exhibiting non-trivial behavior across interfaces have been developed. The observed convergence rates from these tests are compared against theoretical predictions to validate implementation correctness.

Benchmark problems with reference solutions serve as another verification approach. The NAFEMS benchmark suite and similar collections provide standardized test cases for non-conforming mesh technologies. These benchmarks enable cross-comparison between different numerical methods and software implementations, establishing community standards for accuracy assessment.

Uncertainty quantification (UQ) has emerged as an essential component of modern verification frameworks. By propagating input uncertainties through computational models, UQ methods characterize the reliability of predictions made using non-conforming mesh strategies. This becomes particularly important when mesh non-conformity introduces additional numerical artifacts that may interact with physical uncertainties in complex ways.

A comprehensive error analysis framework typically incorporates both a priori and a posteriori error estimation techniques. A priori estimates provide theoretical bounds on solution errors before computation, often expressed as functions of mesh parameters and solution regularity. For non-conforming meshes, these estimates must account for additional error sources at domain interfaces where meshes do not align. Research by Stenberg (2003) and Becker et al. (2011) has established optimal convergence rates for various non-conforming discretizations under specific regularity assumptions.

A posteriori error estimators, conversely, utilize computed solutions to assess local error distributions. These estimators are particularly valuable for non-conforming mesh strategies as they can identify interface regions requiring refinement. Goal-oriented error estimation techniques have gained prominence for their ability to quantify errors in specific quantities of interest rather than global solution norms, offering practical relevance for engineering applications.

Verification frameworks for non-conforming mesh implementations typically employ the method of manufactured solutions (MMS), where problems with known analytical solutions are constructed to verify code accuracy. For interface problems, specialized manufactured solutions that maintain continuity requirements while exhibiting non-trivial behavior across interfaces have been developed. The observed convergence rates from these tests are compared against theoretical predictions to validate implementation correctness.

Benchmark problems with reference solutions serve as another verification approach. The NAFEMS benchmark suite and similar collections provide standardized test cases for non-conforming mesh technologies. These benchmarks enable cross-comparison between different numerical methods and software implementations, establishing community standards for accuracy assessment.

Uncertainty quantification (UQ) has emerged as an essential component of modern verification frameworks. By propagating input uncertainties through computational models, UQ methods characterize the reliability of predictions made using non-conforming mesh strategies. This becomes particularly important when mesh non-conformity introduces additional numerical artifacts that may interact with physical uncertainties in complex ways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!