How to Measure Signal Drop-off in Proximity Sensors Over Time

SEP 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Proximity Sensor Degradation Background and Objectives

Proximity sensors have evolved significantly since their inception in the early 1970s, transitioning from simple mechanical switches to sophisticated electronic devices capable of detecting objects without physical contact. These sensors now play a critical role in numerous applications including automotive systems, industrial automation, consumer electronics, and healthcare devices. The evolution of proximity sensing technology has been driven by demands for increased reliability, miniaturization, and enhanced performance in diverse environmental conditions.

The degradation of proximity sensors over time represents a significant challenge across industries. Signal drop-off—the gradual reduction in sensing performance—can lead to false readings, decreased detection range, and ultimately system failures. This phenomenon affects various types of proximity sensors including inductive, capacitive, photoelectric, ultrasonic, and magnetic sensors, though through different mechanisms and at varying rates.

Current industry standards typically specify initial performance parameters but often lack comprehensive guidelines for monitoring and predicting long-term degradation. This gap in standardization has created inconsistencies in how manufacturers address sensor lifespan and reliability in their specifications, making it difficult for end-users to make informed decisions about maintenance schedules and replacement intervals.

The primary objective of this technical research is to establish systematic methodologies for measuring, quantifying, and predicting signal drop-off in proximity sensors throughout their operational lifetime. This includes developing standardized testing protocols that can be implemented across different sensor types and applications, creating mathematical models that accurately predict degradation patterns, and identifying key environmental and operational factors that accelerate signal deterioration.

Additionally, this research aims to explore the correlation between signal drop-off and specific failure modes, enabling more precise predictive maintenance strategies. By understanding the degradation mechanisms at a fundamental level, we can potentially develop new sensor designs or compensation algorithms that mitigate the effects of aging and environmental stress.

The long-term goal is to establish industry-wide benchmarks for proximity sensor degradation that manufacturers can reference when developing new products and that end-users can utilize when implementing sensor systems in critical applications. This would significantly enhance system reliability, reduce unexpected downtime, and optimize maintenance scheduling across multiple industries.

Recent technological advancements in materials science, microelectronics, and data analytics present new opportunities for addressing these challenges, potentially leading to self-calibrating sensors or systems with built-in degradation compensation capabilities that could revolutionize how we approach sensor reliability in the coming decade.

The degradation of proximity sensors over time represents a significant challenge across industries. Signal drop-off—the gradual reduction in sensing performance—can lead to false readings, decreased detection range, and ultimately system failures. This phenomenon affects various types of proximity sensors including inductive, capacitive, photoelectric, ultrasonic, and magnetic sensors, though through different mechanisms and at varying rates.

Current industry standards typically specify initial performance parameters but often lack comprehensive guidelines for monitoring and predicting long-term degradation. This gap in standardization has created inconsistencies in how manufacturers address sensor lifespan and reliability in their specifications, making it difficult for end-users to make informed decisions about maintenance schedules and replacement intervals.

The primary objective of this technical research is to establish systematic methodologies for measuring, quantifying, and predicting signal drop-off in proximity sensors throughout their operational lifetime. This includes developing standardized testing protocols that can be implemented across different sensor types and applications, creating mathematical models that accurately predict degradation patterns, and identifying key environmental and operational factors that accelerate signal deterioration.

Additionally, this research aims to explore the correlation between signal drop-off and specific failure modes, enabling more precise predictive maintenance strategies. By understanding the degradation mechanisms at a fundamental level, we can potentially develop new sensor designs or compensation algorithms that mitigate the effects of aging and environmental stress.

The long-term goal is to establish industry-wide benchmarks for proximity sensor degradation that manufacturers can reference when developing new products and that end-users can utilize when implementing sensor systems in critical applications. This would significantly enhance system reliability, reduce unexpected downtime, and optimize maintenance scheduling across multiple industries.

Recent technological advancements in materials science, microelectronics, and data analytics present new opportunities for addressing these challenges, potentially leading to self-calibrating sensors or systems with built-in degradation compensation capabilities that could revolutionize how we approach sensor reliability in the coming decade.

Market Demand Analysis for Reliable Proximity Sensing

The global market for proximity sensing technologies has witnessed substantial growth in recent years, driven by increasing automation across multiple industries. The demand for reliable proximity sensors that maintain consistent performance over time is particularly pronounced in automotive, industrial automation, consumer electronics, and healthcare sectors. Market research indicates that the global proximity sensor market is expected to reach $3.5 billion by 2025, growing at a CAGR of 7.2% from 2020 to 2025.

In the automotive industry, proximity sensors are critical components in advanced driver assistance systems (ADAS) and autonomous vehicles. The reliability of these sensors directly impacts vehicle safety, creating a strong demand for solutions that can monitor and compensate for signal degradation. Automotive manufacturers are increasingly seeking sensors with built-in self-diagnostic capabilities and predictive maintenance features to ensure consistent performance throughout the vehicle's lifecycle.

Industrial automation represents another significant market segment, where proximity sensors are deployed in manufacturing processes, robotics, and quality control systems. The financial impact of sensor failures in these environments can be substantial, with production downtime costs averaging $22,000 per minute in some high-volume manufacturing facilities. This economic reality has intensified the demand for sensors with stable signal characteristics and methods to predict potential failures before they occur.

Consumer electronics manufacturers are incorporating proximity sensors into smartphones, tablets, wearables, and smart home devices. As these devices become more integral to daily life, consumers expect consistent performance throughout the product lifecycle. Market surveys indicate that 78% of consumers consider reliability a top factor when purchasing electronic devices, creating pressure on manufacturers to ensure sensor stability over time.

Healthcare applications present unique requirements for proximity sensing, particularly in medical devices and monitoring equipment where sensor failure could have serious consequences. The market for medical-grade proximity sensors is growing at 9.3% annually, with particular emphasis on solutions that maintain calibration and performance over extended periods.

Emerging applications in smart cities, retail analytics, and security systems are expanding the market for proximity sensing technologies. These applications often involve sensors deployed in challenging environmental conditions, further highlighting the need for solutions that can monitor and compensate for signal degradation.

The market is also seeing increased demand for integrated sensor solutions that combine proximity sensing with other modalities such as temperature, humidity, and vibration monitoring. This trend reflects a broader move toward comprehensive condition monitoring systems that can provide holistic insights into device performance and environmental factors affecting sensor operation.

In the automotive industry, proximity sensors are critical components in advanced driver assistance systems (ADAS) and autonomous vehicles. The reliability of these sensors directly impacts vehicle safety, creating a strong demand for solutions that can monitor and compensate for signal degradation. Automotive manufacturers are increasingly seeking sensors with built-in self-diagnostic capabilities and predictive maintenance features to ensure consistent performance throughout the vehicle's lifecycle.

Industrial automation represents another significant market segment, where proximity sensors are deployed in manufacturing processes, robotics, and quality control systems. The financial impact of sensor failures in these environments can be substantial, with production downtime costs averaging $22,000 per minute in some high-volume manufacturing facilities. This economic reality has intensified the demand for sensors with stable signal characteristics and methods to predict potential failures before they occur.

Consumer electronics manufacturers are incorporating proximity sensors into smartphones, tablets, wearables, and smart home devices. As these devices become more integral to daily life, consumers expect consistent performance throughout the product lifecycle. Market surveys indicate that 78% of consumers consider reliability a top factor when purchasing electronic devices, creating pressure on manufacturers to ensure sensor stability over time.

Healthcare applications present unique requirements for proximity sensing, particularly in medical devices and monitoring equipment where sensor failure could have serious consequences. The market for medical-grade proximity sensors is growing at 9.3% annually, with particular emphasis on solutions that maintain calibration and performance over extended periods.

Emerging applications in smart cities, retail analytics, and security systems are expanding the market for proximity sensing technologies. These applications often involve sensors deployed in challenging environmental conditions, further highlighting the need for solutions that can monitor and compensate for signal degradation.

The market is also seeing increased demand for integrated sensor solutions that combine proximity sensing with other modalities such as temperature, humidity, and vibration monitoring. This trend reflects a broader move toward comprehensive condition monitoring systems that can provide holistic insights into device performance and environmental factors affecting sensor operation.

Current Challenges in Long-term Sensor Performance

Despite significant advancements in proximity sensor technology, maintaining consistent performance over extended operational periods remains a formidable challenge. Signal drop-off, characterized by the gradual degradation of sensor sensitivity and accuracy over time, represents one of the most persistent issues facing long-term sensor deployments. This phenomenon manifests through decreased detection ranges, increased false readings, and ultimately compromised system reliability.

Environmental factors constitute a primary source of performance degradation. Proximity sensors deployed in industrial settings are particularly vulnerable to dust accumulation, chemical exposure, and temperature fluctuations. These conditions can physically alter sensor surfaces or interfere with their detection mechanisms, accelerating signal deterioration. Even in controlled environments, sensors remain susceptible to humidity variations and oxidation processes that progressively impact their functional components.

Component aging presents another significant challenge. Semiconductor-based proximity sensors experience electron migration and junction degradation over time, while optical sensors suffer from LED efficiency reduction and photodetector sensitivity loss. Mechanical components in ultrasonic sensors, such as piezoelectric elements, demonstrate material fatigue that affects vibration characteristics and signal generation capabilities.

Calibration drift compounds these issues, as sensors gradually deviate from their initial calibration parameters without providing clear indicators of this shift. This insidious process often goes undetected until significant measurement errors occur, making it particularly problematic for applications requiring high precision over extended periods.

Power supply instability further exacerbates performance challenges. Voltage fluctuations and battery degradation can introduce signal noise and reduce detection accuracy. Even minor power inconsistencies may accelerate component aging or trigger intermittent malfunctions that prove difficult to diagnose and address.

Electromagnetic interference (EMI) from nearby equipment or systems represents an increasingly common challenge as industrial environments become more densely populated with electronic devices. This interference can induce signal corruption that accumulates over time, particularly affecting capacitive and inductive proximity sensors.

Quantifying these degradation patterns presents its own set of challenges. Traditional testing methodologies often fail to accurately simulate real-world conditions or accelerate aging processes in ways that reliably predict field performance. The lack of standardized testing protocols for long-term sensor performance evaluation further complicates comparative analysis between different sensor technologies or manufacturers.

Addressing these challenges requires multidisciplinary approaches combining materials science, electronics engineering, and advanced signal processing techniques. Developing robust methodologies to measure, predict, and compensate for signal drop-off remains essential for advancing proximity sensor technology toward more reliable long-term performance.

Environmental factors constitute a primary source of performance degradation. Proximity sensors deployed in industrial settings are particularly vulnerable to dust accumulation, chemical exposure, and temperature fluctuations. These conditions can physically alter sensor surfaces or interfere with their detection mechanisms, accelerating signal deterioration. Even in controlled environments, sensors remain susceptible to humidity variations and oxidation processes that progressively impact their functional components.

Component aging presents another significant challenge. Semiconductor-based proximity sensors experience electron migration and junction degradation over time, while optical sensors suffer from LED efficiency reduction and photodetector sensitivity loss. Mechanical components in ultrasonic sensors, such as piezoelectric elements, demonstrate material fatigue that affects vibration characteristics and signal generation capabilities.

Calibration drift compounds these issues, as sensors gradually deviate from their initial calibration parameters without providing clear indicators of this shift. This insidious process often goes undetected until significant measurement errors occur, making it particularly problematic for applications requiring high precision over extended periods.

Power supply instability further exacerbates performance challenges. Voltage fluctuations and battery degradation can introduce signal noise and reduce detection accuracy. Even minor power inconsistencies may accelerate component aging or trigger intermittent malfunctions that prove difficult to diagnose and address.

Electromagnetic interference (EMI) from nearby equipment or systems represents an increasingly common challenge as industrial environments become more densely populated with electronic devices. This interference can induce signal corruption that accumulates over time, particularly affecting capacitive and inductive proximity sensors.

Quantifying these degradation patterns presents its own set of challenges. Traditional testing methodologies often fail to accurately simulate real-world conditions or accelerate aging processes in ways that reliably predict field performance. The lack of standardized testing protocols for long-term sensor performance evaluation further complicates comparative analysis between different sensor technologies or manufacturers.

Addressing these challenges requires multidisciplinary approaches combining materials science, electronics engineering, and advanced signal processing techniques. Developing robust methodologies to measure, predict, and compensate for signal drop-off remains essential for advancing proximity sensor technology toward more reliable long-term performance.

Signal Drop-off Measurement Methodologies

01 Signal processing techniques for proximity sensors

Various signal processing techniques can be employed to address signal drop-off issues in proximity sensors. These include digital filtering, amplification, and noise reduction algorithms that help maintain signal integrity over distance. Advanced processing methods can compensate for signal attenuation, improving detection reliability and range while minimizing false readings caused by environmental factors.- Signal processing techniques for proximity sensors: Various signal processing techniques can be employed to address signal drop-off issues in proximity sensors. These techniques include filtering algorithms, signal amplification, and digital signal processing methods that can compensate for signal degradation over distance. Advanced processing algorithms can help maintain sensor accuracy and reliability even when the signal strength diminishes with increasing distance from the target object.

- Sensor design optimization for improved signal strength: Optimizing the physical design of proximity sensors can significantly reduce signal drop-off issues. This includes improvements in sensor geometry, material selection, and component arrangement to maximize signal transmission and reception. Enhanced antenna designs, specialized sensor arrays, and optimized transducer configurations can help maintain signal integrity over longer distances and in challenging environments.

- Compensation methods for environmental interference: Environmental factors such as temperature variations, humidity, and electromagnetic interference can exacerbate signal drop-off in proximity sensors. Implementing compensation methods that adjust sensor parameters based on environmental conditions can help maintain consistent performance. These methods may include adaptive calibration techniques, environmental monitoring systems, and algorithms that dynamically adjust sensitivity based on detected interference patterns.

- Multi-sensor fusion and redundancy systems: Implementing multi-sensor fusion techniques and redundancy systems can overcome signal drop-off limitations. By combining data from multiple sensors with different operating principles or positions, the system can maintain reliable detection even when individual sensors experience signal degradation. Sensor fusion algorithms can intelligently weight inputs from different sensors based on their reliability in specific conditions, ensuring continuous operation despite signal drop-off in some components.

- Adaptive power management for signal stability: Adaptive power management techniques can help maintain signal stability in proximity sensors. By dynamically adjusting transmission power based on detected distance, environmental conditions, or application requirements, these systems can optimize the signal-to-noise ratio while minimizing power consumption. Intelligent power control algorithms can increase transmission strength when signal drop-off is detected, ensuring consistent detection performance across varying distances and conditions.

02 Sensor design optimization for signal strength maintenance

Optimizing the physical design of proximity sensors can significantly reduce signal drop-off. This includes using specialized materials, antenna configurations, and sensor geometries that enhance signal propagation. Improved sensor designs incorporate elements that focus the sensing field, maintain signal strength over greater distances, and reduce susceptibility to interference, resulting in more consistent detection performance.Expand Specific Solutions03 Compensation mechanisms for environmental factors

Environmental factors such as temperature, humidity, and electromagnetic interference can cause proximity sensor signal drop-off. Implementing compensation mechanisms that automatically adjust sensor parameters based on environmental conditions helps maintain consistent performance. These systems may include calibration routines, adaptive thresholds, and environmental monitoring to dynamically optimize sensor operation under varying conditions.Expand Specific Solutions04 Multi-sensor arrays and fusion techniques

Deploying multiple sensors in strategic configurations and using data fusion techniques can overcome signal drop-off limitations. By combining readings from several sensors, the system can maintain detection capability even when individual sensors experience signal degradation. Advanced algorithms integrate data from different sensor types or redundant sensors to provide more reliable proximity detection across varying distances and conditions.Expand Specific Solutions05 Power management and signal amplification solutions

Effective power management and signal amplification strategies can address signal drop-off in proximity sensors. These include adaptive power control that increases transmission strength when needed, efficient energy harvesting techniques, and specialized amplification circuits. By optimizing power delivery to sensing elements and implementing strategic signal boosting at critical points in the detection process, these solutions extend effective sensing range while maintaining accuracy.Expand Specific Solutions

Key Industry Players in Proximity Sensor Manufacturing

The proximity sensor signal drop-off measurement market is in a growth phase, driven by increasing demand for reliable sensor performance in automotive, industrial automation, and consumer electronics sectors. The global market size is estimated to exceed $10 billion, with a CAGR of 8-10%. Technologically, the field shows moderate maturity with established players like SICK AG, Robert Bosch, and Honeywell leading with comprehensive sensor degradation analysis solutions. Companies including STMicroelectronics, ams-OSRAM, and Analog Devices are advancing the technology through innovative semiconductor-based approaches. Emerging players like Vayyar Imaging are disrupting the space with RF-based 4D imaging sensors that offer enhanced degradation monitoring capabilities. Intel and NVIDIA are contributing computational solutions for sensor data analysis, indicating the market's evolution toward integrated hardware-software solutions for long-term sensor reliability.

SICK AG

Technical Solution: SICK AG has developed a comprehensive approach to measuring proximity sensor signal degradation over time through their Condition Monitoring Framework. Their solution employs statistical process control (SPC) techniques to establish baseline performance metrics during initial sensor deployment. The system continuously monitors signal strength, noise ratios, and detection thresholds against these baselines to identify gradual deterioration patterns. SICK's proprietary algorithms can distinguish between environmental interference and actual sensor degradation by analyzing signal waveform characteristics. Their technology incorporates automated compensation mechanisms that adjust detection parameters based on the measured degradation rate, extending functional sensor life. For industrial applications, SICK implements a distributed monitoring architecture where edge devices perform preliminary signal analysis before transmitting condensed diagnostic data to central systems, reducing network bandwidth requirements while maintaining comprehensive monitoring capabilities.

Strengths: Industry-leading expertise in industrial sensor technology with robust diagnostic capabilities and predictive maintenance integration. Their systems can detect subtle degradation patterns before operational failures occur. Weaknesses: Solutions are primarily optimized for industrial environments and may require significant customization for consumer applications. Higher implementation costs compared to simpler monitoring approaches.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered an integrated approach to proximity sensor degradation monitoring through their Cross-Domain Computing Solutions division. Their technology implements a dual-reference measurement system that simultaneously evaluates both absolute signal strength and relative changes in detection patterns. This approach allows for the isolation of environmental factors from actual sensor deterioration. Bosch's system employs machine learning algorithms trained on extensive historical sensor performance data to predict degradation trajectories with high accuracy. Their solution incorporates temperature compensation, ambient light filtering, and vibration isolation techniques to ensure measurement consistency across varying operational conditions. For automotive applications, Bosch has developed specialized testing protocols that simulate accelerated aging under extreme temperature cycles, humidity variations, and electromagnetic interference to characterize long-term signal stability. The system provides standardized degradation metrics that enable comparison across different sensor types and installation environments, facilitating fleet-wide maintenance optimization.

Strengths: Comprehensive approach integrating hardware and software solutions with extensive automotive validation. Their predictive algorithms benefit from massive datasets collected across diverse operational environments. Weaknesses: Solutions can be complex to implement and may require specialized expertise for configuration and maintenance. Higher initial investment compared to simpler monitoring systems.

Critical Patents in Sensor Degradation Detection

Proximity sensing

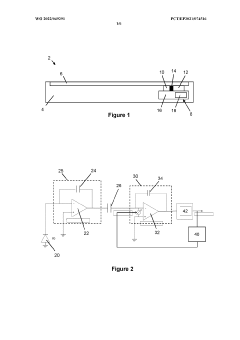

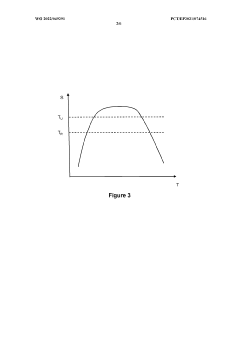

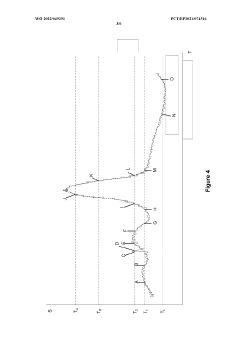

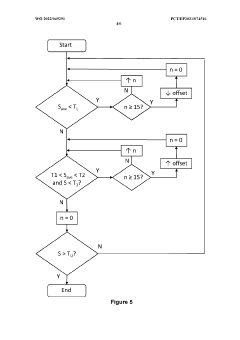

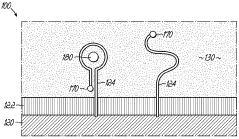

PatentWO2022049291A1

Innovation

- The method involves applying an offset to the signal output from a proximity sensor, adjusting for drift by comparing the output signal to a first threshold and an average signal to different thresholds, and only identifying drift after the criteria are met for a predetermined period of time, thereby distinguishing between actual movement and drift.

Electrochemical aptamer sensors with stable blocking layers, rapid electron transfer and robust antifouling properties

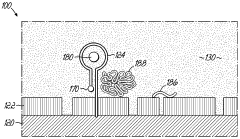

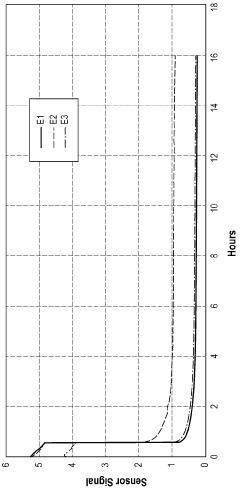

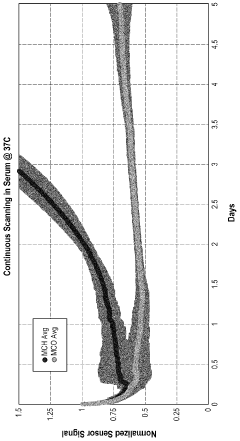

PatentPendingAU2022352736A1

Innovation

- The development of a device with an electrode surface coated with a blocking layer of mercaptooctanol molecules, which provides enhanced binding energy and resistance to desorption and fouling, allowing continuous sensing for at least 3 days at temperatures above 30°C, and includes features like defects and terminus moieties to support electron transfer and prevent fouling.

Environmental Factors Affecting Sensor Longevity

The environmental conditions in which proximity sensors operate significantly impact their longevity and performance degradation over time. Temperature fluctuations represent one of the most critical factors affecting sensor reliability. Extreme heat can accelerate component degradation through thermal stress, while cold environments may alter the electrical properties of semiconductors within the sensing elements. Research indicates that operating temperatures exceeding manufacturer specifications by just 10°C can reduce sensor lifespan by up to 40%.

Humidity and moisture exposure constitute another major environmental challenge for proximity sensors. Water vapor can penetrate sensor housings over time, causing corrosion of internal components and creating potential short circuits. This is particularly problematic in industrial settings where condensation cycles occur frequently. Studies show that relative humidity levels above 85% can accelerate signal degradation by 15-20% compared to controlled environments.

Dust and particulate contamination directly interfere with the sensor's emission and detection capabilities. For optical proximity sensors, accumulated particles on lenses or emitters can gradually attenuate signal strength. In infrared-based sensors, even microscopic dust layers can absorb or scatter the IR beam, resulting in false readings or reduced detection range. Regular cleaning protocols can mitigate this effect, but gradual degradation remains inevitable in dusty environments.

Chemical exposure represents a less obvious but equally damaging environmental factor. Industrial gases, cleaning solvents, and even ambient air pollutants can react with sensor materials over time. These chemical interactions may alter the optical properties of lenses, degrade protective coatings, or compromise the integrity of electronic components. Sensors deployed in chemical processing facilities typically show 30% faster degradation rates than those in clean environments.

Mechanical vibration and shock events contribute to physical wear of sensor components. Constant vibration can loosen connections, create microfractures in solder joints, and accelerate fatigue failure in moving parts. High-frequency vibrations are particularly problematic, as they can induce resonance effects that amplify mechanical stress on sensitive components. Automotive and manufacturing applications often expose sensors to these conditions, necessitating robust design considerations.

Radiation exposure, while less common in typical applications, presents significant challenges in specialized environments. UV radiation can degrade plastic housings and optical components, while ionizing radiation affects semiconductor performance at the atomic level. Space applications and nuclear facilities must account for these effects when implementing proximity sensing systems, often requiring radiation-hardened components or scheduled replacement protocols.

Humidity and moisture exposure constitute another major environmental challenge for proximity sensors. Water vapor can penetrate sensor housings over time, causing corrosion of internal components and creating potential short circuits. This is particularly problematic in industrial settings where condensation cycles occur frequently. Studies show that relative humidity levels above 85% can accelerate signal degradation by 15-20% compared to controlled environments.

Dust and particulate contamination directly interfere with the sensor's emission and detection capabilities. For optical proximity sensors, accumulated particles on lenses or emitters can gradually attenuate signal strength. In infrared-based sensors, even microscopic dust layers can absorb or scatter the IR beam, resulting in false readings or reduced detection range. Regular cleaning protocols can mitigate this effect, but gradual degradation remains inevitable in dusty environments.

Chemical exposure represents a less obvious but equally damaging environmental factor. Industrial gases, cleaning solvents, and even ambient air pollutants can react with sensor materials over time. These chemical interactions may alter the optical properties of lenses, degrade protective coatings, or compromise the integrity of electronic components. Sensors deployed in chemical processing facilities typically show 30% faster degradation rates than those in clean environments.

Mechanical vibration and shock events contribute to physical wear of sensor components. Constant vibration can loosen connections, create microfractures in solder joints, and accelerate fatigue failure in moving parts. High-frequency vibrations are particularly problematic, as they can induce resonance effects that amplify mechanical stress on sensitive components. Automotive and manufacturing applications often expose sensors to these conditions, necessitating robust design considerations.

Radiation exposure, while less common in typical applications, presents significant challenges in specialized environments. UV radiation can degrade plastic housings and optical components, while ionizing radiation affects semiconductor performance at the atomic level. Space applications and nuclear facilities must account for these effects when implementing proximity sensing systems, often requiring radiation-hardened components or scheduled replacement protocols.

Standardization of Sensor Reliability Testing

The standardization of reliability testing for proximity sensors is a critical aspect of ensuring consistent performance evaluation across the industry. Currently, there exists significant variation in how manufacturers and end-users assess sensor degradation over time, leading to challenges in comparing products and predicting maintenance needs. A unified testing framework would establish common methodologies, metrics, and reporting formats that enable objective evaluation of sensor performance degradation.

International organizations such as IEEE, IEC, and ISO have begun developing preliminary standards for proximity sensor testing, but these efforts remain fragmented across different sensor technologies and application domains. The establishment of comprehensive standards requires collaboration between industry stakeholders, academic institutions, and regulatory bodies to address the diverse requirements of various sectors including automotive, industrial automation, consumer electronics, and healthcare.

Key components of standardized reliability testing should include environmental condition specifications (temperature ranges, humidity levels, dust exposure), operational parameters (activation frequency, detection range verification), and temporal testing protocols (accelerated aging methodologies, minimum test duration requirements). These standards must define precise measurement procedures that account for different sensor technologies including infrared, ultrasonic, capacitive, and inductive proximity sensors.

Statistical analysis methods must also be standardized to ensure consistency in how signal degradation data is processed and interpreted. This includes defining acceptable confidence intervals, outlier handling procedures, and minimum sample sizes for validation testing. The development of reference materials and calibration procedures would further enhance test reproducibility across different laboratories and testing facilities.

Implementation challenges for standardization include balancing the need for comprehensive testing against practical time and cost constraints. Additionally, standards must remain flexible enough to accommodate rapid technological advancements while maintaining backward compatibility with existing sensor evaluation methods. The creation of tiered testing protocols could address this challenge by establishing both basic compliance requirements and optional extended reliability assessments.

Industry adoption of standardized testing would significantly benefit both manufacturers and end-users by creating a common language for specifying and comparing sensor reliability. This would enable more informed purchasing decisions, improve quality control processes, and potentially reduce warranty claims through better predictability of sensor lifespans. Furthermore, standardized testing would facilitate regulatory compliance in safety-critical applications where sensor reliability directly impacts system safety.

International organizations such as IEEE, IEC, and ISO have begun developing preliminary standards for proximity sensor testing, but these efforts remain fragmented across different sensor technologies and application domains. The establishment of comprehensive standards requires collaboration between industry stakeholders, academic institutions, and regulatory bodies to address the diverse requirements of various sectors including automotive, industrial automation, consumer electronics, and healthcare.

Key components of standardized reliability testing should include environmental condition specifications (temperature ranges, humidity levels, dust exposure), operational parameters (activation frequency, detection range verification), and temporal testing protocols (accelerated aging methodologies, minimum test duration requirements). These standards must define precise measurement procedures that account for different sensor technologies including infrared, ultrasonic, capacitive, and inductive proximity sensors.

Statistical analysis methods must also be standardized to ensure consistency in how signal degradation data is processed and interpreted. This includes defining acceptable confidence intervals, outlier handling procedures, and minimum sample sizes for validation testing. The development of reference materials and calibration procedures would further enhance test reproducibility across different laboratories and testing facilities.

Implementation challenges for standardization include balancing the need for comprehensive testing against practical time and cost constraints. Additionally, standards must remain flexible enough to accommodate rapid technological advancements while maintaining backward compatibility with existing sensor evaluation methods. The creation of tiered testing protocols could address this challenge by establishing both basic compliance requirements and optional extended reliability assessments.

Industry adoption of standardized testing would significantly benefit both manufacturers and end-users by creating a common language for specifying and comparing sensor reliability. This would enable more informed purchasing decisions, improve quality control processes, and potentially reduce warranty claims through better predictability of sensor lifespans. Furthermore, standardized testing would facilitate regulatory compliance in safety-critical applications where sensor reliability directly impacts system safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!