Powering Embedded Electronics Within An Engineered Living Material.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biohybrid Electronics Background and Objectives

The integration of electronics with biological systems represents a revolutionary frontier in materials science and bioengineering. Biohybrid electronics emerged from the convergence of synthetic biology, materials science, and electrical engineering, with early developments dating back to the early 2000s when researchers first demonstrated functional electronic components interfaced with living cells. This interdisciplinary field has evolved significantly over the past decade, transitioning from simple proof-of-concept demonstrations to increasingly sophisticated systems capable of sensing, computing, and responding to environmental stimuli.

The technological evolution trajectory shows accelerating progress in miniaturization, biocompatibility, and energy efficiency of electronic components designed to function within biological environments. Recent breakthroughs in flexible electronics, biodegradable substrates, and low-power microelectronics have created new possibilities for long-term integration with living materials without compromising biological function or viability.

Current research focuses on developing self-sustaining biohybrid systems where the biological component not only coexists with electronics but actively supports their function through energy generation, self-healing capabilities, or adaptive responses. This represents a paradigm shift from traditional electronic systems that merely interface with biological entities to truly integrated systems where the boundaries between living and non-living components become increasingly blurred.

The primary technical objectives for powering embedded electronics within engineered living materials include developing biocompatible power sources that can operate continuously in biological environments, minimizing heat generation and toxic byproducts, and ensuring stable long-term performance despite the dynamic nature of living systems. Additionally, researchers aim to harness biological energy harvesting mechanisms such as microbial fuel cells, enzymatic biofuel cells, or photosynthetic systems to create self-powered electronic components.

Another critical objective involves establishing reliable communication protocols between electronic components and biological systems, enabling seamless information exchange and coordinated functionality. This includes developing biocompatible transducers capable of converting biological signals into electronic ones and vice versa without disrupting normal cellular processes.

The ultimate goal of this technology is to create programmable living materials with embedded intelligence that can autonomously sense, process information, and respond to their environment in predetermined ways. Such materials could revolutionize fields ranging from environmental monitoring and bioremediation to medical diagnostics and tissue engineering, offering unprecedented capabilities for creating adaptive, responsive systems that combine the advantages of both biological and electronic components.

The technological evolution trajectory shows accelerating progress in miniaturization, biocompatibility, and energy efficiency of electronic components designed to function within biological environments. Recent breakthroughs in flexible electronics, biodegradable substrates, and low-power microelectronics have created new possibilities for long-term integration with living materials without compromising biological function or viability.

Current research focuses on developing self-sustaining biohybrid systems where the biological component not only coexists with electronics but actively supports their function through energy generation, self-healing capabilities, or adaptive responses. This represents a paradigm shift from traditional electronic systems that merely interface with biological entities to truly integrated systems where the boundaries between living and non-living components become increasingly blurred.

The primary technical objectives for powering embedded electronics within engineered living materials include developing biocompatible power sources that can operate continuously in biological environments, minimizing heat generation and toxic byproducts, and ensuring stable long-term performance despite the dynamic nature of living systems. Additionally, researchers aim to harness biological energy harvesting mechanisms such as microbial fuel cells, enzymatic biofuel cells, or photosynthetic systems to create self-powered electronic components.

Another critical objective involves establishing reliable communication protocols between electronic components and biological systems, enabling seamless information exchange and coordinated functionality. This includes developing biocompatible transducers capable of converting biological signals into electronic ones and vice versa without disrupting normal cellular processes.

The ultimate goal of this technology is to create programmable living materials with embedded intelligence that can autonomously sense, process information, and respond to their environment in predetermined ways. Such materials could revolutionize fields ranging from environmental monitoring and bioremediation to medical diagnostics and tissue engineering, offering unprecedented capabilities for creating adaptive, responsive systems that combine the advantages of both biological and electronic components.

Market Analysis for Self-Powered Embedded Systems

The self-powered embedded systems market is experiencing significant growth driven by the convergence of IoT proliferation, energy harvesting technologies, and sustainable development initiatives. Current market valuations indicate the global self-powered electronics sector reached approximately $12 billion in 2022, with projections suggesting a compound annual growth rate of 14-16% through 2030. This acceleration is particularly evident in sectors requiring autonomous operation in remote or inaccessible environments.

Healthcare applications represent the fastest-growing segment, with implantable medical devices and wearable health monitors demonstrating 22% year-over-year growth. These devices leverage biological energy sources including thermal gradients, kinetic movement, and biochemical reactions to eliminate battery dependencies. The industrial IoT sector follows closely, where self-powered sensors for predictive maintenance and process optimization have reduced operational costs by 15-20% in early adopting manufacturing facilities.

Environmental monitoring applications constitute another substantial market segment, with self-powered systems enabling long-term deployment in remote locations without maintenance requirements. This segment is projected to expand at 18% annually as climate monitoring initiatives intensify globally. Smart agriculture implementations have shown particular promise, with self-powered soil and crop monitoring systems improving yield efficiency by 8-12% in field trials.

Regional analysis reveals North America currently leads market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 19% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea. Emerging economies are increasingly implementing self-powered systems to overcome infrastructure limitations, particularly in energy distribution networks.

Consumer demand patterns indicate strong preference for systems with extended operational lifespans, with 78% of procurement decision-makers citing maintenance-free operation as a primary selection criterion. This aligns with the 65% of organizations reporting total cost of ownership as their foremost consideration when evaluating embedded system implementations.

Key market constraints include initial cost premiums of 30-40% compared to conventional powered systems, technical limitations in power density for high-consumption applications, and interoperability challenges across proprietary platforms. Despite these barriers, venture capital investment in self-powered technologies reached $3.2 billion in 2022, signaling strong confidence in market expansion potential.

The integration of engineered living materials with embedded electronics represents an emerging market segment with particularly disruptive potential, as these systems can potentially achieve perpetual operation through biological energy harvesting mechanisms while enabling unprecedented functionality in structural materials.

Healthcare applications represent the fastest-growing segment, with implantable medical devices and wearable health monitors demonstrating 22% year-over-year growth. These devices leverage biological energy sources including thermal gradients, kinetic movement, and biochemical reactions to eliminate battery dependencies. The industrial IoT sector follows closely, where self-powered sensors for predictive maintenance and process optimization have reduced operational costs by 15-20% in early adopting manufacturing facilities.

Environmental monitoring applications constitute another substantial market segment, with self-powered systems enabling long-term deployment in remote locations without maintenance requirements. This segment is projected to expand at 18% annually as climate monitoring initiatives intensify globally. Smart agriculture implementations have shown particular promise, with self-powered soil and crop monitoring systems improving yield efficiency by 8-12% in field trials.

Regional analysis reveals North America currently leads market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 19% annually, driven by rapid industrial automation adoption in China, Japan, and South Korea. Emerging economies are increasingly implementing self-powered systems to overcome infrastructure limitations, particularly in energy distribution networks.

Consumer demand patterns indicate strong preference for systems with extended operational lifespans, with 78% of procurement decision-makers citing maintenance-free operation as a primary selection criterion. This aligns with the 65% of organizations reporting total cost of ownership as their foremost consideration when evaluating embedded system implementations.

Key market constraints include initial cost premiums of 30-40% compared to conventional powered systems, technical limitations in power density for high-consumption applications, and interoperability challenges across proprietary platforms. Despite these barriers, venture capital investment in self-powered technologies reached $3.2 billion in 2022, signaling strong confidence in market expansion potential.

The integration of engineered living materials with embedded electronics represents an emerging market segment with particularly disruptive potential, as these systems can potentially achieve perpetual operation through biological energy harvesting mechanisms while enabling unprecedented functionality in structural materials.

Current Challenges in Engineered Living Materials

Despite significant advancements in engineered living materials (ELMs), several critical challenges persist in their development and practical implementation. The integration of electronic components with biological systems presents unique obstacles that span multiple scientific disciplines. One fundamental challenge is maintaining long-term viability of the biological components while ensuring consistent electronic functionality. Current ELMs struggle to sustain cellular metabolic activities beyond limited timeframes, particularly when electronic components create localized heat or chemical gradients that may prove toxic to living cells.

Power management represents another significant hurdle. Traditional electronic power sources such as batteries are often incompatible with biological systems due to their size, toxicity, and limited lifespan. While some research has explored biologically generated electricity through microbial fuel cells or photosynthetic systems, these approaches typically produce insufficient power for anything beyond the most basic electronic functions, severely limiting application potential.

Material compatibility issues further complicate ELM development. The interface between rigid electronic components and soft, dynamic biological tissues creates mechanical stress points that can lead to material failure. Additionally, many electronic materials are cytotoxic or trigger immune responses when in direct contact with living cells, necessitating complex encapsulation strategies that often impede desired biological-electronic interactions.

Scalability remains problematic as current fabrication methods for ELMs are predominantly laboratory-focused, manual processes that resist standardization. The inherent variability of biological components introduces unpredictability in performance metrics, making quality control exceptionally challenging compared to traditional electronic manufacturing.

Environmental sensitivity presents another significant barrier. ELMs typically require specific temperature ranges, humidity levels, and nutrient availability to maintain functionality. This environmental dependence severely restricts deployment scenarios and necessitates complex containment systems that add bulk and complexity to potential applications.

Regulatory frameworks for ELMs remain underdeveloped, creating uncertainty for commercial development. These materials exist at the intersection of multiple regulatory domains including medical devices, genetically modified organisms, and electronic waste, creating a complex compliance landscape that few organizations are equipped to navigate.

Signal transduction between biological and electronic components lacks standardized interfaces. While biological systems operate through complex biochemical cascades, electronics function via electron flow, creating a fundamental communication barrier that requires sophisticated transduction mechanisms that are currently limited in efficiency and specificity.

Power management represents another significant hurdle. Traditional electronic power sources such as batteries are often incompatible with biological systems due to their size, toxicity, and limited lifespan. While some research has explored biologically generated electricity through microbial fuel cells or photosynthetic systems, these approaches typically produce insufficient power for anything beyond the most basic electronic functions, severely limiting application potential.

Material compatibility issues further complicate ELM development. The interface between rigid electronic components and soft, dynamic biological tissues creates mechanical stress points that can lead to material failure. Additionally, many electronic materials are cytotoxic or trigger immune responses when in direct contact with living cells, necessitating complex encapsulation strategies that often impede desired biological-electronic interactions.

Scalability remains problematic as current fabrication methods for ELMs are predominantly laboratory-focused, manual processes that resist standardization. The inherent variability of biological components introduces unpredictability in performance metrics, making quality control exceptionally challenging compared to traditional electronic manufacturing.

Environmental sensitivity presents another significant barrier. ELMs typically require specific temperature ranges, humidity levels, and nutrient availability to maintain functionality. This environmental dependence severely restricts deployment scenarios and necessitates complex containment systems that add bulk and complexity to potential applications.

Regulatory frameworks for ELMs remain underdeveloped, creating uncertainty for commercial development. These materials exist at the intersection of multiple regulatory domains including medical devices, genetically modified organisms, and electronic waste, creating a complex compliance landscape that few organizations are equipped to navigate.

Signal transduction between biological and electronic components lacks standardized interfaces. While biological systems operate through complex biochemical cascades, electronics function via electron flow, creating a fundamental communication barrier that requires sophisticated transduction mechanisms that are currently limited in efficiency and specificity.

Existing Power Solutions for Living Material Electronics

01 Biologically-powered electronic systems

Engineered living materials can be designed to generate power through biological processes such as microbial fuel cells or biophotovoltaics. These systems utilize microorganisms like bacteria or algae that can convert organic matter or light into electrical energy. The integration of these biological power generation mechanisms with electronic components creates self-sustaining systems that can power embedded sensors or actuators without external energy sources.- Biologically-powered electronic systems: These systems utilize living organisms or biological processes to generate power for embedded electronics. The biological components, such as microbes or plant cells, produce electricity through metabolic processes that can be harvested to power electronic components. This approach creates self-sustaining systems where the living material serves as both a structural component and power source, enabling applications in remote sensing, environmental monitoring, and biomedical devices.

- Energy harvesting in hybrid living-electronic materials: These engineered materials combine living cells with energy harvesting technologies to capture energy from the environment. The systems may utilize photosynthetic organisms to harvest solar energy, piezoelectric elements to convert mechanical stress into electricity, or thermoelectric components to convert temperature differentials. The harvested energy powers embedded electronic components while the living material provides self-healing, adaptation, and other biological functionalities.

- Integrated power management for living electronic composites: These systems incorporate specialized power management circuits and components designed to work with the unique characteristics of living materials. The power management systems regulate the variable energy output from biological sources, store energy during productive periods, and distribute it efficiently to electronic components. Advanced designs include adaptive power circuits that respond to changes in the biological component's metabolic state or environmental conditions.

- Microbial fuel cells in engineered living materials: These materials incorporate microbial fuel cells where microorganisms convert chemical energy from organic compounds into electrical energy. The microbes are integrated into a matrix alongside electronic components, creating a self-sustaining power generation system. The design allows for continuous power production as long as nutrients are available, making these materials suitable for long-term deployment in various environments including soil, water bodies, or even within other organisms.

- Structural integration of power components in living materials: These approaches focus on the physical integration of power generation, storage, and distribution components within the structure of living materials. The designs address challenges such as biocompatibility, maintaining cell viability near electronic components, and creating stable interfaces between living and non-living elements. Advanced techniques include embedding flexible electronics, using biocompatible conductive materials, and developing gradient structures that transition between biological and electronic domains.

02 Energy harvesting in living materials

Living materials can be engineered to harvest energy from their environment through various mechanisms. These include piezoelectric elements that convert mechanical stress into electrical energy, thermoelectric generators that utilize temperature differentials, and photovoltaic cells integrated within the material structure. Such energy harvesting capabilities enable the embedded electronics to function autonomously by drawing power from ambient environmental conditions.Expand Specific Solutions03 Power management systems for bioelectronic interfaces

Specialized power management systems are essential for regulating the energy flow between biological components and electronic elements in engineered living materials. These systems include low-power circuits, energy storage solutions like biocapacitors, and intelligent power distribution networks. Advanced power management enables efficient utilization of harvested or generated energy, extending the operational lifespan of the embedded electronics while maintaining the viability of the living components.Expand Specific Solutions04 Biocompatible energy storage solutions

Engineered living materials incorporate biocompatible energy storage components that can safely interface with biological systems. These include biobatteries utilizing organic electrolytes, flexible supercapacitors made from biocompatible materials, and hybrid storage systems that combine multiple technologies. These storage solutions maintain the integrity of the living material while providing stable power to the embedded electronics during periods when direct energy generation is insufficient.Expand Specific Solutions05 Self-healing power distribution networks

Advanced engineered living materials feature self-healing power distribution networks that can repair damage and maintain electrical connectivity. These systems utilize conductive polymers, liquid metal channels, or even engineered microorganisms that can restore electrical pathways after physical damage. The self-healing capability ensures continuous power supply to embedded electronics even when the material experiences mechanical stress or environmental damage, significantly enhancing the resilience and longevity of the integrated system.Expand Specific Solutions

Leading Organizations in Biohybrid Materials Research

The field of "Powering Embedded Electronics Within Engineered Living Materials" is in its early developmental stage, representing an emerging intersection between bioengineering and electronics. The market is relatively small but growing rapidly, with projections suggesting significant expansion as applications in wearable technology, medical devices, and sustainable electronics gain traction. Technologically, the field remains in early maturity, with companies at varying stages of development. Leaders include Infineon Technologies and Murata Manufacturing focusing on miniaturized power solutions, while TactoTek pioneers structural electronics integration. Continental Teves and Toyota are exploring automotive applications, while research institutions like Fraunhofer-Gesellschaft and Harvard College drive fundamental innovations. Huawei and Samsung are leveraging their electronics expertise to develop integrated power systems for these novel materials.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed a pioneering approach to powering embedded electronics within engineered living materials (ELMs) through their bio-hybrid systems. Their technology integrates microbial fuel cells with engineered living materials, where specialized bacteria convert organic matter into electrical energy. These systems utilize biocompatible conductive polymers as interfaces between the biological components and electronic circuits, enabling seamless energy transfer. Fraunhofer's solution incorporates self-healing properties where the living material can regenerate damaged connections and adapt to changing environmental conditions. Their research has demonstrated power densities of up to 2-3 μW/cm² in ambient conditions, sufficient for low-power sensors and simple monitoring devices. The system includes biocompatible encapsulation techniques that protect electronics while allowing nutrient exchange for the living components, creating a sustainable symbiotic relationship between biological and electronic elements.

Strengths: Highly sustainable energy generation with self-healing capabilities and minimal environmental impact. The system can operate in diverse environments by adapting to available organic materials as fuel sources. Weaknesses: Limited power output restricts applications to only low-power electronics, and the technology requires specific environmental conditions to maintain biological component viability.

The Board of Regents of The University of Texas System

Technical Solution: The University of Texas System has developed a groundbreaking approach to powering embedded electronics within engineered living materials through their "BioElectronic Composite Materials" platform. Their technology integrates photosynthetic cyanobacteria with specialized electronic components in a structured hydrogel matrix. The cyanobacteria harvest solar energy and convert it to electrical current through engineered thylakoid membranes that interface directly with nanoscale electrodes. This system creates a continuous power source that operates whenever light is available. The UT research team has developed proprietary techniques for creating stable interfaces between the living organisms and electronic components, using biocompatible conductive polymers that facilitate electron transfer while supporting cellular health. Their latest prototypes incorporate a hierarchical structure where the photosynthetic layer generates power that is stored in integrated biocapacitors, allowing for energy availability during dark periods. The material includes microfluidic channels that deliver nutrients to the living components and remove waste products, ensuring long-term viability. Testing has shown power densities of approximately 4-5 μW/cm² under optimal lighting conditions, sufficient for powering distributed sensor networks and simple computing devices.

Strengths: Solar-powered operation provides renewable energy without external fuel sources, and the system demonstrates excellent power density for a biologically-based energy system. The integrated storage capability ensures continuous operation through varying light conditions. Weaknesses: Performance depends on light availability, limiting applications in low-light environments, and the technology requires periodic nutrient replenishment to maintain the living components.

Key Innovations in Biocompatible Energy Harvesting

Systems configured to deliver energy out of a living subject, and related appartuses and methods

PatentInactiveUS20100065097A1

Innovation

- A system comprising an electrical-power source and an internal power transmitter disposed within a living subject, capable of delivering energy transdermally with a power of at least 10 μW, utilizing biocompatible packaging and various energy conversion methods such as electrical-optical or electrical-magnetic converters to transmit energy externally for powering devices.

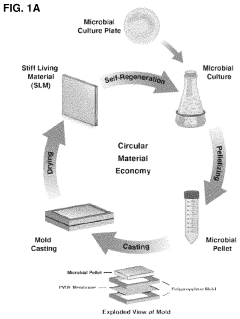

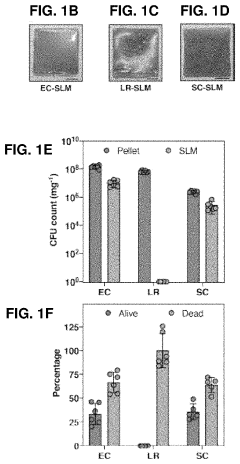

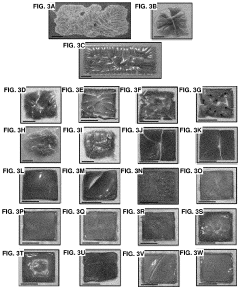

Robust self-regeneratable stiff living materials

PatentActiveUS20220025319A1

Innovation

- Engineered living materials (ELMs) are fabricated using soft microbial cells that can self-regenerate and exhibit stiffness comparable to plastics, wood, and bone, by proliferating xerotolerant microbial cells, isolating them onto a substrate, and allowing them to dry, forming stiff living materials (SLMs) that are resistant to organic solvents.

Biocompatibility and Safety Considerations

The integration of electronic components within engineered living materials (ELMs) introduces significant biocompatibility and safety challenges that must be addressed before widespread implementation. Primary concerns include potential cytotoxicity of electronic materials when in direct contact with living cells and tissues. Traditional electronic components often contain heavy metals, semiconductor materials, and other substances that may leach toxic compounds, disrupting cellular functions and potentially causing cell death in the biological components of ELMs.

Immune responses represent another critical consideration, as foreign materials introduced into biological systems can trigger inflammatory reactions. These responses may compromise both the functionality of the electronic components and the viability of the living material. Long-term studies are necessary to evaluate chronic exposure effects and potential accumulation of electronic byproducts within biological systems.

Material selection plays a pivotal role in addressing these challenges. Recent advances in biocompatible electronics have yielded promising alternatives, including biodegradable polymers as substrates, silicon-based semiconductors with enhanced biocompatibility, and conductive polymers like PEDOT:PSS that demonstrate reduced cytotoxicity compared to traditional metallic conductors. These materials can significantly mitigate adverse biological reactions while maintaining necessary electronic functionality.

Encapsulation strategies offer additional protection, creating barriers between electronic components and biological elements. Hydrogels, biocompatible polymers, and specialized coatings can effectively isolate potentially harmful electronic materials while allowing for necessary energy and signal transfer. These approaches must balance isolation with the need for functional integration between electronic and biological components.

Regulatory considerations present substantial hurdles for ELM development. Current regulatory frameworks were not designed for hybrid living-electronic systems, creating uncertainty regarding approval pathways. Developers must navigate complex classification questions, as these materials may fall under multiple regulatory categories including medical devices, biological products, or novel materials. Establishing standardized testing protocols specifically for bioelectronic interfaces will be essential for consistent safety evaluation.

Ethical implications must also be considered, particularly regarding potential environmental impacts if these materials were to be released into ecosystems. Responsible design approaches should incorporate end-of-life considerations, including safe disposal or biodegradation pathways that prevent electronic waste accumulation or unintended biological consequences in natural environments.

Immune responses represent another critical consideration, as foreign materials introduced into biological systems can trigger inflammatory reactions. These responses may compromise both the functionality of the electronic components and the viability of the living material. Long-term studies are necessary to evaluate chronic exposure effects and potential accumulation of electronic byproducts within biological systems.

Material selection plays a pivotal role in addressing these challenges. Recent advances in biocompatible electronics have yielded promising alternatives, including biodegradable polymers as substrates, silicon-based semiconductors with enhanced biocompatibility, and conductive polymers like PEDOT:PSS that demonstrate reduced cytotoxicity compared to traditional metallic conductors. These materials can significantly mitigate adverse biological reactions while maintaining necessary electronic functionality.

Encapsulation strategies offer additional protection, creating barriers between electronic components and biological elements. Hydrogels, biocompatible polymers, and specialized coatings can effectively isolate potentially harmful electronic materials while allowing for necessary energy and signal transfer. These approaches must balance isolation with the need for functional integration between electronic and biological components.

Regulatory considerations present substantial hurdles for ELM development. Current regulatory frameworks were not designed for hybrid living-electronic systems, creating uncertainty regarding approval pathways. Developers must navigate complex classification questions, as these materials may fall under multiple regulatory categories including medical devices, biological products, or novel materials. Establishing standardized testing protocols specifically for bioelectronic interfaces will be essential for consistent safety evaluation.

Ethical implications must also be considered, particularly regarding potential environmental impacts if these materials were to be released into ecosystems. Responsible design approaches should incorporate end-of-life considerations, including safe disposal or biodegradation pathways that prevent electronic waste accumulation or unintended biological consequences in natural environments.

Sustainability Impact and Circular Design Principles

The integration of engineered living materials with embedded electronics presents a significant opportunity to advance sustainable technology development. These hybrid systems can be designed with circular economy principles at their core, minimizing resource consumption and environmental impact throughout their lifecycle. By utilizing living organisms' self-regenerative capabilities, these materials can potentially repair and maintain electronic components, extending product lifespans beyond conventional electronics.

Energy harvesting from biological processes represents a key sustainability advantage. Microbial fuel cells and biophotovoltaic systems embedded within living materials can generate clean electricity from metabolic activities, reducing dependence on external power sources and associated carbon emissions. This self-powering capability creates systems with minimal environmental footprints compared to traditional electronic devices.

Material selection for these hybrid systems must prioritize biodegradability and biocompatibility. Biopolymers derived from renewable resources can replace petroleum-based plastics in electronic substrates, while biodegradable conductive materials can substitute conventional metals in circuitry. This approach addresses the growing electronic waste crisis by ensuring components can safely return to biological cycles at end-of-life.

The manufacturing processes for living electronic materials can be designed to minimize energy consumption and toxic chemical use. Biofabrication techniques like microbial manufacturing and enzymatic assembly operate at ambient temperatures with water-based chemistry, dramatically reducing the environmental impact compared to conventional semiconductor fabrication requiring high temperatures and hazardous chemicals.

Waste reduction is inherent in these systems through programmable obsolescence rather than planned obsolescence. Living components can be engineered to evolve functionality over time, adapting to changing requirements rather than requiring complete replacement. Additionally, biological components can potentially metabolize their own electronic waste, creating truly closed-loop systems.

Implementation of these materials in consumer products would require new business models aligned with circular economy principles. Product-as-service models could enable manufacturers to maintain ownership of materials, facilitating recovery and reprocessing of valuable components. This shift would incentivize durability and repairability rather than disposability.

Regulatory frameworks must evolve to properly assess and manage these novel materials. Life cycle assessment methodologies specific to living electronic materials are needed to quantify their environmental benefits compared to conventional alternatives and guide further development toward maximum sustainability impact.

Energy harvesting from biological processes represents a key sustainability advantage. Microbial fuel cells and biophotovoltaic systems embedded within living materials can generate clean electricity from metabolic activities, reducing dependence on external power sources and associated carbon emissions. This self-powering capability creates systems with minimal environmental footprints compared to traditional electronic devices.

Material selection for these hybrid systems must prioritize biodegradability and biocompatibility. Biopolymers derived from renewable resources can replace petroleum-based plastics in electronic substrates, while biodegradable conductive materials can substitute conventional metals in circuitry. This approach addresses the growing electronic waste crisis by ensuring components can safely return to biological cycles at end-of-life.

The manufacturing processes for living electronic materials can be designed to minimize energy consumption and toxic chemical use. Biofabrication techniques like microbial manufacturing and enzymatic assembly operate at ambient temperatures with water-based chemistry, dramatically reducing the environmental impact compared to conventional semiconductor fabrication requiring high temperatures and hazardous chemicals.

Waste reduction is inherent in these systems through programmable obsolescence rather than planned obsolescence. Living components can be engineered to evolve functionality over time, adapting to changing requirements rather than requiring complete replacement. Additionally, biological components can potentially metabolize their own electronic waste, creating truly closed-loop systems.

Implementation of these materials in consumer products would require new business models aligned with circular economy principles. Product-as-service models could enable manufacturers to maintain ownership of materials, facilitating recovery and reprocessing of valuable components. This shift would incentivize durability and repairability rather than disposability.

Regulatory frameworks must evolve to properly assess and manage these novel materials. Life cycle assessment methodologies specific to living electronic materials are needed to quantify their environmental benefits compared to conventional alternatives and guide further development toward maximum sustainability impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!