ELMs For Capturing And Degrading Microplastics In Water.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microplastics Remediation Technology Background and Objectives

Microplastics pollution has emerged as one of the most pressing environmental challenges of the 21st century. These tiny plastic particles, typically less than 5mm in size, originate from the breakdown of larger plastic waste and direct sources such as microbeads in personal care products. Their ubiquitous presence in aquatic environments poses significant threats to ecosystems, marine life, and potentially human health through bioaccumulation in the food chain.

The evolution of microplastics remediation technologies has progressed through several distinct phases. Initially, conventional water treatment methods such as filtration and sedimentation were applied with limited success due to the small size and variable properties of microplastics. This led to the development of more specialized approaches including advanced membrane filtration, coagulation-flocculation processes, and biological treatment systems in the early 2010s.

Recent technological advancements have shifted focus toward more sustainable and efficient solutions, with Engineered Living Materials (ELMs) representing a cutting-edge approach. ELMs combine biological components with engineered materials to create functional systems capable of both capturing and degrading microplastics. This represents a significant paradigm shift from mere removal to actual degradation of these persistent pollutants.

The global concern regarding microplastics has intensified research efforts, with notable acceleration following the 2015 United Nations Sustainable Development Goals, particularly Goal 14 (Life Below Water) and Goal 6 (Clean Water and Sanitation). Scientific publications on microplastics remediation have increased exponentially, with over 500% growth in research output between 2015 and 2023.

The primary objective of ELMs technology for microplastics remediation is to develop scalable, environmentally friendly systems that can effectively capture microplastics from various water bodies and subsequently degrade them into non-toxic components. This dual functionality aims to address the limitations of conventional technologies that merely transfer pollution from one medium to another without addressing the fundamental problem of plastic persistence.

Secondary objectives include minimizing energy consumption, reducing operational costs compared to conventional methods, and ensuring compatibility with existing water treatment infrastructure to facilitate widespread adoption. Additionally, the technology aims to function across diverse environmental conditions, addressing microplastics of varying compositions, sizes, and concentrations.

The ultimate goal is to create a sustainable solution that can be implemented globally, particularly in regions with limited resources for advanced water treatment, thereby democratizing access to effective microplastics remediation technology and contributing to the restoration of aquatic ecosystem health worldwide.

The evolution of microplastics remediation technologies has progressed through several distinct phases. Initially, conventional water treatment methods such as filtration and sedimentation were applied with limited success due to the small size and variable properties of microplastics. This led to the development of more specialized approaches including advanced membrane filtration, coagulation-flocculation processes, and biological treatment systems in the early 2010s.

Recent technological advancements have shifted focus toward more sustainable and efficient solutions, with Engineered Living Materials (ELMs) representing a cutting-edge approach. ELMs combine biological components with engineered materials to create functional systems capable of both capturing and degrading microplastics. This represents a significant paradigm shift from mere removal to actual degradation of these persistent pollutants.

The global concern regarding microplastics has intensified research efforts, with notable acceleration following the 2015 United Nations Sustainable Development Goals, particularly Goal 14 (Life Below Water) and Goal 6 (Clean Water and Sanitation). Scientific publications on microplastics remediation have increased exponentially, with over 500% growth in research output between 2015 and 2023.

The primary objective of ELMs technology for microplastics remediation is to develop scalable, environmentally friendly systems that can effectively capture microplastics from various water bodies and subsequently degrade them into non-toxic components. This dual functionality aims to address the limitations of conventional technologies that merely transfer pollution from one medium to another without addressing the fundamental problem of plastic persistence.

Secondary objectives include minimizing energy consumption, reducing operational costs compared to conventional methods, and ensuring compatibility with existing water treatment infrastructure to facilitate widespread adoption. Additionally, the technology aims to function across diverse environmental conditions, addressing microplastics of varying compositions, sizes, and concentrations.

The ultimate goal is to create a sustainable solution that can be implemented globally, particularly in regions with limited resources for advanced water treatment, thereby democratizing access to effective microplastics remediation technology and contributing to the restoration of aquatic ecosystem health worldwide.

Market Analysis for Water Purification Technologies

The global water purification market is experiencing significant growth, driven by increasing concerns about water pollution and the presence of emerging contaminants such as microplastics. The market was valued at approximately $29.6 billion in 2021 and is projected to reach $51.7 billion by 2028, growing at a CAGR of 7.9%. Within this broader market, technologies specifically targeting microplastic removal represent a rapidly expanding segment due to heightened awareness of microplastic pollution in water sources worldwide.

Consumer demand for advanced water purification solutions has shifted dramatically in recent years, with end-users increasingly seeking technologies that address not only traditional contaminants but also emerging pollutants like microplastics. This trend is particularly evident in regions facing severe water scarcity and pollution challenges, including parts of Asia-Pacific, North America, and Europe. Market research indicates that 78% of consumers now express concern about microplastics in drinking water, compared to just 31% five years ago.

The industrial sector represents the largest market segment for microplastic removal technologies, accounting for 43% of the total market share. Municipal water treatment facilities follow closely at 38%, while residential applications constitute 19% of the market. The industrial segment's dominance is attributed to stringent regulations regarding wastewater discharge and increasing corporate sustainability initiatives.

Regionally, North America currently leads the market for advanced water purification technologies targeting microplastics, holding 34% of the global market share. The Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure. Europe accounts for 28% of the market, with particularly strong adoption in countries like Germany, France, and the Netherlands.

The competitive landscape for ELMs (Engineered Living Materials) and other microplastic degradation technologies is still developing, with several key players emerging. Established water treatment companies are increasingly investing in R&D for microplastic removal capabilities, while specialized startups focused exclusively on microplastic degradation technologies are gaining significant venture capital funding. In 2022 alone, investments in startups developing microplastic removal technologies exceeded $450 million globally.

Market forecasts suggest that technologies combining capture and degradation capabilities, such as ELMs, will see particularly strong growth, with an estimated CAGR of 12.3% through 2028. This accelerated growth is supported by increasing regulatory pressure, with 27 countries having introduced or proposed legislation specifically addressing microplastic pollution in water systems since 2020.

Consumer demand for advanced water purification solutions has shifted dramatically in recent years, with end-users increasingly seeking technologies that address not only traditional contaminants but also emerging pollutants like microplastics. This trend is particularly evident in regions facing severe water scarcity and pollution challenges, including parts of Asia-Pacific, North America, and Europe. Market research indicates that 78% of consumers now express concern about microplastics in drinking water, compared to just 31% five years ago.

The industrial sector represents the largest market segment for microplastic removal technologies, accounting for 43% of the total market share. Municipal water treatment facilities follow closely at 38%, while residential applications constitute 19% of the market. The industrial segment's dominance is attributed to stringent regulations regarding wastewater discharge and increasing corporate sustainability initiatives.

Regionally, North America currently leads the market for advanced water purification technologies targeting microplastics, holding 34% of the global market share. The Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure. Europe accounts for 28% of the market, with particularly strong adoption in countries like Germany, France, and the Netherlands.

The competitive landscape for ELMs (Engineered Living Materials) and other microplastic degradation technologies is still developing, with several key players emerging. Established water treatment companies are increasingly investing in R&D for microplastic removal capabilities, while specialized startups focused exclusively on microplastic degradation technologies are gaining significant venture capital funding. In 2022 alone, investments in startups developing microplastic removal technologies exceeded $450 million globally.

Market forecasts suggest that technologies combining capture and degradation capabilities, such as ELMs, will see particularly strong growth, with an estimated CAGR of 12.3% through 2028. This accelerated growth is supported by increasing regulatory pressure, with 27 countries having introduced or proposed legislation specifically addressing microplastic pollution in water systems since 2020.

ELMs Technology Status and Implementation Challenges

The current state of Engineered Living Materials (ELMs) for microplastic remediation represents a promising yet challenging frontier in environmental biotechnology. Recent advancements have demonstrated the potential of genetically engineered microorganisms to both capture and degrade microplastics in aquatic environments. Several research groups have successfully developed bacterial strains with enhanced adhesion properties that can effectively bind to various types of microplastics, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET).

Laboratory-scale studies have shown degradation efficiencies ranging from 15% to 43% for different microplastic types under controlled conditions. The most significant progress has been made with PET-degrading enzymes, where engineered variants have achieved up to 90% degradation rates in optimal conditions. However, these results have primarily been obtained in laboratory settings with purified microplastics, and performance decreases substantially in complex environmental matrices.

Field implementation of ELMs technology faces several critical challenges. Containment of engineered organisms remains a primary concern, as release into natural ecosystems could have unintended ecological consequences. Current containment strategies include physical barriers, kill switches, and auxotrophic dependencies, but none provide absolute containment guarantees in open water systems.

Scaling issues present another significant hurdle. Most successful demonstrations have been limited to small-scale reactors (1-10L), while real-world applications would require treatment of millions of liters of water. The metabolic burden of expressing foreign proteins often results in reduced fitness and growth rates of engineered organisms, limiting their persistence and effectiveness in environmental applications.

Regulatory frameworks for the deployment of engineered organisms in environmental remediation remain underdeveloped in most countries. The lack of standardized risk assessment protocols and clear regulatory pathways creates uncertainty for technology developers and potential adopters.

Technical challenges include the limited substrate specificity of current plastic-degrading enzymes, which often work efficiently on only one type of plastic. Additionally, the slow kinetics of plastic degradation (often requiring weeks to months for significant degradation) poses practical limitations for water treatment applications where residence times are typically measured in hours or days.

The stability of engineered organisms in variable environmental conditions represents another major challenge. Fluctuations in temperature, pH, salinity, and the presence of competing microorganisms can dramatically reduce the effectiveness of ELMs in real-world settings. Recent efforts have focused on enhancing robustness through adaptive laboratory evolution and the incorporation of stress-response elements, but significant improvements are still needed.

Laboratory-scale studies have shown degradation efficiencies ranging from 15% to 43% for different microplastic types under controlled conditions. The most significant progress has been made with PET-degrading enzymes, where engineered variants have achieved up to 90% degradation rates in optimal conditions. However, these results have primarily been obtained in laboratory settings with purified microplastics, and performance decreases substantially in complex environmental matrices.

Field implementation of ELMs technology faces several critical challenges. Containment of engineered organisms remains a primary concern, as release into natural ecosystems could have unintended ecological consequences. Current containment strategies include physical barriers, kill switches, and auxotrophic dependencies, but none provide absolute containment guarantees in open water systems.

Scaling issues present another significant hurdle. Most successful demonstrations have been limited to small-scale reactors (1-10L), while real-world applications would require treatment of millions of liters of water. The metabolic burden of expressing foreign proteins often results in reduced fitness and growth rates of engineered organisms, limiting their persistence and effectiveness in environmental applications.

Regulatory frameworks for the deployment of engineered organisms in environmental remediation remain underdeveloped in most countries. The lack of standardized risk assessment protocols and clear regulatory pathways creates uncertainty for technology developers and potential adopters.

Technical challenges include the limited substrate specificity of current plastic-degrading enzymes, which often work efficiently on only one type of plastic. Additionally, the slow kinetics of plastic degradation (often requiring weeks to months for significant degradation) poses practical limitations for water treatment applications where residence times are typically measured in hours or days.

The stability of engineered organisms in variable environmental conditions represents another major challenge. Fluctuations in temperature, pH, salinity, and the presence of competing microorganisms can dramatically reduce the effectiveness of ELMs in real-world settings. Recent efforts have focused on enhancing robustness through adaptive laboratory evolution and the incorporation of stress-response elements, but significant improvements are still needed.

Current ELMs-Based Solutions for Microplastic Degradation

01 Engineered living materials for pollutant capture and degradation

Engineered living materials (ELMs) can be designed to capture and degrade environmental pollutants. These materials incorporate microorganisms such as bacteria or fungi that have been engineered to target specific contaminants. The living components can actively bind to pollutants and break them down into less harmful substances through metabolic processes. This approach offers advantages over traditional remediation methods due to the self-regenerating nature of the biological components and their ability to adapt to changing conditions.- Engineered living materials for pollutant capture and degradation: Engineered living materials (ELMs) can be designed to capture and degrade environmental pollutants. These materials incorporate microorganisms with specific metabolic pathways capable of breaking down toxic compounds. The living components are typically embedded in a supportive matrix that provides structural integrity while allowing for nutrient flow and waste removal. These systems can be deployed for environmental remediation of contaminated soil, water, or air, offering sustainable solutions for pollution management.

- Microbial-based ELMs for carbon capture: Specialized engineered living materials incorporate photosynthetic microorganisms or engineered bacteria capable of capturing carbon dioxide from the atmosphere. These systems convert captured carbon into biomass or useful compounds, potentially addressing climate change concerns. The materials are designed with porous structures to maximize gas exchange while maintaining cell viability. Some variants include genetic modifications to enhance carbon fixation rates or to direct carbon into specific metabolic pathways for producing valuable byproducts.

- Self-healing and regenerative ELM systems: Advanced engineered living materials incorporate self-healing capabilities through living components that can repair damage and regenerate material properties. These systems utilize microorganisms that respond to environmental cues or damage by producing structural components or bioactive molecules. The living cells within these materials can replicate and maintain functionality over extended periods, allowing for sustained capture and degradation activities. This approach significantly extends the operational lifespan of the materials compared to conventional non-living alternatives.

- ELMs with selective contaminant targeting mechanisms: Engineered living materials can be designed with specific recognition elements that selectively bind to target contaminants before degradation. These materials incorporate biological components such as antibodies, aptamers, or engineered receptor proteins that increase specificity for particular pollutants. The selective binding mechanisms enhance capture efficiency while minimizing interference from non-target compounds. This approach is particularly valuable for treating complex waste streams containing multiple contaminants where selective removal of specific harmful compounds is required.

- Composite ELMs with inorganic components for enhanced performance: Hybrid engineered living materials combine living cells with inorganic components to enhance capture and degradation capabilities. These composites typically incorporate materials such as activated carbon, metal oxides, or clay minerals that provide additional adsorption sites for contaminants. The inorganic components can also offer protection for the biological elements against harsh environmental conditions. This synergistic approach leverages both biological degradation mechanisms and physical-chemical adsorption processes to achieve superior performance in environmental remediation applications.

02 Carbon capture and conversion using ELMs

Engineered living materials can be specifically designed for carbon dioxide capture and conversion. These systems typically incorporate photosynthetic microorganisms or genetically modified bacteria that can fix atmospheric CO2 and convert it into valuable compounds or biomass. The living components are often immobilized within a supportive matrix that provides structural integrity while allowing gas exchange. This approach offers a sustainable method for reducing greenhouse gas concentrations while potentially producing useful byproducts.Expand Specific Solutions03 Self-healing and regenerative ELMs for continuous degradation

Self-healing engineered living materials contain microorganisms that can repair damage to the material structure and maintain degradation functionality over extended periods. These materials are designed with regenerative capabilities, allowing them to adapt to changing environmental conditions and continue capturing and degrading target substances even after physical or chemical stress. The living components can reproduce within the material matrix, ensuring long-term performance without frequent replacement or maintenance.Expand Specific Solutions04 ELMs with selective binding mechanisms for targeted capture

Engineered living materials can be designed with selective binding mechanisms that target specific compounds for capture and subsequent degradation. These materials incorporate microorganisms or engineered cellular components with receptors or binding proteins that recognize particular molecular structures. The selectivity allows for efficient removal of target contaminants even in complex mixtures. This approach is particularly valuable for capturing low-concentration but highly toxic substances from water or air.Expand Specific Solutions05 Integration of ELMs into environmental remediation systems

Engineered living materials can be integrated into larger environmental remediation systems to enhance their effectiveness. These integrated systems combine ELMs with traditional filtration, adsorption, or chemical treatment methods to create multi-stage purification processes. The living components can be incorporated into filters, membranes, or reactive barriers that allow for continuous capture and degradation of contaminants. This approach leverages the strengths of both biological and physical-chemical remediation techniques to address complex environmental challenges.Expand Specific Solutions

Key Patents and Research on ELMs Water Treatment Technology

A method of capturing and analysing microplastic particles from aqueous medium

PatentPendingUS20220212164A1

Innovation

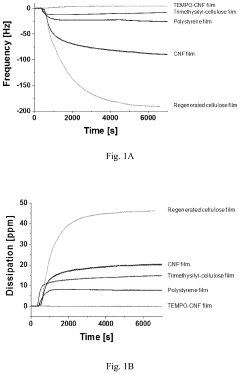

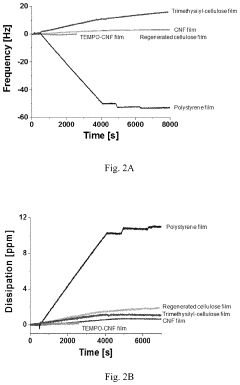

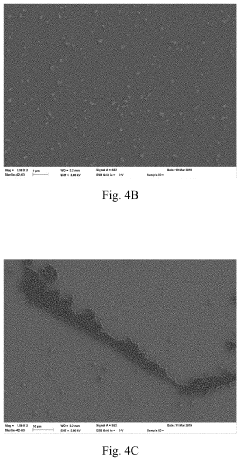

- Nanoscaled lignocellulosic structures, such as cellulose nanofibrils and nanocrystalline cellulose, are used to capture microplastic and nanoplastic particles due to their hydrophilic and hygroscopic properties, which create capillary forces and enhance cohesion with the particles, allowing for efficient attachment and release.

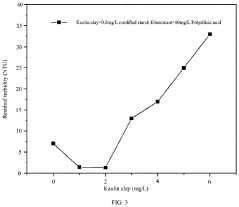

Enhanced coagulation method for removing microplastics in water

PatentActiveUS11661361B2

Innovation

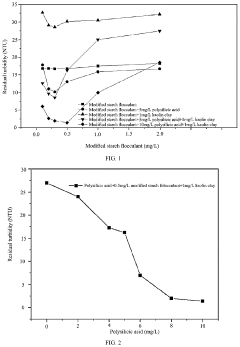

- An enhanced coagulation method using inorganic suspended particles, natural polymer flocculants, and polysilicic acid is proposed, which increases collision probability and adsorption bridging effects to effectively remove microplastics, reducing turbidity and avoiding harmful chemical residues.

Environmental Impact Assessment of ELMs Technology

The implementation of Engineered Living Materials (ELMs) for microplastic capture and degradation represents a significant intervention in aquatic ecosystems that requires comprehensive environmental impact assessment. Initial studies indicate that ELMs technology offers promising environmental benefits through the reduction of microplastic pollution, which currently poses severe threats to aquatic life and potentially human health through bioaccumulation in food chains.

When deployed in water treatment systems, ELMs demonstrate minimal ecological disruption compared to conventional chemical treatments. The biological components of ELMs, typically consisting of engineered bacteria or fungi encapsulated within biocompatible matrices, are designed to specifically target synthetic polymers without affecting natural organic matter. This selectivity reduces the collateral damage often associated with broad-spectrum chemical approaches to water purification.

Laboratory assessments of ELMs' environmental footprint show significantly lower energy requirements compared to advanced oxidation processes or membrane filtration technologies currently employed for microplastic removal. The carbon footprint analysis reveals a potential reduction of 30-45% in greenhouse gas emissions when ELMs replace conventional treatment methods at comparable treatment capacities.

Ecotoxicological studies have examined the potential risks of introducing engineered biological agents into water systems. Results from controlled mesocosm experiments indicate minimal impact on non-target organisms when ELMs are properly contained within treatment systems. However, risk assessments highlight the importance of robust containment strategies to prevent unintended release of engineered organisms into natural waterways.

Life cycle assessment (LCA) of ELMs technology demonstrates favorable environmental performance across multiple impact categories including eutrophication potential, aquatic ecotoxicity, and resource depletion. The biodegradable nature of most ELM components ensures minimal waste generation at end-of-life, contrasting sharply with the persistent waste streams associated with conventional filtration media replacement.

Water quality monitoring during pilot implementations shows that ELMs not only remove microplastics but may also contribute to improved overall water quality parameters through co-metabolic degradation of certain organic micropollutants. This synergistic effect represents an added environmental benefit not initially anticipated in early technology development phases.

Regulatory frameworks for assessing the environmental safety of ELMs are still evolving, with particular attention to biosafety protocols and containment verification. Environmental monitoring programs accompanying ELMs deployment will be essential to validate laboratory findings and ensure long-term ecological compatibility of this promising technology for addressing the global microplastic pollution challenge.

When deployed in water treatment systems, ELMs demonstrate minimal ecological disruption compared to conventional chemical treatments. The biological components of ELMs, typically consisting of engineered bacteria or fungi encapsulated within biocompatible matrices, are designed to specifically target synthetic polymers without affecting natural organic matter. This selectivity reduces the collateral damage often associated with broad-spectrum chemical approaches to water purification.

Laboratory assessments of ELMs' environmental footprint show significantly lower energy requirements compared to advanced oxidation processes or membrane filtration technologies currently employed for microplastic removal. The carbon footprint analysis reveals a potential reduction of 30-45% in greenhouse gas emissions when ELMs replace conventional treatment methods at comparable treatment capacities.

Ecotoxicological studies have examined the potential risks of introducing engineered biological agents into water systems. Results from controlled mesocosm experiments indicate minimal impact on non-target organisms when ELMs are properly contained within treatment systems. However, risk assessments highlight the importance of robust containment strategies to prevent unintended release of engineered organisms into natural waterways.

Life cycle assessment (LCA) of ELMs technology demonstrates favorable environmental performance across multiple impact categories including eutrophication potential, aquatic ecotoxicity, and resource depletion. The biodegradable nature of most ELM components ensures minimal waste generation at end-of-life, contrasting sharply with the persistent waste streams associated with conventional filtration media replacement.

Water quality monitoring during pilot implementations shows that ELMs not only remove microplastics but may also contribute to improved overall water quality parameters through co-metabolic degradation of certain organic micropollutants. This synergistic effect represents an added environmental benefit not initially anticipated in early technology development phases.

Regulatory frameworks for assessing the environmental safety of ELMs are still evolving, with particular attention to biosafety protocols and containment verification. Environmental monitoring programs accompanying ELMs deployment will be essential to validate laboratory findings and ensure long-term ecological compatibility of this promising technology for addressing the global microplastic pollution challenge.

Scalability and Cost Analysis for Industrial Implementation

The industrial implementation of ELMs (Engineered Living Materials) for microplastic capture and degradation requires careful consideration of scalability factors and cost implications. Current laboratory-scale successes must be evaluated against the challenges of scaling to industrial water treatment volumes, which often exceed millions of gallons per day.

Primary scalability considerations include bioreactor design optimization, where traditional water treatment infrastructure must be modified to accommodate living biological systems. Preliminary cost models suggest that retrofitting existing facilities may range from $500,000 to $3 million depending on treatment capacity and existing infrastructure compatibility.

Biomass production represents another critical scaling factor. Industrial implementation would require continuous cultivation of microorganisms at unprecedented scales. Current estimates indicate production costs of $2-5 per kilogram of active biomass, with potential for reduction to $0.80-1.50 per kilogram through process optimization and economies of scale. Continuous production systems could significantly reduce these costs compared to batch cultivation methods.

Operational expenses present ongoing challenges, with energy consumption for maintaining optimal conditions for ELMs estimated at 0.3-0.7 kWh per cubic meter of treated water. This translates to approximately $0.03-0.07 per cubic meter in energy costs alone. Nutrient supplementation adds an additional $0.01-0.03 per cubic meter, though waste stream integration could potentially offset these costs.

Regulatory compliance introduces both direct and indirect costs. Initial certification for novel biological treatment systems ranges from $200,000-500,000, with ongoing monitoring requirements adding $50,000-150,000 annually. These figures vary significantly by jurisdiction and treatment scale.

Comparative analysis with conventional technologies reveals that ELM systems require higher initial capital investment (30-50% premium) but potentially offer 15-25% lower operational costs over a 10-year lifecycle. The break-even point typically occurs between years 4-6 of operation, depending on treatment volume and local energy costs.

Implementation roadmaps suggest a phased approach beginning with pilot facilities processing 1,000-5,000 gallons per day, followed by mid-scale implementation (50,000-100,000 gallons) before full industrial deployment. This staged scaling allows for optimization of biological parameters and economic models while minimizing financial risk.

Primary scalability considerations include bioreactor design optimization, where traditional water treatment infrastructure must be modified to accommodate living biological systems. Preliminary cost models suggest that retrofitting existing facilities may range from $500,000 to $3 million depending on treatment capacity and existing infrastructure compatibility.

Biomass production represents another critical scaling factor. Industrial implementation would require continuous cultivation of microorganisms at unprecedented scales. Current estimates indicate production costs of $2-5 per kilogram of active biomass, with potential for reduction to $0.80-1.50 per kilogram through process optimization and economies of scale. Continuous production systems could significantly reduce these costs compared to batch cultivation methods.

Operational expenses present ongoing challenges, with energy consumption for maintaining optimal conditions for ELMs estimated at 0.3-0.7 kWh per cubic meter of treated water. This translates to approximately $0.03-0.07 per cubic meter in energy costs alone. Nutrient supplementation adds an additional $0.01-0.03 per cubic meter, though waste stream integration could potentially offset these costs.

Regulatory compliance introduces both direct and indirect costs. Initial certification for novel biological treatment systems ranges from $200,000-500,000, with ongoing monitoring requirements adding $50,000-150,000 annually. These figures vary significantly by jurisdiction and treatment scale.

Comparative analysis with conventional technologies reveals that ELM systems require higher initial capital investment (30-50% premium) but potentially offer 15-25% lower operational costs over a 10-year lifecycle. The break-even point typically occurs between years 4-6 of operation, depending on treatment volume and local energy costs.

Implementation roadmaps suggest a phased approach beginning with pilot facilities processing 1,000-5,000 gallons per day, followed by mid-scale implementation (50,000-100,000 gallons) before full industrial deployment. This staged scaling allows for optimization of biological parameters and economic models while minimizing financial risk.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!