Cryogenic Shell And Tube Units: Differential Contraction, Seal Integrity And Materials

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Heat Exchanger Background and Objectives

Cryogenic heat exchangers represent a critical component in various industrial applications involving the processing, storage, and transportation of liquefied gases at extremely low temperatures. The evolution of these specialized heat transfer devices dates back to the early 20th century, coinciding with the industrial-scale production of liquefied gases. Over the decades, significant advancements have been made in design methodologies, material science, and manufacturing techniques to enhance their performance and reliability.

The shell and tube configuration has emerged as one of the most prevalent designs for cryogenic heat exchangers due to its robust construction and versatility. However, operating at temperatures as low as -196°C (for liquid nitrogen) or -269°C (for liquid helium) introduces unique challenges that conventional heat exchangers do not encounter. The extreme temperature differentials create substantial thermal stresses that can compromise structural integrity and operational efficiency.

A primary technical challenge in cryogenic shell and tube units is differential thermal contraction. When materials are cooled from ambient to cryogenic temperatures, they contract at different rates depending on their thermal expansion coefficients. This differential contraction can lead to misalignment, distortion, and potentially catastrophic failure of the heat exchanger components, particularly at joints and interfaces where different materials meet.

Seal integrity represents another critical concern in cryogenic applications. Traditional sealing solutions often become brittle and lose their elasticity at extremely low temperatures, leading to leakage of valuable cryogenic fluids and potential safety hazards. The development of specialized sealing technologies that maintain flexibility and sealing capability across wide temperature ranges has been a significant focus area in the industry.

Material selection for cryogenic heat exchangers requires careful consideration of properties such as low-temperature ductility, thermal conductivity, and resistance to embrittlement. Conventional engineering materials like carbon steel become brittle at cryogenic temperatures, necessitating the use of specialized alloys such as austenitic stainless steels, aluminum alloys, or nickel-based superalloys that maintain their mechanical properties in extreme cold.

The technical objectives for advancing cryogenic shell and tube heat exchangers include developing innovative designs that accommodate differential thermal contraction while maintaining structural integrity, creating more effective sealing solutions for cryogenic service, and identifying or developing new materials with superior performance characteristics at ultra-low temperatures. Additionally, there is a growing emphasis on enhancing energy efficiency, reducing manufacturing costs, and extending operational lifespans to meet the increasingly demanding requirements of industries such as LNG processing, aerospace, and scientific research.

The shell and tube configuration has emerged as one of the most prevalent designs for cryogenic heat exchangers due to its robust construction and versatility. However, operating at temperatures as low as -196°C (for liquid nitrogen) or -269°C (for liquid helium) introduces unique challenges that conventional heat exchangers do not encounter. The extreme temperature differentials create substantial thermal stresses that can compromise structural integrity and operational efficiency.

A primary technical challenge in cryogenic shell and tube units is differential thermal contraction. When materials are cooled from ambient to cryogenic temperatures, they contract at different rates depending on their thermal expansion coefficients. This differential contraction can lead to misalignment, distortion, and potentially catastrophic failure of the heat exchanger components, particularly at joints and interfaces where different materials meet.

Seal integrity represents another critical concern in cryogenic applications. Traditional sealing solutions often become brittle and lose their elasticity at extremely low temperatures, leading to leakage of valuable cryogenic fluids and potential safety hazards. The development of specialized sealing technologies that maintain flexibility and sealing capability across wide temperature ranges has been a significant focus area in the industry.

Material selection for cryogenic heat exchangers requires careful consideration of properties such as low-temperature ductility, thermal conductivity, and resistance to embrittlement. Conventional engineering materials like carbon steel become brittle at cryogenic temperatures, necessitating the use of specialized alloys such as austenitic stainless steels, aluminum alloys, or nickel-based superalloys that maintain their mechanical properties in extreme cold.

The technical objectives for advancing cryogenic shell and tube heat exchangers include developing innovative designs that accommodate differential thermal contraction while maintaining structural integrity, creating more effective sealing solutions for cryogenic service, and identifying or developing new materials with superior performance characteristics at ultra-low temperatures. Additionally, there is a growing emphasis on enhancing energy efficiency, reducing manufacturing costs, and extending operational lifespans to meet the increasingly demanding requirements of industries such as LNG processing, aerospace, and scientific research.

Market Analysis for Cryogenic Shell and Tube Applications

The global market for cryogenic shell and tube heat exchangers is experiencing robust growth, driven by expanding applications in liquefied natural gas (LNG) processing, air separation plants, and hydrogen infrastructure development. Current market valuations indicate the cryogenic equipment sector exceeds $7 billion annually, with shell and tube units representing approximately 25% of this market segment.

Energy transition initiatives worldwide are creating significant demand growth, particularly as countries invest in natural gas infrastructure as a bridge fuel. The LNG market expansion, with over 20 major liquefaction projects under development globally, directly correlates to increased demand for specialized cryogenic heat exchange equipment capable of withstanding extreme temperature differentials.

Industrial gas processing represents another substantial market driver, with air separation units requiring reliable cryogenic heat exchangers for efficient operation. This sector has shown consistent annual growth of 5-7% over the past five years, with particularly strong performance in Asia-Pacific regions where industrial development continues at an accelerated pace.

The emerging hydrogen economy presents perhaps the most promising growth vector, with projections suggesting a tenfold increase in hydrogen production capacity by 2050. This expansion necessitates substantial investment in cryogenic processing equipment, including specialized shell and tube units designed for hydrogen liquefaction and storage applications.

Market analysis reveals distinct regional patterns, with North America leading in technological innovation while Asia dominates in manufacturing capacity. European markets show particular strength in specialized applications requiring advanced materials and precision engineering. The Middle East continues expanding its cryogenic processing capabilities aligned with its strategic position in global energy markets.

Customer requirements increasingly emphasize operational reliability under extreme conditions, with particular focus on addressing differential contraction challenges and maintaining seal integrity across thousands of operational cycles. This has created premium market segments for manufacturers demonstrating superior materials science capabilities and innovative design approaches to these technical challenges.

Competitive analysis indicates market consolidation among tier-one suppliers, with five major manufacturers controlling approximately 60% of global market share. However, specialized niche players have successfully established positions by focusing on specific technical challenges such as advanced sealing technologies or composite material applications that address differential contraction issues.

The aftermarket service sector represents a significant revenue opportunity, with maintenance, repair and optimization services accounting for approximately 30% of lifetime revenue across the product category. This trend is accelerating as operators seek to extend equipment lifecycles while maintaining operational safety and efficiency.

Energy transition initiatives worldwide are creating significant demand growth, particularly as countries invest in natural gas infrastructure as a bridge fuel. The LNG market expansion, with over 20 major liquefaction projects under development globally, directly correlates to increased demand for specialized cryogenic heat exchange equipment capable of withstanding extreme temperature differentials.

Industrial gas processing represents another substantial market driver, with air separation units requiring reliable cryogenic heat exchangers for efficient operation. This sector has shown consistent annual growth of 5-7% over the past five years, with particularly strong performance in Asia-Pacific regions where industrial development continues at an accelerated pace.

The emerging hydrogen economy presents perhaps the most promising growth vector, with projections suggesting a tenfold increase in hydrogen production capacity by 2050. This expansion necessitates substantial investment in cryogenic processing equipment, including specialized shell and tube units designed for hydrogen liquefaction and storage applications.

Market analysis reveals distinct regional patterns, with North America leading in technological innovation while Asia dominates in manufacturing capacity. European markets show particular strength in specialized applications requiring advanced materials and precision engineering. The Middle East continues expanding its cryogenic processing capabilities aligned with its strategic position in global energy markets.

Customer requirements increasingly emphasize operational reliability under extreme conditions, with particular focus on addressing differential contraction challenges and maintaining seal integrity across thousands of operational cycles. This has created premium market segments for manufacturers demonstrating superior materials science capabilities and innovative design approaches to these technical challenges.

Competitive analysis indicates market consolidation among tier-one suppliers, with five major manufacturers controlling approximately 60% of global market share. However, specialized niche players have successfully established positions by focusing on specific technical challenges such as advanced sealing technologies or composite material applications that address differential contraction issues.

The aftermarket service sector represents a significant revenue opportunity, with maintenance, repair and optimization services accounting for approximately 30% of lifetime revenue across the product category. This trend is accelerating as operators seek to extend equipment lifecycles while maintaining operational safety and efficiency.

Technical Challenges in Cryogenic Temperature Operations

Operating at cryogenic temperatures presents significant technical challenges for shell and tube heat exchangers, primarily due to the extreme thermal conditions that materials must withstand. When temperatures plummet to cryogenic levels (typically below -150°C), conventional engineering approaches become inadequate, necessitating specialized solutions to maintain operational integrity.

Differential thermal contraction emerges as one of the most critical challenges in cryogenic operations. Materials contract at different rates when cooled to cryogenic temperatures, creating substantial mechanical stresses at material interfaces. For instance, stainless steel contracts approximately 0.3% when cooled from ambient to liquid nitrogen temperatures, while aluminum contracts by nearly 0.4%. This differential contraction can lead to component misalignment, seal failures, and structural damage within the heat exchanger.

Seal integrity represents another formidable challenge in cryogenic applications. Traditional elastomeric seals become brittle and lose flexibility at extremely low temperatures, compromising their sealing capabilities. The loss of seal integrity can result in dangerous cryogenic fluid leakage, posing both safety hazards and operational inefficiencies. Industry data indicates that approximately 60% of cryogenic system failures are attributed to seal-related issues.

Material selection becomes increasingly complex at cryogenic temperatures as many conventional materials experience significant property changes. Ductile-to-brittle transition is particularly problematic, with materials that exhibit good ductility at room temperature becoming dangerously brittle at cryogenic temperatures. This phenomenon affects carbon steels dramatically, limiting their applicability in cryogenic environments.

Thermal cycling between ambient and cryogenic temperatures introduces fatigue concerns that accelerate component degradation. Each thermal cycle subjects materials to stress-strain cycles that can initiate and propagate cracks, particularly at welded joints and material interfaces. Research indicates that equipment designed for cryogenic service may experience up to 70% reduction in fatigue life compared to ambient temperature operations.

Insulation effectiveness presents additional challenges, as heat leak into cryogenic systems not only reduces energy efficiency but can create localized boiling and two-phase flow conditions that disrupt heat transfer performance. Vacuum-insulated designs offer superior thermal isolation but introduce manufacturing complexity and increased costs.

Addressing these technical challenges requires integrated approaches combining advanced materials science, precision manufacturing techniques, and innovative design methodologies. Recent developments in computational modeling have improved the ability to predict thermal-mechanical behavior, but significant gaps remain in understanding long-term material performance under cryogenic cycling conditions.

Differential thermal contraction emerges as one of the most critical challenges in cryogenic operations. Materials contract at different rates when cooled to cryogenic temperatures, creating substantial mechanical stresses at material interfaces. For instance, stainless steel contracts approximately 0.3% when cooled from ambient to liquid nitrogen temperatures, while aluminum contracts by nearly 0.4%. This differential contraction can lead to component misalignment, seal failures, and structural damage within the heat exchanger.

Seal integrity represents another formidable challenge in cryogenic applications. Traditional elastomeric seals become brittle and lose flexibility at extremely low temperatures, compromising their sealing capabilities. The loss of seal integrity can result in dangerous cryogenic fluid leakage, posing both safety hazards and operational inefficiencies. Industry data indicates that approximately 60% of cryogenic system failures are attributed to seal-related issues.

Material selection becomes increasingly complex at cryogenic temperatures as many conventional materials experience significant property changes. Ductile-to-brittle transition is particularly problematic, with materials that exhibit good ductility at room temperature becoming dangerously brittle at cryogenic temperatures. This phenomenon affects carbon steels dramatically, limiting their applicability in cryogenic environments.

Thermal cycling between ambient and cryogenic temperatures introduces fatigue concerns that accelerate component degradation. Each thermal cycle subjects materials to stress-strain cycles that can initiate and propagate cracks, particularly at welded joints and material interfaces. Research indicates that equipment designed for cryogenic service may experience up to 70% reduction in fatigue life compared to ambient temperature operations.

Insulation effectiveness presents additional challenges, as heat leak into cryogenic systems not only reduces energy efficiency but can create localized boiling and two-phase flow conditions that disrupt heat transfer performance. Vacuum-insulated designs offer superior thermal isolation but introduce manufacturing complexity and increased costs.

Addressing these technical challenges requires integrated approaches combining advanced materials science, precision manufacturing techniques, and innovative design methodologies. Recent developments in computational modeling have improved the ability to predict thermal-mechanical behavior, but significant gaps remain in understanding long-term material performance under cryogenic cycling conditions.

Current Solutions for Differential Contraction Management

01 Seal designs for thermal expansion in cryogenic heat exchangers

Various seal designs are employed to maintain integrity during differential thermal contraction in cryogenic shell and tube units. These include specialized gaskets, flexible sealing elements, and composite seals that can accommodate the movement between components operating at extremely low temperatures. The designs focus on maintaining a tight seal while allowing for the significant dimensional changes that occur when materials contract at cryogenic temperatures.- Thermal expansion compensation mechanisms: Cryogenic shell and tube units experience differential contraction between components due to extreme temperature variations. Various mechanisms are employed to compensate for thermal expansion and contraction, including bellows, flexible connectors, and specialized expansion joints. These components allow for movement between the shell and tube elements while maintaining structural integrity, preventing stress concentration and potential failure points in the system.

- Sealing solutions for cryogenic applications: Maintaining seal integrity in cryogenic environments requires specialized sealing solutions that can withstand extreme cold while preventing leakage. These include cryogenic-rated gaskets, O-rings made from materials like PTFE or specialized elastomers, and metal-to-metal seals. The sealing systems are designed to maintain their properties and sealing capability despite the significant contraction that occurs at cryogenic temperatures, ensuring containment of the cryogenic fluids.

- Material selection for differential thermal contraction: The selection of appropriate materials is critical for managing differential contraction in cryogenic shell and tube units. Materials with similar coefficients of thermal expansion are often paired together to minimize differential movement. Alternatively, materials specifically chosen for their performance at cryogenic temperatures, such as certain stainless steels, aluminum alloys, or specialized composites, are used to ensure structural integrity and operational reliability under extreme temperature conditions.

- Design strategies for thermal stress management: Specific design strategies are employed to manage thermal stresses in cryogenic shell and tube heat exchangers. These include floating head designs, U-tube configurations, and segmented baffles that allow for differential movement. The strategic placement of supports and anchors also helps distribute thermal stresses evenly throughout the structure, preventing localized stress concentrations that could compromise seal integrity or cause structural failure.

- Monitoring and maintenance of seal integrity: Ensuring continued seal integrity in cryogenic shell and tube units requires specialized monitoring and maintenance protocols. This includes regular inspection using techniques such as helium leak detection, acoustic emission testing, and thermal imaging to identify potential seal failures before they occur. Preventative maintenance schedules are designed specifically for cryogenic applications, taking into account the unique challenges posed by extreme temperature cycling and differential contraction.

02 Material selection for differential thermal contraction management

Specific materials are selected for cryogenic applications based on their thermal expansion coefficients and mechanical properties at low temperatures. By strategically combining materials with compatible thermal contraction rates or using materials with minimal contraction at cryogenic temperatures, engineers can reduce stress on seals and connections. These material choices help maintain structural integrity and prevent leakage in shell and tube heat exchangers operating in extreme cold conditions.Expand Specific Solutions03 Structural design solutions for thermal contraction compensation

Innovative structural designs are implemented to accommodate differential contraction in cryogenic equipment. These include bellows, expansion joints, floating tube sheets, and specialized support structures that allow controlled movement between components. Such designs distribute thermal stresses evenly and prevent localized strain that could compromise seal integrity, ensuring reliable operation despite significant temperature gradients across the system.Expand Specific Solutions04 Monitoring and control systems for seal integrity

Advanced monitoring systems are employed to maintain seal integrity in cryogenic shell and tube units. These include temperature sensors, pressure monitors, and leak detection systems that provide real-time data on the condition of seals and connections. Control systems can automatically adjust operating parameters to reduce stress on seals during temperature transitions, helping to prevent failures due to differential contraction effects.Expand Specific Solutions05 Assembly and installation techniques for cryogenic heat exchangers

Specialized assembly and installation methods are critical for ensuring seal integrity in cryogenic applications. These techniques include precise torque specifications, controlled cooling procedures, and specific sequence of assembly that account for eventual contraction. Pre-stressing components during installation can compensate for expected dimensional changes, while proper alignment tools and procedures ensure that seals remain effective throughout the operational temperature range.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The cryogenic shell and tube units market is in a growth phase, driven by increasing demand for LNG and industrial gas applications. The market size is expanding due to energy transition initiatives and growing industrial applications requiring cryogenic temperatures. Technologically, the field faces challenges in managing differential contraction, seal integrity, and materials selection at extreme low temperatures. Companies like Air Liquide, CIMC Sanctum Cryogenic Equipment, and Gaztransport & Technigaz are leading innovation in this space, with significant contributions from Kawasaki Heavy Industries and China International Marine Containers Group. Material science advancements from companies such as Foshan Kaisi Titanium and ElringKlinger are addressing the critical challenges of maintaining seal integrity and preventing thermal stress failures in cryogenic environments.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic heat exchangers with innovative solutions for differential thermal contraction challenges. Their technology employs a multi-layered approach to material selection, using combinations of stainless steel, aluminum alloys, and specialized nickel alloys that maintain structural integrity across extreme temperature gradients (from ambient to -196°C). Their proprietary shell design incorporates flexible bellows and expansion joints strategically positioned to accommodate thermal movement without compromising the pressure boundary. For seal integrity, Air Liquide utilizes advanced cryogenic-rated elastomers and metal-to-metal sealing systems with specialized surface treatments that maintain leak-tight connections even during thermal cycling. Their heat exchangers feature innovative tube-to-tubesheet connections using orbital welding techniques that minimize residual stress and enhance reliability during thermal cycling.

Strengths: Industry-leading expertise in industrial gas applications provides deep understanding of cryogenic thermal management; global manufacturing capabilities ensure consistent quality control; extensive field experience validates long-term reliability. Weaknesses: Higher initial cost compared to conventional designs; proprietary components may limit third-party maintenance options; system complexity requires specialized installation expertise.

Gaztransport & Technigaz SA

Technical Solution: Gaztransport & Technigaz (GTT) has pioneered membrane containment systems for LNG applications that directly address differential contraction challenges in cryogenic environments. Their Mark III Flex technology utilizes a sophisticated multi-layer approach with primary and secondary metallic membranes (typically 36% nickel-steel alloy) separated by insulation layers. This design accommodates differential thermal contraction through controlled deformation of the corrugated membranes. For shell-and-tube heat exchangers in cryogenic service, GTT has developed specialized connection systems between dissimilar metals that manage thermal expansion coefficients through transition joints and flexible elements. Their sealing technology employs proprietary metal-to-metal contact designs with specialized surface treatments and controlled compression to maintain integrity across the full operating temperature range (-163°C to ambient). GTT's material selection methodology optimizes the use of austenitic stainless steels, aluminum alloys, and specialized nickel-based materials based on specific thermal and mechanical requirements.

Strengths: Unparalleled experience in LNG containment systems provides deep expertise in cryogenic thermal management; proven track record with major energy companies validates technology reliability; continuous R&D investment maintains technological leadership. Weaknesses: Solutions often optimized for large-scale applications may be less cost-effective for smaller systems; specialized designs may require dedicated maintenance protocols; higher initial engineering costs compared to standardized solutions.

Critical Materials and Seal Technologies Analysis

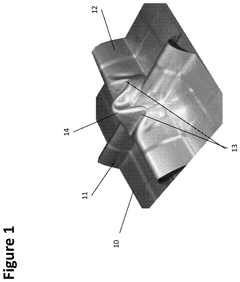

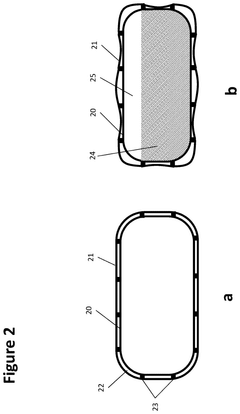

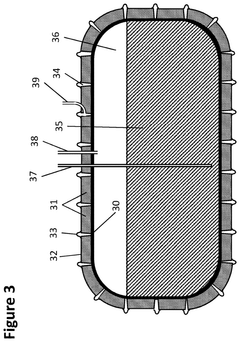

Tank feasible for cryogenic service

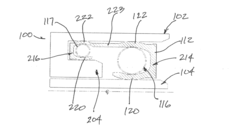

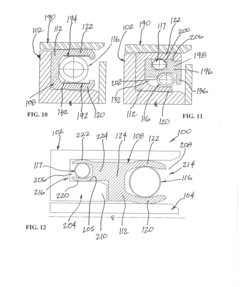

PatentActiveUS12111013B2

Innovation

- A tank design featuring a flexible outer shell with corrugated sections that accommodate thermal contraction, combined with a vacuum-insulated system using modular block elements and a lattice pressure vessel for the inner tank, ensuring efficient thermal insulation and maintaining airtightness across varying temperatures and sizes.

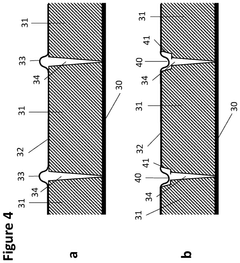

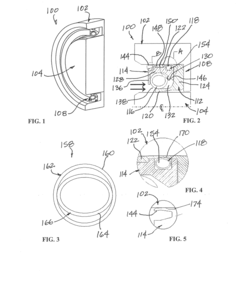

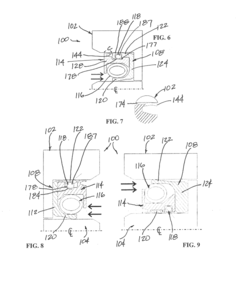

Seal assemblies for extreme temperatures and related methods

PatentActiveUS20180112778A1

Innovation

- The seal assembly design incorporates a rigid component, multiple spring energizers, a housing with a shelf, and an axial sealing component with a flange to provide additional support and maintain sealing contact during thermal expansion and contraction, using materials like fluoropolymers and specific spring configurations to counteract shrinkage and expansion.

Safety Standards and Compliance Requirements

Cryogenic shell and tube units operate under extreme conditions that necessitate strict adherence to comprehensive safety standards and compliance requirements. The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Section VIII provides foundational guidelines for pressure vessels, with specific provisions for cryogenic applications addressing material selection, design parameters, and testing protocols. These standards are particularly critical when considering differential contraction issues that can compromise structural integrity.

The European Pressure Equipment Directive (PED) 2014/68/EU complements these requirements with additional focus on risk assessment methodologies and safety systems specific to extremely low-temperature operations. Both regulatory frameworks mandate regular inspection regimes and documentation of material certifications to ensure ongoing compliance throughout the operational lifecycle of cryogenic equipment.

For seal integrity concerns, ISO 24490:2016 establishes specific requirements for cryogenic vessel gaskets and sealing materials, detailing performance criteria under thermal cycling conditions. This standard is essential for preventing leakage of cryogenic fluids that could lead to catastrophic failures or environmental hazards. Compliance with these specifications requires rigorous testing of seal materials at design temperatures and pressures to validate their performance under differential contraction scenarios.

Material selection for cryogenic applications must adhere to ASTM E1248 standards, which outline testing procedures for evaluating mechanical properties at cryogenic temperatures. Additionally, NFPA 59A provides comprehensive safety requirements specifically for production, storage, and handling of liquefied natural gas (LNG), addressing material compatibility issues that arise in cryogenic environments.

Operational safety compliance extends to personnel protection standards such as those outlined in OSHA 29 CFR 1910.111 for storage and handling of anhydrous ammonia, which shares many safety considerations with other cryogenic fluids. These regulations mandate specific training requirements, emergency response protocols, and personal protective equipment specifications for workers handling cryogenic systems.

Recent regulatory developments have introduced more stringent requirements for monitoring systems and automated safety controls. The International Electrotechnical Commission (IEC) 61511 standard for functional safety in process industries now includes specific provisions for instrumentation in cryogenic applications, requiring redundant monitoring of critical parameters affected by differential contraction, such as stress points and seal integrity.

Compliance documentation must demonstrate thorough risk assessment following methodologies outlined in ISO 31000, with particular attention to thermal cycling effects on material properties and seal performance. This documentation forms a critical component of the safety case required by regulatory authorities before commissioning cryogenic shell and tube units in most jurisdictions.

The European Pressure Equipment Directive (PED) 2014/68/EU complements these requirements with additional focus on risk assessment methodologies and safety systems specific to extremely low-temperature operations. Both regulatory frameworks mandate regular inspection regimes and documentation of material certifications to ensure ongoing compliance throughout the operational lifecycle of cryogenic equipment.

For seal integrity concerns, ISO 24490:2016 establishes specific requirements for cryogenic vessel gaskets and sealing materials, detailing performance criteria under thermal cycling conditions. This standard is essential for preventing leakage of cryogenic fluids that could lead to catastrophic failures or environmental hazards. Compliance with these specifications requires rigorous testing of seal materials at design temperatures and pressures to validate their performance under differential contraction scenarios.

Material selection for cryogenic applications must adhere to ASTM E1248 standards, which outline testing procedures for evaluating mechanical properties at cryogenic temperatures. Additionally, NFPA 59A provides comprehensive safety requirements specifically for production, storage, and handling of liquefied natural gas (LNG), addressing material compatibility issues that arise in cryogenic environments.

Operational safety compliance extends to personnel protection standards such as those outlined in OSHA 29 CFR 1910.111 for storage and handling of anhydrous ammonia, which shares many safety considerations with other cryogenic fluids. These regulations mandate specific training requirements, emergency response protocols, and personal protective equipment specifications for workers handling cryogenic systems.

Recent regulatory developments have introduced more stringent requirements for monitoring systems and automated safety controls. The International Electrotechnical Commission (IEC) 61511 standard for functional safety in process industries now includes specific provisions for instrumentation in cryogenic applications, requiring redundant monitoring of critical parameters affected by differential contraction, such as stress points and seal integrity.

Compliance documentation must demonstrate thorough risk assessment following methodologies outlined in ISO 31000, with particular attention to thermal cycling effects on material properties and seal performance. This documentation forms a critical component of the safety case required by regulatory authorities before commissioning cryogenic shell and tube units in most jurisdictions.

Lifecycle Assessment and Maintenance Protocols

The lifecycle management of cryogenic shell and tube units represents a critical aspect of operational excellence in low-temperature applications. These specialized heat exchangers experience unique degradation patterns due to the extreme temperature differentials they endure throughout their service life. Comprehensive lifecycle assessment begins with establishing baseline performance metrics during commissioning, followed by regular monitoring of thermal efficiency, pressure drop characteristics, and structural integrity indicators.

Differential contraction between materials presents a primary concern for maintenance protocols. As these units cycle between ambient and cryogenic temperatures, the varying thermal expansion coefficients of different components create cumulative stress that must be systematically evaluated. Maintenance schedules should incorporate non-destructive testing methods such as acoustic emission monitoring and thermal imaging to detect early signs of material fatigue or seal compromise before catastrophic failure occurs.

Seal integrity maintenance requires particular attention in cryogenic applications. The maintenance protocol should include regular inspection of gaskets, O-rings, and other sealing elements using helium leak detection systems capable of identifying microscopic breaches that could lead to cryogen loss or contamination. Replacement intervals for sealing components should be determined not merely by time in service but by thermal cycle count, as this more accurately reflects the mechanical stress history.

Material degradation assessment forms another cornerstone of effective lifecycle management. Periodic metallurgical analysis of sample coupons can provide early warning of embrittlement, hydrogen attack, or other material property changes. Advanced protocols now incorporate predictive analytics that combine operational data with materials science to forecast remaining useful life with greater precision than traditional time-based approaches.

Documentation and traceability systems represent an often overlooked but essential element of maintenance protocols. Each maintenance intervention should be recorded with detailed information about findings, actions taken, and components replaced. This historical record enables trend analysis that can inform future design improvements and optimize maintenance intervals based on actual performance data rather than conservative estimates.

Cost-benefit analysis should guide maintenance decision-making throughout the lifecycle. As units age, the increasing frequency of maintenance interventions must be weighed against replacement costs, considering not only direct expenses but also operational reliability requirements and potential downtime impacts. Establishing clear end-of-life criteria based on quantifiable performance metrics ensures timely decommissioning before safety risks become unacceptable.

Differential contraction between materials presents a primary concern for maintenance protocols. As these units cycle between ambient and cryogenic temperatures, the varying thermal expansion coefficients of different components create cumulative stress that must be systematically evaluated. Maintenance schedules should incorporate non-destructive testing methods such as acoustic emission monitoring and thermal imaging to detect early signs of material fatigue or seal compromise before catastrophic failure occurs.

Seal integrity maintenance requires particular attention in cryogenic applications. The maintenance protocol should include regular inspection of gaskets, O-rings, and other sealing elements using helium leak detection systems capable of identifying microscopic breaches that could lead to cryogen loss or contamination. Replacement intervals for sealing components should be determined not merely by time in service but by thermal cycle count, as this more accurately reflects the mechanical stress history.

Material degradation assessment forms another cornerstone of effective lifecycle management. Periodic metallurgical analysis of sample coupons can provide early warning of embrittlement, hydrogen attack, or other material property changes. Advanced protocols now incorporate predictive analytics that combine operational data with materials science to forecast remaining useful life with greater precision than traditional time-based approaches.

Documentation and traceability systems represent an often overlooked but essential element of maintenance protocols. Each maintenance intervention should be recorded with detailed information about findings, actions taken, and components replaced. This historical record enables trend analysis that can inform future design improvements and optimize maintenance intervals based on actual performance data rather than conservative estimates.

Cost-benefit analysis should guide maintenance decision-making throughout the lifecycle. As units age, the increasing frequency of maintenance interventions must be weighed against replacement costs, considering not only direct expenses but also operational reliability requirements and potential downtime impacts. Establishing clear end-of-life criteria based on quantifiable performance metrics ensures timely decommissioning before safety risks become unacceptable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!