Finite Element-Based Simulation Of Battery Thermal Management Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Management Evolution and Objectives

Battery thermal management systems (BTMS) have evolved significantly over the past decades, driven by the increasing demand for high-performance, safe, and reliable energy storage solutions. The evolution began in the early 1990s with simple passive cooling systems for small-scale batteries, primarily focusing on preventing overheating during discharge cycles. As battery technologies advanced from lead-acid to nickel-metal hydride and eventually to lithium-ion chemistries, thermal management requirements became more sophisticated and critical.

The mid-2000s marked a pivotal shift with the commercialization of electric vehicles, necessitating more advanced thermal management approaches. Early EV battery packs relied on air cooling systems, which proved inadequate for high-capacity batteries under demanding operational conditions. This limitation led to the development of liquid cooling systems, offering superior heat transfer capabilities and more uniform temperature distribution across battery modules.

Recent advancements have introduced phase change materials, heat pipes, and hybrid cooling strategies, significantly enhancing thermal performance while reducing system complexity and weight. The integration of smart thermal management systems with predictive algorithms represents the current frontier, enabling dynamic adjustment of cooling parameters based on real-time battery conditions and usage patterns.

The primary objective of modern BTMS is to maintain optimal operating temperature ranges (typically 20-40°C) across all cells within a battery pack, minimizing temperature gradients that can lead to performance degradation, reduced lifespan, and safety risks. Secondary objectives include energy efficiency optimization, system weight and volume reduction, and cost-effectiveness for mass production.

Finite element-based simulation has emerged as an indispensable tool in this evolution, enabling engineers to model complex thermal behaviors without extensive physical prototyping. These simulations allow for detailed analysis of heat generation, distribution, and dissipation under various operating conditions and environmental factors. The predictive capabilities of finite element analysis have accelerated BTMS innovation by identifying potential thermal issues before physical implementation.

Looking forward, BTMS development aims to address several key challenges: supporting ultra-fast charging capabilities, optimizing performance in extreme environmental conditions, reducing parasitic energy consumption, and accommodating next-generation battery chemistries with different thermal characteristics. The integration of artificial intelligence and machine learning algorithms with finite element simulations represents a promising direction for achieving these objectives, potentially enabling self-optimizing thermal management systems that adapt to changing conditions and battery aging.

The mid-2000s marked a pivotal shift with the commercialization of electric vehicles, necessitating more advanced thermal management approaches. Early EV battery packs relied on air cooling systems, which proved inadequate for high-capacity batteries under demanding operational conditions. This limitation led to the development of liquid cooling systems, offering superior heat transfer capabilities and more uniform temperature distribution across battery modules.

Recent advancements have introduced phase change materials, heat pipes, and hybrid cooling strategies, significantly enhancing thermal performance while reducing system complexity and weight. The integration of smart thermal management systems with predictive algorithms represents the current frontier, enabling dynamic adjustment of cooling parameters based on real-time battery conditions and usage patterns.

The primary objective of modern BTMS is to maintain optimal operating temperature ranges (typically 20-40°C) across all cells within a battery pack, minimizing temperature gradients that can lead to performance degradation, reduced lifespan, and safety risks. Secondary objectives include energy efficiency optimization, system weight and volume reduction, and cost-effectiveness for mass production.

Finite element-based simulation has emerged as an indispensable tool in this evolution, enabling engineers to model complex thermal behaviors without extensive physical prototyping. These simulations allow for detailed analysis of heat generation, distribution, and dissipation under various operating conditions and environmental factors. The predictive capabilities of finite element analysis have accelerated BTMS innovation by identifying potential thermal issues before physical implementation.

Looking forward, BTMS development aims to address several key challenges: supporting ultra-fast charging capabilities, optimizing performance in extreme environmental conditions, reducing parasitic energy consumption, and accommodating next-generation battery chemistries with different thermal characteristics. The integration of artificial intelligence and machine learning algorithms with finite element simulations represents a promising direction for achieving these objectives, potentially enabling self-optimizing thermal management systems that adapt to changing conditions and battery aging.

Market Demand Analysis for Advanced Battery Thermal Solutions

The global market for advanced battery thermal management solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the battery thermal management system (BTMS) market is projected to reach $5.2 billion by 2025, growing at a CAGR of 16.7% from 2020. This growth trajectory is directly correlated with the increasing energy density requirements of modern battery systems and the critical need for thermal stability to ensure safety, longevity, and performance.

Consumer demand for extended EV range capabilities has pushed manufacturers to develop higher capacity batteries, which consequently generate more heat during operation. This technical challenge has created a substantial market opportunity for advanced thermal management solutions that can effectively dissipate heat while maintaining optimal operating temperatures between 20-40°C. Industry surveys reveal that over 78% of EV manufacturers consider thermal management as a critical factor in their battery system design.

The market segmentation shows distinct demand patterns across different regions. North America and Europe demonstrate strong preference for liquid cooling systems, particularly in premium vehicle segments, while Asia-Pacific markets show greater diversity in thermal management approaches, including air cooling, phase change materials, and hybrid systems. This regional variation reflects differences in climate conditions, vehicle usage patterns, and regulatory frameworks governing battery safety standards.

Commercial fleet operators represent another significant market segment, with particular emphasis on fast-charging capabilities and battery longevity. These customers typically value thermal management solutions that can handle repeated rapid charging cycles without degradation, as this directly impacts operational efficiency and total cost of ownership. Market research indicates that fleet operators are willing to pay a premium of up to 15% for thermal management systems that can demonstrably extend battery life by at least 20%.

The stationary energy storage sector is emerging as a high-growth market segment for advanced thermal management solutions. Grid-scale battery installations, commercial building energy storage, and residential systems all require effective thermal management to ensure safety and performance. This segment is expected to grow at 22.3% CAGR through 2025, outpacing even the automotive sector in some regions.

Consumer awareness regarding battery safety has significantly increased following widely publicized thermal runaway incidents. This has created market demand for transparent safety features, including advanced thermal management systems with real-time monitoring capabilities. Surveys indicate that 67% of potential EV buyers consider battery safety features as "very important" in their purchasing decisions, creating additional market pull for sophisticated thermal management solutions.

Consumer demand for extended EV range capabilities has pushed manufacturers to develop higher capacity batteries, which consequently generate more heat during operation. This technical challenge has created a substantial market opportunity for advanced thermal management solutions that can effectively dissipate heat while maintaining optimal operating temperatures between 20-40°C. Industry surveys reveal that over 78% of EV manufacturers consider thermal management as a critical factor in their battery system design.

The market segmentation shows distinct demand patterns across different regions. North America and Europe demonstrate strong preference for liquid cooling systems, particularly in premium vehicle segments, while Asia-Pacific markets show greater diversity in thermal management approaches, including air cooling, phase change materials, and hybrid systems. This regional variation reflects differences in climate conditions, vehicle usage patterns, and regulatory frameworks governing battery safety standards.

Commercial fleet operators represent another significant market segment, with particular emphasis on fast-charging capabilities and battery longevity. These customers typically value thermal management solutions that can handle repeated rapid charging cycles without degradation, as this directly impacts operational efficiency and total cost of ownership. Market research indicates that fleet operators are willing to pay a premium of up to 15% for thermal management systems that can demonstrably extend battery life by at least 20%.

The stationary energy storage sector is emerging as a high-growth market segment for advanced thermal management solutions. Grid-scale battery installations, commercial building energy storage, and residential systems all require effective thermal management to ensure safety and performance. This segment is expected to grow at 22.3% CAGR through 2025, outpacing even the automotive sector in some regions.

Consumer awareness regarding battery safety has significantly increased following widely publicized thermal runaway incidents. This has created market demand for transparent safety features, including advanced thermal management systems with real-time monitoring capabilities. Surveys indicate that 67% of potential EV buyers consider battery safety features as "very important" in their purchasing decisions, creating additional market pull for sophisticated thermal management solutions.

Current FEA Simulation Capabilities and Limitations

Finite Element Analysis (FEA) has become an indispensable tool in the design and optimization of Battery Thermal Management Systems (BTMS). Current FEA simulation capabilities offer comprehensive thermal modeling across multiple physical domains, enabling engineers to predict temperature distributions, thermal gradients, and heat transfer mechanisms within battery packs with increasing accuracy.

Modern FEA software packages such as ANSYS, COMSOL Multiphysics, and Siemens Star-CCM+ provide specialized modules for battery thermal analysis that can simulate complex geometries and multi-material interfaces. These tools excel at modeling various cooling strategies including air cooling, liquid cooling, phase change materials, and hybrid approaches, allowing for detailed comparison of thermal management solutions before physical prototyping.

The coupling of electrochemical and thermal models represents a significant advancement, enabling simulation of heat generation based on actual battery operation rather than simplified assumptions. This capability has improved prediction accuracy for temperature-dependent degradation mechanisms and thermal runaway scenarios, critical for safety assessments in electric vehicle applications.

Despite these capabilities, current FEA simulations face several limitations. Computational resource requirements remain substantial, with high-fidelity models of large battery packs often requiring specialized hardware and extended simulation times. This creates a trade-off between simulation accuracy and practical usability in design iteration cycles.

Model validation continues to present challenges, as the internal states of batteries are difficult to measure experimentally without altering the thermal behavior being studied. This leads to uncertainties in simulation results, particularly for novel cell designs or extreme operating conditions where historical validation data is limited.

Parameter identification represents another significant limitation, as material properties can vary with temperature, state of charge, and aging. Obtaining accurate input parameters for all simulation conditions requires extensive experimental characterization, which is time-consuming and expensive.

Multi-scale modeling remains particularly challenging, as phenomena ranging from electrochemical reactions at the nanoscale to pack-level thermal management operate across vastly different time and length scales. Current FEA approaches often struggle to efficiently bridge these scales without introducing prohibitive computational complexity.

Real-time simulation capabilities for control system development and digital twin applications are still limited, with most detailed thermal models running significantly slower than real-time. This restricts their application in hardware-in-the-loop testing and online battery management system optimization.

Modern FEA software packages such as ANSYS, COMSOL Multiphysics, and Siemens Star-CCM+ provide specialized modules for battery thermal analysis that can simulate complex geometries and multi-material interfaces. These tools excel at modeling various cooling strategies including air cooling, liquid cooling, phase change materials, and hybrid approaches, allowing for detailed comparison of thermal management solutions before physical prototyping.

The coupling of electrochemical and thermal models represents a significant advancement, enabling simulation of heat generation based on actual battery operation rather than simplified assumptions. This capability has improved prediction accuracy for temperature-dependent degradation mechanisms and thermal runaway scenarios, critical for safety assessments in electric vehicle applications.

Despite these capabilities, current FEA simulations face several limitations. Computational resource requirements remain substantial, with high-fidelity models of large battery packs often requiring specialized hardware and extended simulation times. This creates a trade-off between simulation accuracy and practical usability in design iteration cycles.

Model validation continues to present challenges, as the internal states of batteries are difficult to measure experimentally without altering the thermal behavior being studied. This leads to uncertainties in simulation results, particularly for novel cell designs or extreme operating conditions where historical validation data is limited.

Parameter identification represents another significant limitation, as material properties can vary with temperature, state of charge, and aging. Obtaining accurate input parameters for all simulation conditions requires extensive experimental characterization, which is time-consuming and expensive.

Multi-scale modeling remains particularly challenging, as phenomena ranging from electrochemical reactions at the nanoscale to pack-level thermal management operate across vastly different time and length scales. Current FEA approaches often struggle to efficiently bridge these scales without introducing prohibitive computational complexity.

Real-time simulation capabilities for control system development and digital twin applications are still limited, with most detailed thermal models running significantly slower than real-time. This restricts their application in hardware-in-the-loop testing and online battery management system optimization.

State-of-the-Art FEA Methods for Battery Thermal Analysis

01 Liquid cooling systems for battery thermal management

Liquid cooling systems are effective for battery thermal management, utilizing coolant circulation through channels or plates in direct contact with battery cells. These systems provide efficient heat transfer, maintaining optimal battery temperature during operation. Advanced designs incorporate flow control mechanisms to adjust cooling intensity based on thermal load, ensuring uniform temperature distribution across battery packs and preventing hotspots that could lead to degradation or safety issues.- Liquid cooling systems for battery thermal management: Liquid cooling systems are employed in battery thermal management to efficiently control temperature. These systems circulate coolant through channels or plates in direct contact with battery cells or modules. The liquid medium provides superior heat transfer capabilities compared to air cooling, allowing for more precise temperature control and uniform heat distribution across the battery pack. Advanced designs incorporate optimized flow paths, specialized coolants, and integrated heat exchangers to enhance cooling efficiency while minimizing system complexity and weight.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into battery thermal management systems to absorb and release thermal energy during phase transitions. These materials can absorb excess heat during battery operation and discharge it when temperatures drop, providing passive thermal regulation. PCMs help maintain optimal operating temperatures, prevent thermal runaway, and reduce the energy requirements of active cooling systems. Integration of PCMs with conventional cooling methods creates hybrid systems that offer improved thermal stability and energy efficiency for battery packs in various applications.

- Air cooling and ventilation techniques: Air cooling systems utilize forced or natural convection to manage battery temperatures. These systems incorporate strategically placed fans, ducts, and heat sinks to direct airflow across battery modules. Advanced designs feature optimized air channels, variable-speed fans, and intelligent control algorithms to adjust cooling intensity based on thermal load. Air cooling solutions are particularly valuable for applications where weight, cost, and simplicity are prioritized, though they may offer lower cooling capacity compared to liquid-based systems for high-power applications.

- Thermal management control systems and algorithms: Sophisticated control systems and algorithms are essential components of battery thermal management. These systems utilize temperature sensors, thermal models, and predictive algorithms to optimize cooling or heating operations based on real-time conditions and usage patterns. Advanced controllers can anticipate thermal needs based on driving profiles, ambient conditions, and battery state of charge. Machine learning approaches enable adaptive thermal management strategies that improve over time, balancing performance requirements with energy efficiency to extend battery life and enhance safety.

- Integration of heating elements for cold-weather operation: Heating elements are integrated into battery thermal management systems to maintain optimal operating temperatures in cold environments. These systems can include resistive heaters, positive temperature coefficient (PTC) elements, or waste heat recovery mechanisms. Preconditioning strategies warm batteries before operation to improve performance and prevent degradation. Advanced systems combine heating with insulation techniques to minimize energy consumption while ensuring batteries remain within their ideal temperature range. This approach is particularly important for electric vehicles operating in cold climates where battery performance would otherwise be significantly reduced.

02 Phase change materials for thermal regulation

Phase change materials (PCMs) offer passive thermal management for battery systems by absorbing excess heat during operation and releasing it when temperatures drop. These materials change state at specific temperatures, helping maintain batteries within optimal operating ranges. PCMs can be integrated into battery modules as dedicated layers or components, providing thermal buffering without requiring active energy input, which is particularly valuable for improving efficiency in electric vehicles and energy storage systems.Expand Specific Solutions03 Air cooling and ventilation systems

Air cooling systems utilize forced or natural convection to regulate battery temperature. These systems incorporate strategically placed fans, ducts, and heat sinks to direct airflow across battery modules. While less efficient than liquid cooling, air-based thermal management offers simplicity, lower weight, and reduced maintenance requirements. Advanced designs feature variable-speed fans and intelligent airflow distribution to optimize cooling performance based on real-time thermal conditions and operational demands.Expand Specific Solutions04 Integrated thermal management control systems

Integrated control systems for battery thermal management utilize sensors, algorithms, and predictive modeling to optimize temperature regulation. These systems continuously monitor battery conditions and adjust cooling or heating parameters accordingly. Advanced implementations incorporate machine learning to predict thermal behavior based on usage patterns and environmental conditions. By integrating with vehicle or energy storage system management, these control systems balance thermal performance with energy efficiency, extending battery life while ensuring safe operation under varying load conditions.Expand Specific Solutions05 Thermal insulation and heat distribution technologies

Thermal insulation and heat distribution technologies focus on managing temperature gradients within battery packs. These solutions incorporate specialized materials and designs to isolate battery modules from external heat sources while promoting uniform heat distribution internally. Techniques include the use of thermal interface materials, heat spreaders, and strategic cell arrangement to minimize temperature differentials. Advanced designs feature composite insulation materials that adapt to changing thermal conditions, preventing both overheating and cold-start issues in extreme environments.Expand Specific Solutions

Leading Companies in Battery Thermal Simulation Software

The Battery Thermal Management Systems (BTMS) market is currently in a growth phase, driven by the expanding electric vehicle industry. The global market size is projected to reach significant value as automotive manufacturers prioritize battery safety and performance. Technologically, the field shows varying maturity levels, with companies like BYD, TWAICE Technologies, and NIO leading innovation through advanced simulation capabilities. Established automotive players including Mercedes-Benz, Stellantis, and Beijing Electric Vehicle are integrating sophisticated thermal management solutions, while research institutions such as Beihang University and IFP Energies Nouvelles contribute fundamental advancements. Battery manufacturers like CALB and Yinlong Energy are developing specialized thermal management technologies to enhance their competitive positioning in this increasingly critical EV subsystem market.

BYD Co., Ltd.

Technical Solution: BYD has developed an advanced finite element-based simulation system for battery thermal management that integrates multi-physics modeling approaches. Their solution employs a comprehensive 3D thermal model that accounts for electrochemical heat generation, fluid dynamics of coolants, and structural integrity under thermal stress. BYD's simulation platform incorporates both cell-level and pack-level thermal analysis, utilizing parallel computing architecture to handle complex geometries with over 10 million mesh elements while maintaining computational efficiency. The system features real-time thermal prediction capabilities that can simulate various driving cycles and extreme environmental conditions, allowing engineers to optimize cooling channel designs and thermal interface materials. BYD has particularly focused on their blade battery technology, using simulation to achieve uniform temperature distribution with maximum temperature differences below 3°C across the pack.

Strengths: Highly integrated with their proprietary battery manufacturing processes, allowing for design-to-manufacturing optimization. Their simulation accuracy has been validated through extensive real-world testing across various climate conditions. Weaknesses: The system requires significant computational resources and specialized expertise to operate effectively, potentially limiting its accessibility to smaller engineering teams.

NIO Technology (Anhui) Co. Ltd.

Technical Solution: NIO has pioneered a sophisticated finite element simulation framework for battery thermal management systems that focuses on their unique battery swapping technology requirements. Their approach combines electrochemical-thermal coupled models with computational fluid dynamics to simulate heat generation and dissipation across their battery packs. NIO's simulation platform incorporates machine learning algorithms that improve prediction accuracy by learning from operational data collected from their extensive network of vehicles. The system can simulate thermal behavior under various charging scenarios, including fast charging and battery swapping operations, with temperature prediction accuracy within 2°C of measured values. NIO's thermal simulation also accounts for thermal runaway propagation, using detailed cell-to-cell heat transfer models to design safety features that can contain thermal events. Their liquid cooling system design has been optimized through these simulations to maintain cell temperature differences below 3°C even during high-power discharge scenarios.

Strengths: Highly specialized for battery swapping applications, with validated models for rapid thermal transients during swap operations. Their cloud-based simulation infrastructure allows for continuous improvement through fleet data integration. Weaknesses: The simulation system is heavily tailored to their proprietary battery architecture, potentially limiting its applicability to standard fixed-battery electric vehicle designs.

Key Algorithms and Models for Thermal Simulation Accuracy

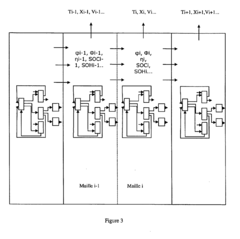

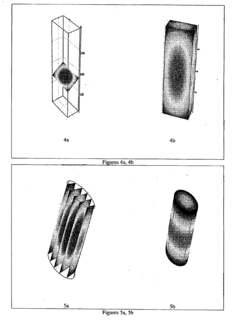

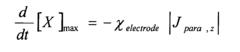

Method for simulating the thermal comportment of an electro-chemical system

PatentInactiveEP2293091A2

Innovation

- A multidimensional mathematical model using finite elements combined with a zero-dimensional electrochemical model is employed to simulate the thermal behavior of batteries, allowing for the calculation of internal temperature gradients and state of charge by discretizing behavioral equations and integrating heat flow at each time step, thereby enhancing precision and reducing computational complexity.

Battery thermal characteristic simulation device for testing battery thermal management system

PatentPendingCN117706394A

Innovation

- A battery thermal characteristics simulation device is designed, including an outer shell, a heat-generating module, a temperature sensor, a controller, a occupancy cavity and a mixed heat-conducting medium. By controlling the heating power of the heat-generating module and the composition of the mixed heat-conducting medium, the battery is simulated The heat generation, heat capacity and heat transfer characteristics ensure that the specific heat capacity and thermal conductivity of the simulation device are consistent with the simulated battery, and the heat transfer boundary is simulated through the geometric size and material of the outer shell.

Computational Resource Requirements and Optimization

Finite element-based simulations of Battery Thermal Management Systems (BTMS) demand substantial computational resources due to their multi-physics nature and complex geometries. Current high-fidelity BTMS simulations typically require workstations with minimum specifications of 16-32 CPU cores, 64-128 GB RAM, and dedicated GPUs with at least 8 GB VRAM. For large-scale battery pack simulations incorporating detailed electrochemical-thermal coupling, these requirements can increase exponentially, necessitating high-performance computing (HPC) clusters.

Resource optimization strategies have emerged as critical factors in making these simulations more accessible and efficient. Adaptive mesh refinement techniques have demonstrated computational savings of 30-45% by concentrating elements in thermal gradient regions while maintaining coarser meshes elsewhere. This approach significantly reduces the total element count while preserving simulation accuracy in critical areas such as cell junctions and cooling channels.

Model order reduction (MOR) methods represent another promising optimization approach, creating simplified mathematical representations that capture essential thermal behaviors while reducing computational complexity. Recent implementations have achieved up to 80% reduction in simulation time for transient thermal analyses, though with accuracy trade-offs of 3-5% compared to full-order models.

GPU acceleration has revolutionized BTMS simulation capabilities, with modern GPU-optimized solvers demonstrating 5-10x speedup compared to CPU-only implementations. This acceleration is particularly effective for parallel computations in thermal conductivity matrices and fluid dynamics calculations within cooling systems. NVIDIA's CUDA architecture and AMD's ROCm platform have become standard frameworks for these implementations.

Cloud-based simulation platforms offer scalable resources for BTMS modeling, allowing on-demand access to computational power. These services typically operate on a pay-per-use model, with costs ranging from $1-5 per core-hour depending on resource requirements. For organizations without dedicated HPC infrastructure, cloud solutions provide cost-effective alternatives to capital-intensive hardware investments.

Simulation workflow optimization represents a complementary approach to hardware solutions. Techniques such as multi-fidelity modeling, where simplified models are used for initial design exploration before transitioning to high-fidelity simulations for final validation, can reduce overall computational requirements by 40-60%. Similarly, batch processing and parametric studies can be optimized through intelligent sampling methods like Latin Hypercube or Optimal Space-Filling designs, reducing the number of required simulation runs by 30-50% compared to full factorial approaches.

Resource optimization strategies have emerged as critical factors in making these simulations more accessible and efficient. Adaptive mesh refinement techniques have demonstrated computational savings of 30-45% by concentrating elements in thermal gradient regions while maintaining coarser meshes elsewhere. This approach significantly reduces the total element count while preserving simulation accuracy in critical areas such as cell junctions and cooling channels.

Model order reduction (MOR) methods represent another promising optimization approach, creating simplified mathematical representations that capture essential thermal behaviors while reducing computational complexity. Recent implementations have achieved up to 80% reduction in simulation time for transient thermal analyses, though with accuracy trade-offs of 3-5% compared to full-order models.

GPU acceleration has revolutionized BTMS simulation capabilities, with modern GPU-optimized solvers demonstrating 5-10x speedup compared to CPU-only implementations. This acceleration is particularly effective for parallel computations in thermal conductivity matrices and fluid dynamics calculations within cooling systems. NVIDIA's CUDA architecture and AMD's ROCm platform have become standard frameworks for these implementations.

Cloud-based simulation platforms offer scalable resources for BTMS modeling, allowing on-demand access to computational power. These services typically operate on a pay-per-use model, with costs ranging from $1-5 per core-hour depending on resource requirements. For organizations without dedicated HPC infrastructure, cloud solutions provide cost-effective alternatives to capital-intensive hardware investments.

Simulation workflow optimization represents a complementary approach to hardware solutions. Techniques such as multi-fidelity modeling, where simplified models are used for initial design exploration before transitioning to high-fidelity simulations for final validation, can reduce overall computational requirements by 40-60%. Similarly, batch processing and parametric studies can be optimized through intelligent sampling methods like Latin Hypercube or Optimal Space-Filling designs, reducing the number of required simulation runs by 30-50% compared to full factorial approaches.

Safety Standards and Validation Protocols

The development of safety standards for Battery Thermal Management Systems (BTMS) has evolved significantly in response to high-profile battery thermal runaway incidents. Key international standards include IEC 62660, ISO 6469, and UL 2580, which establish comprehensive requirements for thermal performance, safety margins, and failure mode analysis. These standards mandate specific temperature thresholds, thermal gradient limitations, and cooling system performance metrics that finite element simulations must validate.

Validation protocols for BTMS simulations follow a multi-tiered approach. Primary validation requires correlation between simulation results and physical testing data across various operational conditions. This includes steady-state temperature distribution, transient thermal response during rapid charging/discharging, and thermal behavior under extreme ambient conditions. The acceptable margin of error typically ranges from 2-5% for critical parameters such as maximum temperature and thermal gradients.

Advanced validation protocols incorporate accelerated aging tests to verify that simulation models accurately predict long-term thermal performance degradation. These protocols typically require simulation models to demonstrate predictive accuracy over 1000+ charge-discharge cycles, with thermal performance deviation remaining within established tolerances. Hardware-in-the-loop (HIL) testing has emerged as a crucial validation methodology, where physical cooling system components interact with simulated battery models in real-time.

Regulatory bodies increasingly require fault condition simulations as part of safety certification. These simulations must demonstrate system response to cooling system failures, sensor malfunctions, and control algorithm errors. The NHTSA and European New Car Assessment Program (Euro NCAP) have established specific thermal runaway propagation tests that BTMS designs must pass, requiring simulations to accurately predict thermal propagation barriers' effectiveness.

Simulation validation documentation has become standardized, requiring traceability between model assumptions, boundary conditions, and physical test results. This documentation must include mesh sensitivity analysis, solver convergence studies, and uncertainty quantification. Many certification processes now require independent third-party verification of simulation methodologies before accepting simulation results as evidence of compliance with safety standards.

The integration of these standards and validation protocols into the development workflow has significantly reduced development cycles while improving safety margins. Companies implementing comprehensive validation frameworks report 30-40% reductions in physical prototype iterations and associated testing costs, while maintaining or improving the robustness of their thermal management solutions.

Validation protocols for BTMS simulations follow a multi-tiered approach. Primary validation requires correlation between simulation results and physical testing data across various operational conditions. This includes steady-state temperature distribution, transient thermal response during rapid charging/discharging, and thermal behavior under extreme ambient conditions. The acceptable margin of error typically ranges from 2-5% for critical parameters such as maximum temperature and thermal gradients.

Advanced validation protocols incorporate accelerated aging tests to verify that simulation models accurately predict long-term thermal performance degradation. These protocols typically require simulation models to demonstrate predictive accuracy over 1000+ charge-discharge cycles, with thermal performance deviation remaining within established tolerances. Hardware-in-the-loop (HIL) testing has emerged as a crucial validation methodology, where physical cooling system components interact with simulated battery models in real-time.

Regulatory bodies increasingly require fault condition simulations as part of safety certification. These simulations must demonstrate system response to cooling system failures, sensor malfunctions, and control algorithm errors. The NHTSA and European New Car Assessment Program (Euro NCAP) have established specific thermal runaway propagation tests that BTMS designs must pass, requiring simulations to accurately predict thermal propagation barriers' effectiveness.

Simulation validation documentation has become standardized, requiring traceability between model assumptions, boundary conditions, and physical test results. This documentation must include mesh sensitivity analysis, solver convergence studies, and uncertainty quantification. Many certification processes now require independent third-party verification of simulation methodologies before accepting simulation results as evidence of compliance with safety standards.

The integration of these standards and validation protocols into the development workflow has significantly reduced development cycles while improving safety margins. Companies implementing comprehensive validation frameworks report 30-40% reductions in physical prototype iterations and associated testing costs, while maintaining or improving the robustness of their thermal management solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!