Distillation Dynamics of Heptane in Multi-Component Systems

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane Distillation Background and Objectives

Heptane distillation has been a critical process in the petrochemical industry for decades, playing a vital role in the separation and purification of hydrocarbon mixtures. The evolution of this technology has been driven by the increasing demand for high-purity heptane in various applications, including as a solvent, fuel component, and chemical intermediate.

The historical development of heptane distillation techniques can be traced back to the early 20th century, with significant advancements occurring in the post-World War II era. Initially, simple batch distillation methods were employed, which gradually gave way to more sophisticated continuous distillation processes. These improvements were necessitated by the growing scale of industrial operations and the need for more efficient separation techniques.

In recent years, the focus has shifted towards optimizing the distillation dynamics of heptane in multi-component systems. This shift is driven by the complexity of real-world feedstocks, which often contain a variety of hydrocarbons and impurities. The challenge lies in achieving high-purity heptane separation while minimizing energy consumption and maximizing throughput.

The current technological landscape is characterized by a push towards more advanced distillation column designs, improved heat integration strategies, and the implementation of process control systems. These developments aim to enhance the overall efficiency and selectivity of heptane separation in complex mixtures.

Looking ahead, the objectives of heptane distillation research and development are multifaceted. Firstly, there is a strong emphasis on improving energy efficiency, as distillation processes are notoriously energy-intensive. This goal aligns with broader industry trends towards sustainability and reduced carbon footprints. Secondly, there is a drive to develop more robust separation techniques that can handle increasingly diverse and challenging feedstocks.

Another key objective is the integration of advanced process modeling and simulation tools to optimize distillation column design and operation. This includes the use of computational fluid dynamics (CFD) and machine learning algorithms to predict and control the behavior of multi-component systems during distillation.

Furthermore, there is growing interest in exploring alternative separation technologies that could complement or potentially replace traditional distillation for heptane purification. These include membrane-based separations, adsorption processes, and hybrid systems that combine multiple separation techniques.

In conclusion, the background and objectives of heptane distillation in multi-component systems reflect a field that is continuously evolving to meet the demands of modern industrial processes. The pursuit of more efficient, flexible, and sustainable separation methods remains at the forefront of research and development efforts in this domain.

The historical development of heptane distillation techniques can be traced back to the early 20th century, with significant advancements occurring in the post-World War II era. Initially, simple batch distillation methods were employed, which gradually gave way to more sophisticated continuous distillation processes. These improvements were necessitated by the growing scale of industrial operations and the need for more efficient separation techniques.

In recent years, the focus has shifted towards optimizing the distillation dynamics of heptane in multi-component systems. This shift is driven by the complexity of real-world feedstocks, which often contain a variety of hydrocarbons and impurities. The challenge lies in achieving high-purity heptane separation while minimizing energy consumption and maximizing throughput.

The current technological landscape is characterized by a push towards more advanced distillation column designs, improved heat integration strategies, and the implementation of process control systems. These developments aim to enhance the overall efficiency and selectivity of heptane separation in complex mixtures.

Looking ahead, the objectives of heptane distillation research and development are multifaceted. Firstly, there is a strong emphasis on improving energy efficiency, as distillation processes are notoriously energy-intensive. This goal aligns with broader industry trends towards sustainability and reduced carbon footprints. Secondly, there is a drive to develop more robust separation techniques that can handle increasingly diverse and challenging feedstocks.

Another key objective is the integration of advanced process modeling and simulation tools to optimize distillation column design and operation. This includes the use of computational fluid dynamics (CFD) and machine learning algorithms to predict and control the behavior of multi-component systems during distillation.

Furthermore, there is growing interest in exploring alternative separation technologies that could complement or potentially replace traditional distillation for heptane purification. These include membrane-based separations, adsorption processes, and hybrid systems that combine multiple separation techniques.

In conclusion, the background and objectives of heptane distillation in multi-component systems reflect a field that is continuously evolving to meet the demands of modern industrial processes. The pursuit of more efficient, flexible, and sustainable separation methods remains at the forefront of research and development efforts in this domain.

Industrial Applications and Market Analysis

Heptane distillation in multi-component systems plays a crucial role in various industrial applications, particularly in the petrochemical and chemical processing sectors. The market for heptane and its separation technologies continues to grow, driven by increasing demand for high-purity solvents and the expansion of industries that rely on hydrocarbon processing.

In the petrochemical industry, heptane distillation is essential for the production of high-quality fuels and lubricants. Refineries utilize advanced distillation techniques to separate heptane from complex hydrocarbon mixtures, ensuring the production of gasoline and other petroleum products with specific octane ratings. The automotive industry's ongoing demand for cleaner-burning fuels has led to an increased focus on efficient heptane separation processes.

The pharmaceutical sector also benefits from heptane distillation technologies. Heptane is widely used as a solvent in drug manufacturing processes, particularly in the extraction and purification of active pharmaceutical ingredients (APIs). The growing pharmaceutical market, especially in emerging economies, is driving the demand for high-purity heptane and related separation technologies.

The electronics industry represents another significant market for heptane distillation applications. Heptane is used in the production of electronic components, such as printed circuit boards and semiconductors, where it serves as a cleaning agent and solvent. As the global demand for electronic devices continues to rise, the market for heptane and its purification technologies is expected to expand accordingly.

Environmental regulations and sustainability concerns are shaping the market landscape for heptane distillation technologies. There is a growing emphasis on developing more energy-efficient and environmentally friendly separation processes. This trend is driving innovation in distillation column design, heat integration systems, and advanced control strategies to optimize heptane recovery while minimizing energy consumption and environmental impact.

The global market for heptane and related separation technologies is characterized by steady growth. Key market players include major chemical companies, equipment manufacturers, and technology providers specializing in distillation and separation processes. These companies are investing in research and development to improve distillation efficiency, reduce operational costs, and meet increasingly stringent product purity requirements.

Emerging markets, particularly in Asia-Pacific and the Middle East, are expected to drive significant growth in the heptane distillation market. Rapid industrialization, increasing chemical production capacities, and growing demand for high-purity solvents in these regions are creating new opportunities for technology providers and equipment manufacturers.

In conclusion, the industrial applications and market analysis for heptane distillation in multi-component systems reveal a dynamic and growing sector. The technology's importance across multiple industries, coupled with ongoing innovation and expanding global markets, suggests a positive outlook for the future of heptane distillation technologies and related products.

In the petrochemical industry, heptane distillation is essential for the production of high-quality fuels and lubricants. Refineries utilize advanced distillation techniques to separate heptane from complex hydrocarbon mixtures, ensuring the production of gasoline and other petroleum products with specific octane ratings. The automotive industry's ongoing demand for cleaner-burning fuels has led to an increased focus on efficient heptane separation processes.

The pharmaceutical sector also benefits from heptane distillation technologies. Heptane is widely used as a solvent in drug manufacturing processes, particularly in the extraction and purification of active pharmaceutical ingredients (APIs). The growing pharmaceutical market, especially in emerging economies, is driving the demand for high-purity heptane and related separation technologies.

The electronics industry represents another significant market for heptane distillation applications. Heptane is used in the production of electronic components, such as printed circuit boards and semiconductors, where it serves as a cleaning agent and solvent. As the global demand for electronic devices continues to rise, the market for heptane and its purification technologies is expected to expand accordingly.

Environmental regulations and sustainability concerns are shaping the market landscape for heptane distillation technologies. There is a growing emphasis on developing more energy-efficient and environmentally friendly separation processes. This trend is driving innovation in distillation column design, heat integration systems, and advanced control strategies to optimize heptane recovery while minimizing energy consumption and environmental impact.

The global market for heptane and related separation technologies is characterized by steady growth. Key market players include major chemical companies, equipment manufacturers, and technology providers specializing in distillation and separation processes. These companies are investing in research and development to improve distillation efficiency, reduce operational costs, and meet increasingly stringent product purity requirements.

Emerging markets, particularly in Asia-Pacific and the Middle East, are expected to drive significant growth in the heptane distillation market. Rapid industrialization, increasing chemical production capacities, and growing demand for high-purity solvents in these regions are creating new opportunities for technology providers and equipment manufacturers.

In conclusion, the industrial applications and market analysis for heptane distillation in multi-component systems reveal a dynamic and growing sector. The technology's importance across multiple industries, coupled with ongoing innovation and expanding global markets, suggests a positive outlook for the future of heptane distillation technologies and related products.

Current Challenges in Multi-Component Distillation

Multi-component distillation systems present several challenges in the context of heptane separation. One of the primary difficulties lies in the complex interactions between different components, which can significantly affect the vapor-liquid equilibrium and, consequently, the separation efficiency. The presence of multiple components often leads to the formation of azeotropes, making it challenging to achieve high purity levels of heptane through conventional distillation methods.

Another major challenge is the energy intensity of multi-component distillation processes. The separation of heptane from a mixture with similar boiling points requires substantial energy input, leading to high operational costs and environmental concerns. This issue is particularly pronounced in large-scale industrial applications where energy efficiency is crucial for economic viability.

The design and optimization of distillation columns for multi-component systems involving heptane pose significant difficulties. The complexity of the system makes it challenging to predict and control the behavior of different components throughout the column. This complexity often necessitates sophisticated modeling and simulation tools, which can be computationally intensive and time-consuming to develop and validate.

Furthermore, the presence of trace impurities in multi-component systems can have a disproportionate impact on the distillation dynamics of heptane. These impurities may alter the vapor-liquid equilibrium, affect the formation of azeotropes, or lead to fouling and corrosion issues in distillation equipment. Identifying and mitigating the effects of these trace components is a significant challenge in ensuring consistent and high-quality separation of heptane.

The variability in feed composition presents another hurdle in multi-component distillation systems. Fluctuations in the concentration of different components can lead to instabilities in the distillation process, requiring robust control systems and adaptive operational strategies. This variability is particularly challenging when dealing with industrial feedstocks that may have inconsistent compositions due to variations in upstream processes or raw material sources.

Lastly, the scale-up of laboratory or pilot-scale distillation processes to industrial-scale operations introduces additional complexities. Phenomena that may be negligible at smaller scales can become significant in large-scale distillation columns, affecting the overall performance and efficiency of heptane separation. Addressing these scale-up challenges requires careful consideration of hydrodynamics, mass transfer limitations, and heat transfer issues specific to multi-component systems.

Another major challenge is the energy intensity of multi-component distillation processes. The separation of heptane from a mixture with similar boiling points requires substantial energy input, leading to high operational costs and environmental concerns. This issue is particularly pronounced in large-scale industrial applications where energy efficiency is crucial for economic viability.

The design and optimization of distillation columns for multi-component systems involving heptane pose significant difficulties. The complexity of the system makes it challenging to predict and control the behavior of different components throughout the column. This complexity often necessitates sophisticated modeling and simulation tools, which can be computationally intensive and time-consuming to develop and validate.

Furthermore, the presence of trace impurities in multi-component systems can have a disproportionate impact on the distillation dynamics of heptane. These impurities may alter the vapor-liquid equilibrium, affect the formation of azeotropes, or lead to fouling and corrosion issues in distillation equipment. Identifying and mitigating the effects of these trace components is a significant challenge in ensuring consistent and high-quality separation of heptane.

The variability in feed composition presents another hurdle in multi-component distillation systems. Fluctuations in the concentration of different components can lead to instabilities in the distillation process, requiring robust control systems and adaptive operational strategies. This variability is particularly challenging when dealing with industrial feedstocks that may have inconsistent compositions due to variations in upstream processes or raw material sources.

Lastly, the scale-up of laboratory or pilot-scale distillation processes to industrial-scale operations introduces additional complexities. Phenomena that may be negligible at smaller scales can become significant in large-scale distillation columns, affecting the overall performance and efficiency of heptane separation. Addressing these scale-up challenges requires careful consideration of hydrodynamics, mass transfer limitations, and heat transfer issues specific to multi-component systems.

State-of-the-Art Distillation Methods

01 Distillation column design for heptane separation

Specialized distillation column designs are employed for efficient heptane separation. These designs may include features such as optimized tray configurations, packing materials, or reflux systems to enhance the separation of heptane from other components. The column design takes into account factors like vapor-liquid equilibrium, pressure drop, and mass transfer to improve the overall distillation dynamics.- Distillation column design for heptane separation: Specialized distillation column designs are employed for efficient heptane separation. These designs may include features such as optimized tray configurations, packing materials, or reflux systems to enhance the separation of heptane from other components. The column design takes into account factors like vapor-liquid equilibrium, pressure drop, and heat transfer to maximize the purity of the heptane product.

- Temperature and pressure control in heptane distillation: Precise control of temperature and pressure is crucial in heptane distillation dynamics. Advanced control systems are implemented to maintain optimal conditions throughout the distillation process. This may involve the use of temperature sensors, pressure regulators, and automated feedback loops to ensure consistent product quality and energy efficiency.

- Energy efficiency improvements in heptane distillation: Various techniques are employed to improve energy efficiency in heptane distillation processes. These may include heat integration systems, vapor recompression, and advanced heat exchanger designs. Such improvements aim to reduce energy consumption, lower operating costs, and minimize environmental impact while maintaining high product purity.

- Continuous vs. batch distillation for heptane: The choice between continuous and batch distillation processes for heptane separation depends on various factors such as production volume, desired purity, and operational flexibility. Continuous distillation is often preferred for large-scale production, while batch distillation may be more suitable for smaller volumes or when frequent changes in feed composition are expected. Each method has its own dynamics and control strategies.

- Modeling and simulation of heptane distillation dynamics: Advanced modeling and simulation techniques are used to optimize heptane distillation processes. These may include computational fluid dynamics (CFD), process simulation software, and machine learning algorithms. Such tools help in predicting distillation column behavior, optimizing operating parameters, and troubleshooting issues before they occur in real-world operations.

02 Temperature and pressure control in heptane distillation

Precise control of temperature and pressure is crucial for maintaining optimal heptane distillation dynamics. Advanced control systems are implemented to regulate these parameters throughout the distillation process. This ensures consistent product quality and energy efficiency. The control strategies may involve the use of sensors, feedback loops, and predictive models to adjust operating conditions in real-time.Expand Specific Solutions03 Energy efficiency improvements in heptane distillation

Various techniques are employed to enhance energy efficiency in heptane distillation processes. These may include heat integration systems, vapor recompression, and advanced heat exchanger designs. By optimizing energy usage, the overall cost and environmental impact of the distillation process can be reduced while maintaining or improving separation efficiency.Expand Specific Solutions04 Continuous monitoring and analysis of heptane distillation

Continuous monitoring and analysis systems are implemented to track the performance of heptane distillation processes. These systems may utilize online analyzers, spectroscopic techniques, or advanced data analytics to provide real-time information on product composition, impurities, and process efficiency. This enables rapid adjustments to maintain optimal distillation dynamics and product quality.Expand Specific Solutions05 Innovative separation techniques for heptane purification

Novel separation techniques are being developed to enhance heptane purification beyond traditional distillation. These may include membrane-based separations, adsorption processes, or hybrid systems combining multiple separation methods. Such innovations aim to improve separation efficiency, reduce energy consumption, and handle challenging separations where conventional distillation may be limited.Expand Specific Solutions

Key Players in Distillation Technology

The competitive landscape for "Distillation Dynamics of Heptane in Multi-Component Systems" is characterized by a mature market with established players and ongoing research. The industry is in a stable growth phase, with a global market size estimated in the billions. Major oil and chemical companies like ExxonMobil, Shell, and Sinopec are at the forefront, leveraging their extensive R&D capabilities. Academic institutions such as Tianjin University and Chongqing University contribute significantly to technological advancements. The technology's maturity is evident in the involvement of specialized firms like UOP LLC and Haldor Topsøe A/S, indicating a high level of expertise and refined processes in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced distillation technologies for heptane separation in multi-component systems. Their approach utilizes a combination of extractive distillation and pressure-swing distillation to achieve high purity heptane recovery[1]. The process employs a specially designed solvent system that enhances the relative volatility of heptane, allowing for more efficient separation from other hydrocarbons[2]. Sinopec's method incorporates a heat integration network to optimize energy consumption, reducing operating costs by up to 15% compared to conventional distillation[3]. Additionally, they have implemented advanced process control strategies using machine learning algorithms to maintain optimal column performance under varying feed compositions[4].

Strengths: High purity heptane recovery, reduced energy consumption, and adaptability to feed variations. Weaknesses: Complexity of the multi-column system and potential high capital costs for implementation.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered a novel approach to heptane distillation in multi-component systems using their proprietary Dual Independent Feed Tray (DIFT) technology[5]. This innovation allows for improved separation efficiency by introducing feeds at two different points in the distillation column, optimizing the concentration profiles and reducing the overall energy requirement[6]. The company has also developed advanced internals for their distillation columns, including high-performance structured packings that enhance mass transfer and reduce pressure drop[7]. ExxonMobil's process is further enhanced by the integration of a vapor recompression system, which recycles energy from the column overhead, leading to a significant reduction in steam consumption[8].

Strengths: Improved separation efficiency, reduced energy consumption, and innovative column design. Weaknesses: Potential higher initial investment and complexity in operation and maintenance.

Breakthrough Technologies in Separation Processes

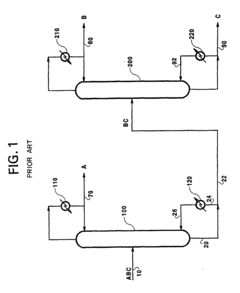

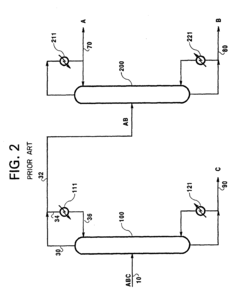

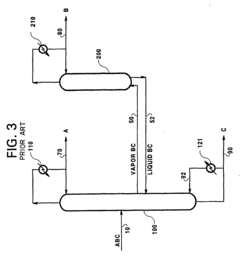

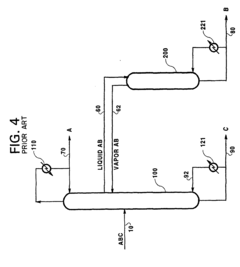

Distillation method and apparatus for multicomponent separations

PatentInactiveEP0948983B1

Innovation

- A distillation process involving at least two distillation columns with a two-way communication at one end and a one-way communication at the other end, allowing for efficient separation of ternary and multicomponent mixtures while reducing heat demand, by optimizing vapor and liquid stream transfers between columns.

Distillation process and multi-column heat-integrated distillation system

PatentWO2011131325A8

Innovation

- A multi-column heat-integrated distillation system where the bottom product from a first column is used as a utility stream to indirectly heat a second column, reducing the need for external heat and optimizing energy efficiency by adjusting pressure and temperature through adiabatic means, such as expansion valves, to minimize excess heat return and fuel gas usage.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of heptane distillation in multi-component systems are crucial aspects that demand thorough examination. The process of distillation, while effective for separating components, often requires significant energy input and can lead to substantial greenhouse gas emissions. In the context of heptane distillation, the energy-intensive nature of the process raises concerns about its carbon footprint and overall environmental sustainability.

One of the primary environmental challenges associated with heptane distillation is the potential for volatile organic compound (VOC) emissions. Heptane, being a highly volatile hydrocarbon, can easily escape into the atmosphere during the distillation process, contributing to air pollution and potentially impacting local air quality. This necessitates the implementation of robust emission control systems and strict adherence to environmental regulations to mitigate these risks.

Water usage and wastewater management are additional environmental considerations in heptane distillation. The cooling processes involved in distillation often require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Furthermore, the wastewater generated from the process may contain trace amounts of heptane and other hydrocarbons, necessitating proper treatment before discharge to prevent water pollution.

From a sustainability perspective, the reliance on fossil fuel-derived heptane raises questions about the long-term viability of the distillation process. As global efforts to transition towards renewable and sustainable resources intensify, there is growing pressure to explore alternative feedstocks or develop more environmentally friendly separation techniques that could replace traditional distillation methods for heptane and similar compounds.

Energy efficiency improvements in distillation processes represent a key area for enhancing the sustainability of heptane separation in multi-component systems. Techniques such as heat integration, advanced process control, and the use of more efficient distillation column designs can significantly reduce energy consumption and, consequently, the environmental impact of the process. Additionally, the exploration of alternative separation technologies, such as membrane-based processes or adsorption techniques, could offer more sustainable pathways for heptane recovery.

The lifecycle assessment of heptane distillation processes is essential for comprehensively evaluating their environmental impact. This includes considering the sourcing of raw materials, energy consumption during distillation, potential environmental releases, and the fate of byproducts and waste streams. Such assessments can guide the development of more sustainable practices and inform decision-making regarding process improvements or alternative technologies.

One of the primary environmental challenges associated with heptane distillation is the potential for volatile organic compound (VOC) emissions. Heptane, being a highly volatile hydrocarbon, can easily escape into the atmosphere during the distillation process, contributing to air pollution and potentially impacting local air quality. This necessitates the implementation of robust emission control systems and strict adherence to environmental regulations to mitigate these risks.

Water usage and wastewater management are additional environmental considerations in heptane distillation. The cooling processes involved in distillation often require substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Furthermore, the wastewater generated from the process may contain trace amounts of heptane and other hydrocarbons, necessitating proper treatment before discharge to prevent water pollution.

From a sustainability perspective, the reliance on fossil fuel-derived heptane raises questions about the long-term viability of the distillation process. As global efforts to transition towards renewable and sustainable resources intensify, there is growing pressure to explore alternative feedstocks or develop more environmentally friendly separation techniques that could replace traditional distillation methods for heptane and similar compounds.

Energy efficiency improvements in distillation processes represent a key area for enhancing the sustainability of heptane separation in multi-component systems. Techniques such as heat integration, advanced process control, and the use of more efficient distillation column designs can significantly reduce energy consumption and, consequently, the environmental impact of the process. Additionally, the exploration of alternative separation technologies, such as membrane-based processes or adsorption techniques, could offer more sustainable pathways for heptane recovery.

The lifecycle assessment of heptane distillation processes is essential for comprehensively evaluating their environmental impact. This includes considering the sourcing of raw materials, energy consumption during distillation, potential environmental releases, and the fate of byproducts and waste streams. Such assessments can guide the development of more sustainable practices and inform decision-making regarding process improvements or alternative technologies.

Economic Feasibility and Cost Analysis

The economic feasibility and cost analysis of heptane distillation in multi-component systems is a critical aspect for industrial applications. The capital expenditure (CAPEX) for setting up a distillation unit capable of handling multi-component systems with heptane is substantial, typically ranging from $5 million to $20 million, depending on the scale and complexity of the operation. This investment includes the cost of distillation columns, heat exchangers, pumps, and associated control systems.

Operating expenses (OPEX) for such systems are primarily driven by energy consumption, as distillation is an energy-intensive process. The energy costs can account for 50-70% of the total operating expenses. For a typical industrial-scale operation, annual energy costs may range from $500,000 to $2 million. Labor costs, maintenance, and replacement of equipment parts contribute to the remaining operational expenses.

The economic viability of heptane distillation in multi-component systems is heavily influenced by the market value of heptane and its derivatives. Current market prices for high-purity heptane range from $2,000 to $3,500 per metric ton, depending on quality and market conditions. The profitability of the operation is thus tied to the ability to achieve high purity levels and optimize the recovery rate of heptane from the multi-component mixture.

Efficiency improvements in the distillation process can significantly impact the economic feasibility. Advanced control systems and optimized column designs can reduce energy consumption by 10-20%, translating to substantial cost savings over the lifecycle of the plant. Additionally, heat integration techniques and the use of waste heat recovery systems can further improve the overall energy efficiency, potentially reducing operating costs by an additional 5-15%.

The scale of operation plays a crucial role in determining the economic viability. Larger-scale operations benefit from economies of scale, with per-unit production costs decreasing as capacity increases. However, this must be balanced against market demand and supply chain considerations to ensure optimal plant utilization.

Regulatory compliance and environmental considerations also factor into the cost analysis. Investments in emission control systems and safety measures to meet stringent environmental and safety standards can add 10-15% to the initial capital costs but are essential for long-term operational sustainability and risk mitigation.

In conclusion, while the initial investment and operating costs for heptane distillation in multi-component systems are significant, the economic feasibility remains attractive for many industrial applications, particularly in the chemical and petrochemical sectors. The key to ensuring profitability lies in optimizing process efficiency, maximizing product purity, and aligning production capacity with market demand.

Operating expenses (OPEX) for such systems are primarily driven by energy consumption, as distillation is an energy-intensive process. The energy costs can account for 50-70% of the total operating expenses. For a typical industrial-scale operation, annual energy costs may range from $500,000 to $2 million. Labor costs, maintenance, and replacement of equipment parts contribute to the remaining operational expenses.

The economic viability of heptane distillation in multi-component systems is heavily influenced by the market value of heptane and its derivatives. Current market prices for high-purity heptane range from $2,000 to $3,500 per metric ton, depending on quality and market conditions. The profitability of the operation is thus tied to the ability to achieve high purity levels and optimize the recovery rate of heptane from the multi-component mixture.

Efficiency improvements in the distillation process can significantly impact the economic feasibility. Advanced control systems and optimized column designs can reduce energy consumption by 10-20%, translating to substantial cost savings over the lifecycle of the plant. Additionally, heat integration techniques and the use of waste heat recovery systems can further improve the overall energy efficiency, potentially reducing operating costs by an additional 5-15%.

The scale of operation plays a crucial role in determining the economic viability. Larger-scale operations benefit from economies of scale, with per-unit production costs decreasing as capacity increases. However, this must be balanced against market demand and supply chain considerations to ensure optimal plant utilization.

Regulatory compliance and environmental considerations also factor into the cost analysis. Investments in emission control systems and safety measures to meet stringent environmental and safety standards can add 10-15% to the initial capital costs but are essential for long-term operational sustainability and risk mitigation.

In conclusion, while the initial investment and operating costs for heptane distillation in multi-component systems are significant, the economic feasibility remains attractive for many industrial applications, particularly in the chemical and petrochemical sectors. The key to ensuring profitability lies in optimizing process efficiency, maximizing product purity, and aligning production capacity with market demand.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!