Proximity Sensors Performance in Structural Stability Monitoring

SEP 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proximity Sensing Technology Background and Objectives

Proximity sensing technology has evolved significantly over the past decades, transitioning from simple mechanical switches to sophisticated electronic systems capable of detecting objects without physical contact. The fundamental principle behind proximity sensors involves the emission of electromagnetic fields or radiation beams and detection of changes when objects enter their detection range. This technology originated in industrial automation during the 1960s but has since expanded into numerous applications including structural health monitoring, automotive safety systems, and consumer electronics.

The evolution of proximity sensing has been marked by several key technological advancements. Early proximity sensors relied primarily on inductive and capacitive principles, offering limited range and accuracy. The introduction of ultrasonic sensors in the 1980s expanded detection capabilities for non-metallic objects. The 1990s saw the emergence of photoelectric and infrared proximity sensors, while the 2000s brought significant miniaturization and integration capabilities, enabling deployment in increasingly compact devices with enhanced sensitivity.

In the context of structural stability monitoring, proximity sensors serve a critical function by continuously measuring minute displacements, vibrations, and positional changes in buildings, bridges, dams, and other critical infrastructure. These measurements provide real-time data on structural integrity, helping to identify potential failures before they occur and enabling proactive maintenance strategies.

The primary objective of proximity sensing in structural monitoring is to develop robust, reliable, and precise measurement systems capable of operating in challenging environmental conditions while maintaining long-term stability. Current research aims to enhance sensor accuracy to sub-millimeter precision while extending operational lifespans to decades rather than years, thereby reducing maintenance requirements and total ownership costs.

Another key objective involves improving the energy efficiency of proximity sensing systems, particularly for remote deployment scenarios where power availability is limited. This includes developing low-power consumption sensors and exploring energy harvesting technologies to create self-sustaining monitoring networks.

Data integration represents another significant goal, with efforts focused on seamlessly incorporating proximity sensor data into comprehensive structural health monitoring systems. This integration enables more sophisticated analysis through machine learning algorithms that can identify subtle patterns indicating structural degradation.

The advancement of wireless communication capabilities for proximity sensors is also a priority, allowing for easier installation in existing structures without extensive wiring requirements. This wireless functionality facilitates the creation of dense sensor networks that can provide more detailed structural information across large infrastructure projects.

The evolution of proximity sensing has been marked by several key technological advancements. Early proximity sensors relied primarily on inductive and capacitive principles, offering limited range and accuracy. The introduction of ultrasonic sensors in the 1980s expanded detection capabilities for non-metallic objects. The 1990s saw the emergence of photoelectric and infrared proximity sensors, while the 2000s brought significant miniaturization and integration capabilities, enabling deployment in increasingly compact devices with enhanced sensitivity.

In the context of structural stability monitoring, proximity sensors serve a critical function by continuously measuring minute displacements, vibrations, and positional changes in buildings, bridges, dams, and other critical infrastructure. These measurements provide real-time data on structural integrity, helping to identify potential failures before they occur and enabling proactive maintenance strategies.

The primary objective of proximity sensing in structural monitoring is to develop robust, reliable, and precise measurement systems capable of operating in challenging environmental conditions while maintaining long-term stability. Current research aims to enhance sensor accuracy to sub-millimeter precision while extending operational lifespans to decades rather than years, thereby reducing maintenance requirements and total ownership costs.

Another key objective involves improving the energy efficiency of proximity sensing systems, particularly for remote deployment scenarios where power availability is limited. This includes developing low-power consumption sensors and exploring energy harvesting technologies to create self-sustaining monitoring networks.

Data integration represents another significant goal, with efforts focused on seamlessly incorporating proximity sensor data into comprehensive structural health monitoring systems. This integration enables more sophisticated analysis through machine learning algorithms that can identify subtle patterns indicating structural degradation.

The advancement of wireless communication capabilities for proximity sensors is also a priority, allowing for easier installation in existing structures without extensive wiring requirements. This wireless functionality facilitates the creation of dense sensor networks that can provide more detailed structural information across large infrastructure projects.

Market Analysis for Structural Health Monitoring Systems

The global Structural Health Monitoring (SHM) market demonstrates robust growth trajectories, driven by increasing infrastructure investments and growing awareness of safety requirements across various sectors. Currently valued at approximately 2.3 billion USD in 2023, the market is projected to reach 4.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 14.3%. This significant expansion reflects the critical importance of structural integrity monitoring in preventing catastrophic failures and optimizing maintenance schedules.

The market segmentation reveals distinct application domains with varying adoption rates. The civil infrastructure sector, including bridges, dams, and high-rise buildings, constitutes the largest market share at 38%, followed by aerospace and defense at 24%, energy infrastructure at 21%, and other applications comprising the remaining 17%. Within these segments, proximity sensor-based monitoring systems are experiencing particularly accelerated growth due to their versatility, reliability, and improving cost-effectiveness.

Regional analysis indicates North America currently leads the market with 35% share, attributed to aging infrastructure concerns and stringent safety regulations. Europe follows at 28%, while Asia-Pacific represents the fastest-growing region with a projected CAGR of 16.8% through 2028, driven by rapid urbanization and massive infrastructure development projects in China, India, and Southeast Asian countries.

Key market drivers include increasing incidents of structural failures globally, rising infrastructure investments (estimated at 94 trillion USD needed globally through 2040), and technological advancements in sensor miniaturization and wireless connectivity. The integration of proximity sensors with IoT platforms and cloud-based analytics has substantially expanded the value proposition of SHM systems, enabling real-time monitoring and predictive maintenance capabilities.

Customer segmentation analysis reveals government agencies and public infrastructure authorities as primary end-users (42%), followed by energy companies (23%), construction and engineering firms (19%), and transportation authorities (16%). These stakeholders increasingly recognize the long-term economic benefits of implementing comprehensive monitoring systems, with ROI studies indicating potential maintenance cost reductions of 15-30% over infrastructure lifecycles.

Market challenges persist, including high initial implementation costs, technical complexity requiring specialized expertise, and interoperability issues between different monitoring systems. Additionally, data security concerns and the need for standardization across different regulatory environments represent significant market barriers that solution providers must address to accelerate adoption rates.

The market segmentation reveals distinct application domains with varying adoption rates. The civil infrastructure sector, including bridges, dams, and high-rise buildings, constitutes the largest market share at 38%, followed by aerospace and defense at 24%, energy infrastructure at 21%, and other applications comprising the remaining 17%. Within these segments, proximity sensor-based monitoring systems are experiencing particularly accelerated growth due to their versatility, reliability, and improving cost-effectiveness.

Regional analysis indicates North America currently leads the market with 35% share, attributed to aging infrastructure concerns and stringent safety regulations. Europe follows at 28%, while Asia-Pacific represents the fastest-growing region with a projected CAGR of 16.8% through 2028, driven by rapid urbanization and massive infrastructure development projects in China, India, and Southeast Asian countries.

Key market drivers include increasing incidents of structural failures globally, rising infrastructure investments (estimated at 94 trillion USD needed globally through 2040), and technological advancements in sensor miniaturization and wireless connectivity. The integration of proximity sensors with IoT platforms and cloud-based analytics has substantially expanded the value proposition of SHM systems, enabling real-time monitoring and predictive maintenance capabilities.

Customer segmentation analysis reveals government agencies and public infrastructure authorities as primary end-users (42%), followed by energy companies (23%), construction and engineering firms (19%), and transportation authorities (16%). These stakeholders increasingly recognize the long-term economic benefits of implementing comprehensive monitoring systems, with ROI studies indicating potential maintenance cost reductions of 15-30% over infrastructure lifecycles.

Market challenges persist, including high initial implementation costs, technical complexity requiring specialized expertise, and interoperability issues between different monitoring systems. Additionally, data security concerns and the need for standardization across different regulatory environments represent significant market barriers that solution providers must address to accelerate adoption rates.

Current Limitations and Technical Challenges of Proximity Sensors

Despite significant advancements in proximity sensor technology, several critical limitations persist when deploying these sensors for structural stability monitoring applications. The primary challenge remains the environmental sensitivity of most proximity sensors. Dust, moisture, temperature fluctuations, and electromagnetic interference can significantly compromise measurement accuracy, particularly in outdoor infrastructure monitoring scenarios where sensors are exposed to harsh weather conditions and industrial environments.

Measurement range constraints represent another substantial limitation. Most proximity sensors operate effectively only within short distances (typically a few millimeters to centimeters), restricting their application in monitoring large-scale structural deformations or displacements. This narrow operational range necessitates deploying numerous sensors across structures, increasing system complexity and cost.

Resolution and accuracy issues further complicate proximity sensor implementation. While high-precision applications demand micrometer or even nanometer-level accuracy, achieving such precision consistently under real-world conditions remains challenging. Sensor drift over time—caused by component aging, temperature variations, and mechanical stress—introduces additional measurement uncertainties that can mask subtle structural changes requiring detection.

Power consumption presents a significant hurdle for remote or inaccessible monitoring locations. Many high-performance proximity sensors require substantial power, limiting deployment options where continuous power supply is unavailable. Although energy harvesting and low-power designs have emerged, these often come with performance trade-offs that may compromise monitoring capabilities.

Data transmission and processing bottlenecks also impede effective implementation. The continuous data streams generated by multiple proximity sensors across large structures create bandwidth challenges and processing demands. Real-time analysis requirements further strain system resources, particularly when attempting to detect rapid structural changes that might indicate imminent failure.

Calibration and maintenance requirements constitute ongoing operational challenges. Proximity sensors typically require regular recalibration to maintain accuracy, especially in environments with variable conditions. This necessity increases the total cost of ownership and may require specialized expertise not readily available at remote monitoring sites.

Integration complexity with existing structural health monitoring systems represents another significant barrier. Many legacy systems lack standardized interfaces for incorporating new sensor technologies, requiring custom integration solutions that increase implementation costs and complexity. Compatibility issues between different sensor types and data formats further complicate comprehensive monitoring approaches.

Measurement range constraints represent another substantial limitation. Most proximity sensors operate effectively only within short distances (typically a few millimeters to centimeters), restricting their application in monitoring large-scale structural deformations or displacements. This narrow operational range necessitates deploying numerous sensors across structures, increasing system complexity and cost.

Resolution and accuracy issues further complicate proximity sensor implementation. While high-precision applications demand micrometer or even nanometer-level accuracy, achieving such precision consistently under real-world conditions remains challenging. Sensor drift over time—caused by component aging, temperature variations, and mechanical stress—introduces additional measurement uncertainties that can mask subtle structural changes requiring detection.

Power consumption presents a significant hurdle for remote or inaccessible monitoring locations. Many high-performance proximity sensors require substantial power, limiting deployment options where continuous power supply is unavailable. Although energy harvesting and low-power designs have emerged, these often come with performance trade-offs that may compromise monitoring capabilities.

Data transmission and processing bottlenecks also impede effective implementation. The continuous data streams generated by multiple proximity sensors across large structures create bandwidth challenges and processing demands. Real-time analysis requirements further strain system resources, particularly when attempting to detect rapid structural changes that might indicate imminent failure.

Calibration and maintenance requirements constitute ongoing operational challenges. Proximity sensors typically require regular recalibration to maintain accuracy, especially in environments with variable conditions. This necessity increases the total cost of ownership and may require specialized expertise not readily available at remote monitoring sites.

Integration complexity with existing structural health monitoring systems represents another significant barrier. Many legacy systems lack standardized interfaces for incorporating new sensor technologies, requiring custom integration solutions that increase implementation costs and complexity. Compatibility issues between different sensor types and data formats further complicate comprehensive monitoring approaches.

Existing Proximity Sensor Solutions for Structural Monitoring

01 Proximity sensor accuracy and calibration techniques

Various methods for improving proximity sensor accuracy through calibration techniques. These include automatic calibration processes that adjust sensor parameters based on environmental conditions, compensation algorithms for interference, and adaptive threshold mechanisms that optimize detection sensitivity. These techniques help maintain reliable performance across different operating conditions and reduce false readings.- Proximity sensor calibration and accuracy improvement: Various methods for calibrating proximity sensors to improve their performance and accuracy. These include automatic calibration techniques, compensation for environmental factors, and algorithms to reduce false readings. Calibration processes can adjust sensor sensitivity based on usage patterns and surrounding conditions, ensuring more reliable detection of objects at various distances.

- Mobile device proximity sensing applications: Implementation of proximity sensors in mobile devices for power management, user interface control, and call handling. These sensors detect when the device is near a user's face or in a pocket, allowing for automatic screen deactivation, prevention of accidental touches, and optimization of antenna performance. Advanced algorithms help distinguish between intentional and unintentional proximity events.

- Automotive proximity sensing systems: Proximity sensors used in automotive applications for obstacle detection, parking assistance, and collision avoidance. These systems employ various sensing technologies to monitor the vehicle's surroundings and alert drivers to potential hazards. Performance enhancements include improved range detection, weather resistance, and integration with other vehicle systems for comprehensive safety features.

- Energy efficiency and power optimization in proximity sensors: Techniques for reducing power consumption in proximity sensing systems while maintaining performance. These include adaptive sampling rates, sleep modes, and power management algorithms that adjust sensor activity based on usage patterns. Energy-efficient designs extend battery life in portable devices and reduce operational costs in fixed installations without compromising detection capabilities.

- Multi-sensor integration and data fusion: Integration of proximity sensors with other sensing technologies such as cameras, accelerometers, and gyroscopes to enhance overall system performance. Data fusion algorithms combine inputs from multiple sensors to provide more accurate and reliable detection results. This approach compensates for individual sensor limitations and enables more sophisticated applications in complex environments.

02 Mobile device proximity sensing applications

Implementation of proximity sensors in mobile devices for power management, user interface control, and call handling. These sensors detect user presence to activate or deactivate device functions, adjust display brightness, prevent accidental touches during calls, and enable gesture recognition. Advanced implementations include multi-sensor arrays that provide enhanced spatial awareness and user interaction capabilities.Expand Specific Solutions03 Automotive proximity sensing systems

Proximity sensors designed specifically for automotive applications, including parking assistance, collision avoidance, and interior occupancy detection. These systems utilize various sensing technologies to monitor the vehicle's surroundings, detect obstacles, and provide driver alerts. Advanced implementations integrate multiple sensor types for comprehensive environmental awareness and improved safety features.Expand Specific Solutions04 Energy efficiency in proximity sensing

Methods for optimizing power consumption in proximity sensing systems through intelligent power management schemes. These include duty cycling, adaptive sampling rates, and sleep modes that activate only when needed. Advanced implementations use context-aware algorithms to predict usage patterns and adjust power states accordingly, significantly extending battery life in portable devices.Expand Specific Solutions05 Multi-technology sensor fusion approaches

Integration of multiple sensing technologies to enhance proximity detection performance. These approaches combine different sensor types such as capacitive, infrared, ultrasonic, and radar to overcome the limitations of individual technologies. Sensor fusion algorithms process data from multiple sources to provide more accurate, reliable, and comprehensive proximity information across varying environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The proximity sensor market for structural stability monitoring is in a growth phase, with increasing adoption across civil engineering, industrial, and smart infrastructure sectors. The market is projected to reach significant scale due to rising safety concerns and infrastructure aging. Technologically, the field shows varying maturity levels, with established players like Honeywell, Bosch, and OMRON offering proven solutions alongside emerging innovations. Companies like Lockheed Martin and Soletanche Freyssinet bring specialized expertise in critical infrastructure applications, while research institutions such as Shanghai Jiao Tong University and China Electric Power Research Institute drive innovation. The integration of proximity sensing with IoT and AI analytics represents the cutting edge, with companies like Rockwell Automation and Donghua Testing developing advanced monitoring systems that provide real-time structural health insights.

OMRON Corp.

Technical Solution: OMRON has developed a comprehensive structural monitoring solution centered around their E2E NEXT series proximity sensors. These sensors utilize a unique combination of inductive and capacitive sensing technologies to achieve high precision in varied environmental conditions. OMRON's proximity sensors feature temperature drift compensation that maintains accuracy within ±0.02mm across temperature ranges from -25°C to +70°C. Their system incorporates a mesh network architecture allowing for redundant data paths and improved reliability in large structural deployments. OMRON's sensors achieve a sampling rate of up to 1kHz, enabling the detection of high-frequency vibrations that may indicate structural issues. The company has implemented advanced signal processing algorithms that can differentiate between normal structural movement and potentially dangerous deformations. Their proximity sensors are designed with IP67/IP69K protection ratings, making them suitable for harsh environmental conditions including bridges, dams, and offshore structures. OMRON's solution includes cloud-based analytics that provide real-time alerts and historical trend analysis to identify gradual structural changes over time.

Strengths: Exceptional environmental protection ratings enabling deployment in harsh conditions; high sampling rates capable of detecting rapid structural movements; proven reliability with MTBF exceeding 100,000 hours. Weaknesses: Higher power consumption compared to some competitors; more complex installation requirements; limited third-party integration options outside of OMRON's ecosystem.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered micro-electromechanical systems (MEMS) proximity sensors specifically designed for structural stability monitoring. Their technology utilizes capacitive and inductive sensing principles with integrated temperature and humidity compensation to ensure measurement stability in varying environmental conditions. Bosch's proximity sensors achieve sub-millimeter accuracy (typically ±0.1mm) and can detect structural displacements as small as 10 micrometers. The sensors are networked through Bosch's proprietary IoT platform, allowing for real-time data collection and analysis across large structural arrays. Their system incorporates self-calibration capabilities that reduce maintenance requirements and ensure long-term measurement stability. Bosch has implemented specialized signal processing algorithms that filter out environmental noise while preserving critical structural movement data, achieving a signal-to-noise ratio improvement of approximately 40% compared to conventional sensors. The sensors operate on ultra-low power consumption (typically <10mW), enabling battery life of up to 5 years in field deployments.

Strengths: Exceptional measurement precision with industry-leading temperature stability; comprehensive IoT integration capabilities; extensive battery life reducing maintenance requirements. Weaknesses: Higher unit cost compared to simpler proximity sensors; proprietary communication protocols may limit integration with third-party systems; requires specialized configuration software.

Key Technical Innovations in Proximity Sensing Accuracy

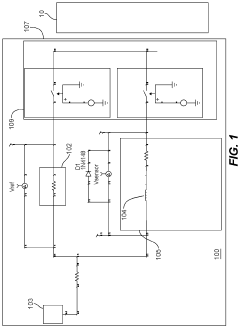

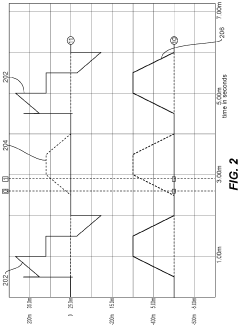

Proximity sensor and method of use

PatentActiveUS20210389161A1

Innovation

- A proximity sensor system that transmits a magnetic field signal, measures the impedance of an inductor, and calculates the relative position of a ferromagnetic target using a ratio of DC voltage changes across the inductor and a reference resistor, providing a near/far output status within 4 milliseconds, with integrated electronics to eliminate long cable lengths and reduce size, weight, and complexity.

Patent

Innovation

- Integration of proximity sensors with structural health monitoring systems to provide real-time data on structural deformations and displacements with high precision.

- Novel calibration methods for proximity sensors that account for environmental factors such as temperature, humidity, and electromagnetic interference to improve measurement accuracy in field conditions.

- Wireless sensor network architecture optimized for proximity sensors in structural monitoring applications, featuring low power consumption and robust data transmission protocols.

Environmental Impact Factors on Sensor Reliability

Environmental conditions significantly influence the reliability and accuracy of proximity sensors deployed in structural stability monitoring systems. Temperature fluctuations represent one of the most critical factors affecting sensor performance. In extreme cold environments, sensor components may contract, altering calibration parameters and potentially reducing sensitivity. Conversely, high temperatures can cause thermal expansion of sensor materials, leading to drift in baseline measurements and decreased precision in detecting structural movements.

Humidity and moisture exposure present another substantial challenge to proximity sensor reliability. Water infiltration can cause short circuits in electronic components, while condensation on sensor surfaces may interfere with optical or capacitive sensing mechanisms. In coastal or marine environments, salt-laden moisture accelerates corrosion of sensor housings and connection points, dramatically reducing operational lifespan and measurement consistency.

Vibration and mechanical stress constitute environmental factors particularly relevant to structural monitoring applications. Constant vibrations from traffic, machinery, or natural sources can gradually loosen sensor mountings, shifting their position relative to the monitored structure. This positional drift introduces systematic errors that may be misinterpreted as structural movement, potentially triggering false alarms or masking actual structural issues.

Electromagnetic interference (EMI) from nearby power lines, radio transmitters, or industrial equipment can significantly degrade the signal quality of proximity sensors. This is especially problematic for inductive and capacitive sensors, where external electromagnetic fields can induce current fluctuations that manifest as measurement noise or phantom readings, compromising data reliability for long-term structural assessment.

Particulate contamination represents an often-overlooked environmental factor affecting sensor performance. Dust, pollen, and industrial particulates can accumulate on sensor surfaces, particularly affecting optical proximity sensors by blocking or scattering light paths. In construction environments or urban settings, concrete dust and airborne pollutants can penetrate sensor housings, causing gradual degradation of internal components and calibration drift.

Weather events such as heavy rainfall, snow accumulation, or direct sunlight exposure create transient but significant challenges for outdoor sensor deployments. Solar radiation can cause localized heating of sensor components, while precipitation may temporarily alter the dielectric properties of the monitoring environment, both resulting in measurement inconsistencies that complicate data interpretation for structural stability assessment.

Humidity and moisture exposure present another substantial challenge to proximity sensor reliability. Water infiltration can cause short circuits in electronic components, while condensation on sensor surfaces may interfere with optical or capacitive sensing mechanisms. In coastal or marine environments, salt-laden moisture accelerates corrosion of sensor housings and connection points, dramatically reducing operational lifespan and measurement consistency.

Vibration and mechanical stress constitute environmental factors particularly relevant to structural monitoring applications. Constant vibrations from traffic, machinery, or natural sources can gradually loosen sensor mountings, shifting their position relative to the monitored structure. This positional drift introduces systematic errors that may be misinterpreted as structural movement, potentially triggering false alarms or masking actual structural issues.

Electromagnetic interference (EMI) from nearby power lines, radio transmitters, or industrial equipment can significantly degrade the signal quality of proximity sensors. This is especially problematic for inductive and capacitive sensors, where external electromagnetic fields can induce current fluctuations that manifest as measurement noise or phantom readings, compromising data reliability for long-term structural assessment.

Particulate contamination represents an often-overlooked environmental factor affecting sensor performance. Dust, pollen, and industrial particulates can accumulate on sensor surfaces, particularly affecting optical proximity sensors by blocking or scattering light paths. In construction environments or urban settings, concrete dust and airborne pollutants can penetrate sensor housings, causing gradual degradation of internal components and calibration drift.

Weather events such as heavy rainfall, snow accumulation, or direct sunlight exposure create transient but significant challenges for outdoor sensor deployments. Solar radiation can cause localized heating of sensor components, while precipitation may temporarily alter the dielectric properties of the monitoring environment, both resulting in measurement inconsistencies that complicate data interpretation for structural stability assessment.

Data Integration and IoT Connectivity Solutions

The integration of proximity sensor data with IoT infrastructure represents a critical component in modern structural stability monitoring systems. Current data integration frameworks typically employ multi-layered architectures that facilitate seamless communication between proximity sensors and centralized monitoring platforms. These frameworks generally consist of three primary layers: the sensor layer, the gateway layer, and the cloud platform layer, each playing a distinct role in ensuring reliable data transmission and processing.

Wireless sensor networks (WSNs) have emerged as the predominant connectivity solution for proximity sensor deployments in structural monitoring applications. Technologies such as LoRaWAN, Zigbee, and Bluetooth Low Energy (BLE) offer varying degrees of range, power consumption, and bandwidth capabilities that can be selected based on specific monitoring requirements. LoRaWAN, for instance, provides long-range communication capabilities (up to 10 km in rural areas) with minimal power consumption, making it particularly suitable for remote structural monitoring applications.

Edge computing implementations have significantly enhanced the efficiency of proximity sensor networks by enabling preliminary data processing at or near the data source. This approach reduces latency, conserves bandwidth, and allows for real-time anomaly detection without constant cloud connectivity. In structural stability monitoring, edge devices can perform initial vibration analysis, filter noise, and identify potential structural issues before transmitting only relevant data to central systems.

Data standardization protocols such as MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol) have become essential for ensuring interoperability between diverse sensor types and monitoring platforms. These lightweight messaging protocols are specifically designed for constrained environments where bandwidth and power are limited, making them ideal for proximity sensor networks deployed in structural monitoring contexts.

Security considerations in IoT connectivity for structural monitoring systems have evolved to address the unique challenges of distributed sensor networks. Implementation of end-to-end encryption, secure boot mechanisms, and certificate-based authentication has become standard practice to protect sensitive structural data from unauthorized access or manipulation. Additionally, secure over-the-air (OTA) update capabilities ensure that sensor firmware can be updated to address vulnerabilities without physical access to often inaccessible sensor locations.

Recent advancements in 5G technology are beginning to transform connectivity options for high-density proximity sensor deployments. The ultra-reliable low-latency communication (URLLC) capabilities of 5G networks enable near real-time monitoring with millisecond-level latency, which is particularly valuable for critical infrastructure monitoring where immediate detection of structural anomalies is essential for public safety.

Wireless sensor networks (WSNs) have emerged as the predominant connectivity solution for proximity sensor deployments in structural monitoring applications. Technologies such as LoRaWAN, Zigbee, and Bluetooth Low Energy (BLE) offer varying degrees of range, power consumption, and bandwidth capabilities that can be selected based on specific monitoring requirements. LoRaWAN, for instance, provides long-range communication capabilities (up to 10 km in rural areas) with minimal power consumption, making it particularly suitable for remote structural monitoring applications.

Edge computing implementations have significantly enhanced the efficiency of proximity sensor networks by enabling preliminary data processing at or near the data source. This approach reduces latency, conserves bandwidth, and allows for real-time anomaly detection without constant cloud connectivity. In structural stability monitoring, edge devices can perform initial vibration analysis, filter noise, and identify potential structural issues before transmitting only relevant data to central systems.

Data standardization protocols such as MQTT (Message Queuing Telemetry Transport) and CoAP (Constrained Application Protocol) have become essential for ensuring interoperability between diverse sensor types and monitoring platforms. These lightweight messaging protocols are specifically designed for constrained environments where bandwidth and power are limited, making them ideal for proximity sensor networks deployed in structural monitoring contexts.

Security considerations in IoT connectivity for structural monitoring systems have evolved to address the unique challenges of distributed sensor networks. Implementation of end-to-end encryption, secure boot mechanisms, and certificate-based authentication has become standard practice to protect sensitive structural data from unauthorized access or manipulation. Additionally, secure over-the-air (OTA) update capabilities ensure that sensor firmware can be updated to address vulnerabilities without physical access to often inaccessible sensor locations.

Recent advancements in 5G technology are beginning to transform connectivity options for high-density proximity sensor deployments. The ultra-reliable low-latency communication (URLLC) capabilities of 5G networks enable near real-time monitoring with millisecond-level latency, which is particularly valuable for critical infrastructure monitoring where immediate detection of structural anomalies is essential for public safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!