Design Optimization: Proximity Sensors in Space-Constrained Applications

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proximity Sensing Technology Background and Objectives

Proximity sensing technology has evolved significantly over the past several decades, transitioning from simple mechanical switches to sophisticated non-contact detection systems. The fundamental principle behind proximity sensors involves detecting the presence of nearby objects without physical contact, which has proven invaluable across numerous industries including automotive, consumer electronics, industrial automation, and aerospace applications. The evolution of this technology has been driven by increasing demands for miniaturization, improved accuracy, and enhanced reliability in increasingly complex operating environments.

The historical trajectory of proximity sensing began with basic mechanical and magnetic reed switches in the 1950s and 1960s, followed by the introduction of inductive sensors in industrial settings during the 1970s. The 1980s and 1990s witnessed significant advancements with the development of capacitive, photoelectric, and ultrasonic sensing technologies. The early 2000s brought about the integration of proximity sensors into consumer electronics, while recent years have seen remarkable innovations in MEMS-based sensors, time-of-flight (ToF) technology, and radar-based solutions.

Current technological trends in proximity sensing are primarily focused on addressing the challenges of space-constrained applications. As devices continue to shrink in size while increasing in functionality, the demand for miniaturized yet highly effective proximity sensors has intensified. This trend is particularly evident in wearable technology, medical devices, and next-generation mobile electronics, where every cubic millimeter of space is valuable.

The primary objectives of proximity sensing technology in space-constrained applications include achieving optimal detection performance while minimizing the sensor footprint, reducing power consumption to extend battery life in portable devices, ensuring reliable operation in varied environmental conditions, and maintaining cost-effectiveness for mass production. Additionally, there is a growing emphasis on developing sensors that can be easily integrated into existing manufacturing processes and product designs.

Another critical objective is enhancing the versatility of proximity sensors to detect various materials and objects with different properties. Traditional proximity sensors often have limitations regarding the types of materials they can reliably detect, which becomes particularly challenging in applications where the sensor might encounter diverse objects or substances.

Looking forward, the technological roadmap for proximity sensing in space-constrained applications aims to develop multi-modal sensing capabilities that combine different sensing technologies in a single compact package. This approach promises to overcome the limitations of individual sensing methods while providing redundancy and improved accuracy. Furthermore, there is significant interest in developing intelligent proximity sensing systems that incorporate machine learning algorithms to adapt to changing environmental conditions and user behaviors.

The historical trajectory of proximity sensing began with basic mechanical and magnetic reed switches in the 1950s and 1960s, followed by the introduction of inductive sensors in industrial settings during the 1970s. The 1980s and 1990s witnessed significant advancements with the development of capacitive, photoelectric, and ultrasonic sensing technologies. The early 2000s brought about the integration of proximity sensors into consumer electronics, while recent years have seen remarkable innovations in MEMS-based sensors, time-of-flight (ToF) technology, and radar-based solutions.

Current technological trends in proximity sensing are primarily focused on addressing the challenges of space-constrained applications. As devices continue to shrink in size while increasing in functionality, the demand for miniaturized yet highly effective proximity sensors has intensified. This trend is particularly evident in wearable technology, medical devices, and next-generation mobile electronics, where every cubic millimeter of space is valuable.

The primary objectives of proximity sensing technology in space-constrained applications include achieving optimal detection performance while minimizing the sensor footprint, reducing power consumption to extend battery life in portable devices, ensuring reliable operation in varied environmental conditions, and maintaining cost-effectiveness for mass production. Additionally, there is a growing emphasis on developing sensors that can be easily integrated into existing manufacturing processes and product designs.

Another critical objective is enhancing the versatility of proximity sensors to detect various materials and objects with different properties. Traditional proximity sensors often have limitations regarding the types of materials they can reliably detect, which becomes particularly challenging in applications where the sensor might encounter diverse objects or substances.

Looking forward, the technological roadmap for proximity sensing in space-constrained applications aims to develop multi-modal sensing capabilities that combine different sensing technologies in a single compact package. This approach promises to overcome the limitations of individual sensing methods while providing redundancy and improved accuracy. Furthermore, there is significant interest in developing intelligent proximity sensing systems that incorporate machine learning algorithms to adapt to changing environmental conditions and user behaviors.

Market Demand for Miniaturized Proximity Sensors

The global market for miniaturized proximity sensors is experiencing robust growth, driven primarily by the increasing demand for compact electronic devices across various industries. According to recent market analyses, the proximity sensor market is projected to reach $2.57 billion by 2025, with miniaturized sensors representing the fastest-growing segment at a CAGR of 7.2% from 2020 to 2025.

Consumer electronics remains the dominant application sector, accounting for approximately 38% of the total market share. The continuous trend toward smaller, thinner smartphones, wearables, and IoT devices has created substantial demand for ultra-compact proximity sensing solutions that can operate effectively within increasingly constrained spaces while maintaining performance standards.

Automotive applications represent another significant growth area, particularly with the integration of advanced driver assistance systems (ADAS) and autonomous driving technologies. These applications require multiple proximity sensors in limited spaces, creating demand for miniaturized solutions that can be seamlessly integrated into vehicle designs without compromising aesthetics or aerodynamics.

Industrial automation and robotics sectors are also driving market expansion, with requirements for precise object detection in compact manufacturing equipment and collaborative robots. The need for sensors that can be embedded in small robotic end effectors and grippers without adding significant bulk or weight has become particularly pronounced.

Healthcare and medical device manufacturers have emerged as important stakeholders in this market, with growing applications in portable diagnostic equipment, wearable health monitors, and minimally invasive surgical tools. These applications demand extremely small form factors combined with high reliability and precision.

Market research indicates that end-users are prioritizing several key features in miniaturized proximity sensors: reduced power consumption (critical for battery-powered devices), improved detection range despite smaller size, enhanced immunity to environmental interference, and cost-effectiveness at scale. Manufacturers capable of addressing these requirements while achieving further miniaturization are gaining competitive advantage.

Regional analysis shows Asia-Pacific leading the market with 42% share, driven by the concentration of consumer electronics manufacturing. North America follows at 28%, with strong demand from medical and industrial automation sectors, while Europe accounts for 23%, primarily from automotive applications.

The market is also witnessing increased demand for multi-functional sensor packages that combine proximity sensing with other capabilities such as ambient light detection, gesture recognition, or temperature sensing—all within a single miniaturized package. This trend toward sensor fusion in space-constrained applications represents a significant opportunity for innovative sensor designs and integration approaches.

Consumer electronics remains the dominant application sector, accounting for approximately 38% of the total market share. The continuous trend toward smaller, thinner smartphones, wearables, and IoT devices has created substantial demand for ultra-compact proximity sensing solutions that can operate effectively within increasingly constrained spaces while maintaining performance standards.

Automotive applications represent another significant growth area, particularly with the integration of advanced driver assistance systems (ADAS) and autonomous driving technologies. These applications require multiple proximity sensors in limited spaces, creating demand for miniaturized solutions that can be seamlessly integrated into vehicle designs without compromising aesthetics or aerodynamics.

Industrial automation and robotics sectors are also driving market expansion, with requirements for precise object detection in compact manufacturing equipment and collaborative robots. The need for sensors that can be embedded in small robotic end effectors and grippers without adding significant bulk or weight has become particularly pronounced.

Healthcare and medical device manufacturers have emerged as important stakeholders in this market, with growing applications in portable diagnostic equipment, wearable health monitors, and minimally invasive surgical tools. These applications demand extremely small form factors combined with high reliability and precision.

Market research indicates that end-users are prioritizing several key features in miniaturized proximity sensors: reduced power consumption (critical for battery-powered devices), improved detection range despite smaller size, enhanced immunity to environmental interference, and cost-effectiveness at scale. Manufacturers capable of addressing these requirements while achieving further miniaturization are gaining competitive advantage.

Regional analysis shows Asia-Pacific leading the market with 42% share, driven by the concentration of consumer electronics manufacturing. North America follows at 28%, with strong demand from medical and industrial automation sectors, while Europe accounts for 23%, primarily from automotive applications.

The market is also witnessing increased demand for multi-functional sensor packages that combine proximity sensing with other capabilities such as ambient light detection, gesture recognition, or temperature sensing—all within a single miniaturized package. This trend toward sensor fusion in space-constrained applications represents a significant opportunity for innovative sensor designs and integration approaches.

Current Limitations and Challenges in Space-Constrained Sensing

The integration of proximity sensors in space-constrained applications presents significant technical challenges that limit their effectiveness and deployment. Current proximity sensing technologies often require substantial physical space for optimal performance, creating a fundamental tension in miniaturized devices. Traditional infrared (IR) and ultrasonic sensors, while effective in many scenarios, struggle to maintain accuracy when their emitter-receiver distances are compromised due to spatial limitations.

Electromagnetic interference (EMI) poses a critical challenge in compact environments where multiple electronic components operate in close proximity. This interference can significantly degrade sensor performance, leading to false readings and reduced reliability. The problem is particularly acute in densely packed consumer electronics, medical devices, and automotive applications where signal integrity is paramount.

Power consumption represents another major limitation. Miniaturized applications typically have strict energy budgets, yet many proximity sensing solutions require substantial power for operation. This creates a difficult trade-off between sensor performance and battery life, especially in wireless or portable devices. Current low-power alternatives often sacrifice detection range, response time, or accuracy to achieve energy efficiency.

Thermal management challenges are exacerbated in confined spaces. Proximity sensors, particularly active variants like IR sensors, generate heat during operation. Without adequate dissipation pathways, this heat can affect both sensor accuracy and the performance of adjacent components. The problem compounds in applications where multiple sensors operate simultaneously within a limited volume.

Manufacturing and integration complexities also present significant hurdles. As device dimensions shrink, the precision required for sensor placement increases exponentially. Current production techniques struggle to consistently achieve the necessary tolerances for optimal sensor positioning in three-dimensional space-constrained environments, leading to performance variations across production batches.

Environmental factors further complicate space-constrained sensing. Dust, moisture, and varying ambient light conditions can disproportionately affect miniaturized sensors due to their reduced operating margins. Protective measures that might be implemented in larger systems often cannot be accommodated without compromising the form factor.

Cross-sensitivity between different sensing modalities represents an emerging challenge as devices incorporate multiple sensor types in limited spaces. For example, the heat generated by a temperature sensor may trigger false readings in an adjacent proximity sensor, creating complex interdependencies that are difficult to calibrate and compensate for in software.

The cost-performance equation becomes increasingly unfavorable as space constraints tighten. High-performance sensors that might function in restricted spaces typically command premium prices, limiting their adoption in mass-market applications where cost sensitivity is high. This economic reality has slowed innovation in certain application domains despite clear technical needs.

Electromagnetic interference (EMI) poses a critical challenge in compact environments where multiple electronic components operate in close proximity. This interference can significantly degrade sensor performance, leading to false readings and reduced reliability. The problem is particularly acute in densely packed consumer electronics, medical devices, and automotive applications where signal integrity is paramount.

Power consumption represents another major limitation. Miniaturized applications typically have strict energy budgets, yet many proximity sensing solutions require substantial power for operation. This creates a difficult trade-off between sensor performance and battery life, especially in wireless or portable devices. Current low-power alternatives often sacrifice detection range, response time, or accuracy to achieve energy efficiency.

Thermal management challenges are exacerbated in confined spaces. Proximity sensors, particularly active variants like IR sensors, generate heat during operation. Without adequate dissipation pathways, this heat can affect both sensor accuracy and the performance of adjacent components. The problem compounds in applications where multiple sensors operate simultaneously within a limited volume.

Manufacturing and integration complexities also present significant hurdles. As device dimensions shrink, the precision required for sensor placement increases exponentially. Current production techniques struggle to consistently achieve the necessary tolerances for optimal sensor positioning in three-dimensional space-constrained environments, leading to performance variations across production batches.

Environmental factors further complicate space-constrained sensing. Dust, moisture, and varying ambient light conditions can disproportionately affect miniaturized sensors due to their reduced operating margins. Protective measures that might be implemented in larger systems often cannot be accommodated without compromising the form factor.

Cross-sensitivity between different sensing modalities represents an emerging challenge as devices incorporate multiple sensor types in limited spaces. For example, the heat generated by a temperature sensor may trigger false readings in an adjacent proximity sensor, creating complex interdependencies that are difficult to calibrate and compensate for in software.

The cost-performance equation becomes increasingly unfavorable as space constraints tighten. High-performance sensors that might function in restricted spaces typically command premium prices, limiting their adoption in mass-market applications where cost sensitivity is high. This economic reality has slowed innovation in certain application domains despite clear technical needs.

Current Design Solutions for Space-Constrained Applications

01 Sensor configuration and layout optimization

Optimizing the physical configuration and layout of proximity sensors to enhance detection accuracy and range. This includes strategic placement of sensors, array configurations, and spatial arrangement to minimize interference and maximize coverage. Design considerations focus on sensor density, orientation, and geometric patterns to achieve optimal sensing performance while maintaining compact form factors.- Sensor circuit design optimization: Optimization of proximity sensor circuits involves designing efficient electronic components that enhance sensitivity and reduce power consumption. This includes the development of specialized integrated circuits, signal processing algorithms, and noise reduction techniques. These optimizations improve the sensor's ability to detect objects accurately while minimizing false readings and extending battery life in portable applications.

- Power efficiency improvements: Techniques for improving power efficiency in proximity sensors focus on reducing energy consumption while maintaining detection performance. This includes implementing power management schemes, sleep modes, and adaptive sampling rates based on usage patterns. Advanced circuit designs that operate at lower voltages and current-efficient components contribute to extending battery life in mobile and IoT devices using proximity sensing.

- Sensor calibration and accuracy enhancement: Methods for improving proximity sensor accuracy through advanced calibration techniques and error compensation algorithms. These approaches address environmental variations, manufacturing tolerances, and drift over time. Automatic calibration routines, temperature compensation, and adaptive thresholding techniques ensure consistent performance across different operating conditions, resulting in more reliable object detection and distance measurement.

- Integration with other sensing technologies: Combining proximity sensors with complementary sensing technologies creates more robust detection systems. This integration may include fusion with ambient light sensors, accelerometers, or touch sensors to provide context-aware functionality. Multi-modal sensing approaches improve reliability by cross-validating readings and enable more sophisticated applications through the combination of different data types.

- Design automation and optimization tools: Software tools and methodologies for automating the design and optimization of proximity sensors. These include simulation environments, automated testing frameworks, and design space exploration algorithms that help engineers identify optimal sensor configurations. Computer-aided design approaches reduce development time and enable rapid prototyping while ensuring that the final sensor design meets performance, size, and cost requirements.

02 Power consumption and efficiency improvements

Techniques for reducing power consumption in proximity sensor designs while maintaining or improving performance. This includes implementing power-saving modes, optimizing duty cycles, and developing energy-efficient signal processing algorithms. Advanced circuit designs minimize current draw during standby and active states, extending battery life in portable devices while ensuring rapid sensor response when needed.Expand Specific Solutions03 Signal processing and noise reduction methods

Advanced signal processing techniques to enhance proximity sensor performance by filtering out environmental noise and improving signal-to-noise ratios. This includes implementing digital filters, adaptive thresholding algorithms, and sophisticated detection methods to distinguish between actual proximity events and false triggers. These methods improve sensor reliability in challenging environments with electromagnetic interference or varying ambient conditions.Expand Specific Solutions04 Integration with other sensing technologies

Methods for integrating proximity sensors with complementary sensing technologies to create more robust and versatile detection systems. This includes fusion with optical, capacitive, or inductive sensors to overcome limitations of individual sensing modalities. Hybrid approaches combine data from multiple sensor types to improve accuracy, extend detection range, and enable operation across diverse environmental conditions.Expand Specific Solutions05 Automated design optimization techniques

Computational methods and tools for automating the design optimization process of proximity sensors. This includes simulation-based approaches, machine learning algorithms for parameter tuning, and automated testing frameworks. These techniques enable rapid prototyping, performance prediction, and systematic exploration of design spaces to identify optimal sensor configurations without extensive physical testing.Expand Specific Solutions

Key Industry Players in Compact Proximity Sensing

The proximity sensor market for space-constrained applications is currently in a growth phase, with increasing demand driven by IoT, wearables, and automotive applications. The market is projected to reach significant scale as miniaturization trends continue across industries. Leading players include established electronics giants like Apple, Google, and Siemens, alongside specialized sensor manufacturers such as ams-OSRAM, STMicroelectronics, and Synaptics. Technology maturity varies across sensing methodologies, with optical and capacitive solutions being most advanced. Companies like OPPO, Xiaomi, and Honeywell are driving innovation in miniaturization techniques, while automotive specialists including Bosch and Mercedes-Benz focus on reliability in harsh environments. Academic-industry partnerships with institutions like Ghent University are accelerating development of next-generation sensor technologies.

Synaptics, Inc.

Technical Solution: Synaptics has developed specialized proximity sensing solutions for space-constrained applications through their ClearPad and ClearForce technology portfolios. Their proximity sensors utilize capacitive sensing technology with multi-layer electrode designs that can be integrated directly into display assemblies, eliminating the need for separate sensor modules in space-limited devices. Synaptics' approach includes custom ASICs that combine proximity detection with other sensing functions, reducing the overall component footprint by up to 30% compared to discrete solutions. Their proximity sensors feature adaptive sensitivity algorithms that automatically adjust detection parameters based on environmental conditions, maintaining reliable performance even when sensor placement is compromised by space constraints. For ultra-thin devices, Synaptics has developed flexible sensor substrates less than 0.3mm thick that can conform to curved surfaces while maintaining detection accuracy. Their proximity sensing technology incorporates advanced noise immunity features specifically designed to address the increased electromagnetic interference challenges in densely packed electronic assemblies. Synaptics' solutions also include power management capabilities that can reduce sensor power consumption by up to 90% during idle periods, critical for battery-powered space-constrained applications.

Strengths: Superior integration capabilities with touch and display systems; highly flexible form factors adaptable to various space constraints; excellent noise immunity in densely packed electronic environments. Weaknesses: More complex implementation requiring specialized integration expertise; higher initial engineering investment; some configurations have more limited detection range compared to larger standalone sensors.

Stmicroelectronics Srl

Technical Solution: STMicroelectronics has developed the VL53L5CX Time-of-Flight (ToF) multi-zone ranging sensor specifically optimized for space-constrained applications. This sensor features a compact 6.4 x 3.0 x 1.5 mm package while delivering 8x8 multi-zone ranging capabilities with a 63° diagonal field of view. For extremely space-limited designs, ST offers the VL53L0X which measures just 2.4 x 2.2 x 1.0 mm while still providing accurate proximity detection up to 2 meters. Their proximity sensors utilize ST's proprietary FlightSense technology that eliminates crosstalk issues common in reflective sensors, allowing for more flexible placement in tight spaces. ST has developed specialized optical stacks with diffractive optical elements that maintain sensing performance despite reduced sensor dimensions. Their proximity sensing solutions incorporate advanced power management with an ultra-low power standby mode consuming less than 5 μA, enabling extended battery life in space-constrained portable devices. ST's sensors feature I²C interfaces with programmable address selection, allowing multiple sensors to share communication lines and further reduce wiring complexity in tight spaces. The company has also developed specialized calibration algorithms that compensate for the optical limitations inherent in miniaturized sensors, maintaining accuracy despite the reduced optical path length.

Strengths: Exceptional balance between miniaturization and performance; comprehensive development ecosystem with ready-to-use software libraries; excellent power efficiency with multiple operating modes. Weaknesses: More complex calibration requirements compared to simpler sensors; performance can degrade in certain ambient light conditions; some advanced features require additional processing resources from the host system.

Critical Technologies for Miniaturized Proximity Sensors

Proximity sensor array

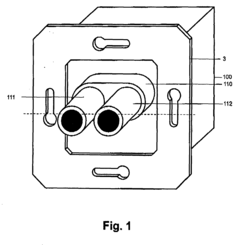

PatentActiveEP3202040A1

Innovation

- A proximity sensor arrangement with a base and a circuit board mounted on its surface, featuring a plug-in connection between a carrier and the base, allowing for a compact and stable setup with integrated contact surfaces and electrodes, enabling efficient electrical contact and easy replacement of sensors.

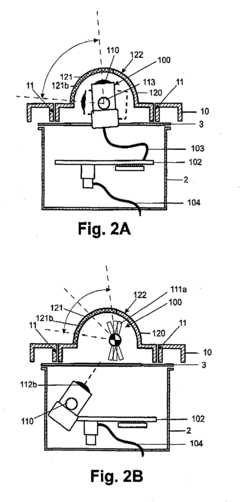

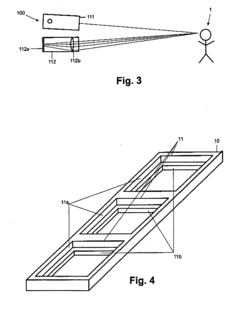

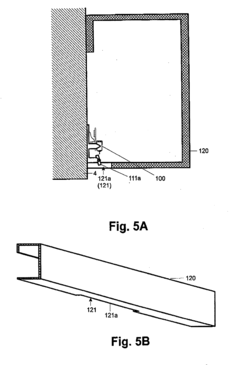

Proximity sensor in particular for door assemblies

PatentInactiveEP2079166A2

Innovation

- A proximity sensor design featuring a pivotable sensor part with a transmitting and receiving element, using infrared radiation and deflection optics, allowing for precise detection and flexible installation in a flush-mounted configuration, which avoids the use of radar radiation and enhances aesthetic integration.

Material Advancements for Sensor Miniaturization

Recent advancements in material science have revolutionized the miniaturization capabilities of proximity sensors for space-constrained applications. Traditional sensor materials like silicon and conventional metals are being supplemented or replaced by novel nanomaterials that offer superior performance characteristics while occupying significantly less space.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes (CNTs), have emerged as frontrunners in sensor miniaturization efforts. These materials exhibit exceptional electrical conductivity, mechanical flexibility, and thermal stability while maintaining functionality at nanoscale dimensions. Graphene-based proximity sensors have demonstrated detection capabilities at thicknesses below 10 nanometers, representing a dramatic reduction compared to conventional alternatives.

Polymer nanocomposites represent another promising material category, combining organic polymers with inorganic nanoparticles to create hybrid materials with enhanced sensing properties. These composites can be engineered to respond to specific stimuli while maintaining structural integrity in extremely confined spaces. Recent developments in piezoelectric polymers like polyvinylidene fluoride (PVDF) have enabled ultrathin sensor configurations that can conform to irregular surfaces.

Metamaterials—artificially engineered structures with properties not found in nature—are pushing the boundaries of sensor miniaturization even further. By manipulating electromagnetic waves at the subwavelength scale, metamaterial-based proximity sensors can achieve unprecedented sensitivity in packages smaller than 1mm³. These materials enable novel sensing mechanisms that transcend the limitations of conventional approaches.

Advances in thin-film deposition techniques have facilitated the development of multi-layered sensor materials with precisely controlled properties. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) allow for the creation of sensor materials with atomic-level precision, optimizing performance while minimizing dimensional requirements. These techniques have enabled the production of functional proximity sensors with thicknesses below 100 nanometers.

Biodegradable and biocompatible materials are gaining traction for specialized applications where environmental impact or biomedical compatibility is crucial. Materials like cellulose nanofibers and silk fibroin derivatives offer sustainable alternatives for disposable sensor applications while maintaining competitive performance metrics in space-constrained environments.

The integration of multiple material types in heterogeneous structures represents the cutting edge of sensor miniaturization. By combining complementary materials in strategic configurations, researchers have developed proximity sensors that leverage the strengths of each component while compensating for individual limitations. These hybrid approaches have yielded some of the most promising results for extreme miniaturization scenarios.

Carbon-based nanomaterials, particularly graphene and carbon nanotubes (CNTs), have emerged as frontrunners in sensor miniaturization efforts. These materials exhibit exceptional electrical conductivity, mechanical flexibility, and thermal stability while maintaining functionality at nanoscale dimensions. Graphene-based proximity sensors have demonstrated detection capabilities at thicknesses below 10 nanometers, representing a dramatic reduction compared to conventional alternatives.

Polymer nanocomposites represent another promising material category, combining organic polymers with inorganic nanoparticles to create hybrid materials with enhanced sensing properties. These composites can be engineered to respond to specific stimuli while maintaining structural integrity in extremely confined spaces. Recent developments in piezoelectric polymers like polyvinylidene fluoride (PVDF) have enabled ultrathin sensor configurations that can conform to irregular surfaces.

Metamaterials—artificially engineered structures with properties not found in nature—are pushing the boundaries of sensor miniaturization even further. By manipulating electromagnetic waves at the subwavelength scale, metamaterial-based proximity sensors can achieve unprecedented sensitivity in packages smaller than 1mm³. These materials enable novel sensing mechanisms that transcend the limitations of conventional approaches.

Advances in thin-film deposition techniques have facilitated the development of multi-layered sensor materials with precisely controlled properties. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) allow for the creation of sensor materials with atomic-level precision, optimizing performance while minimizing dimensional requirements. These techniques have enabled the production of functional proximity sensors with thicknesses below 100 nanometers.

Biodegradable and biocompatible materials are gaining traction for specialized applications where environmental impact or biomedical compatibility is crucial. Materials like cellulose nanofibers and silk fibroin derivatives offer sustainable alternatives for disposable sensor applications while maintaining competitive performance metrics in space-constrained environments.

The integration of multiple material types in heterogeneous structures represents the cutting edge of sensor miniaturization. By combining complementary materials in strategic configurations, researchers have developed proximity sensors that leverage the strengths of each component while compensating for individual limitations. These hybrid approaches have yielded some of the most promising results for extreme miniaturization scenarios.

Power Optimization Strategies for Compact Proximity Sensors

Power optimization remains a critical challenge for proximity sensors in space-constrained applications, where battery life and thermal management directly impact overall system performance. Current optimization strategies focus on balancing power consumption with detection accuracy and response time through several innovative approaches.

Advanced power management circuits represent a significant advancement, incorporating dynamic power scaling that adjusts consumption based on detection frequency requirements. These circuits can reduce power usage by up to 70% during standby periods while maintaining rapid response capabilities when needed. Complementary to this, duty cycling techniques have evolved to intelligently alternate between active sensing and sleep modes, with sophisticated algorithms predicting optimal sensing intervals based on usage patterns.

Material innovations have yielded substantial improvements in sensor efficiency. Low-power piezoelectric materials demonstrate 30-40% greater energy efficiency compared to traditional options, while maintaining comparable sensitivity levels. Similarly, specialized photodiodes with enhanced quantum efficiency require significantly less illumination power to achieve reliable detection thresholds.

Integrated circuit design has progressed toward ultra-low-power architectures specifically optimized for proximity sensing applications. These designs incorporate sub-threshold operation modes that function at voltage levels below traditional thresholds, dramatically reducing power requirements during non-critical operations. Additionally, advanced signal processing algorithms implemented directly in hardware minimize computational overhead and power consumption.

Energy harvesting technologies present promising supplementary power sources for proximity sensors. Ambient light harvesting using high-efficiency photovoltaic cells can extend battery life by 15-25% in well-lit environments. Similarly, thermal gradient and vibration-based energy harvesting systems can recover energy from the operational environment, though their implementation remains challenging in extremely compact form factors.

Software-based optimization strategies have demonstrated remarkable efficiency gains through adaptive sampling rates and context-aware power management. These systems dynamically adjust sensor parameters based on environmental conditions and user behavior patterns, potentially reducing power consumption by 20-35% without compromising detection reliability.

Recent research indicates that hybrid approaches combining multiple power optimization techniques yield the most significant improvements. For instance, systems integrating both hardware-level duty cycling with software-based adaptive sampling have demonstrated power reductions exceeding 60% compared to conventional designs, while maintaining detection performance within acceptable parameters for most applications.

Advanced power management circuits represent a significant advancement, incorporating dynamic power scaling that adjusts consumption based on detection frequency requirements. These circuits can reduce power usage by up to 70% during standby periods while maintaining rapid response capabilities when needed. Complementary to this, duty cycling techniques have evolved to intelligently alternate between active sensing and sleep modes, with sophisticated algorithms predicting optimal sensing intervals based on usage patterns.

Material innovations have yielded substantial improvements in sensor efficiency. Low-power piezoelectric materials demonstrate 30-40% greater energy efficiency compared to traditional options, while maintaining comparable sensitivity levels. Similarly, specialized photodiodes with enhanced quantum efficiency require significantly less illumination power to achieve reliable detection thresholds.

Integrated circuit design has progressed toward ultra-low-power architectures specifically optimized for proximity sensing applications. These designs incorporate sub-threshold operation modes that function at voltage levels below traditional thresholds, dramatically reducing power requirements during non-critical operations. Additionally, advanced signal processing algorithms implemented directly in hardware minimize computational overhead and power consumption.

Energy harvesting technologies present promising supplementary power sources for proximity sensors. Ambient light harvesting using high-efficiency photovoltaic cells can extend battery life by 15-25% in well-lit environments. Similarly, thermal gradient and vibration-based energy harvesting systems can recover energy from the operational environment, though their implementation remains challenging in extremely compact form factors.

Software-based optimization strategies have demonstrated remarkable efficiency gains through adaptive sampling rates and context-aware power management. These systems dynamically adjust sensor parameters based on environmental conditions and user behavior patterns, potentially reducing power consumption by 20-35% without compromising detection reliability.

Recent research indicates that hybrid approaches combining multiple power optimization techniques yield the most significant improvements. For instance, systems integrating both hardware-level duty cycling with software-based adaptive sampling have demonstrated power reductions exceeding 60% compared to conventional designs, while maintaining detection performance within acceptable parameters for most applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!