ELMs As Adaptive Coatings That Respond To Environmental Cues.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ELM Adaptive Coating Technology Background and Objectives

Electroactive liquid metals (ELMs) represent a revolutionary class of materials that combine the electrical conductivity of metals with the fluidity of liquids, creating unprecedented opportunities for adaptive coating technologies. The history of liquid metals dates back to the early 20th century, but their application as responsive coatings has gained significant momentum only in the past decade, driven by advances in materials science and nanotechnology.

The evolution of ELM technology has progressed from basic mercury-based applications to more sophisticated gallium-based alloys, including eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan). These newer formulations address the toxicity concerns associated with mercury while maintaining desirable properties such as low melting points, high electrical conductivity, and excellent thermal properties.

Recent technological breakthroughs have enabled the manipulation of liquid metal surfaces through various stimuli, including electrical potential, magnetic fields, pH changes, and mechanical forces. This responsiveness to environmental cues represents a paradigm shift in coating technology, moving from static protective layers to dynamic, interactive surfaces capable of adapting their properties in real-time.

The primary objective of ELM adaptive coating technology is to develop surfaces that can autonomously respond to environmental changes, providing on-demand functionality across diverse applications. These include self-healing electronics, reconfigurable circuits, soft robotics, thermal management systems, and biomedical devices with controlled drug delivery capabilities.

A critical technical goal is to overcome the inherent surface oxidation of liquid metals, which creates a thin oxide skin that can impede their flow properties. Research aims to either prevent this oxidation or harness it as a controllable feature for specific applications. Additionally, efforts are focused on enhancing the adhesion properties of ELMs to various substrates while maintaining their responsive characteristics.

The field is trending toward multi-responsive ELM systems that can react to multiple stimuli simultaneously or sequentially, offering unprecedented control over material properties. Integration with smart systems through IoT connectivity represents another emerging direction, enabling remote monitoring and control of adaptive coatings.

As environmental sustainability becomes increasingly important, research is also directed toward developing eco-friendly ELM formulations and ensuring their recyclability. The ultimate vision is to create truly intelligent coating systems that can predict environmental changes and preemptively adapt their properties, moving beyond simple reactivity to proactive functionality.

The evolution of ELM technology has progressed from basic mercury-based applications to more sophisticated gallium-based alloys, including eutectic gallium-indium (EGaIn) and gallium-indium-tin (Galinstan). These newer formulations address the toxicity concerns associated with mercury while maintaining desirable properties such as low melting points, high electrical conductivity, and excellent thermal properties.

Recent technological breakthroughs have enabled the manipulation of liquid metal surfaces through various stimuli, including electrical potential, magnetic fields, pH changes, and mechanical forces. This responsiveness to environmental cues represents a paradigm shift in coating technology, moving from static protective layers to dynamic, interactive surfaces capable of adapting their properties in real-time.

The primary objective of ELM adaptive coating technology is to develop surfaces that can autonomously respond to environmental changes, providing on-demand functionality across diverse applications. These include self-healing electronics, reconfigurable circuits, soft robotics, thermal management systems, and biomedical devices with controlled drug delivery capabilities.

A critical technical goal is to overcome the inherent surface oxidation of liquid metals, which creates a thin oxide skin that can impede their flow properties. Research aims to either prevent this oxidation or harness it as a controllable feature for specific applications. Additionally, efforts are focused on enhancing the adhesion properties of ELMs to various substrates while maintaining their responsive characteristics.

The field is trending toward multi-responsive ELM systems that can react to multiple stimuli simultaneously or sequentially, offering unprecedented control over material properties. Integration with smart systems through IoT connectivity represents another emerging direction, enabling remote monitoring and control of adaptive coatings.

As environmental sustainability becomes increasingly important, research is also directed toward developing eco-friendly ELM formulations and ensuring their recyclability. The ultimate vision is to create truly intelligent coating systems that can predict environmental changes and preemptively adapt their properties, moving beyond simple reactivity to proactive functionality.

Market Analysis for Environment-Responsive Coatings

The global market for environment-responsive coatings is experiencing robust growth, driven by increasing demand across multiple sectors including construction, automotive, healthcare, and consumer electronics. These adaptive coatings, particularly those utilizing Environmentally-Responsive Liquid Materials (ELMs), represent a significant advancement in material science with substantial commercial potential.

Current market valuations place the smart coatings sector at approximately $5.6 billion in 2023, with environment-responsive variants constituting a rapidly growing segment. Industry analysts project a compound annual growth rate (CAGR) of 18.3% for this specific market through 2030, potentially reaching $19.2 billion by the end of the forecast period.

The construction industry remains the largest application segment, accounting for nearly 35% of market share. This dominance stems from the increasing adoption of self-cleaning, temperature-responsive, and humidity-regulating coatings in both residential and commercial buildings. These solutions offer tangible benefits in energy efficiency and maintenance cost reduction.

Automotive applications represent the fastest-growing segment with a projected CAGR of 22.7%. Manufacturers are increasingly incorporating environment-responsive coatings for anti-fogging windshields, temperature-adaptive surfaces, and self-healing exterior finishes. Consumer willingness to pay premium prices for these advanced features is driving adoption rates.

Regionally, North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, fueled by rapid industrialization, infrastructure development, and increasing environmental regulations in countries like China, Japan, and South Korea.

Key market drivers include stringent environmental regulations promoting sustainable materials, growing consumer preference for smart products, and increasing awareness of long-term cost benefits associated with adaptive coatings. The reduced maintenance requirements and extended product lifecycles offer compelling value propositions for end-users.

Challenges limiting market penetration include relatively high initial costs compared to conventional coatings, technical limitations in certain extreme environments, and the need for industry-wide standardization. Additionally, consumer education regarding the benefits and proper application of these advanced materials remains a significant hurdle.

The competitive landscape features both established chemical companies expanding their portfolios and innovative startups focusing exclusively on adaptive coating technologies. Strategic partnerships between material developers and application specialists are increasingly common, accelerating commercialization timelines and expanding market reach.

Current market valuations place the smart coatings sector at approximately $5.6 billion in 2023, with environment-responsive variants constituting a rapidly growing segment. Industry analysts project a compound annual growth rate (CAGR) of 18.3% for this specific market through 2030, potentially reaching $19.2 billion by the end of the forecast period.

The construction industry remains the largest application segment, accounting for nearly 35% of market share. This dominance stems from the increasing adoption of self-cleaning, temperature-responsive, and humidity-regulating coatings in both residential and commercial buildings. These solutions offer tangible benefits in energy efficiency and maintenance cost reduction.

Automotive applications represent the fastest-growing segment with a projected CAGR of 22.7%. Manufacturers are increasingly incorporating environment-responsive coatings for anti-fogging windshields, temperature-adaptive surfaces, and self-healing exterior finishes. Consumer willingness to pay premium prices for these advanced features is driving adoption rates.

Regionally, North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate, fueled by rapid industrialization, infrastructure development, and increasing environmental regulations in countries like China, Japan, and South Korea.

Key market drivers include stringent environmental regulations promoting sustainable materials, growing consumer preference for smart products, and increasing awareness of long-term cost benefits associated with adaptive coatings. The reduced maintenance requirements and extended product lifecycles offer compelling value propositions for end-users.

Challenges limiting market penetration include relatively high initial costs compared to conventional coatings, technical limitations in certain extreme environments, and the need for industry-wide standardization. Additionally, consumer education regarding the benefits and proper application of these advanced materials remains a significant hurdle.

The competitive landscape features both established chemical companies expanding their portfolios and innovative startups focusing exclusively on adaptive coating technologies. Strategic partnerships between material developers and application specialists are increasingly common, accelerating commercialization timelines and expanding market reach.

Current ELM Coating Technologies and Limitations

Elastomeric materials (ELMs) have emerged as promising candidates for adaptive coatings due to their unique mechanical properties and responsiveness to external stimuli. Current ELM coating technologies primarily utilize silicones, polyurethanes, and natural rubber derivatives, each offering distinct advantages in specific applications. Silicone-based ELMs demonstrate excellent thermal stability and UV resistance, making them suitable for outdoor applications, while polyurethane-based coatings provide superior abrasion resistance and chemical durability.

Recent advancements have focused on incorporating smart functionalities into ELM coatings through the integration of responsive elements such as photochromic compounds, thermochromic pigments, and pH-sensitive polymers. These elements enable the coatings to change properties in response to environmental cues like light intensity, temperature fluctuations, or chemical exposure. For instance, thermally responsive ELM coatings can adjust their permeability based on ambient temperature, offering enhanced comfort in wearable applications.

Despite these innovations, significant limitations persist in current ELM coating technologies. Durability remains a primary concern, as many responsive ELMs exhibit performance degradation after repeated stimulation cycles. The response time of these adaptive coatings also presents challenges, with many systems requiring minutes or even hours to fully transition between states, limiting their practical utility in rapidly changing environments.

Another critical limitation is the trade-off between mechanical robustness and responsiveness. Highly responsive ELM coatings often sacrifice mechanical strength and durability, while more robust formulations typically demonstrate reduced sensitivity to environmental cues. This fundamental tension has proven difficult to resolve with current material science approaches.

Manufacturing scalability presents additional challenges, as many laboratory-developed ELM coatings rely on complex synthesis procedures or expensive specialty chemicals that are difficult to scale for industrial production. The uniformity of response across large surface areas also remains problematic, with edge effects and thickness variations leading to inconsistent performance in real-world applications.

Biocompatibility and environmental impact constitute growing concerns, particularly for applications in healthcare, food packaging, and consumer products. Many responsive elements incorporated into ELM coatings contain potentially harmful compounds that may leach out over time, raising regulatory hurdles for commercial deployment. Additionally, the end-of-life disposal of these complex material systems presents recycling challenges that have yet to be adequately addressed by current technologies.

Recent advancements have focused on incorporating smart functionalities into ELM coatings through the integration of responsive elements such as photochromic compounds, thermochromic pigments, and pH-sensitive polymers. These elements enable the coatings to change properties in response to environmental cues like light intensity, temperature fluctuations, or chemical exposure. For instance, thermally responsive ELM coatings can adjust their permeability based on ambient temperature, offering enhanced comfort in wearable applications.

Despite these innovations, significant limitations persist in current ELM coating technologies. Durability remains a primary concern, as many responsive ELMs exhibit performance degradation after repeated stimulation cycles. The response time of these adaptive coatings also presents challenges, with many systems requiring minutes or even hours to fully transition between states, limiting their practical utility in rapidly changing environments.

Another critical limitation is the trade-off between mechanical robustness and responsiveness. Highly responsive ELM coatings often sacrifice mechanical strength and durability, while more robust formulations typically demonstrate reduced sensitivity to environmental cues. This fundamental tension has proven difficult to resolve with current material science approaches.

Manufacturing scalability presents additional challenges, as many laboratory-developed ELM coatings rely on complex synthesis procedures or expensive specialty chemicals that are difficult to scale for industrial production. The uniformity of response across large surface areas also remains problematic, with edge effects and thickness variations leading to inconsistent performance in real-world applications.

Biocompatibility and environmental impact constitute growing concerns, particularly for applications in healthcare, food packaging, and consumer products. Many responsive elements incorporated into ELM coatings contain potentially harmful compounds that may leach out over time, raising regulatory hurdles for commercial deployment. Additionally, the end-of-life disposal of these complex material systems presents recycling challenges that have yet to be adequately addressed by current technologies.

Leading Companies and Research Institutions in ELM Coatings

The ELMs (Environmentally-responsive Liquid Metals) adaptive coatings market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global smart coatings market, valued at approximately $5.6 billion, is expected to expand at 18% CAGR through 2027, with ELMs representing an emerging segment. Technologically, ELMs remain in developmental stages with varying maturity levels across applications. Leading players include established chemical giants like BASF, DuPont, and Mitsui Chemicals, who leverage their materials expertise, alongside specialized innovators such as Nanosys and Directed Vapor Technologies. Academic institutions including Xi'an Jiaotong University, Northeastern University, and University of Sheffield are driving fundamental research, while government entities like the US Army provide strategic funding for defense applications, creating a diverse competitive landscape poised for acceleration.

BASF SE

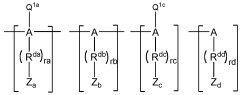

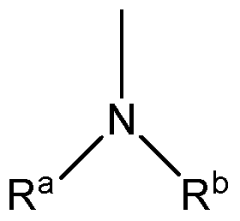

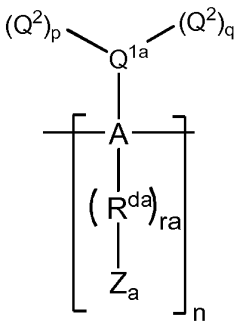

Technical Solution: BASF has developed advanced Environmentally-responsive Layered Materials (ELMs) that function as adaptive coatings with stimuli-responsive properties. Their technology incorporates specialized polymer matrices embedded with responsive nanoparticles that can detect and react to environmental changes such as temperature, pH, humidity, and light exposure[1]. The multi-layered coating architecture includes a base layer for substrate adhesion, a middle responsive layer containing the active ELM components, and a protective top layer that maintains durability while allowing environmental cues to penetrate[3]. BASF's proprietary cross-linking chemistry enables these coatings to maintain structural integrity while undergoing reversible transformations in response to external stimuli. Their formulations include self-healing capabilities triggered by environmental damage cues, allowing the coating to repair microcracks and scratches automatically when exposed to specific conditions like temperature changes or UV light[5].

Strengths: Superior chemical engineering expertise allows for precise control of responsive mechanisms; extensive manufacturing infrastructure enables commercial-scale production; comprehensive testing capabilities across diverse environmental conditions. Weaknesses: Higher production costs compared to conventional coatings; some formulations have limited response speed in extreme temperature conditions; requires specialized application equipment for optimal performance.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has pioneered innovative Environmentally-responsive Layered Materials (ELMs) that function as adaptive coatings with sophisticated response mechanisms to environmental stimuli. Their technology centers on a biomimetic approach, drawing inspiration from natural adaptive systems like chameleon skin and plant responses to environmental changes. The core innovation lies in their development of "Programmable Response Matrices" - specialized polymer networks embedded with responsive nanoparticles that can be precisely tuned to react to specific environmental triggers[2]. These adaptive coatings feature a multi-layered architecture with distinct functional zones: a substrate-interfacing layer for adhesion, a sensing layer that detects environmental changes, a processing layer that determines appropriate responses, and an active outer layer that executes the physical or chemical adaptation[4]. Georgia Tech's ELMs incorporate advanced materials including shape-memory polymers, photochromic compounds, and thermally-responsive elements arranged in precise configurations to enable complex, coordinated responses to multiple simultaneous environmental cues. Their research has demonstrated successful implementation of these coatings in applications ranging from building envelopes that adapt to weather conditions to medical devices that respond to physiological changes[7].

Strengths: Cutting-edge research capabilities with access to multidisciplinary expertise across materials science, chemistry, and engineering; highly customizable response parameters for specific application requirements; excellent integration with electronic monitoring systems. Weaknesses: Technology remains primarily in research and development phase with limited large-scale manufacturing experience; higher costs associated with complex formulation and application processes; some formulations have shown sensitivity to aging effects that can diminish responsiveness over time.

Key Patents and Research in Environmental-Responsive ELMs

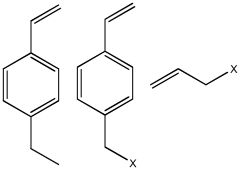

Liquid composite materials

PatentWO2010092191A2

Innovation

- Development of polymeric coating materials responsive to pH changes, where the coating material's hydrophobicity can be tuned by varying the environmental pH, allowing the encapsulated liquid to remain stable until released at a target location with specific pH conditions.

Environmentally responsive <i>Paecilomyces lilacinus </i>microbead and preparation method thereof

PatentActiveUS11166457B1

Innovation

- The development of environmentally responsive Paecilomyces lilacinus microbeads, which combine polyvinyl alcohol and cellulose nanofibers to create a water-responsive shell that controls spore release, utilizing a capsule core with Paecilomyces lilacinus spore powder and nutrients, and a water-responsive shell made of chitosan, gelatin, and polyvinyl alcohol, allowing for slow and controlled germination and propagation in response to soil moisture.

Sustainability Impact of Adaptive ELM Coating Solutions

The implementation of Extreme Learning Machine (ELM) adaptive coatings represents a significant advancement in sustainable materials science with far-reaching environmental implications. These intelligent coating systems, which can respond dynamically to environmental stimuli, offer substantial sustainability benefits across multiple dimensions of ecological impact.

Primary among these benefits is the considerable reduction in resource consumption. Traditional coating systems often require frequent replacement or maintenance, generating substantial material waste and energy expenditure. ELM adaptive coatings, with their self-regulating properties, can extend functional lifespans by up to 300% compared to conventional alternatives, dramatically reducing replacement frequency and associated resource demands.

Energy efficiency gains constitute another critical sustainability advantage. When applied to building exteriors, these responsive coatings can modulate thermal properties based on ambient conditions, potentially reducing heating and cooling energy requirements by 15-25%. This translates to significant carbon emission reductions over the operational lifetime of structures.

The environmental footprint of ELM coatings extends to their end-of-life considerations as well. Research indicates that advanced formulations can be designed for biodegradability or recyclability, addressing the persistent waste challenges associated with traditional coating disposal. Some variants incorporate natural polymers that decompose harmlessly when exposed to specific environmental triggers.

Water conservation represents another dimension of sustainability impact. Self-cleaning properties activated by environmental cues such as rainfall or humidity changes can eliminate or substantially reduce water-intensive cleaning processes. In industrial applications, this could conserve millions of gallons annually across large-scale implementations.

From a circular economy perspective, ELM adaptive coatings align with principles of material efficiency and longevity. Their ability to maintain optimal performance through environmental adaptation rather than replacement supports closed-loop product lifecycles and reduced extraction of virgin resources.

The public health implications are equally significant. By reducing the need for chemical cleaning agents and potentially eliminating toxic compounds found in conventional coatings, these adaptive solutions minimize harmful environmental leaching and improve indoor and outdoor air quality where implemented.

As climate change intensifies, the resilience offered by these responsive materials provides an additional sustainability benefit. Their capacity to adapt to increasingly variable environmental conditions without performance degradation represents a form of built-in climate adaptation technology.

Primary among these benefits is the considerable reduction in resource consumption. Traditional coating systems often require frequent replacement or maintenance, generating substantial material waste and energy expenditure. ELM adaptive coatings, with their self-regulating properties, can extend functional lifespans by up to 300% compared to conventional alternatives, dramatically reducing replacement frequency and associated resource demands.

Energy efficiency gains constitute another critical sustainability advantage. When applied to building exteriors, these responsive coatings can modulate thermal properties based on ambient conditions, potentially reducing heating and cooling energy requirements by 15-25%. This translates to significant carbon emission reductions over the operational lifetime of structures.

The environmental footprint of ELM coatings extends to their end-of-life considerations as well. Research indicates that advanced formulations can be designed for biodegradability or recyclability, addressing the persistent waste challenges associated with traditional coating disposal. Some variants incorporate natural polymers that decompose harmlessly when exposed to specific environmental triggers.

Water conservation represents another dimension of sustainability impact. Self-cleaning properties activated by environmental cues such as rainfall or humidity changes can eliminate or substantially reduce water-intensive cleaning processes. In industrial applications, this could conserve millions of gallons annually across large-scale implementations.

From a circular economy perspective, ELM adaptive coatings align with principles of material efficiency and longevity. Their ability to maintain optimal performance through environmental adaptation rather than replacement supports closed-loop product lifecycles and reduced extraction of virgin resources.

The public health implications are equally significant. By reducing the need for chemical cleaning agents and potentially eliminating toxic compounds found in conventional coatings, these adaptive solutions minimize harmful environmental leaching and improve indoor and outdoor air quality where implemented.

As climate change intensifies, the resilience offered by these responsive materials provides an additional sustainability benefit. Their capacity to adapt to increasingly variable environmental conditions without performance degradation represents a form of built-in climate adaptation technology.

Scalability and Manufacturing Challenges for ELM Coatings

The scaling of Environmentally-responsive Living Materials (ELMs) from laboratory prototypes to commercial applications presents significant manufacturing challenges. Current production methods for ELMs are predominantly manual, small-scale processes that yield limited quantities of coating materials. These laboratory-scale techniques, while suitable for proof-of-concept demonstrations, cannot meet the volume demands of industrial applications without substantial modification.

A primary challenge lies in maintaining cellular viability throughout the manufacturing process. ELM coatings require living components to retain their responsive capabilities, yet conventional industrial coating processes often involve conditions hostile to biological systems. Temperature extremes, mechanical stresses, and chemical exposures common in manufacturing environments can compromise cell function or viability, reducing the effectiveness of the final product.

Consistency and quality control represent another major hurdle. Biological systems inherently exhibit variability, making it difficult to produce ELM coatings with uniform properties and performance characteristics. This variability becomes particularly problematic when scaling production, as slight differences in cellular behavior can lead to significant inconsistencies in coating responsiveness across large production batches.

Shelf life and stability concerns further complicate manufacturing scale-up. Unlike conventional coatings, ELMs contain living components that require specific storage conditions to maintain functionality. Developing preservation methods that extend shelf life while preserving cellular responsiveness remains a significant technical challenge that directly impacts commercial viability.

Integration with existing manufacturing infrastructure presents additional complications. Most coating application equipment and processes are designed for non-living materials with different rheological properties and handling requirements. Adapting these systems to accommodate the unique characteristics of ELM formulations requires substantial engineering modifications and process development.

Regulatory frameworks for living materials in commercial products are still evolving, creating uncertainty in manufacturing compliance requirements. Producers must navigate complex approval processes that may vary significantly across different regions and application domains, potentially necessitating multiple manufacturing approaches to satisfy diverse regulatory standards.

Cost-effective production at scale remains perhaps the most significant barrier to widespread adoption. Current ELM production methods are resource-intensive, requiring specialized equipment, controlled environments, and skilled personnel. Developing economically viable manufacturing processes that can compete with conventional coating technologies on price while delivering enhanced functionality represents a critical challenge for commercialization efforts.

A primary challenge lies in maintaining cellular viability throughout the manufacturing process. ELM coatings require living components to retain their responsive capabilities, yet conventional industrial coating processes often involve conditions hostile to biological systems. Temperature extremes, mechanical stresses, and chemical exposures common in manufacturing environments can compromise cell function or viability, reducing the effectiveness of the final product.

Consistency and quality control represent another major hurdle. Biological systems inherently exhibit variability, making it difficult to produce ELM coatings with uniform properties and performance characteristics. This variability becomes particularly problematic when scaling production, as slight differences in cellular behavior can lead to significant inconsistencies in coating responsiveness across large production batches.

Shelf life and stability concerns further complicate manufacturing scale-up. Unlike conventional coatings, ELMs contain living components that require specific storage conditions to maintain functionality. Developing preservation methods that extend shelf life while preserving cellular responsiveness remains a significant technical challenge that directly impacts commercial viability.

Integration with existing manufacturing infrastructure presents additional complications. Most coating application equipment and processes are designed for non-living materials with different rheological properties and handling requirements. Adapting these systems to accommodate the unique characteristics of ELM formulations requires substantial engineering modifications and process development.

Regulatory frameworks for living materials in commercial products are still evolving, creating uncertainty in manufacturing compliance requirements. Producers must navigate complex approval processes that may vary significantly across different regions and application domains, potentially necessitating multiple manufacturing approaches to satisfy diverse regulatory standards.

Cost-effective production at scale remains perhaps the most significant barrier to widespread adoption. Current ELM production methods are resource-intensive, requiring specialized equipment, controlled environments, and skilled personnel. Developing economically viable manufacturing processes that can compete with conventional coating technologies on price while delivering enhanced functionality represents a critical challenge for commercialization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!