Digital Twins For Exchanger Monitoring: Fouling Prediction And Energy Loss Quantification

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Technology Evolution and Objectives

Digital twin technology has evolved significantly since its conceptual introduction by Michael Grieves at the University of Michigan in 2002. Initially focused on product lifecycle management, digital twins have transformed from simple virtual representations to sophisticated real-time simulation models. The evolution accelerated around 2010 when IoT technologies matured, enabling continuous data exchange between physical assets and their digital counterparts.

For heat exchangers specifically, digital twin technology has progressed through distinct phases. Early implementations (2002-2010) primarily involved static 3D models with limited simulation capabilities. The second generation (2010-2015) incorporated basic sensor data integration and rudimentary predictive capabilities. Current advanced digital twins (2016-present) feature real-time monitoring, machine learning algorithms for fouling prediction, and comprehensive energy efficiency analysis.

The primary objective of digital twins for heat exchanger monitoring is to create a high-fidelity virtual replica that accurately simulates thermal-hydraulic behavior under various operating conditions. This enables predictive maintenance by identifying fouling patterns before they cause significant performance degradation. Another critical goal is quantifying energy losses attributable to fouling, allowing operators to make data-driven decisions about cleaning schedules and operational adjustments.

Technical objectives include developing algorithms capable of distinguishing between different fouling mechanisms (particulate, chemical reaction, crystallization, etc.) based on operational data patterns. Additionally, these systems aim to establish correlations between process variables and fouling rates to optimize operating parameters for minimal fouling progression.

From an operational perspective, digital twins for exchangers seek to reduce maintenance costs by transitioning from time-based to condition-based maintenance strategies. They also target energy consumption reduction by maintaining optimal heat transfer efficiency through timely interventions when fouling is detected.

Looking forward, the technology aims to incorporate more sophisticated physics-based models with machine learning approaches in hybrid systems. These would enable not only fouling prediction but also root cause analysis and automated recommendation of mitigation strategies. The ultimate objective is developing autonomous systems capable of self-optimizing exchanger operation in response to changing process conditions and detected fouling patterns.

For heat exchangers specifically, digital twin technology has progressed through distinct phases. Early implementations (2002-2010) primarily involved static 3D models with limited simulation capabilities. The second generation (2010-2015) incorporated basic sensor data integration and rudimentary predictive capabilities. Current advanced digital twins (2016-present) feature real-time monitoring, machine learning algorithms for fouling prediction, and comprehensive energy efficiency analysis.

The primary objective of digital twins for heat exchanger monitoring is to create a high-fidelity virtual replica that accurately simulates thermal-hydraulic behavior under various operating conditions. This enables predictive maintenance by identifying fouling patterns before they cause significant performance degradation. Another critical goal is quantifying energy losses attributable to fouling, allowing operators to make data-driven decisions about cleaning schedules and operational adjustments.

Technical objectives include developing algorithms capable of distinguishing between different fouling mechanisms (particulate, chemical reaction, crystallization, etc.) based on operational data patterns. Additionally, these systems aim to establish correlations between process variables and fouling rates to optimize operating parameters for minimal fouling progression.

From an operational perspective, digital twins for exchangers seek to reduce maintenance costs by transitioning from time-based to condition-based maintenance strategies. They also target energy consumption reduction by maintaining optimal heat transfer efficiency through timely interventions when fouling is detected.

Looking forward, the technology aims to incorporate more sophisticated physics-based models with machine learning approaches in hybrid systems. These would enable not only fouling prediction but also root cause analysis and automated recommendation of mitigation strategies. The ultimate objective is developing autonomous systems capable of self-optimizing exchanger operation in response to changing process conditions and detected fouling patterns.

Market Demand for Heat Exchanger Monitoring Solutions

The global market for heat exchanger monitoring solutions is experiencing significant growth, driven by increasing industrial focus on operational efficiency, energy conservation, and sustainability initiatives. Industries such as oil and gas, chemical processing, power generation, and food processing rely heavily on heat exchangers, with fouling-related issues costing these sectors billions annually in maintenance, downtime, and energy losses.

Recent market research indicates that the heat exchanger monitoring market is projected to grow at a compound annual growth rate of 7.2% through 2028, with the digital twins segment showing particularly strong momentum. This growth is primarily fueled by the critical need to minimize production losses and optimize energy consumption across process industries.

Energy efficiency regulations and carbon reduction mandates across major economies have created substantial demand for solutions that can quantify and reduce energy losses. Organizations face increasing pressure to demonstrate environmental compliance while maintaining competitive operational costs, making fouling prediction and energy loss quantification essential capabilities.

The industrial Internet of Things (IIoT) adoption has transformed customer expectations regarding heat exchanger monitoring. End-users now demand real-time insights, predictive capabilities, and actionable intelligence rather than simple monitoring tools. This shift has created market opportunities for advanced digital twin solutions that can accurately model fouling behavior and precisely quantify resulting energy losses.

Process industries have demonstrated willingness to invest in technologies that offer clear return on investment through extended equipment lifecycles, reduced maintenance costs, and energy savings. Case studies from early adopters show payback periods typically ranging from 12 to 24 months for comprehensive digital twin monitoring systems.

Regional analysis reveals particularly strong demand in Asia-Pacific, where rapid industrialization coincides with stringent new environmental regulations. North America and Europe represent mature markets with replacement and upgrade cycles driving adoption of advanced monitoring technologies.

Customer pain points consistently identified in market surveys include the inability to predict fouling progression accurately, difficulty quantifying energy losses in financial terms, and challenges integrating monitoring data with existing plant management systems. These unmet needs represent significant opportunities for digital twin solutions that address these specific challenges.

The market increasingly values solutions offering cross-platform compatibility, cloud-based analytics, and the ability to integrate with broader asset management ecosystems. This trend favors vendors capable of delivering comprehensive monitoring solutions rather than standalone products.

Recent market research indicates that the heat exchanger monitoring market is projected to grow at a compound annual growth rate of 7.2% through 2028, with the digital twins segment showing particularly strong momentum. This growth is primarily fueled by the critical need to minimize production losses and optimize energy consumption across process industries.

Energy efficiency regulations and carbon reduction mandates across major economies have created substantial demand for solutions that can quantify and reduce energy losses. Organizations face increasing pressure to demonstrate environmental compliance while maintaining competitive operational costs, making fouling prediction and energy loss quantification essential capabilities.

The industrial Internet of Things (IIoT) adoption has transformed customer expectations regarding heat exchanger monitoring. End-users now demand real-time insights, predictive capabilities, and actionable intelligence rather than simple monitoring tools. This shift has created market opportunities for advanced digital twin solutions that can accurately model fouling behavior and precisely quantify resulting energy losses.

Process industries have demonstrated willingness to invest in technologies that offer clear return on investment through extended equipment lifecycles, reduced maintenance costs, and energy savings. Case studies from early adopters show payback periods typically ranging from 12 to 24 months for comprehensive digital twin monitoring systems.

Regional analysis reveals particularly strong demand in Asia-Pacific, where rapid industrialization coincides with stringent new environmental regulations. North America and Europe represent mature markets with replacement and upgrade cycles driving adoption of advanced monitoring technologies.

Customer pain points consistently identified in market surveys include the inability to predict fouling progression accurately, difficulty quantifying energy losses in financial terms, and challenges integrating monitoring data with existing plant management systems. These unmet needs represent significant opportunities for digital twin solutions that address these specific challenges.

The market increasingly values solutions offering cross-platform compatibility, cloud-based analytics, and the ability to integrate with broader asset management ecosystems. This trend favors vendors capable of delivering comprehensive monitoring solutions rather than standalone products.

Current Challenges in Fouling Detection Technologies

Despite significant advancements in heat exchanger monitoring technologies, fouling detection remains plagued by several persistent challenges that impede accurate prediction and quantification of energy losses. Traditional methods such as pressure drop and heat transfer coefficient monitoring suffer from delayed detection capabilities, often identifying fouling only after significant buildup has occurred, resulting in substantial efficiency losses before remedial action can be taken.

Real-time monitoring systems face significant technical hurdles related to sensor placement and durability. Sensors installed within heat exchangers must withstand harsh operating conditions including high temperatures, pressures, and potentially corrosive fluids. These environmental factors frequently lead to sensor degradation, calibration drift, and premature failure, compromising data reliability and necessitating costly maintenance interventions.

Data interpretation presents another major challenge. The complex, non-linear relationship between measured parameters and actual fouling conditions makes it difficult to develop universally applicable algorithms. Current models often struggle to differentiate between fouling-related performance degradation and other operational variations such as flow rate fluctuations, inlet temperature changes, or process fluid composition alterations.

Heterogeneous fouling patterns further complicate detection efforts. Fouling rarely develops uniformly across heat exchanger surfaces, creating localized "hot spots" that may escape detection by conventional monitoring systems that rely on aggregate measurements. This spatial variability necessitates more sophisticated monitoring approaches capable of capturing localized phenomena.

Integration challenges between monitoring systems and existing plant infrastructure represent another significant barrier. Many industrial facilities operate with legacy control systems that lack the communication protocols necessary for seamless integration with advanced monitoring technologies. This compatibility gap often results in isolated data silos that prevent holistic analysis of exchanger performance.

Cost-benefit considerations also constrain technology adoption. While sophisticated monitoring solutions offer improved detection capabilities, their implementation costs must be justified against the potential energy savings and reduced maintenance expenses. This economic calculus varies significantly across industries and applications, creating uneven technology adoption patterns.

Validation of fouling prediction models remains problematic due to the scarcity of comprehensive field data spanning diverse operating conditions and fouling mechanisms. Laboratory-scale validations often fail to capture the complexity of industrial-scale operations, limiting the transferability of research findings to practical applications.

Real-time monitoring systems face significant technical hurdles related to sensor placement and durability. Sensors installed within heat exchangers must withstand harsh operating conditions including high temperatures, pressures, and potentially corrosive fluids. These environmental factors frequently lead to sensor degradation, calibration drift, and premature failure, compromising data reliability and necessitating costly maintenance interventions.

Data interpretation presents another major challenge. The complex, non-linear relationship between measured parameters and actual fouling conditions makes it difficult to develop universally applicable algorithms. Current models often struggle to differentiate between fouling-related performance degradation and other operational variations such as flow rate fluctuations, inlet temperature changes, or process fluid composition alterations.

Heterogeneous fouling patterns further complicate detection efforts. Fouling rarely develops uniformly across heat exchanger surfaces, creating localized "hot spots" that may escape detection by conventional monitoring systems that rely on aggregate measurements. This spatial variability necessitates more sophisticated monitoring approaches capable of capturing localized phenomena.

Integration challenges between monitoring systems and existing plant infrastructure represent another significant barrier. Many industrial facilities operate with legacy control systems that lack the communication protocols necessary for seamless integration with advanced monitoring technologies. This compatibility gap often results in isolated data silos that prevent holistic analysis of exchanger performance.

Cost-benefit considerations also constrain technology adoption. While sophisticated monitoring solutions offer improved detection capabilities, their implementation costs must be justified against the potential energy savings and reduced maintenance expenses. This economic calculus varies significantly across industries and applications, creating uneven technology adoption patterns.

Validation of fouling prediction models remains problematic due to the scarcity of comprehensive field data spanning diverse operating conditions and fouling mechanisms. Laboratory-scale validations often fail to capture the complexity of industrial-scale operations, limiting the transferability of research findings to practical applications.

Existing Digital Twin Implementations for Heat Exchangers

01 Digital twin models for fouling prediction in industrial systems

Digital twin technology can be used to create virtual models of industrial systems that predict fouling accumulation based on operational data. These models integrate real-time sensor data with physics-based simulations to forecast when and where fouling will occur in heat exchangers, pipelines, and other equipment. By accurately predicting fouling patterns, operators can optimize maintenance schedules and prevent unexpected downtime.- Digital twin modeling for fouling prediction in industrial systems: Digital twin technology can be used to create virtual models of industrial systems that predict fouling accumulation based on operational data. These models integrate real-time sensor data with physics-based simulations to forecast when and where fouling will occur in heat exchangers, pipelines, and other equipment. By accurately predicting fouling patterns, operators can optimize maintenance schedules and prevent unexpected downtime due to fouling-related failures.

- Energy loss quantification through digital twin simulation: Digital twin simulations can quantify energy losses caused by fouling in thermal systems. These simulations calculate the reduction in heat transfer efficiency, increased pumping power requirements, and overall system performance degradation due to fouling deposits. By continuously monitoring these parameters, the digital twin provides accurate estimates of energy consumption increases and associated operational costs, enabling data-driven decisions about when cleaning or maintenance becomes economically justified.

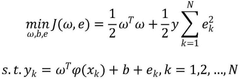

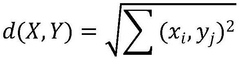

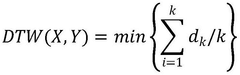

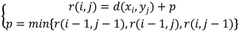

- AI and machine learning integration for predictive fouling analytics: Advanced digital twin systems incorporate artificial intelligence and machine learning algorithms to enhance fouling prediction accuracy. These algorithms analyze historical operational data, environmental conditions, and fluid characteristics to identify patterns and correlations that contribute to fouling development. The AI models continuously improve their predictive capabilities through feedback loops, enabling more precise forecasting of fouling rates and their impact on energy efficiency across various operating conditions.

- Real-time monitoring and optimization of cleaning schedules: Digital twin technology enables real-time monitoring of fouling progression and optimization of cleaning schedules based on energy loss quantification. The system continuously evaluates the economic trade-off between energy losses due to fouling and the costs associated with system downtime for cleaning. This approach allows for condition-based maintenance rather than time-based maintenance, maximizing operational efficiency while minimizing energy consumption and maintenance expenses.

- Multi-physics simulation for comprehensive fouling impact assessment: Advanced digital twin platforms utilize multi-physics simulation capabilities to provide comprehensive assessment of fouling impacts across different system components. These simulations simultaneously model fluid dynamics, heat transfer, chemical reactions, and material properties to capture the complex interactions that influence fouling development and energy losses. By accounting for these interdependent factors, the digital twin can accurately quantify energy efficiency degradation and predict system performance under various operating scenarios and fouling conditions.

02 Energy loss quantification through digital twin simulation

Digital twins enable precise quantification of energy losses caused by fouling in industrial equipment. These simulations calculate efficiency reductions by comparing ideal operating conditions with actual performance affected by fouling. The technology can measure heat transfer degradation, increased pumping power requirements, and overall system efficiency losses, providing monetary valuations of energy waste to justify maintenance interventions.Expand Specific Solutions03 Predictive maintenance optimization using AI and machine learning

Advanced digital twin systems incorporate artificial intelligence and machine learning algorithms to optimize predictive maintenance for fouled equipment. These systems analyze historical fouling patterns, operational conditions, and maintenance outcomes to recommend optimal cleaning schedules. By learning from past data, the AI models continuously improve their prediction accuracy, balancing maintenance costs against energy efficiency losses to maximize overall operational economics.Expand Specific Solutions04 Real-time monitoring and adaptive control systems

Digital twin technology enables real-time monitoring of fouling progression and implements adaptive control strategies to mitigate energy losses. These systems continuously analyze sensor data to detect early signs of fouling and automatically adjust operational parameters to minimize efficiency losses. The adaptive control mechanisms can modify flow rates, temperatures, or chemical dosing to extend equipment runtime while maintaining acceptable efficiency levels until scheduled maintenance.Expand Specific Solutions05 Economic impact assessment and ROI calculation for fouling mitigation

Digital twin platforms provide comprehensive economic impact assessments of fouling-related energy losses and evaluate return on investment for different mitigation strategies. These tools quantify direct energy costs, production losses, maintenance expenses, and environmental impacts associated with fouling. By simulating various intervention scenarios, the technology helps decision-makers select cost-effective fouling mitigation approaches based on projected energy savings and operational improvements.Expand Specific Solutions

Key Industry Players in Digital Twin Solutions

The digital twin technology for exchanger monitoring is in an early growth phase, with market size expanding due to increasing focus on energy efficiency and predictive maintenance. The technology maturity varies across players, with Siemens AG and Siemens Energy leading the field through advanced simulation capabilities and established industrial presence. State Grid Corporation of China and its subsidiaries are developing region-specific implementations, while research institutions like Wuhan University and King Fahd University contribute to theoretical foundations. Companies like Maschinenfabrik Reinhausen and Robert Bosch are integrating digital twin technology into their industrial equipment offerings, creating a competitive landscape where established industrial giants compete with specialized energy monitoring solutions providers.

Siemens AG

Technical Solution: Siemens AG has developed an advanced Digital Twin platform for heat exchanger monitoring that combines physics-based modeling with machine learning algorithms. Their solution creates high-fidelity virtual replicas of physical exchangers that simulate thermal-hydraulic behaviors in real-time. The system employs multiple sensor arrays strategically positioned throughout the exchanger to collect temperature, pressure, flow rate, and vibration data. This data feeds into their proprietary fouling prediction algorithm that can detect early-stage fouling formation by identifying subtle deviations from optimal performance patterns. The platform quantifies energy losses through comparative analysis between ideal and actual operating conditions, providing monetary valuations of efficiency decreases. Siemens' solution includes a predictive maintenance module that recommends optimal cleaning schedules based on operational costs versus cleaning expenses. Their digital twin technology integrates with existing plant management systems through standardized interfaces and provides visualization tools that enable operators to monitor exchanger performance through intuitive dashboards.

Strengths: Comprehensive integration with existing industrial automation systems; extensive experience with industrial equipment monitoring; strong physics-based modeling capabilities combined with AI. Weaknesses: Implementation typically requires significant customization; higher initial investment compared to simpler monitoring solutions; requires specialized expertise for deployment and maintenance.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed a specialized Digital Twin solution for heat exchanger monitoring focused on power generation applications. Their system employs a multi-layered approach combining thermodynamic modeling, computational fluid dynamics (CFD), and machine learning to create comprehensive digital representations of heat exchangers. The platform utilizes distributed temperature and pressure sensors along with flow meters to gather real-time operational data. Their proprietary fouling detection algorithm analyzes heat transfer coefficient degradation patterns to identify fouling accumulation at early stages. The system quantifies energy losses by comparing actual performance against baseline efficiency models, translating thermal inefficiencies into direct financial impact metrics. Siemens Energy's solution features advanced visualization capabilities that allow operators to view fouling distribution within the exchanger through 3D heat maps. The platform integrates with their broader power plant management systems, enabling holistic analysis of how exchanger performance affects overall plant efficiency. Their predictive maintenance module uses historical data and operational patterns to forecast optimal cleaning intervals that maximize economic benefit.

Strengths: Deep domain expertise in power generation applications; robust integration with broader plant management systems; advanced visualization capabilities for fouling distribution. Weaknesses: Solutions primarily optimized for power generation sector; complex implementation requiring specialized knowledge; higher cost structure compared to more generic monitoring solutions.

Core Algorithms for Fouling Prediction Models

Transformer state prediction model construction method and system for digital twin platform

PatentPendingCN117421918A

Innovation

- A method for building a transformer state prediction model for the digital twin platform is proposed. By collecting operating condition data under different operating conditions, two parallel random configuration networks are constructed, point-block hybrid parallel learning is performed, and the error convergence speed is selected faster. The network performs point augmentation or block augmentation, combining knowledge-driven error and data-driven methods for model training and sample selection.

Power transmission and transformation equipment data filling method and system based on time sequence prediction

PatentPendingCN119884592A

Innovation

- Using a time series prediction method, by collecting and analyzing the historical operation data of power transmission and transformation equipment, a multivariate time series is obtained, missing values are detected and filled, missing values are inferred using the left squares support vector machine and dynamic Bayesian network, and the parameters of the filling algorithm are optimized to ensure the continuity and integrity of the data.

ROI Analysis of Digital Twin Implementation

Implementing digital twin technology for heat exchanger monitoring represents a significant investment that requires thorough financial analysis. The return on investment (ROI) calculation must account for both direct cost savings and indirect benefits that contribute to operational excellence.

Initial implementation costs typically include software development or licensing, sensor installation, integration with existing systems, and staff training. For a medium-sized industrial facility with 50-100 heat exchangers, these upfront costs range from $250,000 to $750,000 depending on the complexity of the installation and the sophistication of the digital twin solution.

Quantifiable returns manifest primarily through energy savings and maintenance optimization. By accurately predicting fouling conditions, digital twins enable proactive cleaning schedules that maintain optimal heat transfer efficiency. Studies across various industries indicate energy savings of 7-15% through improved exchanger performance, translating to annual cost reductions of $100,000-$300,000 for facilities with significant heat exchange operations.

Maintenance cost reductions represent another substantial ROI component. Traditional time-based maintenance approaches often result in either premature servicing or delayed interventions causing unexpected failures. Digital twin-enabled condition-based maintenance typically reduces maintenance costs by 15-25%, with annual savings of $80,000-$150,000 for facilities with extensive heat exchanger networks.

Extended equipment lifespan delivers additional financial benefits. By preventing severe fouling conditions that accelerate corrosion and material degradation, digital twins can extend exchanger service life by 2-5 years. This postponement of capital expenditure for replacement equipment represents significant value, particularly for specialized or high-pressure exchangers where replacement costs can exceed $500,000 per unit.

Production loss avoidance constitutes perhaps the most substantial ROI component. Unplanned downtime due to exchanger failure can cost $10,000-$50,000 per hour in lost production. Digital twins reduce these incidents by 30-50%, protecting revenue streams and maintaining production commitments.

Most implementations achieve positive ROI within 12-24 months, with more complex installations requiring up to 36 months to reach breakeven. The long-term ROI typically ranges from 150% to 400% over a five-year period, making digital twin technology for exchanger monitoring a financially sound investment for most process industries.

Initial implementation costs typically include software development or licensing, sensor installation, integration with existing systems, and staff training. For a medium-sized industrial facility with 50-100 heat exchangers, these upfront costs range from $250,000 to $750,000 depending on the complexity of the installation and the sophistication of the digital twin solution.

Quantifiable returns manifest primarily through energy savings and maintenance optimization. By accurately predicting fouling conditions, digital twins enable proactive cleaning schedules that maintain optimal heat transfer efficiency. Studies across various industries indicate energy savings of 7-15% through improved exchanger performance, translating to annual cost reductions of $100,000-$300,000 for facilities with significant heat exchange operations.

Maintenance cost reductions represent another substantial ROI component. Traditional time-based maintenance approaches often result in either premature servicing or delayed interventions causing unexpected failures. Digital twin-enabled condition-based maintenance typically reduces maintenance costs by 15-25%, with annual savings of $80,000-$150,000 for facilities with extensive heat exchanger networks.

Extended equipment lifespan delivers additional financial benefits. By preventing severe fouling conditions that accelerate corrosion and material degradation, digital twins can extend exchanger service life by 2-5 years. This postponement of capital expenditure for replacement equipment represents significant value, particularly for specialized or high-pressure exchangers where replacement costs can exceed $500,000 per unit.

Production loss avoidance constitutes perhaps the most substantial ROI component. Unplanned downtime due to exchanger failure can cost $10,000-$50,000 per hour in lost production. Digital twins reduce these incidents by 30-50%, protecting revenue streams and maintaining production commitments.

Most implementations achieve positive ROI within 12-24 months, with more complex installations requiring up to 36 months to reach breakeven. The long-term ROI typically ranges from 150% to 400% over a five-year period, making digital twin technology for exchanger monitoring a financially sound investment for most process industries.

Sustainability Impact of Optimized Heat Exchanger Operations

The optimization of heat exchanger operations through digital twin technology offers significant sustainability benefits that extend far beyond operational efficiency. By accurately predicting fouling and quantifying energy losses, organizations can substantially reduce their environmental footprint while contributing to global sustainability goals.

Energy consumption reduction represents one of the most immediate sustainability impacts. Heat exchangers are energy-intensive components in industrial processes, and fouling can increase energy requirements by 2-5% annually. Digital twin monitoring enables proactive maintenance scheduling that maintains optimal thermal efficiency, potentially reducing greenhouse gas emissions by 15-30% compared to traditional maintenance approaches.

Resource conservation is another critical sustainability benefit. Optimized heat exchanger operations extend equipment lifespan by 20-40%, reducing the need for premature replacements and associated raw material extraction. This conservation effect cascades throughout the supply chain, decreasing environmental impacts from manufacturing, transportation, and installation of replacement equipment.

Water usage optimization also emerges as a significant sustainability advantage. Many industrial heat exchangers utilize water as a heat transfer medium, and fouling often necessitates increased water circulation or chemical cleaning processes. Digital twin monitoring can reduce water consumption by 10-25% through optimized cleaning schedules and improved operational parameters.

Chemical usage reduction further enhances the sustainability profile. Traditional cleaning methods for fouled heat exchangers typically involve harsh chemicals that pose environmental risks. Predictive maintenance enabled by digital twins can reduce chemical cleaning frequency by 30-50%, minimizing the release of potentially harmful substances into wastewater streams.

From a regulatory compliance perspective, optimized heat exchanger operations support adherence to increasingly stringent environmental regulations. Digital twin technology provides detailed documentation of energy efficiency improvements and emissions reductions, facilitating compliance reporting and potentially qualifying organizations for sustainability incentives or carbon credits.

The economic sustainability dimension cannot be overlooked. Energy savings from optimized heat exchanger operations typically deliver 15-25% cost reductions, while maintenance cost savings average 10-30%. These financial benefits make sustainability initiatives economically viable and attractive to stakeholders, creating a positive feedback loop that encourages further investment in environmental technologies.

Energy consumption reduction represents one of the most immediate sustainability impacts. Heat exchangers are energy-intensive components in industrial processes, and fouling can increase energy requirements by 2-5% annually. Digital twin monitoring enables proactive maintenance scheduling that maintains optimal thermal efficiency, potentially reducing greenhouse gas emissions by 15-30% compared to traditional maintenance approaches.

Resource conservation is another critical sustainability benefit. Optimized heat exchanger operations extend equipment lifespan by 20-40%, reducing the need for premature replacements and associated raw material extraction. This conservation effect cascades throughout the supply chain, decreasing environmental impacts from manufacturing, transportation, and installation of replacement equipment.

Water usage optimization also emerges as a significant sustainability advantage. Many industrial heat exchangers utilize water as a heat transfer medium, and fouling often necessitates increased water circulation or chemical cleaning processes. Digital twin monitoring can reduce water consumption by 10-25% through optimized cleaning schedules and improved operational parameters.

Chemical usage reduction further enhances the sustainability profile. Traditional cleaning methods for fouled heat exchangers typically involve harsh chemicals that pose environmental risks. Predictive maintenance enabled by digital twins can reduce chemical cleaning frequency by 30-50%, minimizing the release of potentially harmful substances into wastewater streams.

From a regulatory compliance perspective, optimized heat exchanger operations support adherence to increasingly stringent environmental regulations. Digital twin technology provides detailed documentation of energy efficiency improvements and emissions reductions, facilitating compliance reporting and potentially qualifying organizations for sustainability incentives or carbon credits.

The economic sustainability dimension cannot be overlooked. Energy savings from optimized heat exchanger operations typically deliver 15-25% cost reductions, while maintenance cost savings average 10-30%. These financial benefits make sustainability initiatives economically viable and attractive to stakeholders, creating a positive feedback loop that encourages further investment in environmental technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!