Verification And Validation Workflow For Finite Element Simulations

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FEA V&V Background and Objectives

Finite Element Analysis (FEA) has evolved significantly since its inception in the 1950s, becoming an indispensable tool in modern engineering design and analysis. The verification and validation (V&V) of FEA simulations represents a critical aspect of ensuring simulation reliability and accuracy. Historically, V&V methodologies have progressed from simple analytical comparisons to sophisticated frameworks incorporating uncertainty quantification and statistical methods.

The evolution of computational power has dramatically expanded the scope and complexity of FEA applications, from basic structural analysis to multiphysics simulations involving fluid-structure interaction, thermomechanical coupling, and nonlinear material behavior. This expansion has necessitated increasingly robust V&V protocols to maintain confidence in simulation outcomes across diverse engineering domains.

Current industry standards for FEA V&V include ASME V&V 10, AIAA G-077, and ISO 16949, each providing structured approaches to simulation verification and validation. These standards have emerged in response to high-profile engineering failures attributed to inadequate simulation validation, highlighting the critical importance of systematic V&V workflows.

The primary objective of FEA V&V is to establish quantifiable confidence in simulation predictions through systematic comparison with analytical solutions, benchmark problems, and experimental data. This process aims to identify and quantify both numerical errors (verification) and modeling errors (validation), ensuring that simulations accurately represent physical reality within defined tolerances.

Secondary objectives include optimizing computational efficiency without compromising accuracy, establishing clear documentation protocols for simulation assumptions and limitations, and developing standardized procedures for model calibration and uncertainty quantification. These objectives support the broader goal of integrating simulation-based decision-making into critical engineering processes.

The technological trajectory of FEA V&V is moving toward automated verification procedures, machine learning-enhanced validation techniques, and real-time uncertainty quantification. These advancements aim to address the increasing complexity of engineering systems while maintaining or improving confidence in simulation outcomes.

Emerging challenges include the validation of multiscale models spanning nanoscopic to macroscopic domains, verification of simulations incorporating novel materials with complex constitutive behaviors, and development of efficient V&V methodologies for large-scale optimization and probabilistic analyses. Addressing these challenges requires interdisciplinary collaboration between computational scientists, experimental researchers, and domain experts.

The evolution of computational power has dramatically expanded the scope and complexity of FEA applications, from basic structural analysis to multiphysics simulations involving fluid-structure interaction, thermomechanical coupling, and nonlinear material behavior. This expansion has necessitated increasingly robust V&V protocols to maintain confidence in simulation outcomes across diverse engineering domains.

Current industry standards for FEA V&V include ASME V&V 10, AIAA G-077, and ISO 16949, each providing structured approaches to simulation verification and validation. These standards have emerged in response to high-profile engineering failures attributed to inadequate simulation validation, highlighting the critical importance of systematic V&V workflows.

The primary objective of FEA V&V is to establish quantifiable confidence in simulation predictions through systematic comparison with analytical solutions, benchmark problems, and experimental data. This process aims to identify and quantify both numerical errors (verification) and modeling errors (validation), ensuring that simulations accurately represent physical reality within defined tolerances.

Secondary objectives include optimizing computational efficiency without compromising accuracy, establishing clear documentation protocols for simulation assumptions and limitations, and developing standardized procedures for model calibration and uncertainty quantification. These objectives support the broader goal of integrating simulation-based decision-making into critical engineering processes.

The technological trajectory of FEA V&V is moving toward automated verification procedures, machine learning-enhanced validation techniques, and real-time uncertainty quantification. These advancements aim to address the increasing complexity of engineering systems while maintaining or improving confidence in simulation outcomes.

Emerging challenges include the validation of multiscale models spanning nanoscopic to macroscopic domains, verification of simulations incorporating novel materials with complex constitutive behaviors, and development of efficient V&V methodologies for large-scale optimization and probabilistic analyses. Addressing these challenges requires interdisciplinary collaboration between computational scientists, experimental researchers, and domain experts.

Market Demand for Reliable FEA Simulation

The global market for Finite Element Analysis (FEA) simulation software has experienced substantial growth, driven by increasing demands for product reliability, safety, and performance optimization across multiple industries. According to recent market analyses, the FEA software market is projected to reach $9.2 billion by 2027, with a compound annual growth rate of approximately 11.4% from 2022.

Manufacturing industries, particularly automotive and aerospace sectors, represent the largest market segments demanding reliable FEA simulation capabilities. These industries face stringent regulatory requirements and competitive pressures to reduce development cycles while ensuring product integrity. The automotive industry alone accounts for nearly 24% of the total FEA software market, with aerospace following at 19%.

The shift toward digital prototyping and virtual testing has accelerated dramatically, with companies reporting up to 70% reduction in physical testing costs when implementing comprehensive verification and validation workflows for FEA simulations. This trend has been further amplified by the COVID-19 pandemic, which disrupted traditional physical testing capabilities and accelerated digital transformation initiatives.

Engineering service providers report that clients increasingly demand not just simulation software but complete verification and validation methodologies that can provide documented evidence of simulation reliability. A survey of 500 engineering firms revealed that 78% consider verification and validation capabilities as "critical" or "very important" when selecting simulation partners or tools.

The energy sector, particularly renewable energy development, has emerged as a rapidly growing market for validated FEA simulations. Wind turbine manufacturers, for instance, rely heavily on structural simulations that must be rigorously verified against field data to predict component lifespans accurately under variable environmental conditions.

Healthcare and medical device industries represent another growth segment, with regulatory bodies like the FDA increasingly accepting simulation evidence as part of approval submissions when backed by comprehensive verification and validation documentation. This regulatory acceptance has created a premium market for simulation workflows that can meet stringent documentation and traceability requirements.

Small and medium enterprises (SMEs) are showing increased adoption of FEA technologies, but cite concerns about verification methodologies as a significant barrier. This indicates a market opportunity for simplified yet robust verification and validation workflows tailored to organizations with limited simulation expertise.

Manufacturing industries, particularly automotive and aerospace sectors, represent the largest market segments demanding reliable FEA simulation capabilities. These industries face stringent regulatory requirements and competitive pressures to reduce development cycles while ensuring product integrity. The automotive industry alone accounts for nearly 24% of the total FEA software market, with aerospace following at 19%.

The shift toward digital prototyping and virtual testing has accelerated dramatically, with companies reporting up to 70% reduction in physical testing costs when implementing comprehensive verification and validation workflows for FEA simulations. This trend has been further amplified by the COVID-19 pandemic, which disrupted traditional physical testing capabilities and accelerated digital transformation initiatives.

Engineering service providers report that clients increasingly demand not just simulation software but complete verification and validation methodologies that can provide documented evidence of simulation reliability. A survey of 500 engineering firms revealed that 78% consider verification and validation capabilities as "critical" or "very important" when selecting simulation partners or tools.

The energy sector, particularly renewable energy development, has emerged as a rapidly growing market for validated FEA simulations. Wind turbine manufacturers, for instance, rely heavily on structural simulations that must be rigorously verified against field data to predict component lifespans accurately under variable environmental conditions.

Healthcare and medical device industries represent another growth segment, with regulatory bodies like the FDA increasingly accepting simulation evidence as part of approval submissions when backed by comprehensive verification and validation documentation. This regulatory acceptance has created a premium market for simulation workflows that can meet stringent documentation and traceability requirements.

Small and medium enterprises (SMEs) are showing increased adoption of FEA technologies, but cite concerns about verification methodologies as a significant barrier. This indicates a market opportunity for simplified yet robust verification and validation workflows tailored to organizations with limited simulation expertise.

Current Challenges in FEA Verification

Despite significant advancements in Finite Element Analysis (FEA) verification methodologies, several persistent challenges continue to impede the development of robust verification and validation workflows. One of the primary obstacles remains the complexity of establishing appropriate verification benchmarks for increasingly sophisticated simulation scenarios. As models incorporate multiphysics interactions, nonlinear material behaviors, and complex geometries, traditional verification approaches often prove inadequate or computationally prohibitive.

The computational expense of comprehensive verification represents another significant hurdle. High-fidelity simulations demand substantial computational resources, creating a practical trade-off between verification thoroughness and time-to-solution requirements in industrial settings. This challenge is particularly acute when verification must be performed across multiple scales or when uncertainty quantification is required.

Mesh sensitivity and discretization error quantification continue to present formidable challenges. While techniques such as mesh convergence studies are well-established, their application to complex geometries with singularities or multi-scale features remains problematic. Furthermore, the automation of adaptive mesh refinement strategies that balance accuracy and computational efficiency across diverse problem domains has not been fully realized.

The verification of coupled multiphysics simulations introduces additional layers of complexity. Interactions between different physical phenomena often lead to emergent behaviors that are difficult to verify independently. The lack of standardized verification procedures for coupled problems frequently results in ad hoc approaches that may not adequately capture all relevant error sources.

Software implementation verification presents another persistent challenge. As FEA codes grow more complex and incorporate advanced algorithms, ensuring the correct implementation of mathematical models becomes increasingly difficult. Code verification through the method of manufactured solutions, while powerful, requires significant expertise and is not uniformly applied across the industry.

The gap between verification and validation activities represents a conceptual challenge that impacts workflow efficiency. While verification addresses mathematical correctness, validation concerns physical relevance—bridging these domains requires careful experimental design and uncertainty quantification that many organizations struggle to implement systematically.

Finally, the documentation and communication of verification results remain inconsistent across the industry. The lack of standardized reporting formats and metrics makes it difficult to compare verification approaches or establish confidence levels in simulation results, particularly when communicating across disciplinary boundaries or between organizations with different verification cultures.

The computational expense of comprehensive verification represents another significant hurdle. High-fidelity simulations demand substantial computational resources, creating a practical trade-off between verification thoroughness and time-to-solution requirements in industrial settings. This challenge is particularly acute when verification must be performed across multiple scales or when uncertainty quantification is required.

Mesh sensitivity and discretization error quantification continue to present formidable challenges. While techniques such as mesh convergence studies are well-established, their application to complex geometries with singularities or multi-scale features remains problematic. Furthermore, the automation of adaptive mesh refinement strategies that balance accuracy and computational efficiency across diverse problem domains has not been fully realized.

The verification of coupled multiphysics simulations introduces additional layers of complexity. Interactions between different physical phenomena often lead to emergent behaviors that are difficult to verify independently. The lack of standardized verification procedures for coupled problems frequently results in ad hoc approaches that may not adequately capture all relevant error sources.

Software implementation verification presents another persistent challenge. As FEA codes grow more complex and incorporate advanced algorithms, ensuring the correct implementation of mathematical models becomes increasingly difficult. Code verification through the method of manufactured solutions, while powerful, requires significant expertise and is not uniformly applied across the industry.

The gap between verification and validation activities represents a conceptual challenge that impacts workflow efficiency. While verification addresses mathematical correctness, validation concerns physical relevance—bridging these domains requires careful experimental design and uncertainty quantification that many organizations struggle to implement systematically.

Finally, the documentation and communication of verification results remain inconsistent across the industry. The lack of standardized reporting formats and metrics makes it difficult to compare verification approaches or establish confidence levels in simulation results, particularly when communicating across disciplinary boundaries or between organizations with different verification cultures.

Established V&V Frameworks

01 Verification methodologies for finite element simulations

Verification methodologies ensure that finite element simulations correctly solve the mathematical models they are based on. These methodologies include comparing simulation results with analytical solutions, conducting mesh convergence studies, and implementing error estimation techniques. Verification focuses on the mathematical accuracy of the computational model and ensures that the numerical algorithms are implemented correctly and solve the equations with acceptable accuracy.- Verification methodologies for finite element simulations: Verification methodologies ensure that finite element simulations correctly solve the mathematical models they are based on. These methodologies include comparing simulation results with analytical solutions, conducting mesh convergence studies, and implementing error estimation techniques. Verification focuses on the mathematical accuracy of the computational model and ensures that the numerical algorithms are implemented correctly and solve the equations with acceptable accuracy.

- Validation techniques for finite element models: Validation techniques assess how well finite element models represent physical reality by comparing simulation results with experimental data. These techniques include benchmark testing, uncertainty quantification, and statistical analysis of discrepancies between simulated and measured responses. Validation processes establish the degree to which a model accurately represents real-world phenomena for its intended use and application domain.

- Integration of verification and validation in simulation workflows: Effective integration of verification and validation processes into simulation workflows enhances the reliability of finite element analyses. This integration involves establishing systematic procedures for model quality assessment, implementing automated testing frameworks, and developing documentation standards. Integrated approaches ensure consistent application of verification and validation throughout the simulation lifecycle, from model development to results interpretation.

- Machine learning approaches for simulation verification and validation: Machine learning techniques are increasingly applied to enhance verification and validation of finite element simulations. These approaches include using neural networks to identify simulation anomalies, employing clustering algorithms to categorize validation results, and implementing reinforcement learning for adaptive mesh refinement. Machine learning methods can improve the efficiency and effectiveness of verification and validation processes by automating pattern recognition and decision-making tasks.

- Industry-specific verification and validation standards: Different industries have developed specialized verification and validation standards for finite element simulations based on their specific requirements and regulatory frameworks. These standards define acceptance criteria, testing protocols, and documentation requirements tailored to applications such as aerospace, automotive, medical devices, and civil engineering. Industry-specific approaches ensure that simulation results meet the reliability and safety requirements particular to each field.

02 Validation techniques for finite element models

Validation techniques assess how well finite element models represent physical reality by comparing simulation results with experimental data. These techniques include benchmark testing, uncertainty quantification, and statistical analysis of discrepancies between simulated and measured responses. Validation processes establish the degree to which a model accurately represents real-world phenomena for its intended use case.Expand Specific Solutions03 Automated verification and validation frameworks

Automated frameworks streamline the verification and validation process for finite element simulations by implementing standardized testing protocols, automated comparison tools, and continuous integration systems. These frameworks can automatically execute test cases, compare results against benchmarks, and generate comprehensive reports, reducing manual effort and increasing reliability in the verification and validation workflow.Expand Specific Solutions04 Industry-specific verification and validation approaches

Different industries have developed specialized verification and validation approaches for finite element simulations that address their unique requirements and regulatory standards. These approaches include domain-specific test cases, acceptance criteria, and certification processes tailored to industries such as aerospace, automotive, medical devices, and civil engineering, ensuring that simulations meet industry-specific performance and safety standards.Expand Specific Solutions05 Machine learning integration for simulation verification

Machine learning techniques are being integrated into verification and validation processes for finite element simulations to improve accuracy and efficiency. These approaches use artificial intelligence to identify patterns in simulation errors, predict model accuracy, optimize verification test cases, and automate the detection of anomalies in simulation results, leading to more robust verification methodologies and higher confidence in simulation outcomes.Expand Specific Solutions

Leading FEA Software Providers

The Verification and Validation (V&V) workflow for Finite Element Simulations market is currently in a growth phase, with increasing adoption across engineering sectors. The global market size is estimated to exceed $2 billion, driven by demands for higher accuracy in complex simulations. Leading technology providers like Synopsys, Cadence Design Systems, and Siemens AG have developed mature V&V solutions with comprehensive validation frameworks, while companies such as IBM, GLOBALFOUNDRIES, and Analog Devices are integrating these workflows into their semiconductor design processes. Newer entrants like Imagination Technologies are focusing on specialized V&V tools for specific applications, creating a competitive landscape that balances established enterprise solutions with emerging specialized offerings.

International Business Machines Corp.

Technical Solution: IBM has pioneered an advanced V&V workflow for FEA simulations that leverages their expertise in high-performance computing and artificial intelligence. Their approach centers on a hierarchical verification methodology that systematically addresses verification at multiple scales and fidelity levels. IBM's workflow begins with unit testing of individual simulation components, followed by integration testing of coupled physics modules, and culminates in system-level verification. For validation, IBM employs a Bayesian framework that quantifies uncertainties in both simulation models and experimental data, allowing for rigorous model calibration and validation metrics. Their methodology incorporates machine learning techniques to create surrogate models that accelerate uncertainty quantification and sensitivity analysis while maintaining accuracy[2]. IBM's workflow also features automated documentation generation that captures the complete V&V process, creating an audit trail that meets regulatory requirements in industries like aerospace and healthcare. The system integrates with IBM's quantum computing resources for tackling particularly complex uncertainty propagation problems that would be intractable with conventional computing approaches.

Strengths: Integration of AI/ML techniques to enhance verification efficiency; robust uncertainty quantification framework; scalable high-performance computing implementation for complex simulations; comprehensive documentation capabilities. Weaknesses: Potentially high computational cost for full implementation; steep learning curve for users; may require specialized hardware for optimal performance.

Fujitsu Ltd.

Technical Solution: Fujitsu has developed an innovative V&V workflow for FEA simulations that leverages their high-performance computing infrastructure and digital transformation expertise. Their approach integrates traditional verification methodologies with advanced AI-assisted validation techniques. Fujitsu's workflow begins with automated code verification using the Method of Manufactured Solutions to verify the correctness of numerical implementations. Their solution implements adaptive mesh refinement strategies guided by adjoint-based error estimators to optimize computational efficiency while maintaining solution accuracy. For validation, Fujitsu employs a digital twin framework that continuously compares simulation predictions with sensor data from physical systems, enabling real-time validation and model updating[5]. Their methodology incorporates Bayesian calibration techniques to systematically reduce discrepancies between simulations and experimental measurements while quantifying remaining uncertainties. Fujitsu's workflow features specialized verification tools for high-performance computing environments, including parallel scalability verification and numerical consistency checks across different processor configurations. Their platform provides comprehensive visualization capabilities for verification metrics and validation comparisons, enabling engineers to quickly identify areas requiring further refinement or investigation.

Strengths: Strong integration with high-performance computing resources; advanced digital twin capabilities for continuous validation; AI-assisted verification processes; comprehensive visualization tools. Weaknesses: May require significant computing infrastructure; complex implementation process; potential challenges in data integration from diverse sources; high initial setup costs.

Critical Benchmarks and Standards

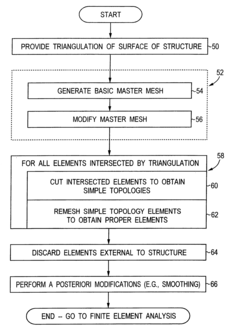

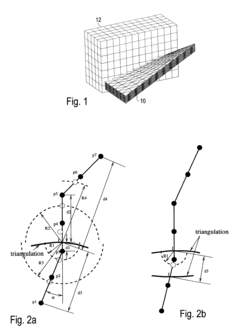

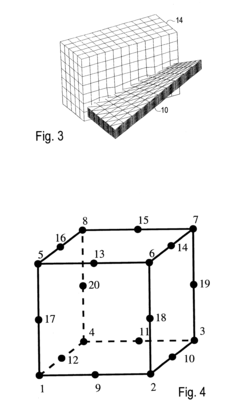

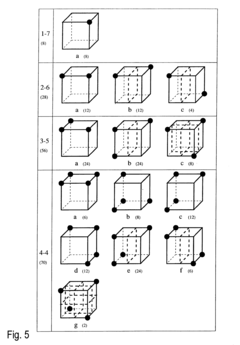

Generating a three-dimensional mesh for finite element analysis

PatentInactiveUS6804635B1

Innovation

- A cutting and remeshing procedure is employed, starting with a master mesh that is cut along the structure's boundaries, with intersected elements being processed to achieve simple topologies and then remeshed into 20-node brick elements, optimizing the mesh for accuracy and efficiency.

System and method for finite element analysis of parts having variable spatial density graded regions produced via 3D printers

PatentInactiveUS20190146457A1

Innovation

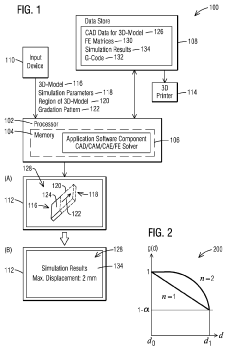

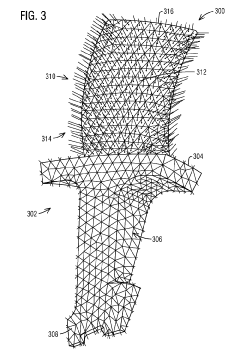

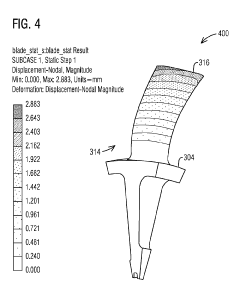

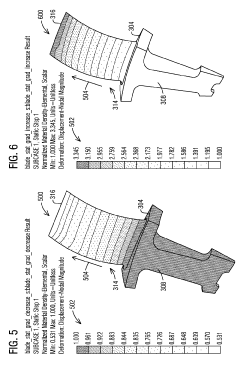

- A data processing system configured to receive inputs for 3D models, simulation parameters, and gradation patterns, which modifies finite element material coefficients automatically based on location and gradation patterns, reducing computational intensity by applying these modifications during the design phase before printing.

Uncertainty Quantification

Uncertainty quantification (UQ) represents a critical dimension in the verification and validation workflow for finite element simulations, addressing the inherent variability and knowledge gaps that affect simulation reliability. In engineering applications, UQ methodologies systematically identify, characterize, and quantify uncertainties across the simulation pipeline, from input parameters to model assumptions and numerical implementations.

The primary sources of uncertainty in finite element simulations can be categorized as aleatory (inherent randomness) and epistemic (knowledge limitations). Aleatory uncertainties include material property variations, geometric tolerances, and loading condition fluctuations, while epistemic uncertainties encompass model form errors, numerical approximations, and parameter estimation limitations. Effective UQ frameworks must address both types to provide comprehensive reliability assessments.

Modern UQ approaches employ sophisticated statistical techniques including Monte Carlo sampling, polynomial chaos expansion, and Bayesian inference methods. Monte Carlo methods, while computationally intensive, offer robust uncertainty propagation through repeated sampling across the parameter space. For complex finite element models with high computational demands, surrogate modeling techniques such as Kriging and response surface methodologies provide efficient alternatives by approximating the input-output relationships.

Sensitivity analysis constitutes an essential component of UQ, identifying which input parameters most significantly influence simulation outcomes. Global sensitivity methods like Sobol indices and Morris screening enable engineers to prioritize uncertainty reduction efforts by focusing on parameters with the greatest impact on simulation results, thereby optimizing resource allocation in validation campaigns.

The integration of UQ with verification and validation workflows enables quantitative reliability metrics such as confidence intervals, prediction intervals, and probability of failure estimates. These metrics provide decision-makers with transparent assessments of simulation trustworthiness, facilitating risk-informed design decisions and regulatory compliance documentation.

Industry implementation of UQ in finite element simulations has accelerated with the development of specialized software frameworks like DAKOTA, UQLab, and COSSAN, which provide accessible interfaces for engineers to incorporate uncertainty analysis into existing simulation workflows. Despite these advances, challenges remain in handling high-dimensional parameter spaces, computationally intensive models, and the integration of experimental data with varying fidelity levels.

Future directions in UQ for finite element simulations include multi-fidelity approaches that leverage hierarchical modeling, advanced machine learning techniques for uncertainty representation, and real-time uncertainty quantification for digital twin applications where simulations must continuously adapt to incoming operational data.

The primary sources of uncertainty in finite element simulations can be categorized as aleatory (inherent randomness) and epistemic (knowledge limitations). Aleatory uncertainties include material property variations, geometric tolerances, and loading condition fluctuations, while epistemic uncertainties encompass model form errors, numerical approximations, and parameter estimation limitations. Effective UQ frameworks must address both types to provide comprehensive reliability assessments.

Modern UQ approaches employ sophisticated statistical techniques including Monte Carlo sampling, polynomial chaos expansion, and Bayesian inference methods. Monte Carlo methods, while computationally intensive, offer robust uncertainty propagation through repeated sampling across the parameter space. For complex finite element models with high computational demands, surrogate modeling techniques such as Kriging and response surface methodologies provide efficient alternatives by approximating the input-output relationships.

Sensitivity analysis constitutes an essential component of UQ, identifying which input parameters most significantly influence simulation outcomes. Global sensitivity methods like Sobol indices and Morris screening enable engineers to prioritize uncertainty reduction efforts by focusing on parameters with the greatest impact on simulation results, thereby optimizing resource allocation in validation campaigns.

The integration of UQ with verification and validation workflows enables quantitative reliability metrics such as confidence intervals, prediction intervals, and probability of failure estimates. These metrics provide decision-makers with transparent assessments of simulation trustworthiness, facilitating risk-informed design decisions and regulatory compliance documentation.

Industry implementation of UQ in finite element simulations has accelerated with the development of specialized software frameworks like DAKOTA, UQLab, and COSSAN, which provide accessible interfaces for engineers to incorporate uncertainty analysis into existing simulation workflows. Despite these advances, challenges remain in handling high-dimensional parameter spaces, computationally intensive models, and the integration of experimental data with varying fidelity levels.

Future directions in UQ for finite element simulations include multi-fidelity approaches that leverage hierarchical modeling, advanced machine learning techniques for uncertainty representation, and real-time uncertainty quantification for digital twin applications where simulations must continuously adapt to incoming operational data.

Regulatory Compliance

Regulatory compliance represents a critical dimension in the verification and validation (V&V) workflow for finite element simulations across various industries. The landscape of regulatory requirements for simulation-based engineering has evolved significantly, with regulatory bodies increasingly recognizing the value of computational methods while imposing stringent standards to ensure public safety and product reliability.

In the medical device sector, the FDA has established comprehensive guidelines through its "Guidance for Industry and FDA Staff: Reporting of Computational Modeling Studies in Medical Device Submissions." This framework requires manufacturers to demonstrate the validity of their simulation methodologies through rigorous V&V processes before simulation results can be accepted as regulatory evidence.

Similarly, the aerospace industry operates under strict regulations from authorities like the FAA and EASA, which have developed specific protocols for simulation-based certification through documents such as FAA Advisory Circular 20-146 and the European Aviation Safety Agency's Certification Memoranda. These frameworks mandate extensive documentation of verification benchmarks and validation against physical tests.

The automotive sector faces comparable requirements through standards like ISO 26262 for functional safety, which explicitly addresses the reliability of simulation tools in safety-critical applications. Manufacturers must demonstrate that their finite element models accurately represent real-world behavior through comprehensive validation protocols.

Nuclear regulatory bodies have perhaps the most stringent requirements, with the Nuclear Regulatory Commission (NRC) in the United States and similar organizations globally requiring extensive qualification of simulation codes before they can be used in safety analyses. This includes blind validation studies and uncertainty quantification.

Cross-industry standards like ASME V&V 10-2006 (Standard for Verification and Validation in Computational Solid Mechanics) provide generalized frameworks that align with regulatory expectations across sectors. These standards emphasize the importance of systematic approaches to model verification, validation, and uncertainty quantification.

Compliance documentation has become increasingly standardized, with regulatory bodies expecting detailed reports covering mesh convergence studies, sensitivity analyses, uncertainty quantification, and comprehensive comparisons between simulation predictions and experimental results. This documentation must establish traceability from requirements to validation evidence.

The trend toward risk-based regulatory approaches is reshaping compliance strategies, with higher-risk applications requiring more extensive validation evidence. This has led to the development of graduated V&V protocols that scale validation rigor according to the criticality of the application and potential consequences of simulation error.

In the medical device sector, the FDA has established comprehensive guidelines through its "Guidance for Industry and FDA Staff: Reporting of Computational Modeling Studies in Medical Device Submissions." This framework requires manufacturers to demonstrate the validity of their simulation methodologies through rigorous V&V processes before simulation results can be accepted as regulatory evidence.

Similarly, the aerospace industry operates under strict regulations from authorities like the FAA and EASA, which have developed specific protocols for simulation-based certification through documents such as FAA Advisory Circular 20-146 and the European Aviation Safety Agency's Certification Memoranda. These frameworks mandate extensive documentation of verification benchmarks and validation against physical tests.

The automotive sector faces comparable requirements through standards like ISO 26262 for functional safety, which explicitly addresses the reliability of simulation tools in safety-critical applications. Manufacturers must demonstrate that their finite element models accurately represent real-world behavior through comprehensive validation protocols.

Nuclear regulatory bodies have perhaps the most stringent requirements, with the Nuclear Regulatory Commission (NRC) in the United States and similar organizations globally requiring extensive qualification of simulation codes before they can be used in safety analyses. This includes blind validation studies and uncertainty quantification.

Cross-industry standards like ASME V&V 10-2006 (Standard for Verification and Validation in Computational Solid Mechanics) provide generalized frameworks that align with regulatory expectations across sectors. These standards emphasize the importance of systematic approaches to model verification, validation, and uncertainty quantification.

Compliance documentation has become increasingly standardized, with regulatory bodies expecting detailed reports covering mesh convergence studies, sensitivity analyses, uncertainty quantification, and comprehensive comparisons between simulation predictions and experimental results. This documentation must establish traceability from requirements to validation evidence.

The trend toward risk-based regulatory approaches is reshaping compliance strategies, with higher-risk applications requiring more extensive validation evidence. This has led to the development of graduated V&V protocols that scale validation rigor according to the criticality of the application and potential consequences of simulation error.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!