Multiple Application Proximity Sensors: Alignment and Calibration Tactics

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proximity Sensing Technology Background and Objectives

Proximity sensing technology has evolved significantly over the past decades, transitioning from simple mechanical switches to sophisticated non-contact detection systems. The fundamental principle behind proximity sensors involves detecting the presence of nearby objects without physical contact, utilizing various physical phenomena such as electromagnetic fields, infrared radiation, ultrasonic waves, or capacitive coupling. Initially developed for industrial automation in the 1960s, proximity sensors have since expanded into consumer electronics, automotive systems, healthcare devices, and smart infrastructure applications.

The evolution of proximity sensing technology has been driven by miniaturization, power efficiency improvements, and integration capabilities. Early proximity sensors were bulky, power-hungry devices primarily used in manufacturing environments. Modern sensors, however, can be as small as a few millimeters in dimension while consuming minimal power, making them ideal for portable and wearable devices. This miniaturization trend has enabled the proliferation of proximity sensors in smartphones, tablets, and wearable technology.

Multi-application proximity sensing represents the latest frontier in this technological progression. Unlike traditional single-purpose sensors, these advanced systems are designed to serve multiple functions simultaneously within the same device. For example, in modern smartphones, proximity sensors not only detect when the device is held near the user's face during calls but also contribute to ambient light sensing, gesture recognition, and even health monitoring applications. This multi-functionality creates significant technical challenges, particularly in terms of sensor alignment and calibration.

The primary objective of current research and development in multiple application proximity sensing is to overcome the inherent challenges of cross-functional interference, environmental adaptability, and calibration stability. When multiple sensing functions operate in close proximity, signal interference can compromise accuracy and reliability. Additionally, environmental factors such as temperature fluctuations, humidity changes, and electromagnetic interference can affect sensor performance differently across various applications.

Looking forward, the technological trajectory points toward integrated sensor arrays with advanced signal processing capabilities, self-calibration mechanisms, and machine learning algorithms for adaptive operation. The goal is to develop proximity sensing systems that can maintain optimal performance across diverse applications without requiring frequent manual calibration or adjustment. This evolution will likely incorporate emerging technologies such as time-of-flight (ToF) sensors, structured light systems, and advanced MEMS (Micro-Electro-Mechanical Systems) to enhance precision and reliability.

The ultimate vision for proximity sensing technology is to create seamless, invisible interaction capabilities that anticipate user needs across multiple contexts while maintaining energy efficiency and reliability. This vision aligns with broader trends toward ambient intelligence and context-aware computing, where devices understand and respond to their environment without explicit user commands.

The evolution of proximity sensing technology has been driven by miniaturization, power efficiency improvements, and integration capabilities. Early proximity sensors were bulky, power-hungry devices primarily used in manufacturing environments. Modern sensors, however, can be as small as a few millimeters in dimension while consuming minimal power, making them ideal for portable and wearable devices. This miniaturization trend has enabled the proliferation of proximity sensors in smartphones, tablets, and wearable technology.

Multi-application proximity sensing represents the latest frontier in this technological progression. Unlike traditional single-purpose sensors, these advanced systems are designed to serve multiple functions simultaneously within the same device. For example, in modern smartphones, proximity sensors not only detect when the device is held near the user's face during calls but also contribute to ambient light sensing, gesture recognition, and even health monitoring applications. This multi-functionality creates significant technical challenges, particularly in terms of sensor alignment and calibration.

The primary objective of current research and development in multiple application proximity sensing is to overcome the inherent challenges of cross-functional interference, environmental adaptability, and calibration stability. When multiple sensing functions operate in close proximity, signal interference can compromise accuracy and reliability. Additionally, environmental factors such as temperature fluctuations, humidity changes, and electromagnetic interference can affect sensor performance differently across various applications.

Looking forward, the technological trajectory points toward integrated sensor arrays with advanced signal processing capabilities, self-calibration mechanisms, and machine learning algorithms for adaptive operation. The goal is to develop proximity sensing systems that can maintain optimal performance across diverse applications without requiring frequent manual calibration or adjustment. This evolution will likely incorporate emerging technologies such as time-of-flight (ToF) sensors, structured light systems, and advanced MEMS (Micro-Electro-Mechanical Systems) to enhance precision and reliability.

The ultimate vision for proximity sensing technology is to create seamless, invisible interaction capabilities that anticipate user needs across multiple contexts while maintaining energy efficiency and reliability. This vision aligns with broader trends toward ambient intelligence and context-aware computing, where devices understand and respond to their environment without explicit user commands.

Market Applications and Demand Analysis

Proximity sensors have witnessed substantial market growth across multiple industries, with the global proximity sensor market valued at approximately 3.5 billion USD in 2022 and projected to reach 5.8 billion USD by 2027, representing a CAGR of 10.6%. This growth is primarily driven by increasing automation in manufacturing processes, rising adoption of smartphones and consumer electronics, and expanding applications in automotive safety systems.

The consumer electronics sector represents the largest market segment for proximity sensors, accounting for nearly 35% of the total market share. In smartphones alone, proximity sensors are essential components that detect when users hold devices to their ears during calls, preventing accidental screen touches. The average smartphone today contains between 2-5 proximity sensors serving different functions, highlighting the need for sophisticated alignment and calibration tactics to ensure optimal performance in limited space.

Automotive applications constitute the fastest-growing segment for proximity sensors, with a growth rate exceeding 12% annually. Modern vehicles incorporate an average of 8-12 proximity sensors for applications ranging from parking assistance to collision avoidance systems. The trend toward autonomous driving has further accelerated demand, with Level 3+ autonomous vehicles requiring up to 20 properly calibrated proximity sensors working in concert.

Industrial automation represents another significant market, valued at approximately 950 million USD, where proximity sensors enable precise object detection, positioning, and safety functions. Manufacturing facilities increasingly deploy multiple proximity sensors throughout production lines, with a typical automotive assembly line utilizing over 100 sensors that require regular calibration to maintain production efficiency.

Healthcare applications are emerging as a promising growth area, particularly in medical devices and equipment positioning. The medical proximity sensor market segment is growing at 9.8% annually, with applications in patient monitoring systems, surgical equipment, and diagnostic devices requiring high precision alignment and calibration.

Market research indicates that approximately 72% of end-users across industries report challenges related to multi-sensor alignment and calibration, with 38% experiencing performance issues directly attributable to improper sensor calibration. This highlights a significant market need for advanced calibration tactics and solutions that can address the complexities of multiple sensor environments.

The geographical distribution of market demand shows Asia-Pacific leading with 42% market share, followed by North America (28%) and Europe (22%). China, Japan, and South Korea represent key manufacturing hubs where proximity sensor implementation and calibration technologies are in particularly high demand, driven by their dominant positions in consumer electronics production.

The consumer electronics sector represents the largest market segment for proximity sensors, accounting for nearly 35% of the total market share. In smartphones alone, proximity sensors are essential components that detect when users hold devices to their ears during calls, preventing accidental screen touches. The average smartphone today contains between 2-5 proximity sensors serving different functions, highlighting the need for sophisticated alignment and calibration tactics to ensure optimal performance in limited space.

Automotive applications constitute the fastest-growing segment for proximity sensors, with a growth rate exceeding 12% annually. Modern vehicles incorporate an average of 8-12 proximity sensors for applications ranging from parking assistance to collision avoidance systems. The trend toward autonomous driving has further accelerated demand, with Level 3+ autonomous vehicles requiring up to 20 properly calibrated proximity sensors working in concert.

Industrial automation represents another significant market, valued at approximately 950 million USD, where proximity sensors enable precise object detection, positioning, and safety functions. Manufacturing facilities increasingly deploy multiple proximity sensors throughout production lines, with a typical automotive assembly line utilizing over 100 sensors that require regular calibration to maintain production efficiency.

Healthcare applications are emerging as a promising growth area, particularly in medical devices and equipment positioning. The medical proximity sensor market segment is growing at 9.8% annually, with applications in patient monitoring systems, surgical equipment, and diagnostic devices requiring high precision alignment and calibration.

Market research indicates that approximately 72% of end-users across industries report challenges related to multi-sensor alignment and calibration, with 38% experiencing performance issues directly attributable to improper sensor calibration. This highlights a significant market need for advanced calibration tactics and solutions that can address the complexities of multiple sensor environments.

The geographical distribution of market demand shows Asia-Pacific leading with 42% market share, followed by North America (28%) and Europe (22%). China, Japan, and South Korea represent key manufacturing hubs where proximity sensor implementation and calibration technologies are in particularly high demand, driven by their dominant positions in consumer electronics production.

Current Challenges in Multi-Sensor Alignment

The alignment of multiple proximity sensors in complex systems presents significant technical challenges that impede optimal performance and reliability. Current sensor arrays often suffer from misalignment issues during both initial installation and throughout operational lifecycles. Manufacturing tolerances introduce inherent positioning variations between sensors, creating inconsistencies in detection zones and measurement accuracy. These variations, while minor individually, compound across multi-sensor arrays, resulting in significant system-level performance degradation.

Environmental factors further exacerbate alignment challenges. Thermal expansion and contraction cause subtle shifts in sensor positioning, particularly in applications exposed to wide temperature fluctuations. Mechanical vibration and shock gradually alter sensor orientation, especially in automotive, industrial, and aerospace applications where constant movement is inevitable. These dynamic misalignments often occur progressively, making them difficult to detect until system performance has already deteriorated substantially.

Cross-talk between adjacent sensors represents another critical challenge. When multiple proximity sensors operate in close proximity, signal interference creates false readings and detection anomalies. Current shielding techniques provide only partial solutions, as they often introduce additional space constraints and weight penalties that may be unacceptable in compact or lightweight applications.

Calibration drift compounds these alignment issues. Even initially well-aligned sensors experience performance divergence over time due to component aging, environmental exposure, and usage patterns. The rate of drift varies between individual sensors, creating increasingly unpredictable system behavior as operational time increases. Current calibration methodologies typically require system downtime and specialized equipment, making frequent recalibration economically and logistically impractical.

Integration with existing software frameworks presents additional complications. Many legacy systems lack the sophisticated algorithms necessary to compensate for sensor misalignment in real-time. Implementing such capabilities often requires fundamental architecture changes that manufacturers are reluctant to undertake due to cost and compatibility concerns.

Power consumption optimization further complicates alignment solutions. Advanced calibration techniques that could potentially address misalignment issues often demand significant computational resources, increasing energy requirements. This creates a particular challenge for battery-powered or energy-efficient applications where power budgets are strictly limited.

Standardization gaps across the industry hinder universal solutions. Different manufacturers employ proprietary sensor mounting designs and calibration protocols, making it difficult to develop alignment techniques that work consistently across heterogeneous sensor arrays. This fragmentation slows innovation and increases implementation costs for end-users deploying multi-vendor sensor systems.

Environmental factors further exacerbate alignment challenges. Thermal expansion and contraction cause subtle shifts in sensor positioning, particularly in applications exposed to wide temperature fluctuations. Mechanical vibration and shock gradually alter sensor orientation, especially in automotive, industrial, and aerospace applications where constant movement is inevitable. These dynamic misalignments often occur progressively, making them difficult to detect until system performance has already deteriorated substantially.

Cross-talk between adjacent sensors represents another critical challenge. When multiple proximity sensors operate in close proximity, signal interference creates false readings and detection anomalies. Current shielding techniques provide only partial solutions, as they often introduce additional space constraints and weight penalties that may be unacceptable in compact or lightweight applications.

Calibration drift compounds these alignment issues. Even initially well-aligned sensors experience performance divergence over time due to component aging, environmental exposure, and usage patterns. The rate of drift varies between individual sensors, creating increasingly unpredictable system behavior as operational time increases. Current calibration methodologies typically require system downtime and specialized equipment, making frequent recalibration economically and logistically impractical.

Integration with existing software frameworks presents additional complications. Many legacy systems lack the sophisticated algorithms necessary to compensate for sensor misalignment in real-time. Implementing such capabilities often requires fundamental architecture changes that manufacturers are reluctant to undertake due to cost and compatibility concerns.

Power consumption optimization further complicates alignment solutions. Advanced calibration techniques that could potentially address misalignment issues often demand significant computational resources, increasing energy requirements. This creates a particular challenge for battery-powered or energy-efficient applications where power budgets are strictly limited.

Standardization gaps across the industry hinder universal solutions. Different manufacturers employ proprietary sensor mounting designs and calibration protocols, making it difficult to develop alignment techniques that work consistently across heterogeneous sensor arrays. This fragmentation slows innovation and increases implementation costs for end-users deploying multi-vendor sensor systems.

Current Alignment and Calibration Methodologies

01 Calibration methods for proximity sensors

Various methods for calibrating proximity sensors to ensure accurate distance measurements. These methods include using reference objects at known distances, automated calibration procedures, and software algorithms that compensate for environmental factors. Calibration processes typically involve measuring sensor responses at multiple distances and creating correction factors to improve accuracy across the detection range.- Calibration methods for proximity sensors: Various methods are employed to calibrate proximity sensors to ensure accurate distance measurements. These methods include using reference objects at known distances, automated calibration routines, and compensation algorithms that account for environmental factors. Calibration processes typically involve measuring sensor responses at multiple distances and creating calibration curves or lookup tables to convert raw sensor readings into accurate distance values.

- Alignment techniques for sensor arrays: Proper alignment of proximity sensors in multi-sensor arrays is critical for accurate spatial detection. Techniques include mechanical fixtures for precise positioning, optical alignment methods using laser references, and software-based alignment verification. These approaches ensure that sensor arrays maintain proper geometric relationships to each other, enabling accurate triangulation and spatial mapping of detected objects.

- Self-calibration and adaptive systems: Advanced proximity sensing systems incorporate self-calibration capabilities that automatically adjust sensor parameters based on environmental conditions. These adaptive systems use machine learning algorithms to continuously refine calibration parameters, compensate for drift, and adjust to changing conditions. Self-calibration routines may run periodically or be triggered by detected anomalies in sensor readings to maintain accuracy over time.

- Sensor fusion for improved accuracy: Combining data from multiple proximity sensors or different sensor types enhances measurement accuracy and reliability. Sensor fusion techniques integrate readings from various sensors using algorithms such as Kalman filtering, weighted averaging, or Bayesian methods. This approach compensates for individual sensor limitations, reduces noise, and provides more robust detection capabilities across varying environmental conditions.

- Testing and validation frameworks: Comprehensive testing frameworks are essential for validating proximity sensor alignment and calibration. These frameworks include automated test equipment, standardized test protocols, and performance metrics to quantify sensor accuracy. Validation procedures typically measure sensor performance across various distances, object types, and environmental conditions to ensure reliable operation in real-world applications.

02 Alignment techniques for sensor arrays

Techniques for properly aligning multiple proximity sensors in array configurations to ensure optimal coverage and performance. These include mechanical alignment fixtures, optical alignment systems, and digital alignment verification methods. Proper alignment is critical for applications requiring precise spatial awareness, such as robotics, automotive systems, and industrial automation where multiple sensors must work together cohesively.Expand Specific Solutions03 Self-calibration and adaptive systems

Self-calibrating proximity sensor systems that can automatically adjust their parameters based on environmental conditions or usage patterns. These systems incorporate feedback mechanisms to continuously optimize performance without manual intervention. Adaptive algorithms can compensate for drift, temperature variations, and other factors that might otherwise affect sensor accuracy over time.Expand Specific Solutions04 Multi-sensor fusion and cross-calibration

Methods for calibrating and aligning multiple types of proximity sensors (ultrasonic, infrared, capacitive, etc.) to work together in integrated systems. These approaches involve cross-referencing data between different sensor types to improve overall system accuracy and reliability. Sensor fusion techniques combine inputs from multiple sensors to create more robust detection capabilities that overcome the limitations of individual sensor technologies.Expand Specific Solutions05 In-field calibration and maintenance procedures

Procedures and tools for performing calibration and alignment of proximity sensors after installation or during routine maintenance. These methods allow for adjustment without removing sensors from their operational environment, reducing downtime and ensuring continued accuracy. Field calibration techniques often utilize portable reference tools and specialized software interfaces that can be operated by maintenance personnel.Expand Specific Solutions

Leading Proximity Sensor Manufacturers and Integrators

The proximity sensor technology market is currently in a growth phase, characterized by increasing adoption across automotive, consumer electronics, and industrial sectors. The market size is expanding rapidly, driven by applications in smartphones, autonomous vehicles, and industrial automation. Technologically, the field is maturing with companies at different stages of development. Industry leaders like OPPO, Bosch, and Qualcomm have established advanced calibration techniques for multi-sensor arrays, while Boeing and GM are implementing sophisticated alignment strategies for aerospace and automotive applications. Emerging players like Brain Corp and NextNav are innovating with novel approaches to sensor fusion and environmental mapping. The competitive landscape shows a mix of established electronics manufacturers, automotive companies, and specialized technology firms working to overcome challenges in sensor alignment, environmental interference, and cross-device calibration.

Robert Bosch GmbH

Technical Solution: Bosch has developed sophisticated multi-sensor proximity systems utilizing their MEMS sensor technology combined with advanced calibration methodologies. Their approach incorporates factory-calibrated reference tables with dynamic field calibration capabilities, allowing systems to maintain accuracy throughout their operational lifetime. Bosch's proximity sensor arrays employ differential measurement techniques to eliminate common-mode environmental interference, critical for automotive and industrial applications where operating conditions vary widely. Their technology includes cross-sensor verification protocols where readings from multiple proximity sensors are compared against expected geometric relationships to detect miscalibration or sensor failures. Bosch has implemented sensor fusion algorithms that combine proximity data with inertial measurements to improve alignment accuracy during dynamic operations. Their automotive-grade proximity sensor systems feature redundant sensing elements with independent calibration channels to ensure functional safety compliance.

Strengths: Exceptional durability and reliability in harsh environments; comprehensive safety certification for automotive applications. Weaknesses: Higher cost structure compared to consumer-grade alternatives; more complex integration requirements due to safety-critical design approach.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed comprehensive proximity sensor solutions featuring multi-sensor arrays with advanced calibration algorithms. Their technology employs time-of-flight (ToF) principles combined with proprietary signal processing to enable precise alignment across multiple proximity sensors. TI's approach includes factory calibration methodologies and dynamic in-field recalibration capabilities that compensate for environmental variations and sensor drift over time. Their MSP430 microcontroller family specifically supports multi-sensor proximity applications with dedicated hardware accelerators for sensor fusion and calibration. TI has implemented cross-talk cancellation techniques that allow multiple proximity sensors to operate simultaneously without interference, critical for applications requiring 360-degree sensing coverage. Their solutions incorporate temperature compensation algorithms to maintain calibration accuracy across varying thermal conditions.

Strengths: Industry-leading power efficiency making their solutions ideal for battery-powered devices; extensive ecosystem of development tools facilitating rapid implementation. Weaknesses: Higher implementation complexity requiring specialized engineering knowledge; calibration procedures may require additional manufacturing steps increasing production costs.

Key Patents in Multi-Sensor Calibration Techniques

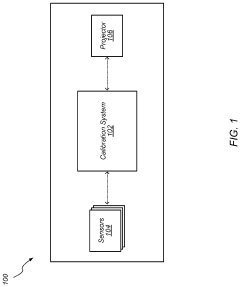

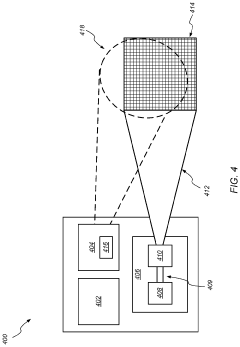

Multi-sensor real-time alignment and calibration

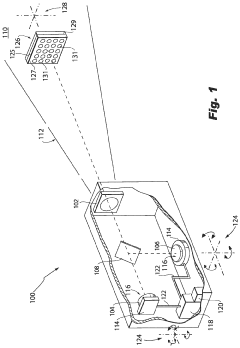

PatentActiveUS10788316B1

Innovation

- A multi-sensor real-time alignment system using a projector to project a pattern on a target location, allowing sensors to detect and adjust their alignment based on the relative position of the pattern, ensuring accurate data collection and restoring autonomous functions.

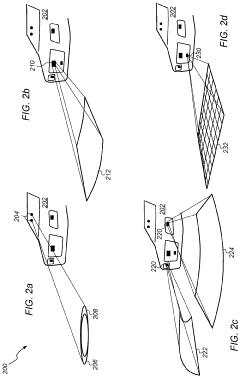

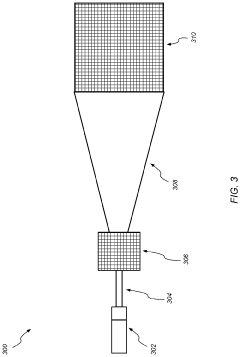

Multi-sensor alignment and real time distortion correction and image registration

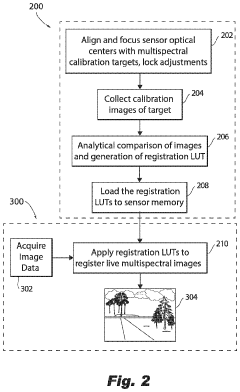

PatentActiveUS20200184683A1

Innovation

- Mechanical alignment of sensors to boresight and focus their optical centers, combined with the creation and application of a look-up table (LUT) for optical distortion and spatial registration, allowing for precise registration of image data from multiple sensors sensitive to various wavelengths, including SWIR and LWIR.

Cross-Platform Compatibility Standards

Cross-platform compatibility has emerged as a critical consideration in the deployment of proximity sensor systems across multiple applications. The increasing diversity of operating systems, hardware configurations, and software environments necessitates standardized approaches to ensure seamless integration. Current industry standards primarily focus on three key areas: communication protocols, data formatting, and calibration methodologies.

Communication protocol standards such as I2C, SPI, and UART provide foundational frameworks for proximity sensor integration across platforms. However, these standards alone are insufficient for complex multi-sensor arrays used in modern applications. The development of middleware abstraction layers has become essential, with initiatives like the Proximity Sensor Interface Standard (PSIS) gaining traction among major hardware manufacturers.

Data formatting standards represent another crucial aspect of cross-platform compatibility. The JSON-based Proximity Sensor Data Format (PSDF) has emerged as a leading standard, offering platform-agnostic representation of sensor readings, calibration parameters, and alignment configurations. This standardization enables consistent interpretation of sensor data regardless of the underlying hardware or operating system.

Calibration procedure standardization remains particularly challenging due to the diverse environmental factors affecting proximity sensor performance. The Open Sensor Calibration Framework (OSCF) has made significant progress in establishing universal calibration protocols that can be implemented across Android, iOS, Windows, and Linux environments. These protocols define standardized procedures for sensor initialization, environmental compensation, and cross-sensor alignment.

Hardware abstraction layers (HALs) play a pivotal role in bridging platform-specific implementations with standardized interfaces. Notable examples include Android's Sensor HAL and the cross-platform libsensor library, which provide consistent APIs for accessing proximity sensor functionality across diverse hardware configurations. These abstraction mechanisms significantly reduce development overhead when deploying multi-sensor solutions across heterogeneous platforms.

Interoperability testing frameworks have evolved to validate cross-platform compatibility. The Proximity Sensor Compatibility Test Suite (PSCTS) offers standardized validation procedures to verify sensor behavior across different platforms. This testing framework evaluates alignment accuracy, calibration persistence, and data consistency when the same sensor array is accessed from multiple operating systems or applications.

Future standardization efforts are focusing on cloud-based calibration data sharing, enabling proximity sensor arrays to maintain consistent alignment and calibration parameters across different devices and platforms. This approach promises to simplify multi-device deployments while ensuring uniform sensor performance regardless of the accessing platform.

Communication protocol standards such as I2C, SPI, and UART provide foundational frameworks for proximity sensor integration across platforms. However, these standards alone are insufficient for complex multi-sensor arrays used in modern applications. The development of middleware abstraction layers has become essential, with initiatives like the Proximity Sensor Interface Standard (PSIS) gaining traction among major hardware manufacturers.

Data formatting standards represent another crucial aspect of cross-platform compatibility. The JSON-based Proximity Sensor Data Format (PSDF) has emerged as a leading standard, offering platform-agnostic representation of sensor readings, calibration parameters, and alignment configurations. This standardization enables consistent interpretation of sensor data regardless of the underlying hardware or operating system.

Calibration procedure standardization remains particularly challenging due to the diverse environmental factors affecting proximity sensor performance. The Open Sensor Calibration Framework (OSCF) has made significant progress in establishing universal calibration protocols that can be implemented across Android, iOS, Windows, and Linux environments. These protocols define standardized procedures for sensor initialization, environmental compensation, and cross-sensor alignment.

Hardware abstraction layers (HALs) play a pivotal role in bridging platform-specific implementations with standardized interfaces. Notable examples include Android's Sensor HAL and the cross-platform libsensor library, which provide consistent APIs for accessing proximity sensor functionality across diverse hardware configurations. These abstraction mechanisms significantly reduce development overhead when deploying multi-sensor solutions across heterogeneous platforms.

Interoperability testing frameworks have evolved to validate cross-platform compatibility. The Proximity Sensor Compatibility Test Suite (PSCTS) offers standardized validation procedures to verify sensor behavior across different platforms. This testing framework evaluates alignment accuracy, calibration persistence, and data consistency when the same sensor array is accessed from multiple operating systems or applications.

Future standardization efforts are focusing on cloud-based calibration data sharing, enabling proximity sensor arrays to maintain consistent alignment and calibration parameters across different devices and platforms. This approach promises to simplify multi-device deployments while ensuring uniform sensor performance regardless of the accessing platform.

Environmental Factors Affecting Sensor Performance

Environmental factors significantly impact the performance and reliability of proximity sensors in multi-application systems. Temperature variations represent one of the most critical factors affecting sensor accuracy. When operating in environments with extreme temperatures, proximity sensors may experience drift in their calibration parameters. For instance, capacitive sensors show decreased sensitivity in cold environments due to changes in dielectric properties of materials, while infrared sensors may exhibit false readings in high-temperature settings due to ambient thermal radiation interfering with their detection mechanisms.

Humidity and moisture present another substantial challenge for proximity sensor systems. High humidity environments can cause condensation on sensor surfaces, potentially creating false triggers in capacitive sensors or reducing the effective range of ultrasonic sensors. In industrial applications where water spray or mist is present, special consideration must be given to sensor selection and protective housing design to maintain calibration integrity across varying moisture conditions.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication systems can severely compromise proximity sensor performance. This is particularly problematic in manufacturing environments with multiple machines operating simultaneously. Sensors utilizing electromagnetic principles, such as inductive or capacitive types, are especially vulnerable to EMI, necessitating proper shielding and filtering techniques to maintain reliable operation and accurate calibration.

Ambient light conditions critically affect optical proximity sensors, including infrared and photoelectric variants. Direct sunlight or bright artificial lighting can saturate photodetectors, while insufficient lighting may reduce detection range. Modern sensor systems often incorporate ambient light compensation algorithms, but these require regular recalibration when environmental lighting conditions change significantly to maintain detection accuracy across multiple applications.

Vibration and mechanical shock represent significant challenges for sensor alignment in industrial and automotive applications. Continuous vibration can gradually shift sensor positioning, while sudden impacts may immediately disrupt calibration parameters. Robust mounting solutions and periodic verification of alignment become essential in environments subject to mechanical disturbances, particularly when multiple sensors must work in concert for complex detection tasks.

Airborne particulates such as dust, smoke, or fog can interfere with sensor operation by scattering light beams in optical sensors or creating false echoes in ultrasonic systems. In manufacturing environments where airborne contaminants are common, regular cleaning protocols and appropriate IP-rated enclosures must be implemented to maintain sensor performance. Some advanced systems incorporate self-diagnostic capabilities to detect when environmental contamination has reached levels that compromise calibration integrity.

Humidity and moisture present another substantial challenge for proximity sensor systems. High humidity environments can cause condensation on sensor surfaces, potentially creating false triggers in capacitive sensors or reducing the effective range of ultrasonic sensors. In industrial applications where water spray or mist is present, special consideration must be given to sensor selection and protective housing design to maintain calibration integrity across varying moisture conditions.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication systems can severely compromise proximity sensor performance. This is particularly problematic in manufacturing environments with multiple machines operating simultaneously. Sensors utilizing electromagnetic principles, such as inductive or capacitive types, are especially vulnerable to EMI, necessitating proper shielding and filtering techniques to maintain reliable operation and accurate calibration.

Ambient light conditions critically affect optical proximity sensors, including infrared and photoelectric variants. Direct sunlight or bright artificial lighting can saturate photodetectors, while insufficient lighting may reduce detection range. Modern sensor systems often incorporate ambient light compensation algorithms, but these require regular recalibration when environmental lighting conditions change significantly to maintain detection accuracy across multiple applications.

Vibration and mechanical shock represent significant challenges for sensor alignment in industrial and automotive applications. Continuous vibration can gradually shift sensor positioning, while sudden impacts may immediately disrupt calibration parameters. Robust mounting solutions and periodic verification of alignment become essential in environments subject to mechanical disturbances, particularly when multiple sensors must work in concert for complex detection tasks.

Airborne particulates such as dust, smoke, or fog can interfere with sensor operation by scattering light beams in optical sensors or creating false echoes in ultrasonic systems. In manufacturing environments where airborne contaminants are common, regular cleaning protocols and appropriate IP-rated enclosures must be implemented to maintain sensor performance. Some advanced systems incorporate self-diagnostic capabilities to detect when environmental contamination has reached levels that compromise calibration integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!