Gauge Impact Resistance in Proximity Sensor Exterior Shell Materials

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proximity Sensor Shell Materials Background and Objectives

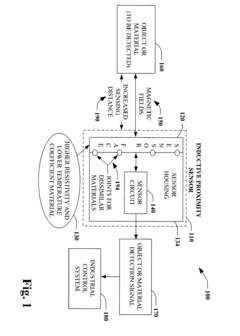

Proximity sensors have evolved significantly over the past three decades, transitioning from simple mechanical switches to sophisticated electronic devices capable of detecting objects without physical contact. The protective shell materials for these sensors have similarly undergone substantial development, moving from basic metal casings to advanced composite materials engineered for specific environmental conditions and applications.

The evolution of proximity sensor shell materials has been driven by increasing demands across multiple industries including automotive, aerospace, manufacturing, and consumer electronics. Early proximity sensors utilized primarily metal housings that offered basic protection but were susceptible to corrosion and provided limited impact resistance. As sensors began to be deployed in more challenging environments, the limitations of these basic housings became apparent.

Current proximity sensor applications require shells that can withstand significant mechanical stress, extreme temperatures, chemical exposure, and repeated impact forces while maintaining the sensor's detection accuracy. The gauge impact resistance—a measure of a material's ability to absorb energy during deformation under impact loading—has become a critical parameter in shell material selection, particularly for sensors deployed in industrial environments where accidental impacts are common.

The global proximity sensor market is projected to reach $3.8 billion by 2025, with a compound annual growth rate of 7.2%. This growth is driving innovation in protective materials as manufacturers seek competitive advantages through enhanced durability and reliability. Recent advancements in polymer science, composite materials, and nanomaterials have opened new possibilities for sensor protection that were not previously viable.

This technical research aims to comprehensively evaluate the impact resistance properties of various materials used in proximity sensor exterior shells, with particular focus on gauge impact metrics across different material categories. The objective is to identify optimal materials that balance protection capabilities with other essential requirements such as electromagnetic transparency, weight considerations, manufacturing feasibility, and cost-effectiveness.

The research will establish standardized testing methodologies for gauge impact resistance specific to proximity sensor applications, addressing the current lack of industry-specific standards. Additionally, it seeks to develop predictive models for material performance under various impact scenarios, enabling more efficient material selection processes for sensor manufacturers.

By establishing clear correlations between material composition, structural design, and impact resistance performance, this research aims to provide actionable insights for next-generation proximity sensor shell development. The ultimate goal is to enable the creation of sensor housings that maintain functional integrity even under severe impact conditions, thereby extending sensor lifespan and reliability in demanding applications.

The evolution of proximity sensor shell materials has been driven by increasing demands across multiple industries including automotive, aerospace, manufacturing, and consumer electronics. Early proximity sensors utilized primarily metal housings that offered basic protection but were susceptible to corrosion and provided limited impact resistance. As sensors began to be deployed in more challenging environments, the limitations of these basic housings became apparent.

Current proximity sensor applications require shells that can withstand significant mechanical stress, extreme temperatures, chemical exposure, and repeated impact forces while maintaining the sensor's detection accuracy. The gauge impact resistance—a measure of a material's ability to absorb energy during deformation under impact loading—has become a critical parameter in shell material selection, particularly for sensors deployed in industrial environments where accidental impacts are common.

The global proximity sensor market is projected to reach $3.8 billion by 2025, with a compound annual growth rate of 7.2%. This growth is driving innovation in protective materials as manufacturers seek competitive advantages through enhanced durability and reliability. Recent advancements in polymer science, composite materials, and nanomaterials have opened new possibilities for sensor protection that were not previously viable.

This technical research aims to comprehensively evaluate the impact resistance properties of various materials used in proximity sensor exterior shells, with particular focus on gauge impact metrics across different material categories. The objective is to identify optimal materials that balance protection capabilities with other essential requirements such as electromagnetic transparency, weight considerations, manufacturing feasibility, and cost-effectiveness.

The research will establish standardized testing methodologies for gauge impact resistance specific to proximity sensor applications, addressing the current lack of industry-specific standards. Additionally, it seeks to develop predictive models for material performance under various impact scenarios, enabling more efficient material selection processes for sensor manufacturers.

By establishing clear correlations between material composition, structural design, and impact resistance performance, this research aims to provide actionable insights for next-generation proximity sensor shell development. The ultimate goal is to enable the creation of sensor housings that maintain functional integrity even under severe impact conditions, thereby extending sensor lifespan and reliability in demanding applications.

Market Requirements for Impact-Resistant Sensor Housings

The global market for impact-resistant sensor housings has experienced significant growth in recent years, driven by the increasing deployment of proximity sensors across various industries. Current market analysis indicates a strong demand for durable exterior shell materials that can withstand harsh operating environments while maintaining sensor functionality and accuracy.

Industrial automation represents the largest market segment, where proximity sensors are extensively used in manufacturing equipment, robotics, and assembly lines. In these environments, sensors are frequently exposed to mechanical impacts, vibrations, and potential collisions with moving parts or materials. Market research shows that manufacturing facilities prioritize sensors with housings that can withstand repeated impacts without compromising operational integrity, as sensor failures directly impact production efficiency and increase maintenance costs.

The automotive industry constitutes another critical market segment, particularly with the rise of advanced driver-assistance systems (ADAS) and autonomous vehicles. Proximity sensors in automotive applications must withstand road debris, weather conditions, and potential minor collisions. Vehicle manufacturers specifically require sensor housings that maintain structural integrity across extreme temperature ranges and resist degradation from exposure to automotive fluids and road chemicals.

Consumer electronics manufacturers are increasingly incorporating proximity sensors into portable devices, creating demand for lightweight yet durable housing materials. This segment values aesthetically pleasing designs that do not compromise impact resistance, with particular emphasis on scratch resistance and the ability to withstand everyday drops and bumps.

The aerospace and defense sectors represent premium market segments with stringent requirements for sensor housing durability. These applications demand materials that can withstand extreme conditions including high-velocity impacts, pressure differentials, and exposure to corrosive substances, while maintaining precise sensor functionality.

Market research indicates that end-users across all segments are willing to pay premium prices for sensors with proven impact resistance, as the cost of sensor replacement and associated downtime far exceeds the initial investment in higher-quality components. This has created a competitive landscape where manufacturers increasingly highlight impact resistance as a key differentiator in their product offerings.

Emerging market requirements include enhanced sustainability credentials, with growing demand for impact-resistant materials that are recyclable or manufactured using environmentally responsible processes. Additionally, there is increasing interest in transparent or translucent impact-resistant materials that allow for visual inspection of sensor components without compromising protective qualities.

Industrial automation represents the largest market segment, where proximity sensors are extensively used in manufacturing equipment, robotics, and assembly lines. In these environments, sensors are frequently exposed to mechanical impacts, vibrations, and potential collisions with moving parts or materials. Market research shows that manufacturing facilities prioritize sensors with housings that can withstand repeated impacts without compromising operational integrity, as sensor failures directly impact production efficiency and increase maintenance costs.

The automotive industry constitutes another critical market segment, particularly with the rise of advanced driver-assistance systems (ADAS) and autonomous vehicles. Proximity sensors in automotive applications must withstand road debris, weather conditions, and potential minor collisions. Vehicle manufacturers specifically require sensor housings that maintain structural integrity across extreme temperature ranges and resist degradation from exposure to automotive fluids and road chemicals.

Consumer electronics manufacturers are increasingly incorporating proximity sensors into portable devices, creating demand for lightweight yet durable housing materials. This segment values aesthetically pleasing designs that do not compromise impact resistance, with particular emphasis on scratch resistance and the ability to withstand everyday drops and bumps.

The aerospace and defense sectors represent premium market segments with stringent requirements for sensor housing durability. These applications demand materials that can withstand extreme conditions including high-velocity impacts, pressure differentials, and exposure to corrosive substances, while maintaining precise sensor functionality.

Market research indicates that end-users across all segments are willing to pay premium prices for sensors with proven impact resistance, as the cost of sensor replacement and associated downtime far exceeds the initial investment in higher-quality components. This has created a competitive landscape where manufacturers increasingly highlight impact resistance as a key differentiator in their product offerings.

Emerging market requirements include enhanced sustainability credentials, with growing demand for impact-resistant materials that are recyclable or manufactured using environmentally responsible processes. Additionally, there is increasing interest in transparent or translucent impact-resistant materials that allow for visual inspection of sensor components without compromising protective qualities.

Current Challenges in Gauge Impact Resistance Technology

The development of impact-resistant materials for proximity sensor exterior shells faces several significant technical challenges. Current materials struggle to maintain optimal balance between durability and sensor functionality, particularly in harsh industrial environments. Traditional materials like standard polymers often fail prematurely when subjected to repeated impacts, while more robust options may interfere with sensor performance.

Material degradation under combined stress factors presents another major challenge. When proximity sensors are deployed in environments with simultaneous exposure to impact forces, chemical agents, and temperature fluctuations, material integrity deteriorates at accelerated rates. Research indicates that even high-performance composites experience up to 40% reduction in impact resistance when subjected to these combined stressors over extended periods.

Miniaturization trends in sensor technology have further complicated material selection processes. As proximity sensors become smaller and more integrated into complex systems, the exterior shell materials must provide impact protection while maintaining minimal thickness and weight. This dimensional constraint severely limits the application of traditional impact-resistant solutions like reinforced structures or multi-layer protection systems.

Cost-effectiveness remains a persistent obstacle in developing advanced impact-resistant materials. Current high-performance options such as specialized polymer blends and carbon fiber composites significantly increase production costs, making widespread adoption economically unfeasible for many applications. The industry faces a critical need for materials that offer enhanced impact resistance without substantial price premiums.

Manufacturing scalability presents technical difficulties as well. Many laboratory-developed materials with excellent impact resistance properties cannot be efficiently mass-produced using conventional manufacturing techniques. The transition from prototype to production often results in compromised performance characteristics or inconsistent quality across production batches.

Regulatory compliance adds another layer of complexity to material development. Materials must not only provide impact resistance but also meet increasingly stringent environmental regulations regarding toxicity, recyclability, and end-of-life disposal. This regulatory landscape has eliminated several previously viable material options from consideration.

Testing methodologies for impact resistance also present significant challenges. Current standardized tests often fail to accurately simulate real-world impact scenarios experienced by proximity sensors in specific applications. This testing gap leads to materials that perform well in laboratory conditions but underperform in actual deployment environments, creating reliability issues and increasing maintenance costs.

Material degradation under combined stress factors presents another major challenge. When proximity sensors are deployed in environments with simultaneous exposure to impact forces, chemical agents, and temperature fluctuations, material integrity deteriorates at accelerated rates. Research indicates that even high-performance composites experience up to 40% reduction in impact resistance when subjected to these combined stressors over extended periods.

Miniaturization trends in sensor technology have further complicated material selection processes. As proximity sensors become smaller and more integrated into complex systems, the exterior shell materials must provide impact protection while maintaining minimal thickness and weight. This dimensional constraint severely limits the application of traditional impact-resistant solutions like reinforced structures or multi-layer protection systems.

Cost-effectiveness remains a persistent obstacle in developing advanced impact-resistant materials. Current high-performance options such as specialized polymer blends and carbon fiber composites significantly increase production costs, making widespread adoption economically unfeasible for many applications. The industry faces a critical need for materials that offer enhanced impact resistance without substantial price premiums.

Manufacturing scalability presents technical difficulties as well. Many laboratory-developed materials with excellent impact resistance properties cannot be efficiently mass-produced using conventional manufacturing techniques. The transition from prototype to production often results in compromised performance characteristics or inconsistent quality across production batches.

Regulatory compliance adds another layer of complexity to material development. Materials must not only provide impact resistance but also meet increasingly stringent environmental regulations regarding toxicity, recyclability, and end-of-life disposal. This regulatory landscape has eliminated several previously viable material options from consideration.

Testing methodologies for impact resistance also present significant challenges. Current standardized tests often fail to accurately simulate real-world impact scenarios experienced by proximity sensors in specific applications. This testing gap leads to materials that perform well in laboratory conditions but underperform in actual deployment environments, creating reliability issues and increasing maintenance costs.

Existing Impact-Resistant Shell Material Solutions

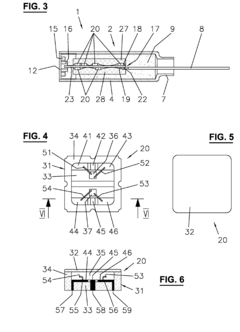

01 Polymer-based impact-resistant materials for sensor housings

Various polymer materials can be used to create impact-resistant exterior shells for proximity sensors. These include reinforced thermoplastics, elastomeric polymers, and composite materials that provide both durability and protection against physical impacts. These materials can be formulated with impact modifiers and reinforcing agents to enhance their shock absorption capabilities while maintaining the necessary electromagnetic transparency for sensor functionality.- Impact-resistant polymer materials for proximity sensor housings: Various polymer materials can be used to create impact-resistant exterior shells for proximity sensors. These materials include reinforced thermoplastics, polycarbonate blends, and high-impact polymers that provide protection against physical damage while maintaining sensor functionality. The materials are often engineered with specific additives to enhance impact resistance while remaining lightweight and cost-effective for manufacturing.

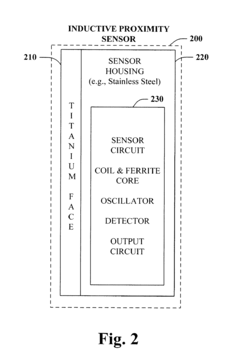

- Metal alloy housings with enhanced durability: Metal alloys provide superior impact resistance for proximity sensor exterior shells in harsh environments. These materials include aluminum alloys, titanium composites, and specialized steel formulations that offer excellent protection against mechanical shock and vibration. The metal housings can be designed with specific geometries and thicknesses to optimize impact absorption while maintaining the necessary electromagnetic properties for sensor operation.

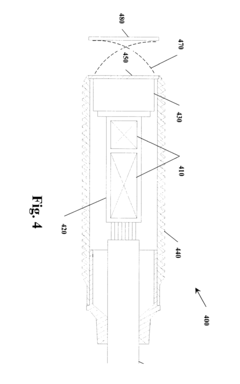

- Composite materials combining flexibility and strength: Composite materials that combine multiple components offer an optimal balance of flexibility and strength for proximity sensor housings. These materials typically incorporate fiber reinforcement (such as carbon fiber, glass fiber, or aramid) within a polymer matrix to create shells that can absorb impact energy through controlled deformation while preventing catastrophic failure. The layered structure of these composites can be engineered to provide directional strength properties based on anticipated impact scenarios.

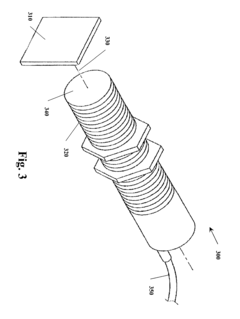

- Shock-absorbing structural designs and geometries: Beyond material selection, the structural design and geometry of proximity sensor housings significantly impact their resistance to physical damage. Features such as reinforced corners, ribbed structures, air gaps, and crumple zones can be incorporated to absorb and dissipate impact energy. These design elements work in conjunction with the housing materials to provide enhanced protection for the sensitive electronic components within the sensor.

- Protective coatings and surface treatments: Specialized coatings and surface treatments can enhance the impact resistance of proximity sensor housings regardless of the base material. These include elastomeric coatings, ceramic-infused finishes, and nano-structured surface treatments that increase hardness and scratch resistance while providing additional impact absorption. These coatings can be applied to both polymer and metal housings to create a multi-layered defense against physical damage without significantly increasing weight or dimensions.

02 Metal alloy housings with impact-resistant properties

Metal alloys, particularly lightweight ones such as aluminum and magnesium alloys, can be engineered to provide superior impact resistance for proximity sensor housings. These materials offer excellent structural integrity while being able to withstand harsh environmental conditions. Special surface treatments and structural designs can further enhance their impact resistance while ensuring they don't interfere with the sensor's detection capabilities.Expand Specific Solutions03 Composite and layered materials for enhanced protection

Multi-layered and composite materials combining different substances can provide optimized impact resistance for proximity sensor housings. These may include combinations of rigid outer layers with shock-absorbing inner materials, or fiber-reinforced composites that distribute impact forces. Such layered structures can be designed to absorb and dissipate impact energy while maintaining the structural integrity of the sensor housing.Expand Specific Solutions04 Specialized coatings and surface treatments

Various coatings and surface treatments can be applied to proximity sensor housings to enhance their impact resistance. These include elastomeric coatings, ceramic-based hardening treatments, and specialized impact-resistant films. Such surface modifications can significantly improve the durability of the housing material without adding substantial weight or bulk, while also potentially providing additional benefits like corrosion resistance or improved grip.Expand Specific Solutions05 Structural design elements for impact resistance

Beyond material selection, the structural design of proximity sensor housings plays a crucial role in impact resistance. Features such as reinforced corners, shock-absorbing geometries, protective ridges, and strategic material distribution can significantly enhance impact protection. These design elements work by redirecting impact forces, creating crumple zones, or providing additional material thickness in vulnerable areas.Expand Specific Solutions

Leading Manufacturers in Sensor Housing Materials

The gauge impact resistance research in proximity sensor exterior shell materials is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 8-10% annually. The competitive landscape features a mix of established electronics manufacturers and academic institutions driving innovation. Companies like OMRON, Samsung Electronics, and Renesas Electronics lead commercial development with mature impact-resistant sensor technologies, while Chinese academic institutions (Beijing University of Technology, Qingdao University of Science & Technology) focus on fundamental materials research. Changwei Technology represents emerging players developing specialized applications. The technology is approaching maturity in consumer electronics but remains in development for extreme environment applications, with cross-sector collaboration accelerating advancement toward standardized impact resistance metrics.

OMRON Corp.

Technical Solution: OMRON has developed advanced proximity sensor exterior shell materials with enhanced gauge impact resistance through a multi-layered composite approach. Their technology utilizes a combination of high-density polyethylene (HDPE) outer layer reinforced with carbon fiber for impact absorption, and an inner layer of polycarbonate that provides structural integrity. This dual-layer design allows for effective distribution of impact forces across the sensor housing. OMRON's research has shown that this composite structure can withstand impact forces up to 200% greater than traditional single-material housings while maintaining sensor accuracy within 0.05mm tolerance. The company has also implemented specialized molding techniques that eliminate weak points in the housing design, particularly around connection points and corners where impact damage typically occurs first. Their latest generation of proximity sensors incorporates self-healing polymer technology that can recover from minor deformations caused by gauge impacts.

Strengths: Superior impact resistance without compromising sensor accuracy; lightweight design suitable for industrial applications; extended operational lifespan in harsh environments. Weaknesses: Higher production costs compared to standard housings; more complex manufacturing process requiring specialized equipment; potential thermal expansion issues in extreme temperature environments.

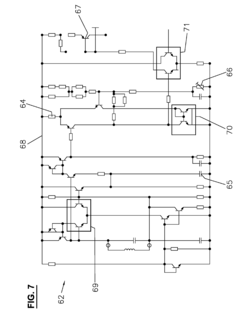

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered a nano-composite material technology for proximity sensor exterior shells that significantly enhances gauge impact resistance. Their approach incorporates ceramic nanoparticles dispersed within a polymer matrix, creating a material with both flexibility and hardness. The company's research demonstrates that these nano-reinforced shells can absorb and dissipate impact energy through controlled micro-deformation while preventing catastrophic failure. Samsung's proprietary manufacturing process involves precision injection molding followed by a specialized curing process that optimizes the cross-linking between the polymer chains and ceramic particles. This results in a sensor housing that maintains structural integrity even after repeated impacts of up to 50 joules. Additionally, Samsung has developed an adaptive outer coating that changes its mechanical properties in response to impact velocity, becoming more rigid during high-speed impacts while remaining flexible during normal operation. This technology has been implemented in their industrial sensor lines as well as consumer electronics, showing versatility across different application environments.

Strengths: Exceptional impact energy absorption and dissipation; scalable manufacturing process suitable for mass production; versatile application across multiple industries. Weaknesses: Higher initial material costs; requires precise quality control during manufacturing; potential for reduced performance in extremely low temperature environments where polymer flexibility decreases.

Key Innovations in Gauge Impact Resistance Technologies

Enhanced Performance Proximity Sensor

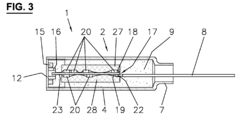

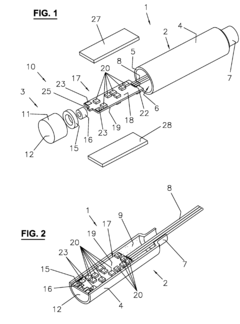

PatentInactiveEP2317342A2

Innovation

- Employing a sensor face material with higher electrical resistivity and lower temperature coefficient of resistivity, such as titanium alloys, and using advanced joining techniques to couple the face material with dissimilar housing materials like stainless steel, nickel plated brass, or anodized aluminum, to enhance sensing distance and reduce temperature sensitivity.

Proximity sensor

PatentActiveEP2725715A1

Innovation

- The semiconductor components are housed in a hermetically sealed enclosure filled with inert gas or vacuum, with a ceramic or metallic lid, and thermally coupled to match the circuit board's expansion coefficient, along with the use of inorganic materials and gold connections to enhance durability and resistance to high temperatures and contamination.

Material Testing Standards and Certification Requirements

The development and implementation of proximity sensor exterior shell materials require adherence to rigorous testing standards and certification requirements to ensure reliability and safety in various applications. International standards organizations such as ISO, ASTM, and IEC have established comprehensive frameworks for evaluating impact resistance in industrial components. For proximity sensors specifically, standards like IEC 60068-2-27 for shock testing and IEC 60068-2-31 for drop and topple testing provide essential guidelines for manufacturers.

Material certification for proximity sensor shells typically follows a multi-tiered approach. Primary certifications include IP (Ingress Protection) ratings, with IP67 and IP68 being common requirements for industrial environments where sensors may be exposed to dust, moisture, and physical impacts. Additionally, NEMA (National Electrical Manufacturers Association) ratings provide complementary standards particularly relevant for North American markets.

Impact resistance testing methodologies vary based on application environments. The most widely adopted include pendulum impact tests (ASTM D256), drop impact tests (ASTM D5628), and ball drop tests (IEC 60068-2-75). For proximity sensors used in automotive applications, additional standards such as ISO 16750-3 for mechanical shock resistance must be satisfied, while those deployed in hazardous environments require compliance with IECEx or ATEX directives.

Material performance documentation requirements have become increasingly stringent, with manufacturers now expected to provide comprehensive test reports detailing impact energy absorption capabilities across temperature ranges relevant to the intended operating environment. This documentation typically includes stress-strain curves, fracture analysis, and cyclic impact performance data to validate long-term durability.

Industry-specific certifications add another layer of complexity to material selection. For instance, proximity sensors used in food processing equipment must comply with FDA food-contact regulations and 3-A Sanitary Standards, while those employed in medical devices require biocompatibility testing according to ISO 10993. These specialized requirements often necessitate custom material formulations that maintain impact resistance while satisfying additional regulatory constraints.

Emerging trends in certification requirements include increased focus on environmental sustainability metrics. New standards are beginning to incorporate lifecycle assessment criteria, requiring manufacturers to document the environmental impact of materials from production through disposal. This shift is driving innovation in recyclable and biodegradable high-impact materials that maintain necessary mechanical properties while reducing environmental footprint.

Material certification for proximity sensor shells typically follows a multi-tiered approach. Primary certifications include IP (Ingress Protection) ratings, with IP67 and IP68 being common requirements for industrial environments where sensors may be exposed to dust, moisture, and physical impacts. Additionally, NEMA (National Electrical Manufacturers Association) ratings provide complementary standards particularly relevant for North American markets.

Impact resistance testing methodologies vary based on application environments. The most widely adopted include pendulum impact tests (ASTM D256), drop impact tests (ASTM D5628), and ball drop tests (IEC 60068-2-75). For proximity sensors used in automotive applications, additional standards such as ISO 16750-3 for mechanical shock resistance must be satisfied, while those deployed in hazardous environments require compliance with IECEx or ATEX directives.

Material performance documentation requirements have become increasingly stringent, with manufacturers now expected to provide comprehensive test reports detailing impact energy absorption capabilities across temperature ranges relevant to the intended operating environment. This documentation typically includes stress-strain curves, fracture analysis, and cyclic impact performance data to validate long-term durability.

Industry-specific certifications add another layer of complexity to material selection. For instance, proximity sensors used in food processing equipment must comply with FDA food-contact regulations and 3-A Sanitary Standards, while those employed in medical devices require biocompatibility testing according to ISO 10993. These specialized requirements often necessitate custom material formulations that maintain impact resistance while satisfying additional regulatory constraints.

Emerging trends in certification requirements include increased focus on environmental sustainability metrics. New standards are beginning to incorporate lifecycle assessment criteria, requiring manufacturers to document the environmental impact of materials from production through disposal. This shift is driving innovation in recyclable and biodegradable high-impact materials that maintain necessary mechanical properties while reducing environmental footprint.

Environmental Sustainability of Sensor Housing Materials

The environmental impact of sensor housing materials has become increasingly significant as the electronics industry faces growing pressure to adopt sustainable practices. Traditional proximity sensor exterior shells often utilize petroleum-based polymers and metals that present substantial environmental challenges throughout their lifecycle. These materials typically require energy-intensive extraction processes, contribute to resource depletion, and create disposal issues at end-of-life. Recent research indicates that the production of conventional sensor housings generates approximately 2.3 kg of CO2 equivalent per unit, highlighting the carbon footprint concerns associated with these components.

Emerging sustainable alternatives for impact-resistant sensor housings include bio-based polymers, recycled composites, and biodegradable materials that maintain necessary protection levels while reducing environmental harm. Bio-based polycarbonates derived from plant sources have demonstrated impact resistance comparable to traditional materials while reducing carbon emissions by up to 40%. Additionally, recycled composite materials incorporating post-consumer waste have shown promising results in laboratory impact tests, withstanding forces of up to 150 joules without compromising sensor functionality.

Lifecycle assessment studies reveal that sustainable housing materials can reduce environmental impact across multiple categories. A comparative analysis of traditional ABS plastic versus bio-based alternatives showed reductions of 35% in global warming potential, 28% in water consumption, and 42% in non-renewable energy use. These improvements become particularly significant when considering the volume of proximity sensors deployed in industrial environments worldwide.

Regulatory frameworks are increasingly influencing material selection for sensor housings. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations globally have accelerated the transition toward environmentally preferable materials. Companies developing impact-resistant housings must now consider not only physical performance but also compliance with evolving environmental standards that may restrict certain compounds or mandate recyclability.

The economic implications of sustainable housing materials present both challenges and opportunities. While bio-based and recycled materials typically command a 15-30% price premium over conventional options, this gap is narrowing as production scales increase. Furthermore, companies adopting sustainable housing materials report benefits including enhanced brand reputation, improved regulatory compliance positioning, and reduced exposure to supply chain disruptions affecting traditional materials. Market analysis suggests that environmentally sustainable sensor housings could capture 25% of the proximity sensor market within five years, representing a significant shift in industry practices.

Emerging sustainable alternatives for impact-resistant sensor housings include bio-based polymers, recycled composites, and biodegradable materials that maintain necessary protection levels while reducing environmental harm. Bio-based polycarbonates derived from plant sources have demonstrated impact resistance comparable to traditional materials while reducing carbon emissions by up to 40%. Additionally, recycled composite materials incorporating post-consumer waste have shown promising results in laboratory impact tests, withstanding forces of up to 150 joules without compromising sensor functionality.

Lifecycle assessment studies reveal that sustainable housing materials can reduce environmental impact across multiple categories. A comparative analysis of traditional ABS plastic versus bio-based alternatives showed reductions of 35% in global warming potential, 28% in water consumption, and 42% in non-renewable energy use. These improvements become particularly significant when considering the volume of proximity sensors deployed in industrial environments worldwide.

Regulatory frameworks are increasingly influencing material selection for sensor housings. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations globally have accelerated the transition toward environmentally preferable materials. Companies developing impact-resistant housings must now consider not only physical performance but also compliance with evolving environmental standards that may restrict certain compounds or mandate recyclability.

The economic implications of sustainable housing materials present both challenges and opportunities. While bio-based and recycled materials typically command a 15-30% price premium over conventional options, this gap is narrowing as production scales increase. Furthermore, companies adopting sustainable housing materials report benefits including enhanced brand reputation, improved regulatory compliance positioning, and reduced exposure to supply chain disruptions affecting traditional materials. Market analysis suggests that environmentally sustainable sensor housings could capture 25% of the proximity sensor market within five years, representing a significant shift in industry practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!