The Challenge Of Creating Anaerobic Or Anoxic Living Materials.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anaerobic Living Materials Background and Objectives

Living materials represent a frontier in biotechnology where engineered biological systems are integrated with non-living components to create functional materials with unique capabilities. Historically, most research in this domain has focused on aerobic organisms due to their relative ease of cultivation and manipulation. However, the development of anaerobic or anoxic living materials presents both significant challenges and unprecedented opportunities for technological advancement.

The evolution of living materials technology began in the early 2000s with simple bacterial cellulose and biofilms, progressing to more complex engineered living materials (ELMs) in the 2010s. The incorporation of anaerobic organisms represents the next logical progression in this field, driven by their unique metabolic capabilities and potential applications in oxygen-limited environments.

Anaerobic organisms possess distinctive metabolic pathways that enable them to thrive in oxygen-depleted conditions, offering novel functionalities such as specific fermentation processes, production of unique secondary metabolites, and the ability to interact with metals and minerals in ways aerobic organisms cannot. These characteristics make them particularly valuable for applications in deep-sea environments, subsurface operations, and certain industrial bioprocesses where oxygen is limited or undesirable.

The primary objective of research in anaerobic living materials is to develop robust biological systems that maintain viability and functionality in oxygen-free environments while performing specific engineered tasks. This includes creating materials capable of self-repair, responsive behavior, and sustainable operation without oxygen dependency, potentially revolutionizing fields from environmental remediation to space exploration.

Technical goals in this domain include establishing reliable cultivation and maintenance protocols for anaerobic living materials, developing genetic tools specifically adapted for anaerobic organisms, and creating interfaces between anaerobic biological components and non-living substrates that preserve functionality in oxygen-free conditions.

The trajectory of this technology is increasingly influenced by advances in synthetic biology, materials science, and microfluidics, which together are enabling more sophisticated control over anaerobic biological systems. Recent breakthroughs in genome editing tools like CRISPR-Cas systems adapted for anaerobic organisms have accelerated progress, though significant challenges remain in maintaining long-term stability and performance.

As climate change and resource limitations drive interest in sustainable technologies, anaerobic living materials offer promising solutions for waste treatment, bioremediation, and renewable energy production with minimal environmental footprint. Their potential to function in extreme environments also makes them candidates for extraterrestrial applications, aligning with long-term space exploration objectives.

The evolution of living materials technology began in the early 2000s with simple bacterial cellulose and biofilms, progressing to more complex engineered living materials (ELMs) in the 2010s. The incorporation of anaerobic organisms represents the next logical progression in this field, driven by their unique metabolic capabilities and potential applications in oxygen-limited environments.

Anaerobic organisms possess distinctive metabolic pathways that enable them to thrive in oxygen-depleted conditions, offering novel functionalities such as specific fermentation processes, production of unique secondary metabolites, and the ability to interact with metals and minerals in ways aerobic organisms cannot. These characteristics make them particularly valuable for applications in deep-sea environments, subsurface operations, and certain industrial bioprocesses where oxygen is limited or undesirable.

The primary objective of research in anaerobic living materials is to develop robust biological systems that maintain viability and functionality in oxygen-free environments while performing specific engineered tasks. This includes creating materials capable of self-repair, responsive behavior, and sustainable operation without oxygen dependency, potentially revolutionizing fields from environmental remediation to space exploration.

Technical goals in this domain include establishing reliable cultivation and maintenance protocols for anaerobic living materials, developing genetic tools specifically adapted for anaerobic organisms, and creating interfaces between anaerobic biological components and non-living substrates that preserve functionality in oxygen-free conditions.

The trajectory of this technology is increasingly influenced by advances in synthetic biology, materials science, and microfluidics, which together are enabling more sophisticated control over anaerobic biological systems. Recent breakthroughs in genome editing tools like CRISPR-Cas systems adapted for anaerobic organisms have accelerated progress, though significant challenges remain in maintaining long-term stability and performance.

As climate change and resource limitations drive interest in sustainable technologies, anaerobic living materials offer promising solutions for waste treatment, bioremediation, and renewable energy production with minimal environmental footprint. Their potential to function in extreme environments also makes them candidates for extraterrestrial applications, aligning with long-term space exploration objectives.

Market Applications for Anaerobic Biological Systems

Anaerobic biological systems represent a significant untapped market opportunity across multiple industries. The absence of oxygen in these systems creates unique biochemical environments that can be leveraged for various commercial applications. The wastewater treatment sector currently dominates the market for anaerobic technologies, with anaerobic digesters being widely implemented for biogas production and sludge reduction. This market segment is projected to grow substantially as municipalities and industries seek more energy-efficient treatment solutions.

The renewable energy sector presents another substantial market for anaerobic biological systems. Biogas production from anaerobic digestion of organic waste materials offers a sustainable alternative to fossil fuels. Agricultural waste, food processing byproducts, and municipal solid waste can all serve as feedstocks for these systems, creating value from materials that would otherwise require costly disposal.

Pharmaceutical and fine chemical manufacturing represents a high-value niche market for anaerobic biological processes. Certain valuable compounds can only be synthesized under oxygen-free conditions, and anaerobic microorganisms often produce unique metabolites with potential therapeutic applications. Companies are increasingly exploring these biological routes as alternatives to traditional chemical synthesis methods.

The food and beverage industry utilizes anaerobic fermentation processes for products ranging from cheese and yogurt to alcoholic beverages. There is growing interest in novel fermented products with unique flavor profiles and potential health benefits derived from anaerobic microbial communities.

Environmental remediation presents another emerging application area. Anaerobic microorganisms can degrade certain persistent pollutants that aerobic processes cannot effectively address, including chlorinated solvents and some petroleum hydrocarbons. This capability creates opportunities for specialized bioremediation services and technologies.

The development of anaerobic living materials could revolutionize biomanufacturing by enabling continuous production processes that operate without oxygen input. This would significantly reduce operational costs associated with aeration in conventional bioreactors while potentially opening new product categories impossible to create under aerobic conditions.

Agricultural applications are expanding beyond traditional biogas production to include specialized soil amendments and biofertilizers based on anaerobic microbial consortia. These products aim to enhance crop resilience and reduce dependence on synthetic fertilizers by improving nutrient cycling in soil environments.

The market for anaerobic biological systems faces challenges related to process control, scalability, and integration with existing infrastructure. However, advances in monitoring technologies, genetic engineering tools, and materials science are gradually addressing these limitations, expanding the commercial viability of these systems across diverse sectors.

The renewable energy sector presents another substantial market for anaerobic biological systems. Biogas production from anaerobic digestion of organic waste materials offers a sustainable alternative to fossil fuels. Agricultural waste, food processing byproducts, and municipal solid waste can all serve as feedstocks for these systems, creating value from materials that would otherwise require costly disposal.

Pharmaceutical and fine chemical manufacturing represents a high-value niche market for anaerobic biological processes. Certain valuable compounds can only be synthesized under oxygen-free conditions, and anaerobic microorganisms often produce unique metabolites with potential therapeutic applications. Companies are increasingly exploring these biological routes as alternatives to traditional chemical synthesis methods.

The food and beverage industry utilizes anaerobic fermentation processes for products ranging from cheese and yogurt to alcoholic beverages. There is growing interest in novel fermented products with unique flavor profiles and potential health benefits derived from anaerobic microbial communities.

Environmental remediation presents another emerging application area. Anaerobic microorganisms can degrade certain persistent pollutants that aerobic processes cannot effectively address, including chlorinated solvents and some petroleum hydrocarbons. This capability creates opportunities for specialized bioremediation services and technologies.

The development of anaerobic living materials could revolutionize biomanufacturing by enabling continuous production processes that operate without oxygen input. This would significantly reduce operational costs associated with aeration in conventional bioreactors while potentially opening new product categories impossible to create under aerobic conditions.

Agricultural applications are expanding beyond traditional biogas production to include specialized soil amendments and biofertilizers based on anaerobic microbial consortia. These products aim to enhance crop resilience and reduce dependence on synthetic fertilizers by improving nutrient cycling in soil environments.

The market for anaerobic biological systems faces challenges related to process control, scalability, and integration with existing infrastructure. However, advances in monitoring technologies, genetic engineering tools, and materials science are gradually addressing these limitations, expanding the commercial viability of these systems across diverse sectors.

Current Challenges in Anaerobic Living Materials Development

The development of anaerobic or anoxic living materials faces significant technical challenges that have hindered progress in this specialized field. One primary obstacle is the maintenance of viable anaerobic conditions during material fabrication and operation. Unlike aerobic systems, anaerobic living materials require strict oxygen exclusion, necessitating specialized equipment and protocols that substantially increase production complexity and cost.

Cellular viability represents another major hurdle, as anaerobic microorganisms typically exhibit slower growth rates and lower biomass yields compared to their aerobic counterparts. This fundamental biological limitation affects material formation kinetics and ultimately impacts the functional properties of the resulting living materials. Additionally, many anaerobic species demonstrate heightened sensitivity to environmental perturbations, further complicating their incorporation into robust materials.

Metabolic engineering of anaerobic organisms presents unique difficulties due to less developed genetic toolkits compared to model aerobic organisms like E. coli. The limited availability of well-characterized genetic parts, efficient transformation protocols, and expression systems specifically optimized for anaerobic conditions restricts the design space for engineered functionality in these materials.

Interface challenges between biological components and material matrices are particularly pronounced in anaerobic systems. The chemical compatibility between anaerobic microbes and material precursors must be carefully managed, as many common material chemistries can inhibit anaerobic metabolism or compromise cell membrane integrity under oxygen-limited conditions.

Characterization and quality control of anaerobic living materials face technical limitations as many standard analytical techniques require aerobic conditions or sample preparation steps that compromise anaerobic integrity. This creates significant barriers to understanding material properties and performance, ultimately slowing development cycles.

Scalability remains problematic as the transition from laboratory-scale production to industrial manufacturing introduces additional complexities in maintaining anaerobic conditions throughout larger-scale processes. The energy requirements and infrastructure needed for industrial-scale anaerobic production systems represent substantial economic barriers to commercialization.

Stability and shelf-life considerations present further challenges, with anaerobic materials often exhibiting reduced longevity compared to aerobic counterparts. The metabolic state of anaerobic organisms during storage and the potential for contamination by facultative organisms that might outcompete strictly anaerobic species under certain conditions create significant hurdles for practical applications.

Cellular viability represents another major hurdle, as anaerobic microorganisms typically exhibit slower growth rates and lower biomass yields compared to their aerobic counterparts. This fundamental biological limitation affects material formation kinetics and ultimately impacts the functional properties of the resulting living materials. Additionally, many anaerobic species demonstrate heightened sensitivity to environmental perturbations, further complicating their incorporation into robust materials.

Metabolic engineering of anaerobic organisms presents unique difficulties due to less developed genetic toolkits compared to model aerobic organisms like E. coli. The limited availability of well-characterized genetic parts, efficient transformation protocols, and expression systems specifically optimized for anaerobic conditions restricts the design space for engineered functionality in these materials.

Interface challenges between biological components and material matrices are particularly pronounced in anaerobic systems. The chemical compatibility between anaerobic microbes and material precursors must be carefully managed, as many common material chemistries can inhibit anaerobic metabolism or compromise cell membrane integrity under oxygen-limited conditions.

Characterization and quality control of anaerobic living materials face technical limitations as many standard analytical techniques require aerobic conditions or sample preparation steps that compromise anaerobic integrity. This creates significant barriers to understanding material properties and performance, ultimately slowing development cycles.

Scalability remains problematic as the transition from laboratory-scale production to industrial manufacturing introduces additional complexities in maintaining anaerobic conditions throughout larger-scale processes. The energy requirements and infrastructure needed for industrial-scale anaerobic production systems represent substantial economic barriers to commercialization.

Stability and shelf-life considerations present further challenges, with anaerobic materials often exhibiting reduced longevity compared to aerobic counterparts. The metabolic state of anaerobic organisms during storage and the potential for contamination by facultative organisms that might outcompete strictly anaerobic species under certain conditions create significant hurdles for practical applications.

Existing Approaches to Anaerobic Material Engineering

01 Anaerobic wastewater treatment systems

Systems designed for treating wastewater under oxygen-free conditions, utilizing anaerobic microorganisms to break down organic matter. These systems often include bioreactors, filters, and settling tanks that create controlled environments for anaerobic digestion processes. The absence of oxygen allows specialized bacteria to convert organic pollutants into biogas (primarily methane and carbon dioxide) while reducing sludge production compared to aerobic systems.- Anaerobic wastewater treatment systems: Systems designed for treating wastewater under oxygen-free conditions, utilizing anaerobic microorganisms to break down organic matter. These systems include anaerobic digesters, bioreactors, and specialized treatment processes that function in the absence of oxygen. The anaerobic microorganisms convert organic pollutants into biogas (primarily methane and carbon dioxide) while reducing sludge production compared to aerobic processes.

- Anaerobic microbial cultures and biofilms: Specialized microbial communities that thrive in oxygen-free environments, including bacteria, archaea, and fungi that perform anaerobic respiration or fermentation. These living materials are cultivated for various applications including waste degradation, bioremediation, and production of valuable metabolites. The microbial cultures can be immobilized as biofilms on various support materials to enhance their stability and performance in anaerobic processes.

- Anoxic bioreactors for environmental applications: Specialized reactor systems that maintain low-oxygen conditions for biological processes such as denitrification and phosphorus removal. These bioreactors support anoxic living materials that can convert nitrates to nitrogen gas or perform other environmentally beneficial transformations. The design includes mechanisms for controlling oxygen levels while providing necessary nutrients and support for the microbial communities.

- Anaerobic fermentation systems for biogas production: Systems designed to harness anaerobic microorganisms for the production of biogas from organic waste materials. These systems create controlled environments where anaerobic digestion can occur efficiently, converting biomass into methane-rich biogas. The living materials involved include complex consortia of hydrolytic, acidogenic, acetogenic, and methanogenic microorganisms working in syntrophic relationships.

- Anoxic soil and sediment remediation technologies: Technologies that utilize anaerobic or anoxic microorganisms for the remediation of contaminated soils and sediments. These approaches leverage the unique metabolic capabilities of anaerobic microbes to degrade or transform pollutants such as chlorinated solvents, petroleum hydrocarbons, and heavy metals under oxygen-limited conditions. The technologies include in-situ bioremediation methods and engineered treatment systems that create and maintain anoxic conditions.

02 Anaerobic microbial fuel cells and bioelectrochemical systems

Devices that utilize anaerobic microorganisms to generate electricity or valuable products through bioelectrochemical processes. These systems harness the metabolic activities of electroactive bacteria that can transfer electrons to electrodes in oxygen-free environments. Applications include sustainable energy production, waste treatment, and biosynthesis of chemicals under controlled anoxic conditions.Expand Specific Solutions03 Anoxic bioremediation technologies

Methods and materials for environmental cleanup using microorganisms that thrive in oxygen-depleted conditions. These technologies leverage specialized bacteria and fungi to degrade contaminants like chlorinated solvents, petroleum hydrocarbons, and heavy metals in soil and groundwater where oxygen is limited or absent. The process often involves creating controlled anoxic zones and introducing specific microbial communities or nutrients to enhance natural degradation pathways.Expand Specific Solutions04 Anaerobic fermentation and bioprocessing systems

Equipment and methods for industrial-scale fermentation processes conducted in oxygen-free environments. These systems are used for producing biofuels, organic acids, alcohols, and other valuable compounds through controlled anaerobic metabolism of microorganisms. The technology includes specialized bioreactors, monitoring systems, and process controls that maintain strict anoxic conditions while optimizing production efficiency and product yield.Expand Specific Solutions05 Anoxic cultivation of aquatic organisms

Systems and methods for growing aquatic organisms in low-oxygen or oxygen-free environments. These technologies include specialized tanks, bioreactors, and water treatment systems that maintain controlled anoxic conditions for cultivating certain types of algae, bacteria, or other aquatic microorganisms that thrive in such environments. Applications include production of specialty biochemicals, pharmaceuticals, and nutritional supplements that require anoxic biosynthesis pathways.Expand Specific Solutions

Leading Organizations in Anaerobic Living Materials Research

The anaerobic/anoxic living materials market is in an early development stage, characterized by significant research activity but limited commercial applications. The global market for engineered living materials is projected to grow substantially as industries seek sustainable solutions for environmental challenges. Companies like Viridos and Evelo Biosciences are pioneering commercial applications in bioenergy and therapeutics, while established corporations including Dow Global Technologies, 3M, and Veolia Water Solutions are exploring industrial applications. Academic institutions such as Harvard, Nanjing University, and CUHK are driving fundamental research. Technical challenges remain in maintaining anaerobic conditions, controlling material properties, and scaling production, indicating the field is still evolving toward technological maturity.

Viridos, Inc.

Technical Solution: Viridos has developed advanced bioengineering platforms for creating anaerobic living materials focused on algae-based systems. Their proprietary technology involves genetic modification of microalgae to optimize performance under oxygen-limited conditions, enabling the production of sustainable biofuels and biomaterials. The company employs synthetic biology approaches to engineer metabolic pathways that function efficiently in anaerobic environments, allowing for carbon capture and conversion into valuable compounds. Their platform includes specialized bioreactors designed to maintain precise oxygen gradients and support the growth of these engineered organisms at commercial scale. Viridos has demonstrated successful cultivation of anaerobic microalgae strains that can produce lipids and other high-value compounds with significantly reduced oxygen requirements compared to conventional systems.

Strengths: Specialized expertise in algae bioengineering; proprietary genetic modification techniques optimized for low-oxygen environments; integrated bioreactor systems designed specifically for anaerobic cultivation. Weaknesses: Scale-up challenges for commercial production; potential regulatory hurdles for genetically modified organisms; higher production costs compared to conventional aerobic systems.

The Regents of the University of California

Technical Solution: The University of California has pioneered research in anaerobic living materials through their interdisciplinary approach combining synthetic biology, materials science, and environmental engineering. Their technology focuses on developing self-regenerating materials that incorporate anaerobic microorganisms within engineered matrices. These living materials are designed to maintain functionality in oxygen-depleted environments through specialized encapsulation techniques that protect the anaerobic microbes while allowing nutrient exchange. The university's research teams have successfully developed prototype materials that can perform bioremediation of contaminants in anoxic environments, produce bioelectricity through microbial fuel cells, and synthesize valuable compounds without oxygen. Their approach includes innovative methods for controlling material properties through selective pressure on the embedded microbial communities, allowing for adaptive responses to environmental changes while maintaining anaerobic conditions.

Strengths: Strong interdisciplinary research foundation; access to diverse scientific expertise across multiple campuses; established intellectual property portfolio in bioengineered materials. Weaknesses: Challenges in transitioning from laboratory research to practical applications; limited commercial development compared to industry players; potential durability issues with living materials in extreme environments.

Key Innovations in Oxygen-Free Biological Systems

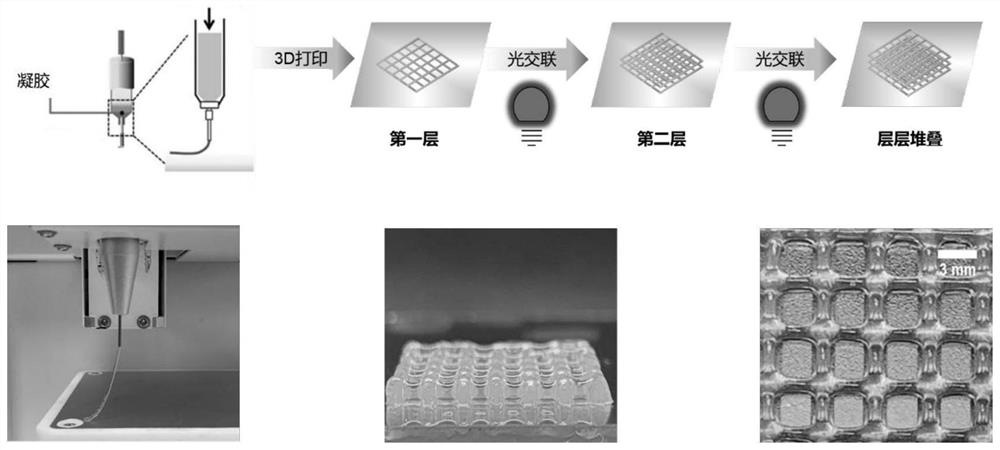

Method for constructing coexistence of aerobic fungi and facultative or anaerobic microorganisms by utilizing 3D printing

PatentActiveCN114703072A

Innovation

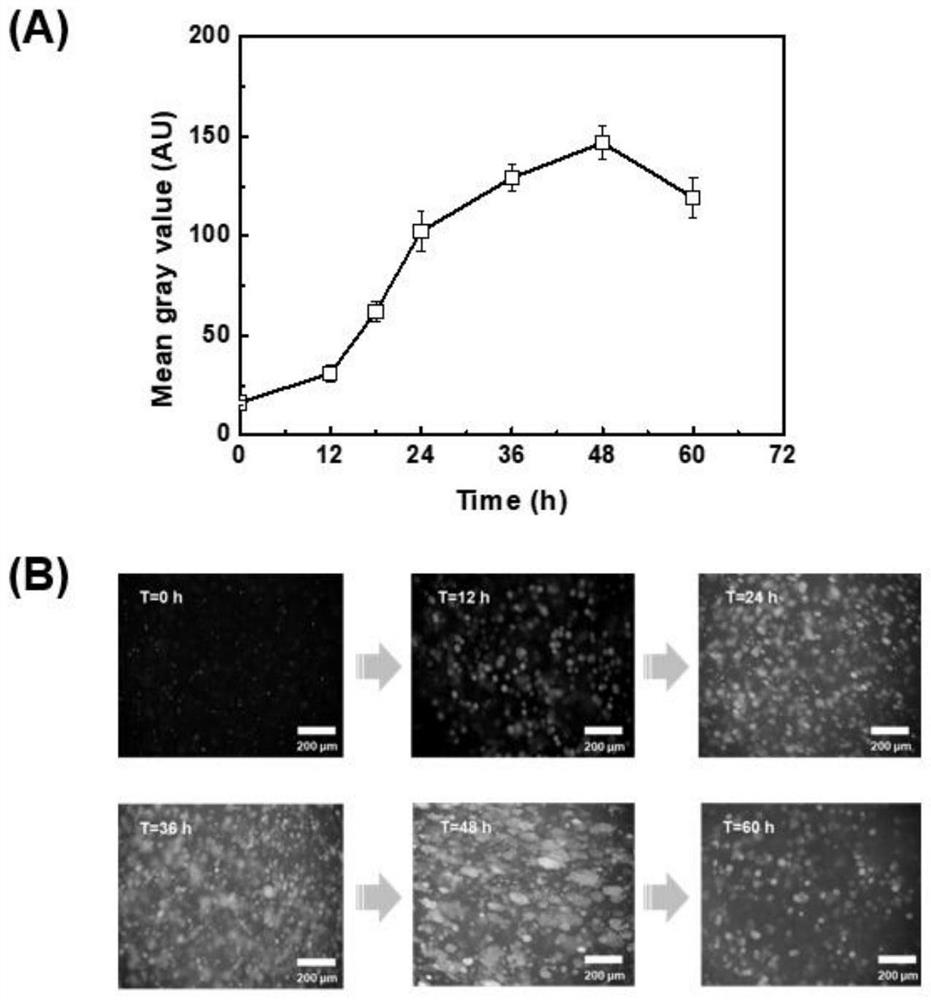

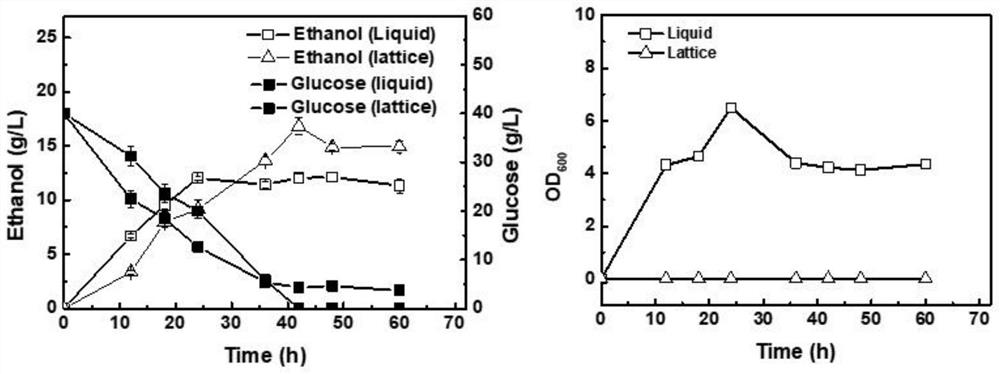

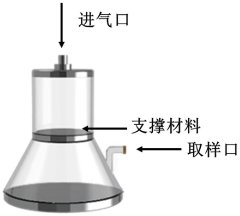

- A method of constructing a coexistence of aerobic fungi and facultative or anaerobic microorganisms through 3D printing, using support materials with pores to form biofilms, and making facultative or anaerobic microorganisms into living materials with a fence structure, creating a suitable environment through oxygen consumption Growth and production conditions, combined with double bond-modified polyvinyl alcohol and phenylboronic acid-functionalized sodium alginate double-crosslinked bioink, designed a reversible covalently cross-linked bioink to maintain microbial activity and fermentation capacity.

Built-in anaerobic environment-generating culture apparatus

PatentInactiveJP2021106588A

Innovation

- A self-contained anaerobic culture device with a waterproof base and cover sheet, containing a growth compartment with a dry oxygen scavenging reagent and cold water-soluble gelling agent, which creates a low-oxygen environment for microbial growth without the need for dedicated incubation equipment.

Sustainability Impact of Anaerobic Biotechnologies

The development of anaerobic biotechnologies represents a significant advancement in sustainable practices across multiple industries. These technologies harness the metabolic capabilities of microorganisms that thrive in oxygen-free environments to transform waste materials into valuable resources, thereby creating circular economic models that reduce environmental impact.

Anaerobic digestion processes have demonstrated remarkable potential in waste management systems, converting organic waste into biogas while simultaneously reducing landfill volumes and associated methane emissions. This dual benefit addresses two critical environmental challenges: renewable energy generation and waste reduction. Studies indicate that widespread implementation of anaerobic digestion could reduce global greenhouse gas emissions by 3-4% while providing decentralized energy solutions for communities worldwide.

In wastewater treatment, anaerobic technologies require significantly less energy than conventional aerobic systems, with energy consumption reductions of up to 60%. This efficiency translates to lower operational costs and carbon footprints for municipal and industrial treatment facilities. Additionally, these systems produce valuable byproducts such as biogas and nutrient-rich digestate that can be utilized as fertilizer, creating additional value streams.

The food production sector benefits substantially from anaerobic biotechnologies through reduced waste management costs and potential energy self-sufficiency. Breweries, dairy processors, and other food manufacturers implementing these systems have reported payback periods as short as 2-5 years, demonstrating strong economic sustainability alongside environmental benefits.

From a resource conservation perspective, anaerobic processes preserve valuable nutrients like nitrogen and phosphorus in forms that remain bioavailable, unlike many conventional treatment methods that convert these nutrients to forms requiring energy-intensive recovery processes. This nutrient preservation is particularly valuable given the increasing scarcity of phosphorus resources globally.

Water conservation represents another significant sustainability impact, as anaerobic systems typically require less water than aerobic alternatives. In regions facing water scarcity, this advantage becomes increasingly critical for sustainable development and resource management.

The scalability of anaerobic biotechnologies further enhances their sustainability profile, with successful implementations ranging from household-scale digesters in rural communities to industrial-scale facilities processing thousands of tons of waste daily. This flexibility enables appropriate technology deployment across diverse socioeconomic contexts, supporting sustainable development goals in both developed and developing regions.

Anaerobic digestion processes have demonstrated remarkable potential in waste management systems, converting organic waste into biogas while simultaneously reducing landfill volumes and associated methane emissions. This dual benefit addresses two critical environmental challenges: renewable energy generation and waste reduction. Studies indicate that widespread implementation of anaerobic digestion could reduce global greenhouse gas emissions by 3-4% while providing decentralized energy solutions for communities worldwide.

In wastewater treatment, anaerobic technologies require significantly less energy than conventional aerobic systems, with energy consumption reductions of up to 60%. This efficiency translates to lower operational costs and carbon footprints for municipal and industrial treatment facilities. Additionally, these systems produce valuable byproducts such as biogas and nutrient-rich digestate that can be utilized as fertilizer, creating additional value streams.

The food production sector benefits substantially from anaerobic biotechnologies through reduced waste management costs and potential energy self-sufficiency. Breweries, dairy processors, and other food manufacturers implementing these systems have reported payback periods as short as 2-5 years, demonstrating strong economic sustainability alongside environmental benefits.

From a resource conservation perspective, anaerobic processes preserve valuable nutrients like nitrogen and phosphorus in forms that remain bioavailable, unlike many conventional treatment methods that convert these nutrients to forms requiring energy-intensive recovery processes. This nutrient preservation is particularly valuable given the increasing scarcity of phosphorus resources globally.

Water conservation represents another significant sustainability impact, as anaerobic systems typically require less water than aerobic alternatives. In regions facing water scarcity, this advantage becomes increasingly critical for sustainable development and resource management.

The scalability of anaerobic biotechnologies further enhances their sustainability profile, with successful implementations ranging from household-scale digesters in rural communities to industrial-scale facilities processing thousands of tons of waste daily. This flexibility enables appropriate technology deployment across diverse socioeconomic contexts, supporting sustainable development goals in both developed and developing regions.

Scalability and Industrial Implementation Considerations

Scaling anaerobic or anoxic living materials from laboratory settings to industrial applications presents significant engineering challenges that must be addressed for commercial viability. The primary obstacle lies in maintaining oxygen-free environments throughout the production pipeline while ensuring consistent material performance and quality. Current industrial bioreactors designed for anaerobic processes typically operate at scales of 10,000-100,000 liters, but adapting these systems for living materials production requires substantial modifications to accommodate the unique requirements of engineered biological systems.

The economic considerations for industrial implementation include high initial capital expenditure for specialized equipment, ongoing operational costs for maintaining anaerobic conditions, and potential regulatory compliance expenses. Analysis of production economics indicates that anaerobic living materials may initially cost 30-50% more than their aerobic counterparts due to these specialized requirements, though this gap may narrow with technological advancement and economies of scale.

Process engineering for anaerobic living materials necessitates innovative approaches to bioreactor design, incorporating features such as efficient gas exchange systems, precise redox potential control, and contamination prevention mechanisms. Several companies have developed modular anaerobic chambers that could potentially be adapted for scaled production, though these systems currently max out at approximately 1,000-liter capacity, highlighting the need for further engineering solutions.

Quality control presents another significant challenge, as traditional industrial bioprocess monitoring tools often require oxygen exposure for sampling and analysis. Recent developments in non-invasive monitoring technologies, including near-infrared spectroscopy and in-line electrochemical sensors, offer promising solutions but require further validation for anaerobic living materials applications. Standardization of these monitoring protocols will be essential for consistent product quality across production batches.

Supply chain considerations must account for the specialized handling requirements of anaerobic materials throughout distribution networks. This includes developing packaging solutions that maintain anoxic conditions during transport and storage, potentially utilizing oxygen scavengers, modified atmosphere packaging, or active barrier technologies. Several packaging technology companies have demonstrated proof-of-concept solutions, though cost-effective options for large-scale implementation remain limited.

Regulatory frameworks for industrial-scale anaerobic living materials production are still evolving, with particular attention to biosafety considerations and environmental impact assessments. Proactive engagement with regulatory bodies during scale-up planning can help identify potential compliance challenges and develop appropriate risk mitigation strategies, potentially accelerating the path to market for these innovative materials.

The economic considerations for industrial implementation include high initial capital expenditure for specialized equipment, ongoing operational costs for maintaining anaerobic conditions, and potential regulatory compliance expenses. Analysis of production economics indicates that anaerobic living materials may initially cost 30-50% more than their aerobic counterparts due to these specialized requirements, though this gap may narrow with technological advancement and economies of scale.

Process engineering for anaerobic living materials necessitates innovative approaches to bioreactor design, incorporating features such as efficient gas exchange systems, precise redox potential control, and contamination prevention mechanisms. Several companies have developed modular anaerobic chambers that could potentially be adapted for scaled production, though these systems currently max out at approximately 1,000-liter capacity, highlighting the need for further engineering solutions.

Quality control presents another significant challenge, as traditional industrial bioprocess monitoring tools often require oxygen exposure for sampling and analysis. Recent developments in non-invasive monitoring technologies, including near-infrared spectroscopy and in-line electrochemical sensors, offer promising solutions but require further validation for anaerobic living materials applications. Standardization of these monitoring protocols will be essential for consistent product quality across production batches.

Supply chain considerations must account for the specialized handling requirements of anaerobic materials throughout distribution networks. This includes developing packaging solutions that maintain anoxic conditions during transport and storage, potentially utilizing oxygen scavengers, modified atmosphere packaging, or active barrier technologies. Several packaging technology companies have demonstrated proof-of-concept solutions, though cost-effective options for large-scale implementation remain limited.

Regulatory frameworks for industrial-scale anaerobic living materials production are still evolving, with particular attention to biosafety considerations and environmental impact assessments. Proactive engagement with regulatory bodies during scale-up planning can help identify potential compliance challenges and develop appropriate risk mitigation strategies, potentially accelerating the path to market for these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!