Cryostat-Level Considerations For Large-Scale QEC Deployments

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryostat Technology Background and Objectives

Quantum Error Correction (QEC) represents a critical frontier in quantum computing, enabling the realization of fault-tolerant quantum systems capable of performing complex computations beyond the reach of classical computers. At the heart of QEC implementation lies cryostat technology, which provides the ultra-low temperature environment essential for quantum bit (qubit) operation and coherence maintenance.

Cryostats have evolved significantly since their inception in the early 20th century. Initially developed for fundamental physics research, these systems have transformed into sophisticated platforms capable of maintaining stable millikelvin temperatures for extended periods. The progression from simple liquid helium baths to modern dilution refrigerators marks a technological journey spanning decades of innovation in materials science, thermodynamics, and precision engineering.

The current technological landscape features several cryostat architectures, including wet systems utilizing liquid helium, dry systems employing pulse tube coolers, and hybrid approaches combining multiple cooling stages. Each design presents distinct advantages and limitations regarding cooling power, base temperature, vibration isolation, and operational costs. The state-of-the-art dilution refrigerators can maintain temperatures below 10 millikelvin, providing the necessary thermal environment for superconducting qubits and other quantum technologies.

For large-scale QEC deployments, cryostat technology faces unprecedented challenges. Current systems typically accommodate tens to hundreds of qubits, whereas practical quantum error correction requires thousands to millions of physical qubits. This scaling requirement necessitates fundamental rethinking of cryostat design, thermal management, and system integration.

The primary objective of cryostat technology advancement for QEC is to develop systems capable of housing and operating large-scale qubit arrays while maintaining quantum coherence. This involves increasing physical volume while preserving ultra-low temperatures, enhancing cooling power to manage increased heat loads from control electronics, and designing modular architectures that facilitate maintenance without compromising the quantum environment.

Secondary objectives include reducing operational costs through improved energy efficiency, developing more reliable and automated cooling cycles, and integrating sophisticated wiring and filtering solutions to support the complex control infrastructure required by QEC protocols. Additionally, there is a growing emphasis on developing cryostat designs compatible with industrial manufacturing processes to enable mass production of quantum computing systems.

The trajectory of cryostat technology development is increasingly influenced by the specific requirements of quantum computing applications, representing a shift from general-purpose scientific instruments to application-specific integrated systems. This evolution mirrors the historical development of classical computing infrastructure, suggesting potential pathways for future innovation and standardization in quantum computing hardware.

Cryostats have evolved significantly since their inception in the early 20th century. Initially developed for fundamental physics research, these systems have transformed into sophisticated platforms capable of maintaining stable millikelvin temperatures for extended periods. The progression from simple liquid helium baths to modern dilution refrigerators marks a technological journey spanning decades of innovation in materials science, thermodynamics, and precision engineering.

The current technological landscape features several cryostat architectures, including wet systems utilizing liquid helium, dry systems employing pulse tube coolers, and hybrid approaches combining multiple cooling stages. Each design presents distinct advantages and limitations regarding cooling power, base temperature, vibration isolation, and operational costs. The state-of-the-art dilution refrigerators can maintain temperatures below 10 millikelvin, providing the necessary thermal environment for superconducting qubits and other quantum technologies.

For large-scale QEC deployments, cryostat technology faces unprecedented challenges. Current systems typically accommodate tens to hundreds of qubits, whereas practical quantum error correction requires thousands to millions of physical qubits. This scaling requirement necessitates fundamental rethinking of cryostat design, thermal management, and system integration.

The primary objective of cryostat technology advancement for QEC is to develop systems capable of housing and operating large-scale qubit arrays while maintaining quantum coherence. This involves increasing physical volume while preserving ultra-low temperatures, enhancing cooling power to manage increased heat loads from control electronics, and designing modular architectures that facilitate maintenance without compromising the quantum environment.

Secondary objectives include reducing operational costs through improved energy efficiency, developing more reliable and automated cooling cycles, and integrating sophisticated wiring and filtering solutions to support the complex control infrastructure required by QEC protocols. Additionally, there is a growing emphasis on developing cryostat designs compatible with industrial manufacturing processes to enable mass production of quantum computing systems.

The trajectory of cryostat technology development is increasingly influenced by the specific requirements of quantum computing applications, representing a shift from general-purpose scientific instruments to application-specific integrated systems. This evolution mirrors the historical development of classical computing infrastructure, suggesting potential pathways for future innovation and standardization in quantum computing hardware.

Market Analysis for Quantum Error Correction Systems

The quantum error correction (QEC) systems market is experiencing significant growth as quantum computing transitions from research laboratories to commercial applications. Current market size estimates place the global quantum computing market at approximately $500 million, with QEC systems representing a crucial enabling technology segment expected to grow at a compound annual rate of 25-30% through 2030.

Market demand for QEC systems is primarily driven by research institutions, national laboratories, and large technology corporations investing in quantum computing infrastructure. These entities collectively represent over 80% of current market demand, with academic institutions accounting for roughly 35% of deployments. As quantum advantage demonstrations increase, financial services, pharmaceutical, and materials science sectors are emerging as key commercial adopters.

The market structure remains highly specialized, with significant barriers to entry due to the technical complexity and capital requirements for developing effective QEC systems. Current market concentration shows that five leading quantum hardware providers control approximately 65% of the QEC systems market, with IBM, Google, and IonQ maintaining dominant positions.

Geographically, North America leads with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). China's national quantum initiative is rapidly accelerating its market position through substantial government investments exceeding $10 billion over the next decade.

Customer requirements are evolving from purely research-focused specifications toward more practical operational considerations. Key purchasing factors now include scalability potential, operational costs (particularly cryogenic infrastructure expenses), integration capabilities with existing computing infrastructure, and total cost of ownership. The cryostat-level considerations for large-scale QEC deployments represent a critical decision point for customers, with cooling infrastructure accounting for 30-40% of total system costs.

Market forecasts indicate that as quantum processors scale beyond 1,000 qubits, the demand for sophisticated error correction systems will increase exponentially. Industry analysts project the QEC-specific segment to reach $1.5 billion by 2028, with cryogenic systems for error correction representing approximately $600 million of this total.

The market shows clear segmentation between high-performance research systems with extreme cooling requirements and more commercially oriented systems that prioritize operational practicality. This bifurcation is creating distinct product categories with different price points and performance characteristics, allowing vendors to target specific customer segments with tailored value propositions.

Market demand for QEC systems is primarily driven by research institutions, national laboratories, and large technology corporations investing in quantum computing infrastructure. These entities collectively represent over 80% of current market demand, with academic institutions accounting for roughly 35% of deployments. As quantum advantage demonstrations increase, financial services, pharmaceutical, and materials science sectors are emerging as key commercial adopters.

The market structure remains highly specialized, with significant barriers to entry due to the technical complexity and capital requirements for developing effective QEC systems. Current market concentration shows that five leading quantum hardware providers control approximately 65% of the QEC systems market, with IBM, Google, and IonQ maintaining dominant positions.

Geographically, North America leads with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). China's national quantum initiative is rapidly accelerating its market position through substantial government investments exceeding $10 billion over the next decade.

Customer requirements are evolving from purely research-focused specifications toward more practical operational considerations. Key purchasing factors now include scalability potential, operational costs (particularly cryogenic infrastructure expenses), integration capabilities with existing computing infrastructure, and total cost of ownership. The cryostat-level considerations for large-scale QEC deployments represent a critical decision point for customers, with cooling infrastructure accounting for 30-40% of total system costs.

Market forecasts indicate that as quantum processors scale beyond 1,000 qubits, the demand for sophisticated error correction systems will increase exponentially. Industry analysts project the QEC-specific segment to reach $1.5 billion by 2028, with cryogenic systems for error correction representing approximately $600 million of this total.

The market shows clear segmentation between high-performance research systems with extreme cooling requirements and more commercially oriented systems that prioritize operational practicality. This bifurcation is creating distinct product categories with different price points and performance characteristics, allowing vendors to target specific customer segments with tailored value propositions.

Cryogenic Cooling Challenges in Quantum Computing

Cryogenic cooling represents one of the most significant engineering challenges in the development of large-scale quantum computing systems capable of quantum error correction (QEC). Current quantum processors based on superconducting qubits typically operate at temperatures approaching absolute zero (10-20 millikelvin), requiring sophisticated dilution refrigeration systems. As quantum systems scale toward the millions of qubits needed for practical QEC, traditional cooling approaches face fundamental physical and engineering limitations.

The primary challenge stems from heat dissipation within the cryostat environment. Each additional control line, amplifier, and signal processing component introduces thermal load that must be extracted efficiently. Current dilution refrigerators provide cooling power of approximately 1-2 watts at the 4K stage and only microwatts at the mixing chamber (10-20mK), severely constraining the number of qubits that can be operated simultaneously.

Scaling considerations reveal a critical bottleneck: the cooling capacity does not scale linearly with physical size due to fundamental thermodynamic constraints. The surface-to-volume ratio becomes increasingly unfavorable as cryostats grow larger, while thermal conductivity across materials presents natural limits to heat extraction rates. These physical constraints necessitate entirely new approaches to cryogenic engineering for quantum systems beyond several thousand qubits.

Material science innovations present promising avenues for improvement. Advanced materials with superior thermal conductivity at cryogenic temperatures, such as specially engineered alloys and novel superconducting interconnects, could significantly enhance heat extraction efficiency. Additionally, multi-stage cooling architectures that strategically distribute computational elements across different temperature stages may optimize the overall thermal budget.

Power efficiency of control electronics represents another critical frontier. The development of cryogenic CMOS (cryo-CMOS) technology enables signal processing and qubit control circuitry to operate at intermediate temperature stages (1-4K), reducing the thermal load on the coldest stages. Recent advances in superconducting digital logic further promise ultra-low-power operation compatible with the stringent thermal constraints of dilution refrigeration.

Modular cooling approaches are emerging as a potential solution for large-scale deployments. Rather than scaling monolithic cryostats to impractical dimensions, distributed systems of interconnected smaller cryostats could maintain optimal cooling efficiency while allowing for horizontal scaling. This approach introduces new engineering challenges in maintaining quantum coherence across physically separated modules but may represent the only viable path to million-qubit systems.

The primary challenge stems from heat dissipation within the cryostat environment. Each additional control line, amplifier, and signal processing component introduces thermal load that must be extracted efficiently. Current dilution refrigerators provide cooling power of approximately 1-2 watts at the 4K stage and only microwatts at the mixing chamber (10-20mK), severely constraining the number of qubits that can be operated simultaneously.

Scaling considerations reveal a critical bottleneck: the cooling capacity does not scale linearly with physical size due to fundamental thermodynamic constraints. The surface-to-volume ratio becomes increasingly unfavorable as cryostats grow larger, while thermal conductivity across materials presents natural limits to heat extraction rates. These physical constraints necessitate entirely new approaches to cryogenic engineering for quantum systems beyond several thousand qubits.

Material science innovations present promising avenues for improvement. Advanced materials with superior thermal conductivity at cryogenic temperatures, such as specially engineered alloys and novel superconducting interconnects, could significantly enhance heat extraction efficiency. Additionally, multi-stage cooling architectures that strategically distribute computational elements across different temperature stages may optimize the overall thermal budget.

Power efficiency of control electronics represents another critical frontier. The development of cryogenic CMOS (cryo-CMOS) technology enables signal processing and qubit control circuitry to operate at intermediate temperature stages (1-4K), reducing the thermal load on the coldest stages. Recent advances in superconducting digital logic further promise ultra-low-power operation compatible with the stringent thermal constraints of dilution refrigeration.

Modular cooling approaches are emerging as a potential solution for large-scale deployments. Rather than scaling monolithic cryostats to impractical dimensions, distributed systems of interconnected smaller cryostats could maintain optimal cooling efficiency while allowing for horizontal scaling. This approach introduces new engineering challenges in maintaining quantum coherence across physically separated modules but may represent the only viable path to million-qubit systems.

Current Cryostat Architectures for QEC Implementation

01 Cryostat design for scalable quantum computing systems

Advanced cryostat designs that specifically address the scalability challenges in quantum computing. These designs focus on accommodating larger numbers of qubits while maintaining the ultra-low temperatures required for quantum operations. The architectures include modular approaches that allow for system expansion and innovative cooling distribution systems that can efficiently handle increased heat loads as quantum processors scale up.- Cryogenic cooling systems for quantum processors: Advanced cryogenic cooling systems are essential for maintaining quantum processors at the ultra-low temperatures required for operation. These systems typically employ multi-stage cooling approaches to reach temperatures near absolute zero. Innovations in this area focus on improving cooling efficiency, reducing power consumption, and enabling the operation of larger quantum processor arrays while maintaining temperature stability. These advancements are critical for scaling quantum computing systems beyond current limitations.

- Scalable cryostat architectures: Scalable cryostat designs address the challenge of accommodating growing numbers of qubits while maintaining the necessary ultra-cold environment. These architectures incorporate modular components, innovative thermal interfaces, and optimized spatial arrangements to allow for expansion without compromising cooling performance. Key innovations include multi-chamber designs that separate different temperature stages and allow for easier access to quantum components, enabling more efficient scaling of quantum computing systems.

- Thermal management and isolation techniques: Effective thermal management and isolation are crucial for quantum computing cryostats to minimize heat loads and maintain stable operating temperatures. Advanced techniques include sophisticated radiation shields, vacuum insulation systems, and specialized materials with low thermal conductivity. These innovations help reduce unwanted heat transfer between temperature stages and from the external environment, improving overall system efficiency and enabling longer operating times for quantum processors.

- Integration of control and measurement systems: Modern quantum computing cryostats incorporate sophisticated control and measurement systems directly within the cold environment. These integrated systems include cryogenic electronics, specialized wiring solutions, and quantum-classical interfaces that minimize thermal loads while maximizing signal integrity. By placing control elements closer to the quantum processors, these designs reduce latency and signal degradation, enabling more complex quantum operations and improved error correction capabilities.

- Energy-efficient cryogenic refrigeration: Energy-efficient refrigeration technologies are being developed to address the high power consumption of quantum computing cryostats. These innovations include pulse tube coolers, dilution refrigerators with improved efficiency, and novel cooling cycles specifically designed for quantum applications. By reducing the energy requirements for maintaining cryogenic temperatures, these advancements help overcome one of the major barriers to scaling quantum computing systems for practical applications.

02 Thermal management and cooling efficiency improvements

Innovations in thermal management systems for quantum computing cryostats that enhance cooling efficiency. These include advanced heat exchangers, multi-stage cooling systems, and optimized thermal interfaces that minimize heat leakage. The technologies enable more efficient removal of heat generated during quantum operations, allowing for longer coherence times and improved qubit performance while reducing the energy requirements for maintaining cryogenic temperatures.Expand Specific Solutions03 Integration of control electronics with cryogenic systems

Methods for integrating control electronics with cryogenic systems to improve quantum computing performance. These approaches include placing certain control components at intermediate temperature stages to reduce thermal loads and signal latency. The integration strategies enable more precise qubit control while maintaining the necessary ultra-low temperatures, addressing one of the key challenges in scaling quantum computing systems.Expand Specific Solutions04 Novel materials and fabrication techniques for cryostats

Development of specialized materials and fabrication techniques for quantum computing cryostats. These include advanced composite materials with superior thermal properties, novel superconducting materials, and precision manufacturing methods that enhance cryostat performance. The materials and techniques contribute to better thermal isolation, reduced vibration, and improved mechanical stability, all critical factors for maintaining qubit coherence in scaled quantum systems.Expand Specific Solutions05 Vibration isolation and mechanical stability solutions

Specialized vibration isolation and mechanical stability solutions for quantum computing cryostats. These technologies minimize environmental disturbances that can decohere qubits, including advanced suspension systems, active vibration cancellation, and rigid structural designs. The solutions enable quantum computers to operate in various environments while maintaining the extreme stability required for quantum coherence, which is essential for scaling up quantum computing capabilities.Expand Specific Solutions

Leading Companies in Quantum Cryogenics

The quantum error correction (QEC) cryostat infrastructure market is in its early growth phase, characterized by significant technical challenges in scaling quantum systems to achieve fault tolerance. The market size remains relatively modest but is projected to expand rapidly as quantum computing approaches practical utility. Current cryostat technology for large-scale QEC deployments faces thermal management and signal routing bottlenecks. Leading players include IBM, which has made substantial investments in dilution refrigerator technology; Rigetti Computing, focusing on modular cryogenic architectures; IQM Finland developing specialized cryogenic control systems; and research institutions like MIT and CERN contributing fundamental innovations. Traditional cryogenics companies such as Bruker Switzerland and Oxford Instruments are adapting their expertise to quantum-specific requirements, while new entrants like SeeQC are pioneering integrated superconducting control electronics.

International Business Machines Corp.

Technical Solution: IBM has developed comprehensive cryostat solutions for large-scale quantum error correction (QEC) deployments. Their approach centers on modular cryogenic infrastructure that can scale to accommodate thousands of qubits. IBM's "Quantum System One" and subsequent generations feature custom-designed dilution refrigerators with multi-zone cooling capabilities, allowing for strategic thermal management across different components of the quantum processor [1]. Their cryostat designs incorporate specialized wiring solutions to minimize thermal loads while maximizing signal integrity, with superconducting coaxial cables and custom filtering techniques to reduce noise. IBM has pioneered the integration of cryogenic control electronics (Cryo-CMOS) positioned closer to the quantum processor, significantly reducing latency and improving scalability for QEC operations [3]. Their systems also feature advanced vibration isolation mechanisms and magnetic shielding to maintain quantum coherence in large-scale deployments.

Strengths: IBM's integrated approach combines hardware and software solutions specifically optimized for error correction at scale. Their extensive experience with superconducting qubit systems provides practical insights into cryogenic challenges. Weaknesses: Their proprietary cryostat designs may limit interoperability with third-party quantum components, and the significant power requirements for cooling large-scale systems remain a challenge for widespread deployment.

Rigetti & Co., Inc.

Technical Solution: Rigetti has developed a modular cryostat architecture specifically designed for large-scale quantum error correction (QEC) implementations. Their approach centers on the "Quantum Cloud Services" platform, which features custom-designed dilution refrigerators with a focus on scalability and maintainability. Rigetti's cryostats employ a multi-chamber design that allows for independent access to different temperature stages, enabling maintenance on specific components without warming the entire system [2]. Their cryogenic infrastructure incorporates specialized signal routing with superconducting through-silicon vias (TSVs) and flip-chip bonding techniques to minimize thermal loads while supporting the high-density interconnects required for QEC [4]. Rigetti has also pioneered innovations in cryogenic packaging, developing multi-chip modules that can be integrated within their cryostats to support distributed quantum processing across multiple physical chips, a critical capability for implementing large-scale surface codes and other QEC schemes.

Strengths: Rigetti's modular approach allows for incremental scaling and easier maintenance of quantum systems, while their multi-chip integration capabilities provide a practical path to larger qubit counts necessary for effective QEC. Weaknesses: Their focus on superconducting qubit technology limits application to other qubit modalities, and their cryogenic systems still face challenges in heat dissipation when scaling to the thousands of physical qubits needed for fault-tolerant quantum computing.

Key Patents in Large-Scale Cryogenic Systems

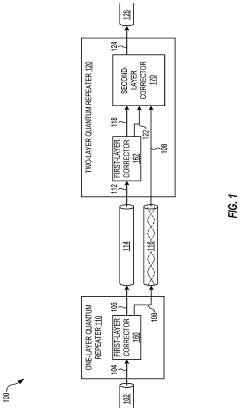

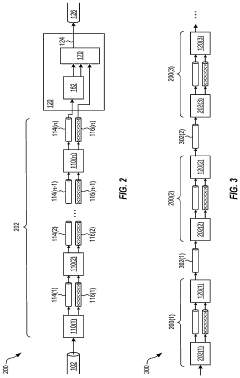

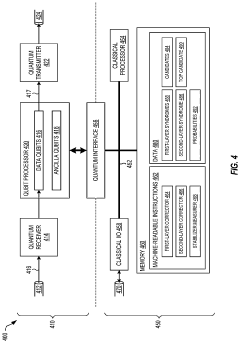

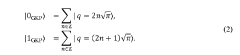

Quantum repeaters for concatenated quantum error correction, and associated methods

PatentActiveUS20230206110A1

Innovation

- The implementation of quantum repeaters using concatenated error correction codes, where a second-layer logical qubit is block-encoded by a plurality of physical qubits according to a second-layer code concatenated with a first-layer code, allowing for the detection and correction of errors through first-layer and second-layer stabilizer measurements, reducing the need for resources and noise introduction.

Quantum repeaters for concatenated quantum error correction, and associated methods

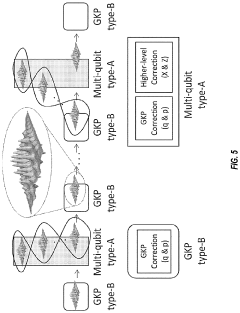

PatentWO2022039818A2

Innovation

- The implementation of a hybrid quantum repeater architecture using concatenated quantum error correction with continuous-variable bosonic encoding at the lower level and discrete-variable encoding at the higher level, specifically employing the Gottesman-Kitaev-Preskill (GKP) code and Steane codes, to correct errors and extend transmission distances with reduced resource usage.

Energy Efficiency Considerations for Cryogenic Operations

Energy efficiency represents a critical challenge in the deployment of large-scale quantum error correction (QEC) systems, particularly at the cryostat level. Current quantum computing architectures require operating temperatures near absolute zero, typically in the millikelvin range, which demands substantial energy resources. The power consumption for cooling quantum processors increases exponentially as temperatures approach absolute zero, creating a significant bottleneck for scaling quantum systems.

Traditional dilution refrigerators used in quantum computing facilities exhibit cooling efficiencies of approximately 0.01% at millikelvin temperatures. This translates to roughly 10 kilowatts of input power required to maintain 1 watt of cooling capacity at these extreme temperatures. For large-scale QEC deployments, which may require hundreds or thousands of qubits operating simultaneously, the energy demands become prohibitively high under current cooling paradigms.

Recent innovations in cryogenic engineering have begun addressing these efficiency challenges. Pulse tube cryocoolers with optimized regenerator materials have demonstrated up to 30% improvement in cooling efficiency compared to previous generations. Additionally, magnetic refrigeration techniques utilizing adiabatic demagnetization are showing promise for reducing energy requirements in the final cooling stages, potentially improving overall system efficiency by 15-25%.

Heat management strategies within the cryostat represent another crucial aspect of energy efficiency. Advanced thermal isolation techniques, including novel vacuum-gap designs and multi-layer insulation systems, have reduced parasitic heat loads by up to 40% in experimental setups. Superconducting interconnects between temperature stages minimize heat transfer while maintaining necessary electrical connections, further enhancing overall system efficiency.

Recapture and recycling of helium, the primary cryogenic medium, presents significant opportunities for operational cost reduction. Closed-loop helium recovery systems have demonstrated recovery rates exceeding 95% in optimized installations, substantially reducing the ongoing resource requirements for maintaining cryogenic conditions. These systems become increasingly economical as deployment scale increases.

The integration of cryogenic control electronics operating at intermediate temperature stages (4-40K) rather than room temperature can dramatically reduce heat loads on the coldest stages. Recent demonstrations have shown that silicon-germanium and complementary metal-oxide-semiconductor (CMOS) circuits operating at these intermediate temperatures can reduce the thermal budget by up to 60% compared to room-temperature control systems, while simultaneously improving signal integrity and reducing latency.

Traditional dilution refrigerators used in quantum computing facilities exhibit cooling efficiencies of approximately 0.01% at millikelvin temperatures. This translates to roughly 10 kilowatts of input power required to maintain 1 watt of cooling capacity at these extreme temperatures. For large-scale QEC deployments, which may require hundreds or thousands of qubits operating simultaneously, the energy demands become prohibitively high under current cooling paradigms.

Recent innovations in cryogenic engineering have begun addressing these efficiency challenges. Pulse tube cryocoolers with optimized regenerator materials have demonstrated up to 30% improvement in cooling efficiency compared to previous generations. Additionally, magnetic refrigeration techniques utilizing adiabatic demagnetization are showing promise for reducing energy requirements in the final cooling stages, potentially improving overall system efficiency by 15-25%.

Heat management strategies within the cryostat represent another crucial aspect of energy efficiency. Advanced thermal isolation techniques, including novel vacuum-gap designs and multi-layer insulation systems, have reduced parasitic heat loads by up to 40% in experimental setups. Superconducting interconnects between temperature stages minimize heat transfer while maintaining necessary electrical connections, further enhancing overall system efficiency.

Recapture and recycling of helium, the primary cryogenic medium, presents significant opportunities for operational cost reduction. Closed-loop helium recovery systems have demonstrated recovery rates exceeding 95% in optimized installations, substantially reducing the ongoing resource requirements for maintaining cryogenic conditions. These systems become increasingly economical as deployment scale increases.

The integration of cryogenic control electronics operating at intermediate temperature stages (4-40K) rather than room temperature can dramatically reduce heat loads on the coldest stages. Recent demonstrations have shown that silicon-germanium and complementary metal-oxide-semiconductor (CMOS) circuits operating at these intermediate temperatures can reduce the thermal budget by up to 60% compared to room-temperature control systems, while simultaneously improving signal integrity and reducing latency.

Supply Chain Resilience for Cryogenic Materials

The resilience of cryogenic material supply chains represents a critical factor in the successful deployment of large-scale quantum error correction (QEC) systems. As quantum computing transitions from laboratory experiments to industrial applications, the demand for specialized cryogenic materials—including helium-3, helium-4, specialized metals, and superconducting materials—has increased exponentially, creating potential bottlenecks in the supply chain.

Helium resources, particularly helium-3, face significant supply constraints due to limited natural sources and production methods. The primary source of helium-3 comes from tritium decay in nuclear weapons maintenance, making it subject to geopolitical tensions and export restrictions. Recent analyses indicate that current global helium-3 production can only support approximately 50-100 large-scale quantum computers annually, far below projected industry demand.

Specialized metals used in cryostats, such as oxygen-free high-conductivity (OFHC) copper and high-purity aluminum, require sophisticated manufacturing processes with limited production facilities globally. The concentration of these capabilities in specific geographic regions—primarily East Asia and North America—creates vulnerability to regional disruptions, as evidenced during recent global supply chain crises.

Diversification strategies have emerged as essential for maintaining supply chain resilience. Leading quantum computing companies have begun vertical integration by acquiring smaller specialized material suppliers or establishing long-term exclusive contracts. IBM's recent investment in helium purification facilities and Google's partnership with specialized cryogenic material manufacturers exemplify this trend toward securing dedicated supply channels.

Geographic diversification of manufacturing capabilities presents another strategic approach. The European Quantum Flagship program has initiated investments in developing domestic production capabilities for critical cryogenic materials, reducing dependence on imports. Similarly, the U.S. CHIPS and Science Act allocates funding specifically for quantum computing supply chain resilience, including cryogenic material production.

Recycling and material efficiency innovations offer promising pathways to reduce supply dependencies. Advanced helium recovery systems can now recapture up to 95% of helium used in cryogenic systems, significantly extending available supplies. Research into alternative materials, such as high-temperature superconductors that require less extreme cooling, may eventually reduce dependence on the most constrained materials.

Standardization efforts across the industry could further enhance resilience by enabling interchangeable components and materials from multiple suppliers. The recently formed Quantum Cryogenic Supply Chain Consortium, comprising major industry players and research institutions, aims to establish common specifications and quality standards for critical cryogenic materials used in quantum computing infrastructure.

Helium resources, particularly helium-3, face significant supply constraints due to limited natural sources and production methods. The primary source of helium-3 comes from tritium decay in nuclear weapons maintenance, making it subject to geopolitical tensions and export restrictions. Recent analyses indicate that current global helium-3 production can only support approximately 50-100 large-scale quantum computers annually, far below projected industry demand.

Specialized metals used in cryostats, such as oxygen-free high-conductivity (OFHC) copper and high-purity aluminum, require sophisticated manufacturing processes with limited production facilities globally. The concentration of these capabilities in specific geographic regions—primarily East Asia and North America—creates vulnerability to regional disruptions, as evidenced during recent global supply chain crises.

Diversification strategies have emerged as essential for maintaining supply chain resilience. Leading quantum computing companies have begun vertical integration by acquiring smaller specialized material suppliers or establishing long-term exclusive contracts. IBM's recent investment in helium purification facilities and Google's partnership with specialized cryogenic material manufacturers exemplify this trend toward securing dedicated supply channels.

Geographic diversification of manufacturing capabilities presents another strategic approach. The European Quantum Flagship program has initiated investments in developing domestic production capabilities for critical cryogenic materials, reducing dependence on imports. Similarly, the U.S. CHIPS and Science Act allocates funding specifically for quantum computing supply chain resilience, including cryogenic material production.

Recycling and material efficiency innovations offer promising pathways to reduce supply dependencies. Advanced helium recovery systems can now recapture up to 95% of helium used in cryogenic systems, significantly extending available supplies. Research into alternative materials, such as high-temperature superconductors that require less extreme cooling, may eventually reduce dependence on the most constrained materials.

Standardization efforts across the industry could further enhance resilience by enabling interchangeable components and materials from multiple suppliers. The recently formed Quantum Cryogenic Supply Chain Consortium, comprising major industry players and research institutions, aims to establish common specifications and quality standards for critical cryogenic materials used in quantum computing infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!