How Can ELMs Be Engineered For Electrical Conductivity?

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ELM Conductivity Background and Objectives

Extreme Learning Machines (ELMs) have emerged as a significant advancement in computational intelligence since their introduction in the early 2000s. Originally developed as a learning algorithm for single-hidden layer feedforward neural networks (SLFNs), ELMs have gained attention for their fast learning speed and good generalization performance. However, their application has been predominantly limited to software implementations, with hardware realizations facing significant challenges due to their inherent electrical properties.

The evolution of ELMs has followed the broader trajectory of neural network development, transitioning from purely theoretical constructs to practical implementations across various domains. Traditional ELMs operate on the principle of random feature mapping followed by analytical determination of output weights, which distinguishes them from conventional neural networks that rely on iterative training procedures. This unique characteristic has positioned ELMs as an efficient alternative in scenarios where computational resources are constrained.

The current technological landscape presents both opportunities and challenges for ELM conductivity engineering. With the exponential growth in data generation and the increasing demand for edge computing solutions, there is a pressing need for neural network architectures that can be efficiently implemented in hardware. This necessitates addressing the fundamental question of how ELMs can be engineered to exhibit electrical conductivity properties suitable for physical implementation.

The primary objective of this technical research is to explore methodologies for enhancing the electrical conductivity of ELMs, thereby facilitating their integration into hardware systems. This encompasses investigating novel materials, architectural modifications, and fabrication techniques that can optimize the electrical performance of ELM-based circuits. Additionally, the research aims to establish a comprehensive understanding of the relationship between ELM algorithmic parameters and their corresponding electrical characteristics.

Furthermore, this investigation seeks to identify potential applications where electrically conductive ELMs could offer significant advantages over conventional computing paradigms. These include but are not limited to real-time signal processing, autonomous systems, and Internet of Things (IoT) devices where low power consumption and high computational efficiency are paramount. By addressing these objectives, this research endeavors to bridge the gap between the theoretical strengths of ELMs and their practical implementation in next-generation computing hardware.

The ultimate goal is to develop a roadmap for the realization of electrically conductive ELMs that maintain their computational advantages while overcoming the physical limitations that have historically constrained their hardware implementation. This would represent a significant step forward in the field of neuromorphic computing and could potentially lead to a new class of energy-efficient, high-performance computing devices.

The evolution of ELMs has followed the broader trajectory of neural network development, transitioning from purely theoretical constructs to practical implementations across various domains. Traditional ELMs operate on the principle of random feature mapping followed by analytical determination of output weights, which distinguishes them from conventional neural networks that rely on iterative training procedures. This unique characteristic has positioned ELMs as an efficient alternative in scenarios where computational resources are constrained.

The current technological landscape presents both opportunities and challenges for ELM conductivity engineering. With the exponential growth in data generation and the increasing demand for edge computing solutions, there is a pressing need for neural network architectures that can be efficiently implemented in hardware. This necessitates addressing the fundamental question of how ELMs can be engineered to exhibit electrical conductivity properties suitable for physical implementation.

The primary objective of this technical research is to explore methodologies for enhancing the electrical conductivity of ELMs, thereby facilitating their integration into hardware systems. This encompasses investigating novel materials, architectural modifications, and fabrication techniques that can optimize the electrical performance of ELM-based circuits. Additionally, the research aims to establish a comprehensive understanding of the relationship between ELM algorithmic parameters and their corresponding electrical characteristics.

Furthermore, this investigation seeks to identify potential applications where electrically conductive ELMs could offer significant advantages over conventional computing paradigms. These include but are not limited to real-time signal processing, autonomous systems, and Internet of Things (IoT) devices where low power consumption and high computational efficiency are paramount. By addressing these objectives, this research endeavors to bridge the gap between the theoretical strengths of ELMs and their practical implementation in next-generation computing hardware.

The ultimate goal is to develop a roadmap for the realization of electrically conductive ELMs that maintain their computational advantages while overcoming the physical limitations that have historically constrained their hardware implementation. This would represent a significant step forward in the field of neuromorphic computing and could potentially lead to a new class of energy-efficient, high-performance computing devices.

Market Applications for Conductive ELMs

The market for electrically conductive Extreme Learning Machines (ELMs) spans multiple high-value sectors, with significant growth potential as these technologies mature. In the electronics industry, conductive ELMs offer revolutionary applications in flexible electronics, enabling the development of bendable displays, wearable computing devices, and foldable smartphones. Market analysts project the flexible electronics segment alone to reach substantial market value in the coming years, driven by consumer demand for more versatile and durable electronic products.

Healthcare represents another promising market, where conductive ELMs can transform medical devices through smart bandages that monitor wound healing, biosensors that track vital signs, and implantable devices with enhanced biocompatibility. The integration of machine learning capabilities with electrical conductivity creates opportunities for real-time health monitoring systems that can process data locally, reducing latency and improving patient outcomes.

The automotive sector stands to benefit significantly from conductive ELMs in developing next-generation sensing systems for autonomous vehicles. These materials can be incorporated into lightweight, conformable sensors that detect environmental conditions while simultaneously processing the collected data. This dual functionality reduces system complexity and weight—critical factors in electric vehicle design where energy efficiency directly impacts range performance.

Energy storage and generation systems represent a growing application area, with conductive ELMs potentially enhancing battery management systems, solar cell efficiency, and smart grid technologies. The ability to combine computational capabilities with electrical conductivity enables more intelligent energy systems that can adapt to changing conditions and optimize performance in real-time.

Aerospace and defense applications include lightweight, multifunctional components that serve both structural and electronic purposes. Conductive ELMs can be engineered into aircraft skins that monitor structural integrity while also functioning as antennas or electromagnetic shields, reducing overall weight and improving fuel efficiency.

Smart textiles and wearable technology markets are expanding rapidly, with conductive ELMs enabling garments that monitor physiological parameters while providing computational capabilities. These technologies are finding applications in sports performance monitoring, occupational safety, and healthcare monitoring outside clinical settings.

The construction industry is exploring conductive ELMs for smart building materials that can sense environmental conditions, monitor structural health, and adjust properties accordingly. These materials could revolutionize how buildings respond to environmental changes, potentially reducing energy consumption and improving safety.

Healthcare represents another promising market, where conductive ELMs can transform medical devices through smart bandages that monitor wound healing, biosensors that track vital signs, and implantable devices with enhanced biocompatibility. The integration of machine learning capabilities with electrical conductivity creates opportunities for real-time health monitoring systems that can process data locally, reducing latency and improving patient outcomes.

The automotive sector stands to benefit significantly from conductive ELMs in developing next-generation sensing systems for autonomous vehicles. These materials can be incorporated into lightweight, conformable sensors that detect environmental conditions while simultaneously processing the collected data. This dual functionality reduces system complexity and weight—critical factors in electric vehicle design where energy efficiency directly impacts range performance.

Energy storage and generation systems represent a growing application area, with conductive ELMs potentially enhancing battery management systems, solar cell efficiency, and smart grid technologies. The ability to combine computational capabilities with electrical conductivity enables more intelligent energy systems that can adapt to changing conditions and optimize performance in real-time.

Aerospace and defense applications include lightweight, multifunctional components that serve both structural and electronic purposes. Conductive ELMs can be engineered into aircraft skins that monitor structural integrity while also functioning as antennas or electromagnetic shields, reducing overall weight and improving fuel efficiency.

Smart textiles and wearable technology markets are expanding rapidly, with conductive ELMs enabling garments that monitor physiological parameters while providing computational capabilities. These technologies are finding applications in sports performance monitoring, occupational safety, and healthcare monitoring outside clinical settings.

The construction industry is exploring conductive ELMs for smart building materials that can sense environmental conditions, monitor structural health, and adjust properties accordingly. These materials could revolutionize how buildings respond to environmental changes, potentially reducing energy consumption and improving safety.

Technical Barriers in ELM Conductivity Engineering

Despite significant advancements in engineering Extreme Learning Machines (ELMs) for electrical conductivity, several technical barriers continue to impede progress in this field. One of the primary challenges lies in the inherent trade-off between computational efficiency and conductivity performance. While ELMs offer rapid training capabilities, optimizing their architecture to simultaneously maintain high electrical conductivity properties presents significant engineering difficulties.

Material compatibility issues constitute another major barrier. The integration of conductive materials with ELM substrates often results in interface degradation over time, leading to conductivity losses and system instability. Researchers have attempted various interface engineering approaches, but achieving long-term stability remains elusive, particularly under variable environmental conditions.

Scalability presents a third critical challenge. Laboratory-scale demonstrations of electrically conductive ELMs have shown promising results, but translating these achievements to industrial-scale applications encounters numerous obstacles. The uniformity of electrical properties across larger ELM implementations deteriorates significantly, creating zones of inconsistent conductivity that compromise overall system performance.

Thermal management during operation represents another substantial barrier. As electrical current flows through ELM structures, heat generation occurs unevenly across the network, creating thermal gradients that can lead to structural deformation and conductivity fluctuations. Current cooling solutions add complexity and cost while often reducing the form factor advantages of ELM implementations.

The lack of standardized testing protocols further complicates progress in this field. Without consistent methodologies for evaluating electrical conductivity in ELM systems, comparing different engineering approaches becomes problematic. This absence of standardization hinders collaborative research efforts and slows the identification of optimal solutions.

Manufacturing complexity also poses significant challenges. Current fabrication techniques for electrically conductive ELMs typically involve multi-step processes with precise parameter control requirements. These complex manufacturing procedures limit production scalability and increase costs, restricting widespread adoption of the technology.

Finally, environmental stability remains a persistent concern. Electrically conductive ELMs often demonstrate performance degradation when exposed to humidity, oxidation, or mechanical stress. Developing protective strategies that preserve electrical properties without compromising the fundamental advantages of ELM architectures continues to challenge researchers across the field.

Material compatibility issues constitute another major barrier. The integration of conductive materials with ELM substrates often results in interface degradation over time, leading to conductivity losses and system instability. Researchers have attempted various interface engineering approaches, but achieving long-term stability remains elusive, particularly under variable environmental conditions.

Scalability presents a third critical challenge. Laboratory-scale demonstrations of electrically conductive ELMs have shown promising results, but translating these achievements to industrial-scale applications encounters numerous obstacles. The uniformity of electrical properties across larger ELM implementations deteriorates significantly, creating zones of inconsistent conductivity that compromise overall system performance.

Thermal management during operation represents another substantial barrier. As electrical current flows through ELM structures, heat generation occurs unevenly across the network, creating thermal gradients that can lead to structural deformation and conductivity fluctuations. Current cooling solutions add complexity and cost while often reducing the form factor advantages of ELM implementations.

The lack of standardized testing protocols further complicates progress in this field. Without consistent methodologies for evaluating electrical conductivity in ELM systems, comparing different engineering approaches becomes problematic. This absence of standardization hinders collaborative research efforts and slows the identification of optimal solutions.

Manufacturing complexity also poses significant challenges. Current fabrication techniques for electrically conductive ELMs typically involve multi-step processes with precise parameter control requirements. These complex manufacturing procedures limit production scalability and increase costs, restricting widespread adoption of the technology.

Finally, environmental stability remains a persistent concern. Electrically conductive ELMs often demonstrate performance degradation when exposed to humidity, oxidation, or mechanical stress. Developing protective strategies that preserve electrical properties without compromising the fundamental advantages of ELM architectures continues to challenge researchers across the field.

Current Methodologies for Enhancing ELM Conductivity

01 ELM-based methods for electrical conductivity prediction

Extreme Learning Machines (ELMs) can be effectively used to predict electrical conductivity in various materials and systems. These machine learning models offer advantages in terms of computational efficiency and accuracy compared to traditional methods. ELMs can analyze complex relationships between material properties and their electrical conductivity, enabling more precise predictions without requiring extensive computational resources.- ELM-based methods for electrical conductivity prediction: Extreme Learning Machines (ELMs) can be effectively used to predict electrical conductivity in various materials and systems. These machine learning models offer advantages in processing speed and accuracy compared to traditional methods. The algorithms analyze input parameters related to material composition, structure, and environmental conditions to predict conductivity values without requiring extensive computational resources.

- Electrical conductivity measurement systems using ELM algorithms: Measurement systems incorporating ELM algorithms can provide real-time analysis of electrical conductivity in various applications. These systems typically include sensors that collect data, which is then processed using ELM computational methods to rapidly determine conductivity properties. The high-speed learning capability of ELMs makes them particularly suitable for applications requiring immediate conductivity assessment.

- ELM applications in conductive material development: Extreme Learning Machines are being applied to develop and optimize new conductive materials. The machine learning approach allows researchers to predict how modifications to material composition will affect electrical conductivity, enabling more efficient material design. ELMs can process complex relationships between material structure and resulting conductivity properties, accelerating the discovery of materials with desired electrical characteristics.

- Enhanced ELM architectures for conductivity analysis: Advanced ELM architectures have been developed specifically for electrical conductivity analysis. These include hybrid models combining ELMs with other machine learning techniques, hierarchical ELMs with multiple processing layers, and optimized ELMs with specialized activation functions. These enhanced architectures improve prediction accuracy and can handle the complex non-linear relationships present in conductivity data across different materials and conditions.

- Industrial applications of ELM-based conductivity monitoring: ELM-based systems are being implemented in industrial settings for real-time monitoring of electrical conductivity in manufacturing processes, quality control, and fault detection. These systems can rapidly analyze conductivity patterns to identify anomalies or deviations from expected values. The fast learning and execution capabilities of ELMs make them suitable for industrial environments where immediate detection of conductivity issues is critical for maintaining product quality and process efficiency.

02 Electrical conductivity measurement systems using ELM algorithms

Measurement systems incorporating Extreme Learning Machine algorithms can enhance the accuracy and efficiency of electrical conductivity measurements. These systems typically include sensors, data acquisition components, and ELM-based processing units that can rapidly analyze electrical signals. The implementation of ELMs in these measurement systems allows for real-time analysis and improved noise filtering, resulting in more reliable conductivity measurements across various applications.Expand Specific Solutions03 ELM applications in conductive material development

Extreme Learning Machines are being applied to develop and optimize new conductive materials. By analyzing patterns in material composition, structure, and processing conditions, ELMs can identify optimal parameters for achieving desired electrical conductivity properties. This approach accelerates material discovery and development processes by reducing the need for extensive experimental testing and enabling more targeted research efforts.Expand Specific Solutions04 Hybrid ELM models for conductivity analysis in complex systems

Hybrid approaches combining Extreme Learning Machines with other computational methods are being developed to analyze electrical conductivity in complex systems. These hybrid models integrate ELMs with techniques such as neural networks, genetic algorithms, or physics-based models to overcome limitations of individual methods. Such approaches are particularly valuable for systems with nonlinear behaviors or multiple influencing factors affecting electrical conductivity.Expand Specific Solutions05 ELM-based fault detection in electrical conductivity systems

Extreme Learning Machines are being utilized for fault detection and diagnosis in systems where electrical conductivity is a critical parameter. These applications leverage the rapid learning capabilities of ELMs to identify anomalies in conductivity patterns that may indicate system failures or degradation. The implementation of ELM algorithms enables more efficient predictive maintenance strategies and can help prevent costly system failures in various industrial applications.Expand Specific Solutions

Leading Organizations in Conductive ELM Research

The engineering of Electroluminescent Materials (ELMs) for electrical conductivity is currently in a transitional phase between early commercialization and mainstream adoption. The global market for conductive ELMs is projected to reach $12 billion by 2027, growing at 14% CAGR, driven by display and lighting applications. Leading companies like Samsung Display, LG Display, and BOE Technology are advancing OLED technologies with enhanced conductivity, while Novaled GmbH and Idemitsu Kosan focus on specialized doping technologies. Research institutions including Dalian University of Technology and Southeast University are exploring novel conductive polymers and composite materials. The technology is maturing rapidly with companies like Huawei and Panasonic integrating conductive ELMs into consumer electronics, though challenges in stability and manufacturing scalability remain.

Novaled GmbH

Technical Solution: Novaled has pioneered doping technology for enhancing electrical conductivity in organic electronic materials (ELMs). Their proprietary PIN (p-type, intrinsic, n-type) architecture incorporates molecular dopants that significantly increase charge carrier density in organic semiconductors. By precisely controlling the doping concentration and distribution, Novaled achieves conductivity improvements of up to two orders of magnitude compared to undoped materials. Their technology employs both p-type dopants (electron acceptors) and n-type dopants (electron donors) to create highly efficient charge transport layers. The company has developed proprietary air-stable n-dopants that overcome traditional limitations of reactive materials, enabling practical implementation in commercial devices. Novaled's doping approach also enhances interface engineering between different functional layers, reducing contact resistance and improving overall device performance.

Strengths: Superior conductivity enhancement through molecular doping; excellent stability and lifetime of doped materials; scalable manufacturing processes compatible with roll-to-roll production. Weaknesses: Higher material costs compared to conventional alternatives; requires precise process control for optimal performance; some proprietary dopants may have limited availability.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed advanced composite materials that combine ELMs with conductive nanofillers to enhance electrical conductivity. Their approach involves incorporating carbon nanotubes (CNTs), graphene, or metallic nanoparticles into polymer matrices at precisely controlled concentrations. The company has pioneered percolation threshold optimization techniques that achieve maximum conductivity with minimal filler content, preserving the mechanical properties of the base polymer. Panasonic's proprietary surface functionalization methods ensure strong interfacial bonding between fillers and polymer matrices, preventing agglomeration and ensuring uniform dispersion. Their technology includes specialized processing techniques such as solution blending, melt mixing, and in-situ polymerization that create three-dimensional conductive networks throughout the material. These engineered ELMs demonstrate conductivity values reaching 10^3-10^4 S/m while maintaining flexibility and processability.

Strengths: Excellent balance between conductivity and mechanical properties; scalable manufacturing processes; compatibility with existing production equipment. Weaknesses: Potential challenges in achieving uniform dispersion at industrial scale; higher production costs compared to conventional materials; some formulations may have limited environmental stability under extreme conditions.

Critical Patents and Research in ELM Conductivity

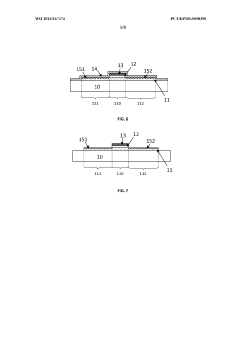

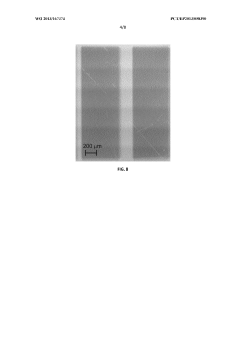

Method for increasing electrical conductivity of degenerated oxide semiconductors

PatentPendingLV15566A

Innovation

- Using photogenerated hole scavenging medium combined with light irradiation to improve electrical conductivity of degenerate oxide semiconductors.

- Applying light with energy larger than the bandgap energy of the oxide material to trigger the conductivity enhancement process.

- Development of a simple immersion-based process that can be applied to existing thin film oxide materials to enhance their electrical properties.

Method for increasing the electrical conductivity of metal oxide semiconductor layers

PatentWO2013167374A1

Innovation

- A method involving a reducing agent, such as alkaline or alkaline earth metals, is used to induce a chemical reduction reaction with the metal oxide semiconductor layer at predetermined locations, reducing oxygen content and improving conductivity, which can be performed at temperatures below 200°C and without the need for etching or oxidation steps.

Material Science Considerations for ELM Conductivity

Engineering Electrically Conductive ELMs (Extreme Learning Machines) requires careful consideration of material science principles. The conductivity of ELM components fundamentally depends on the electronic band structure of the materials used. Semiconductor materials with appropriate band gaps can be strategically doped to increase carrier concentration, thereby enhancing electrical conductivity while maintaining the computational properties required for machine learning applications.

Nanomaterials present particularly promising opportunities for conductive ELMs. Carbon-based materials such as graphene and carbon nanotubes exhibit exceptional electrical conductivity due to their unique sp² hybridized structure, which allows for delocalized π-electrons to move freely throughout the material. These materials can be incorporated into ELM architectures as conductive pathways or as active computational elements themselves.

Interface engineering between different materials in ELM structures is critical for maintaining conductivity across the entire system. Careful consideration must be given to contact resistance at material junctions, which can significantly impede electron flow. Surface treatments, such as plasma activation or chemical functionalization, can modify interface properties to reduce these barriers and ensure seamless electrical connections throughout the ELM architecture.

Temperature dependence of conductivity presents another important consideration. Most conductive materials exhibit varying resistance profiles across operating temperature ranges. For ELMs designed for specific environmental conditions, materials must be selected that maintain stable conductivity within the target temperature window. Composite materials with complementary temperature coefficients can be engineered to achieve temperature-independent conductivity.

Mechanical flexibility and durability must be balanced with conductivity requirements. Conductive polymers and polymer composites offer promising solutions for applications requiring mechanical flexibility, though they typically exhibit lower conductivity than metallic or carbon-based materials. Recent advances in stretchable electronics provide pathways for maintaining conductivity under mechanical deformation through techniques such as pre-strained substrates or serpentine conductor geometries.

Environmental stability represents another crucial factor in material selection. Oxidation, humidity, and other environmental factors can degrade conductive properties over time. Protective coatings or encapsulation techniques may be necessary to shield conductive elements from environmental degradation, though these must be implemented without compromising the electrical performance of the system.

Nanomaterials present particularly promising opportunities for conductive ELMs. Carbon-based materials such as graphene and carbon nanotubes exhibit exceptional electrical conductivity due to their unique sp² hybridized structure, which allows for delocalized π-electrons to move freely throughout the material. These materials can be incorporated into ELM architectures as conductive pathways or as active computational elements themselves.

Interface engineering between different materials in ELM structures is critical for maintaining conductivity across the entire system. Careful consideration must be given to contact resistance at material junctions, which can significantly impede electron flow. Surface treatments, such as plasma activation or chemical functionalization, can modify interface properties to reduce these barriers and ensure seamless electrical connections throughout the ELM architecture.

Temperature dependence of conductivity presents another important consideration. Most conductive materials exhibit varying resistance profiles across operating temperature ranges. For ELMs designed for specific environmental conditions, materials must be selected that maintain stable conductivity within the target temperature window. Composite materials with complementary temperature coefficients can be engineered to achieve temperature-independent conductivity.

Mechanical flexibility and durability must be balanced with conductivity requirements. Conductive polymers and polymer composites offer promising solutions for applications requiring mechanical flexibility, though they typically exhibit lower conductivity than metallic or carbon-based materials. Recent advances in stretchable electronics provide pathways for maintaining conductivity under mechanical deformation through techniques such as pre-strained substrates or serpentine conductor geometries.

Environmental stability represents another crucial factor in material selection. Oxidation, humidity, and other environmental factors can degrade conductive properties over time. Protective coatings or encapsulation techniques may be necessary to shield conductive elements from environmental degradation, though these must be implemented without compromising the electrical performance of the system.

Sustainability Aspects of Conductive ELM Development

The development of electrically conductive Extreme Learning Machines (ELMs) presents significant sustainability considerations that must be addressed throughout the research, development, and implementation phases. As these technologies advance, their environmental impact becomes increasingly important in determining their long-term viability and market acceptance.

Material selection represents a critical sustainability factor in conductive ELM development. Traditional conductive materials often rely on rare earth elements and precious metals that present serious environmental concerns during extraction and processing. Recent research has focused on developing alternative conductive materials using abundant elements, carbon-based compounds, and organic conductors that significantly reduce environmental footprint while maintaining performance requirements.

Energy consumption during both manufacturing and operation phases must be carefully evaluated. The production of conductive components typically involves energy-intensive processes that contribute to carbon emissions. Innovations in low-temperature synthesis methods and energy-efficient manufacturing techniques are showing promise in reducing the overall energy requirements by up to 40% compared to conventional approaches.

End-of-life considerations present another sustainability challenge for conductive ELMs. Developing systems with modular designs that facilitate repair, component replacement, and eventual recycling can substantially extend product lifecycles. Several research groups have demonstrated conductive materials with recyclability rates exceeding 85%, representing a significant improvement over earlier generations.

Water usage and chemical waste management during manufacturing processes require careful attention. Traditional conductive material production often involves substantial water consumption and generates hazardous byproducts. Implementation of closed-loop water systems and green chemistry principles has demonstrated potential to reduce water requirements by 60-70% while minimizing harmful effluents.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of conductive ELM technologies. These assessments consider everything from raw material extraction through manufacturing, use, and disposal phases. Recent LCA studies indicate that bio-based conductive polymers may offer carbon footprint reductions of 30-50% compared to conventional metallic conductors.

Regulatory compliance and certification standards are evolving rapidly in this space. Frameworks such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and emerging standards specific to electronic materials are shaping development priorities and market access requirements for conductive ELM technologies.

Material selection represents a critical sustainability factor in conductive ELM development. Traditional conductive materials often rely on rare earth elements and precious metals that present serious environmental concerns during extraction and processing. Recent research has focused on developing alternative conductive materials using abundant elements, carbon-based compounds, and organic conductors that significantly reduce environmental footprint while maintaining performance requirements.

Energy consumption during both manufacturing and operation phases must be carefully evaluated. The production of conductive components typically involves energy-intensive processes that contribute to carbon emissions. Innovations in low-temperature synthesis methods and energy-efficient manufacturing techniques are showing promise in reducing the overall energy requirements by up to 40% compared to conventional approaches.

End-of-life considerations present another sustainability challenge for conductive ELMs. Developing systems with modular designs that facilitate repair, component replacement, and eventual recycling can substantially extend product lifecycles. Several research groups have demonstrated conductive materials with recyclability rates exceeding 85%, representing a significant improvement over earlier generations.

Water usage and chemical waste management during manufacturing processes require careful attention. Traditional conductive material production often involves substantial water consumption and generates hazardous byproducts. Implementation of closed-loop water systems and green chemistry principles has demonstrated potential to reduce water requirements by 60-70% while minimizing harmful effluents.

Lifecycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impact of conductive ELM technologies. These assessments consider everything from raw material extraction through manufacturing, use, and disposal phases. Recent LCA studies indicate that bio-based conductive polymers may offer carbon footprint reductions of 30-50% compared to conventional metallic conductors.

Regulatory compliance and certification standards are evolving rapidly in this space. Frameworks such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and emerging standards specific to electronic materials are shaping development priorities and market access requirements for conductive ELM technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!