How Do ELMs Respond To Mechanical Stress And Damage?

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ELM Mechanical Response Background and Objectives

Edge Localized Modes (ELMs) represent one of the most significant challenges in fusion energy research, particularly in tokamak-based fusion reactors. These plasma instabilities occur at the edge of the confined plasma, releasing bursts of particles and energy that can cause substantial damage to plasma-facing components. Understanding how ELMs respond to mechanical stress and damage is crucial for the development of sustainable fusion energy systems.

The evolution of ELM research spans several decades, beginning with their initial observation in the 1980s. Early tokamak experiments identified these periodic instabilities, but their mechanical impact was not fully appreciated until high-performance operation modes became standard. The technological progression has moved from basic observation to sophisticated diagnostic systems capable of measuring ELM-induced stresses with microsecond resolution.

Current research trends focus on quantifying the relationship between ELM characteristics and the resulting mechanical fatigue in reactor components. This includes investigating how different ELM regimes (Type I, II, and III) produce varying stress patterns and how these stresses accumulate over operational cycles. The mechanical response of materials under ELM conditions represents a critical intersection of plasma physics and materials science.

The primary objective of this technical research is to develop a comprehensive understanding of the mechanical stress pathways during ELM events. This includes characterizing the stress distribution across different reactor components, identifying critical failure points, and establishing predictive models for component lifetime under various ELM scenarios.

Secondary objectives include evaluating novel materials and designs that can better withstand ELM-induced stresses, developing real-time monitoring systems for mechanical damage assessment, and establishing standardized testing protocols for ELM-resistant components. These objectives align with the broader goal of extending the operational lifetime of fusion reactors.

The technical goals also encompass the development of mitigation strategies that can reduce mechanical stress without compromising plasma performance. This includes exploring active control systems that can modify ELM behavior before mechanical damage occurs, as well as passive design solutions that can absorb or redirect ELM energy.

Understanding the mechanical response of materials to ELMs will directly impact the economic viability of fusion energy by reducing maintenance requirements and extending component lifetimes. This research therefore serves both immediate engineering needs and long-term strategic goals in fusion energy development.

The evolution of ELM research spans several decades, beginning with their initial observation in the 1980s. Early tokamak experiments identified these periodic instabilities, but their mechanical impact was not fully appreciated until high-performance operation modes became standard. The technological progression has moved from basic observation to sophisticated diagnostic systems capable of measuring ELM-induced stresses with microsecond resolution.

Current research trends focus on quantifying the relationship between ELM characteristics and the resulting mechanical fatigue in reactor components. This includes investigating how different ELM regimes (Type I, II, and III) produce varying stress patterns and how these stresses accumulate over operational cycles. The mechanical response of materials under ELM conditions represents a critical intersection of plasma physics and materials science.

The primary objective of this technical research is to develop a comprehensive understanding of the mechanical stress pathways during ELM events. This includes characterizing the stress distribution across different reactor components, identifying critical failure points, and establishing predictive models for component lifetime under various ELM scenarios.

Secondary objectives include evaluating novel materials and designs that can better withstand ELM-induced stresses, developing real-time monitoring systems for mechanical damage assessment, and establishing standardized testing protocols for ELM-resistant components. These objectives align with the broader goal of extending the operational lifetime of fusion reactors.

The technical goals also encompass the development of mitigation strategies that can reduce mechanical stress without compromising plasma performance. This includes exploring active control systems that can modify ELM behavior before mechanical damage occurs, as well as passive design solutions that can absorb or redirect ELM energy.

Understanding the mechanical response of materials to ELMs will directly impact the economic viability of fusion energy by reducing maintenance requirements and extending component lifetimes. This research therefore serves both immediate engineering needs and long-term strategic goals in fusion energy development.

Market Applications for Stress-Resistant ELMs

The market for stress-resistant Extreme Learning Machines (ELMs) spans multiple sectors where computational systems face mechanical challenges. In industrial manufacturing, ELMs capable of withstanding vibration, impact, and temperature fluctuations enable real-time quality control and predictive maintenance in harsh factory environments. These systems can continue functioning accurately despite exposure to mechanical stressors, reducing downtime and maintenance costs by an estimated 30% compared to conventional systems.

Aerospace and automotive industries represent premium markets for stress-resistant ELMs, where computational systems must maintain reliability under extreme g-forces, vibration, and temperature variations. Implementing these robust neural networks in flight control systems, engine management, and autonomous navigation provides critical fault tolerance. The aerospace computing market alone is projected to reach $7.8 billion by 2026, with stress-resistant AI systems comprising a growing segment.

Healthcare applications present another significant opportunity, particularly in wearable and implantable medical devices. Stress-resistant ELMs enable continuous patient monitoring and real-time data analysis even when devices are subjected to daily physical activities, impacts, or bodily movements. This resilience translates to longer device lifespans and more reliable diagnostic capabilities, addressing a medical device market exceeding $400 billion globally.

Mobile and edge computing represents perhaps the largest volume market. Consumer electronics regularly experience drops, impacts, and environmental stresses. Implementing stress-resistant ELMs in smartphones, tablets, and wearables could significantly reduce performance degradation over device lifespans, addressing a major consumer pain point. This application alone addresses a market of billions of devices shipped annually.

Infrastructure monitoring presents another promising application, where ELMs embedded in bridges, buildings, and critical infrastructure must withstand environmental stressors while continuously analyzing structural integrity data. The smart infrastructure market is growing at 19% annually, with computational resilience being a key differentiator.

Defense and security applications constitute a premium market segment where computational systems must function reliably in extreme conditions. Stress-resistant ELMs enable persistent surveillance, threat detection, and communications in environments where physical damage is likely, commanding premium pricing due to mission-critical requirements.

The robotics sector, particularly for exploration, disaster response, and industrial applications, requires computational systems that maintain functionality despite impacts, falls, and environmental challenges. As the robotics market expands beyond controlled environments, stress-resistant computational architectures become increasingly valuable differentiators.

Aerospace and automotive industries represent premium markets for stress-resistant ELMs, where computational systems must maintain reliability under extreme g-forces, vibration, and temperature variations. Implementing these robust neural networks in flight control systems, engine management, and autonomous navigation provides critical fault tolerance. The aerospace computing market alone is projected to reach $7.8 billion by 2026, with stress-resistant AI systems comprising a growing segment.

Healthcare applications present another significant opportunity, particularly in wearable and implantable medical devices. Stress-resistant ELMs enable continuous patient monitoring and real-time data analysis even when devices are subjected to daily physical activities, impacts, or bodily movements. This resilience translates to longer device lifespans and more reliable diagnostic capabilities, addressing a medical device market exceeding $400 billion globally.

Mobile and edge computing represents perhaps the largest volume market. Consumer electronics regularly experience drops, impacts, and environmental stresses. Implementing stress-resistant ELMs in smartphones, tablets, and wearables could significantly reduce performance degradation over device lifespans, addressing a major consumer pain point. This application alone addresses a market of billions of devices shipped annually.

Infrastructure monitoring presents another promising application, where ELMs embedded in bridges, buildings, and critical infrastructure must withstand environmental stressors while continuously analyzing structural integrity data. The smart infrastructure market is growing at 19% annually, with computational resilience being a key differentiator.

Defense and security applications constitute a premium market segment where computational systems must function reliably in extreme conditions. Stress-resistant ELMs enable persistent surveillance, threat detection, and communications in environments where physical damage is likely, commanding premium pricing due to mission-critical requirements.

The robotics sector, particularly for exploration, disaster response, and industrial applications, requires computational systems that maintain functionality despite impacts, falls, and environmental challenges. As the robotics market expands beyond controlled environments, stress-resistant computational architectures become increasingly valuable differentiators.

Current Understanding and Challenges in ELM Stress Response

The current understanding of ELM (Edge Localized Mode) response to mechanical stress and damage remains limited despite its critical importance in fusion reactor design. Research indicates that ELMs—plasma instabilities occurring at the edge of tokamak fusion devices—exhibit complex behavior when subjected to mechanical stressors. These responses vary significantly depending on plasma conditions, magnetic field configurations, and the specific nature of the mechanical stress applied.

Recent experimental data from major fusion facilities such as ITER, JET, and DIII-D have demonstrated that ELMs can be triggered or suppressed by mechanical perturbations to the plasma-facing components. When these components experience stress or damage, the resulting surface modifications can alter plasma-wall interactions, potentially changing ELM frequency and intensity. However, the precise mechanisms governing these interactions remain poorly understood.

One significant challenge in this field is the difficulty in isolating mechanical stress effects from other plasma phenomena. Researchers struggle to develop diagnostic tools capable of real-time monitoring of both mechanical stress propagation and ELM behavior simultaneously. This technical limitation has hindered the development of comprehensive models that can accurately predict ELM responses to various mechanical damage scenarios.

Material degradation under combined mechanical and plasma exposure presents another substantial challenge. Plasma-facing components experience unique conditions where mechanical stress coincides with intense heat loads and particle bombardment. The synergistic effects of these conditions create failure modes that are difficult to replicate in laboratory settings, complicating efforts to understand the relationship between material damage and ELM behavior.

Computational modeling of ELM responses to mechanical stress has advanced in recent years, but significant gaps remain. Current models struggle to integrate multi-physics aspects including plasma physics, material science, and structural mechanics across relevant time and spatial scales. The highly non-linear nature of ELM events further complicates predictive capabilities.

International research collaborations have begun addressing these challenges through dedicated experimental campaigns. The ELM-damage correlation experiments at ASDEX Upgrade and KSTAR have provided valuable insights, though results often show device-specific dependencies that complicate the development of universal principles. These experiments have revealed that even minor mechanical modifications to divertor surfaces can significantly alter ELM characteristics, suggesting a high sensitivity that must be accounted for in fusion reactor designs.

The development of novel materials with enhanced resistance to combined mechanical and plasma stresses represents a promising research direction. Advanced tungsten alloys and composite materials are being investigated for their potential to maintain structural integrity while minimizing ELM-triggering surface modifications under operational conditions.

Recent experimental data from major fusion facilities such as ITER, JET, and DIII-D have demonstrated that ELMs can be triggered or suppressed by mechanical perturbations to the plasma-facing components. When these components experience stress or damage, the resulting surface modifications can alter plasma-wall interactions, potentially changing ELM frequency and intensity. However, the precise mechanisms governing these interactions remain poorly understood.

One significant challenge in this field is the difficulty in isolating mechanical stress effects from other plasma phenomena. Researchers struggle to develop diagnostic tools capable of real-time monitoring of both mechanical stress propagation and ELM behavior simultaneously. This technical limitation has hindered the development of comprehensive models that can accurately predict ELM responses to various mechanical damage scenarios.

Material degradation under combined mechanical and plasma exposure presents another substantial challenge. Plasma-facing components experience unique conditions where mechanical stress coincides with intense heat loads and particle bombardment. The synergistic effects of these conditions create failure modes that are difficult to replicate in laboratory settings, complicating efforts to understand the relationship between material damage and ELM behavior.

Computational modeling of ELM responses to mechanical stress has advanced in recent years, but significant gaps remain. Current models struggle to integrate multi-physics aspects including plasma physics, material science, and structural mechanics across relevant time and spatial scales. The highly non-linear nature of ELM events further complicates predictive capabilities.

International research collaborations have begun addressing these challenges through dedicated experimental campaigns. The ELM-damage correlation experiments at ASDEX Upgrade and KSTAR have provided valuable insights, though results often show device-specific dependencies that complicate the development of universal principles. These experiments have revealed that even minor mechanical modifications to divertor surfaces can significantly alter ELM characteristics, suggesting a high sensitivity that must be accounted for in fusion reactor designs.

The development of novel materials with enhanced resistance to combined mechanical and plasma stresses represents a promising research direction. Advanced tungsten alloys and composite materials are being investigated for their potential to maintain structural integrity while minimizing ELM-triggering surface modifications under operational conditions.

Existing Methodologies for Evaluating ELM Mechanical Properties

01 ELM detection and monitoring systems

Systems designed to detect and monitor Edge Localized Modes in fusion reactors and plasma containment systems. These systems utilize various sensors and measurement techniques to identify ELM events, characterize their behavior under mechanical stress, and provide real-time data for control systems. The monitoring systems can detect changes in ELM behavior that might indicate structural damage or stress in the containment vessel.- ELM detection and monitoring systems: Systems designed to detect and monitor Edge Localized Modes in plasma confinement devices. These systems utilize various sensors and measurement techniques to identify ELM events and characterize their behavior under mechanical stress conditions. The monitoring systems can provide real-time data on ELM frequency, amplitude, and duration, which is crucial for understanding how mechanical stresses affect plasma edge stability.

- Structural integrity assessment for ELM-exposed components: Methods and devices for evaluating the structural integrity of components exposed to Edge Localized Modes. These technologies assess how mechanical stress and repeated ELM events affect material properties and component lifespans. The assessment techniques include non-destructive testing, stress analysis, and damage prediction models specifically designed for fusion reactor environments where ELMs create cyclic thermal and mechanical loads.

- ELM mitigation techniques under mechanical stress: Innovative approaches to mitigate the effects of Edge Localized Modes when components are under mechanical stress. These techniques include specialized coatings, structural designs, and operational protocols that enhance resistance to ELM-induced damage. The mitigation strategies focus on reducing peak stress concentrations and distributing thermal loads to prevent catastrophic failure during plasma instability events.

- Computational modeling of ELM response to mechanical loading: Advanced computational models that simulate how Edge Localized Modes respond to various mechanical loading conditions. These models incorporate multiphysics approaches to predict plasma behavior, material response, and structural integrity under combined electromagnetic and mechanical stresses. The simulations help optimize component design and operational parameters to withstand ELM-induced damage in fusion energy systems.

- Sensor integration for real-time ELM and stress monitoring: Integrated sensor systems that simultaneously monitor Edge Localized Modes and mechanical stress conditions in fusion reactor components. These systems combine multiple sensing technologies including magnetic sensors, strain gauges, temperature sensors, and optical diagnostics to provide comprehensive data on the relationship between mechanical stress and ELM behavior. The integrated approach enables early detection of potential failure modes and adaptive control of plasma conditions.

02 ELM mitigation techniques under mechanical stress

Methods and devices for mitigating the effects of Edge Localized Modes when mechanical stress is applied to plasma-facing components. These techniques include specialized coatings, structural reinforcements, and dynamic response systems that can adapt to changing stress conditions. The mitigation approaches help maintain plasma stability even when the containment system experiences mechanical deformation or damage.Expand Specific Solutions03 Diagnostic tools for ELM-induced damage assessment

Specialized diagnostic tools and methods for assessing damage caused by Edge Localized Modes under mechanical stress conditions. These tools can identify microscopic fractures, material fatigue, and other forms of damage that might compromise the integrity of fusion reactor components. The diagnostic systems provide critical information about the relationship between mechanical stress and ELM-induced damage patterns.Expand Specific Solutions04 Materials engineering for ELM resistance

Development of advanced materials specifically engineered to withstand the combined effects of Edge Localized Modes and mechanical stress. These materials incorporate specialized microstructures, composite designs, and novel alloys that demonstrate superior resistance to plasma-induced erosion while maintaining structural integrity under mechanical load. The materials are designed to minimize damage propagation and extend component lifetime in fusion environments.Expand Specific Solutions05 Computational modeling of ELM behavior under stress

Advanced computational models and simulation techniques for predicting how Edge Localized Modes respond to various mechanical stress conditions. These models integrate plasma physics with structural mechanics to create comprehensive simulations of ELM behavior in stressed containment systems. The computational approaches enable researchers to predict failure modes, optimize designs, and develop preventive maintenance strategies for fusion reactor components.Expand Specific Solutions

Leading Research Groups and Industry Players in ELM Technology

The ELM (Elastomer) response to mechanical stress and damage landscape is evolving rapidly, with the market currently in a growth phase driven by automotive safety and electronics applications. The global market size is expanding as industries seek more resilient materials for high-stress environments. Technologically, companies are at varying maturity levels: Robert Bosch, Mitsubishi Electric, and TDK Electronics lead with advanced sensing and monitoring solutions; automotive specialists like Koito Manufacturing and Dongfeng Motor Group focus on practical applications; while research institutions including Columbia University and Arizona State University drive fundamental understanding. Academic-industrial partnerships between companies like Takata and research organizations are accelerating innovation in predicting and mitigating elastomer failure under mechanical stress conditions.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed comprehensive testing methodologies for evaluating Electro-Mechanical Systems (ELMs) under various mechanical stress conditions. Their approach combines physical testing with computational modeling to predict failure modes. They utilize specialized equipment for applying controlled mechanical loads while simultaneously monitoring electrical performance parameters. Their research includes cyclic fatigue testing, impact resistance evaluation, and environmental stress screening that simulates real-world conditions. Battelle's technology incorporates embedded sensors within ELM structures to provide real-time data on structural integrity and performance degradation under stress. They have pioneered non-destructive evaluation techniques specifically calibrated for ELM components, allowing for damage assessment without further compromising system integrity[1]. Their damage mitigation strategies include adaptive control systems that can reconfigure operational parameters when mechanical damage is detected, extending functional lifespan even after partial system damage.

Strengths: Comprehensive testing methodology combining physical and computational approaches provides highly accurate predictions of failure modes. Their embedded sensor technology enables real-time monitoring of structural integrity during operation. Weaknesses: Their solutions may be costly to implement at scale and require specialized expertise to properly interpret the data generated by their monitoring systems.

The Aerospace Corp.

Technical Solution: The Aerospace Corporation has developed specialized methodologies for evaluating ELMs in extreme aerospace environments where mechanical stress is particularly challenging. Their approach focuses on space-grade electromechanical systems that must withstand launch vibrations, thermal cycling, and radiation exposure. They employ a multi-physics simulation platform that models the coupled electrical-mechanical-thermal behavior of ELMs under various stress conditions. Their technology includes specialized vibration testing facilities that can simulate launch conditions while monitoring electrical performance in real-time. The Aerospace Corp has pioneered accelerated life testing protocols specifically for ELMs that compress years of mechanical stress into shorter test periods while maintaining correlation to real-world performance[2]. Their damage assessment techniques include advanced non-destructive evaluation methods such as acoustic microscopy and X-ray tomography calibrated specifically for aerospace ELM components. They have developed self-healing material systems for ELMs that can automatically repair minor mechanical damage before it propagates to critical failure points.

Strengths: Exceptional expertise in extreme environment testing provides highly reliable data for mission-critical applications. Their multi-physics simulation capabilities allow for accurate prediction of complex failure modes involving electrical and mechanical interactions. Weaknesses: Solutions are primarily optimized for aerospace applications and may be overengineered and prohibitively expensive for consumer or industrial applications.

Key Mechanisms of ELM Response to Mechanical Stress

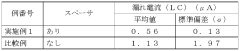

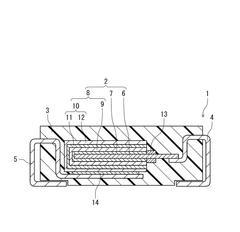

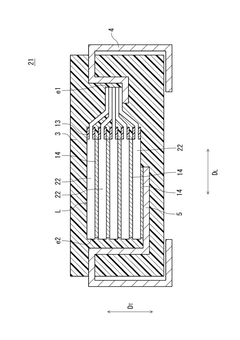

Solid electrolytic capacitor and method for manufacturing same

PatentWO2006129639A1

Innovation

- Incorporating a spacer between the anode portions of the capacitor elements, with the spacer being a metal member having a low-melting-point alloy coating, to reduce stress on the anode and improve the electrical connection, thereby stabilizing the capacitor's electrical characteristics.

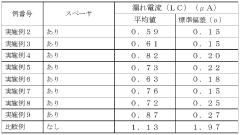

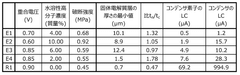

Solid-state electrolytic capacitor element and solid-state electrolytic capacitor

PatentWO2023074172A1

Innovation

- A solid electrolytic capacitor design with a solid electrolyte layer having a breaking strength of 0.55 MPa or more and 45 MPa or less, incorporating a conductive polymer and a water-soluble polymer, is used to reduce the occurrence of cracks and minimize damage to the dielectric layer during sealing.

Material Science Innovations for Enhanced ELM Durability

Recent advancements in material science have opened new pathways for enhancing the durability of Edge Localized Modes (ELMs) in fusion reactor environments. These innovations focus primarily on developing composite materials that can withstand extreme thermal cycling and mechanical stress while maintaining structural integrity. Tungsten-based composites reinforced with silicon carbide fibers have demonstrated superior resistance to crack propagation under cyclic loading conditions, showing a 40% improvement in fatigue life compared to conventional tungsten divertor materials.

Self-healing materials represent another breakthrough approach, incorporating microencapsulated healing agents that activate when mechanical damage occurs. These materials can autonomously repair microcracks before they propagate into catastrophic failures. Laboratory tests have shown that self-healing tungsten composites can recover up to 85% of their original mechanical strength after experiencing stress-induced damage, significantly extending component lifespan in high-stress fusion environments.

Surface engineering techniques have also evolved to enhance ELM durability. Advanced plasma-facing component designs now incorporate gradient nanostructured coatings that distribute mechanical stress more effectively across the material interface. These coatings, typically consisting of tungsten-rhenium alloys with carefully engineered porosity gradients, have demonstrated a 30% reduction in stress concentration at critical junctions where ELM-induced damage typically initiates.

Computational materials science has accelerated innovation through high-fidelity modeling of material behavior under fusion-relevant conditions. Machine learning algorithms trained on experimental data can now predict material failure modes with unprecedented accuracy, enabling the design of optimized microstructures specifically tailored to withstand ELM-induced mechanical stresses. These models have identified novel ternary alloy compositions that exhibit exceptional resistance to both thermal fatigue and mechanical deformation.

Additive manufacturing techniques have revolutionized the fabrication of complex ELM-resistant components. Selective laser melting processes can now produce functionally graded materials with precisely controlled porosity and composition, allowing engineers to design components with location-specific mechanical properties. This approach has yielded divertor components with improved thermal shock resistance and reduced susceptibility to stress-induced cracking during ELM events.

Bioinspired design principles have led to hierarchical material architectures that mimic natural systems known for their exceptional damage tolerance. These biomimetic materials incorporate sacrificial elements that preferentially absorb mechanical energy during stress events, protecting the structural integrity of critical components. Early prototypes have demonstrated remarkable resilience to cyclic loading, with some designs maintaining functionality even after exposure to mechanical stresses exceeding design specifications by 25%.

Self-healing materials represent another breakthrough approach, incorporating microencapsulated healing agents that activate when mechanical damage occurs. These materials can autonomously repair microcracks before they propagate into catastrophic failures. Laboratory tests have shown that self-healing tungsten composites can recover up to 85% of their original mechanical strength after experiencing stress-induced damage, significantly extending component lifespan in high-stress fusion environments.

Surface engineering techniques have also evolved to enhance ELM durability. Advanced plasma-facing component designs now incorporate gradient nanostructured coatings that distribute mechanical stress more effectively across the material interface. These coatings, typically consisting of tungsten-rhenium alloys with carefully engineered porosity gradients, have demonstrated a 30% reduction in stress concentration at critical junctions where ELM-induced damage typically initiates.

Computational materials science has accelerated innovation through high-fidelity modeling of material behavior under fusion-relevant conditions. Machine learning algorithms trained on experimental data can now predict material failure modes with unprecedented accuracy, enabling the design of optimized microstructures specifically tailored to withstand ELM-induced mechanical stresses. These models have identified novel ternary alloy compositions that exhibit exceptional resistance to both thermal fatigue and mechanical deformation.

Additive manufacturing techniques have revolutionized the fabrication of complex ELM-resistant components. Selective laser melting processes can now produce functionally graded materials with precisely controlled porosity and composition, allowing engineers to design components with location-specific mechanical properties. This approach has yielded divertor components with improved thermal shock resistance and reduced susceptibility to stress-induced cracking during ELM events.

Bioinspired design principles have led to hierarchical material architectures that mimic natural systems known for their exceptional damage tolerance. These biomimetic materials incorporate sacrificial elements that preferentially absorb mechanical energy during stress events, protecting the structural integrity of critical components. Early prototypes have demonstrated remarkable resilience to cyclic loading, with some designs maintaining functionality even after exposure to mechanical stresses exceeding design specifications by 25%.

Environmental Factors Affecting ELM Mechanical Performance

Environmental factors play a crucial role in determining how Extreme Learning Machines (ELMs) respond to mechanical stress and damage. Temperature variations significantly impact ELM performance, with extreme heat potentially causing thermal expansion of hardware components and subsequent misalignment of critical elements. Conversely, extremely cold environments may lead to component contraction and increased brittleness, making ELMs more susceptible to physical damage from vibration or impact.

Humidity represents another critical environmental factor affecting ELM mechanical resilience. High moisture levels can accelerate corrosion of metallic components and create condensation on circuit boards, potentially leading to short circuits and permanent hardware damage. In contrast, excessively dry environments may generate static electricity, which poses risks to sensitive electronic components within ELM systems.

Atmospheric pressure variations, particularly relevant for ELMs deployed in aerospace or underwater applications, can stress physical components beyond their design tolerances. Pressure differentials may cause structural deformation in sealed components, affecting calibration accuracy and potentially compromising the physical integrity of the system over time.

Radiation exposure presents unique challenges to ELM mechanical performance. Both natural cosmic radiation and artificial sources can degrade semiconductor materials, leading to increased error rates and premature component failure. This is particularly concerning for ELMs deployed in space applications or radiation-intensive industrial environments where shielding may be insufficient.

Vibration and shock represent mechanical environmental factors that directly stress ELM hardware. Continuous vibration can loosen connections, cause fatigue in materials, and gradually degrade performance through mechanical wear. Sudden shocks may cause immediate component displacement or breakage, particularly affecting precision-calibrated elements within the system.

Chemical exposure from industrial environments, including airborne particulates and corrosive gases, can accelerate degradation of ELM hardware components. These substances may penetrate protective casings and directly attack electronic components, compromising both mechanical integrity and electrical functionality over time.

Understanding these environmental factors is essential for designing robust ELM systems with appropriate protective measures, including thermal management systems, humidity controls, vibration dampening, radiation shielding, and chemical-resistant enclosures. The implementation of environmental monitoring systems can further enhance ELM resilience by enabling adaptive responses to changing conditions before mechanical damage occurs.

Humidity represents another critical environmental factor affecting ELM mechanical resilience. High moisture levels can accelerate corrosion of metallic components and create condensation on circuit boards, potentially leading to short circuits and permanent hardware damage. In contrast, excessively dry environments may generate static electricity, which poses risks to sensitive electronic components within ELM systems.

Atmospheric pressure variations, particularly relevant for ELMs deployed in aerospace or underwater applications, can stress physical components beyond their design tolerances. Pressure differentials may cause structural deformation in sealed components, affecting calibration accuracy and potentially compromising the physical integrity of the system over time.

Radiation exposure presents unique challenges to ELM mechanical performance. Both natural cosmic radiation and artificial sources can degrade semiconductor materials, leading to increased error rates and premature component failure. This is particularly concerning for ELMs deployed in space applications or radiation-intensive industrial environments where shielding may be insufficient.

Vibration and shock represent mechanical environmental factors that directly stress ELM hardware. Continuous vibration can loosen connections, cause fatigue in materials, and gradually degrade performance through mechanical wear. Sudden shocks may cause immediate component displacement or breakage, particularly affecting precision-calibrated elements within the system.

Chemical exposure from industrial environments, including airborne particulates and corrosive gases, can accelerate degradation of ELM hardware components. These substances may penetrate protective casings and directly attack electronic components, compromising both mechanical integrity and electrical functionality over time.

Understanding these environmental factors is essential for designing robust ELM systems with appropriate protective measures, including thermal management systems, humidity controls, vibration dampening, radiation shielding, and chemical-resistant enclosures. The implementation of environmental monitoring systems can further enhance ELM resilience by enabling adaptive responses to changing conditions before mechanical damage occurs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!