Emerging Trends in Cellulose Acetate for Sustainable Development

Cellulose Acetate Evolution and Sustainability Goals

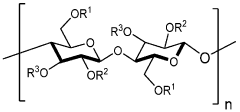

Cellulose acetate has undergone significant evolution since its discovery in the late 19th century. Initially developed as a photographic film base, it has since found applications in various industries, including textiles, packaging, and personal care products. The journey of cellulose acetate reflects the broader trend towards sustainable materials in response to growing environmental concerns.

In recent years, the focus on cellulose acetate has shifted towards enhancing its sustainability profile. This shift is driven by increasing awareness of environmental issues such as plastic pollution and the need for biodegradable alternatives. The sustainability goals for cellulose acetate encompass several key areas, including improving production processes, enhancing biodegradability, and expanding its use in eco-friendly applications.

One of the primary sustainability objectives is to optimize the production of cellulose acetate to reduce its environmental footprint. This involves developing more efficient manufacturing processes that consume less energy and water while minimizing waste generation. Additionally, there is a push to source cellulose from sustainable forestry practices or alternative sources like agricultural residues.

Enhancing the biodegradability of cellulose acetate products is another crucial goal. While cellulose acetate is inherently biodegradable, the rate of decomposition can vary significantly depending on environmental conditions. Research efforts are focused on accelerating this process without compromising the material's performance during its intended use.

The expansion of cellulose acetate into new sustainable applications is a key trend. Industries are exploring its potential as a replacement for conventional plastics in various products, from disposable items to durable goods. This includes developing cellulose acetate-based materials with improved mechanical properties and resistance to environmental factors.

Collaboration between academia, industry, and government bodies is playing a vital role in advancing these sustainability goals. Joint research initiatives are exploring novel production techniques, such as using green solvents and catalysts, to make cellulose acetate manufacturing more environmentally friendly.

As we look to the future, the evolution of cellulose acetate is closely tied to broader sustainability objectives. The material's potential to contribute to a circular economy model, where products are designed for reuse and recycling, is a significant driver of innovation. This aligns with global efforts to reduce reliance on fossil-based materials and move towards renewable, bio-based alternatives.

Market Demand for Eco-friendly Cellulose Acetate Products

The market demand for eco-friendly cellulose acetate products has been steadily increasing in recent years, driven by growing environmental awareness and stringent regulations on plastic usage. Cellulose acetate, derived from natural sources such as wood pulp and cotton fibers, offers a sustainable alternative to traditional petroleum-based plastics in various applications.

In the packaging industry, there is a significant shift towards biodegradable and compostable materials. Cellulose acetate films and sheets are gaining traction as replacements for conventional plastic packaging, particularly in food and beverage sectors. The demand for cellulose acetate-based packaging is expected to grow as more companies commit to reducing their environmental footprint and meeting consumer preferences for sustainable products.

The textile industry is another key market for eco-friendly cellulose acetate products. Cellulose acetate fibers are increasingly used in the production of sustainable fabrics, offering properties such as breathability, moisture-wicking, and biodegradability. This trend is particularly evident in the fashion and apparel sectors, where brands are actively seeking alternatives to synthetic fibers to meet the growing demand for eco-conscious clothing.

In the consumer goods sector, cellulose acetate is finding applications in various products, including disposable items like cutlery, straws, and personal care products. The ban on single-use plastics in many countries has created a substantial market opportunity for biodegradable alternatives, with cellulose acetate emerging as a viable solution.

The automotive industry is also exploring the use of cellulose acetate composites as lightweight, sustainable materials for interior components. This trend aligns with the industry's efforts to reduce vehicle weight and improve fuel efficiency while meeting sustainability goals.

The healthcare sector presents another growing market for cellulose acetate products. Biodegradable medical devices, drug delivery systems, and packaging materials made from cellulose acetate are gaining attention due to their biocompatibility and reduced environmental impact.

While the demand for eco-friendly cellulose acetate products is on the rise, challenges such as production costs and scalability need to be addressed to fully capitalize on market opportunities. Ongoing research and development efforts are focused on improving the performance and cost-effectiveness of cellulose acetate-based materials to enhance their competitiveness against traditional plastics.

As sustainability continues to be a key driver in consumer choices and corporate strategies, the market for eco-friendly cellulose acetate products is poised for significant growth across multiple industries. This trend is likely to accelerate as technological advancements and economies of scale make cellulose acetate-based solutions more accessible and economically viable.

Current State and Challenges in Cellulose Acetate Production

Cellulose acetate production has reached a mature stage in the global market, with established manufacturing processes and widespread applications. However, the industry faces several challenges in the context of sustainable development and emerging environmental concerns.

The current production methods for cellulose acetate primarily rely on wood pulp as the raw material, which raises sustainability issues due to deforestation and the environmental impact of intensive forestry practices. While efforts have been made to utilize alternative cellulose sources, such as cotton linters and agricultural residues, these alternatives have not yet been widely adopted on a commercial scale.

One of the main challenges in cellulose acetate production is the use of acetic anhydride and acetic acid as acetylating agents. These chemicals are derived from fossil fuels and contribute to the carbon footprint of the production process. Additionally, the recovery and recycling of these agents present technical and economic challenges, leading to increased production costs and environmental concerns.

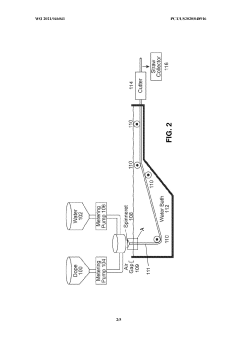

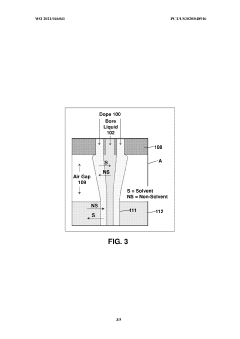

The production process also involves the use of solvents, particularly in the dissolution and shaping stages of cellulose acetate. Many of these solvents are volatile organic compounds (VOCs) that can contribute to air pollution and pose health risks to workers. Developing safer, more environmentally friendly solvents or solvent-free processes remains a significant challenge for the industry.

Energy consumption in cellulose acetate production is another area of concern. The process requires substantial energy inputs for heating, cooling, and drying stages, which contribute to greenhouse gas emissions. Improving energy efficiency and transitioning to renewable energy sources are critical challenges that need to be addressed to enhance the sustainability of cellulose acetate production.

Furthermore, the end-of-life management of cellulose acetate products poses environmental challenges. While cellulose acetate is biodegradable under certain conditions, the rate of degradation can be slow, leading to accumulation in the environment. Developing more readily biodegradable formulations and establishing effective recycling systems are ongoing challenges for the industry.

In terms of product quality and performance, cellulose acetate manufacturers face the challenge of meeting increasingly stringent requirements from various industries. This includes developing cellulose acetate grades with enhanced properties, such as improved thermal stability, mechanical strength, and barrier properties, while maintaining or reducing production costs.

Innovative Solutions for Eco-friendly Cellulose Acetate

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

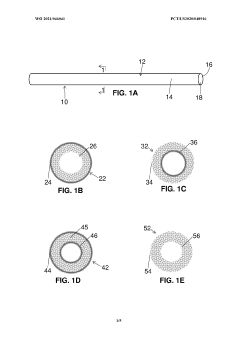

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and composite materials. The properties of these fibers can be tailored for specific uses through modifications in the production process or post-treatment methods.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing techniques, enhanced properties, and novel applications in areas such as separation processes and packaging materials.

- Cellulose acetate derivatives and modifications: Research on cellulose acetate derivatives and modifications is discussed, including chemical modifications, blending with other polymers, and the development of novel composites to enhance performance characteristics for specific applications.

- Cellulose acetate in sustainable and biodegradable materials: The use of cellulose acetate in developing sustainable and biodegradable materials is explored, with a focus on eco-friendly alternatives to conventional plastics and the creation of bio-based products with improved environmental profiles.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are detailed, covering aspects such as spinning processes, film formation, and modification of properties. These innovations contribute to the development of improved materials for textiles, packaging, and other applications.Expand Specific Solutions03 Cellulose acetate composites and blends

Research on cellulose acetate composites and blends with other materials is presented, focusing on enhancing mechanical, thermal, and barrier properties. These developments expand the range of applications for cellulose acetate-based materials in various industries.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate are explored, including chemical treatments, surface modifications, and incorporation of additives. These techniques aim to tailor the properties of cellulose acetate for specific applications and improve its performance.Expand Specific Solutions05 Applications of cellulose acetate in various industries

Diverse applications of cellulose acetate are discussed, including its use in filtration, membranes, biomedical devices, and environmental remediation. These applications showcase the versatility and potential of cellulose acetate as a sustainable and functional material.Expand Specific Solutions

Key Players in Sustainable Cellulose Acetate Industry

The cellulose acetate market for sustainable development is in a growth phase, driven by increasing demand for eco-friendly materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, cellulose acetate is mature but evolving, with companies like Daicel Corp., Eastman Chemical Co., and BASF Corp. leading innovation. Research institutions such as the Chinese Academy of Sciences and universities like South China University of Technology are advancing the field. Emerging players like Nantong Cellulose Fibers Co. Ltd. and Futamura Chemical Co. Ltd. are also contributing to technological advancements. The competitive landscape is characterized by a mix of established chemical companies and specialized manufacturers, with a growing focus on sustainable applications and improved production processes.

Daicel Corp.

Eastman Chemical Co.

Breakthrough Technologies in Cellulose Acetate Sustainability

- A cellulose acetate with a total degree of acetyl substitution not greater than 2.7, a specific ratio of acetyl substitution at different positions, and a sulfate component content of 20-400 ppm, along with additives like magnesium oxide and triacetin, enhances biodegradability in seawater.

- Development of biodegradable products, specifically elongated tubular members made from cellulose esters with controlled porosity and acetyl degree of substitution, which are compostable under industrial and home conditions, and suitable for applications like drinking straws and packaging, using a solvent casting or extrusion process.

Environmental Impact Assessment of Cellulose Acetate

The environmental impact assessment of cellulose acetate is crucial for understanding its role in sustainable development. Cellulose acetate, a versatile biopolymer derived from natural sources, has gained attention for its potential to replace conventional plastics in various applications. However, its environmental footprint must be carefully evaluated to ensure its sustainability credentials.

One of the primary environmental benefits of cellulose acetate is its biodegradability. Unlike traditional petroleum-based plastics, cellulose acetate can decompose naturally in the environment, reducing long-term pollution and microplastic accumulation. Studies have shown that cellulose acetate can biodegrade in soil and marine environments within months to years, depending on conditions. This characteristic significantly reduces its impact on ecosystems and wildlife compared to conventional plastics.

The production process of cellulose acetate also presents environmental considerations. While it is derived from renewable resources, primarily wood pulp or cotton linters, the acetylation process involves the use of acetic anhydride and other chemicals. This raises concerns about chemical emissions and waste management during manufacturing. However, advancements in green chemistry and closed-loop production systems are mitigating these impacts, with some manufacturers implementing solvent recovery and recycling processes.

Energy consumption and greenhouse gas emissions associated with cellulose acetate production are generally lower than those of petroleum-based plastics. The renewable nature of its raw materials contributes to a reduced carbon footprint. However, the energy-intensive nature of the acetylation process still presents opportunities for improvement in terms of overall environmental performance.

Water usage in cellulose acetate production is another critical factor to consider. The process requires significant amounts of water, particularly in the initial stages of cellulose extraction. This can strain local water resources, especially in water-scarce regions. Implementing water recycling and efficient treatment systems is essential to minimize this impact.

End-of-life considerations for cellulose acetate products are generally favorable. While recycling infrastructure for cellulose acetate is not as well-established as for some other materials, its biodegradability offers an alternative disposal route. Composting facilities can process cellulose acetate products, returning nutrients to the soil and closing the material loop.

The land use impact of cellulose acetate production is an important aspect of its environmental assessment. The cultivation of trees or cotton for raw materials can compete with food crops or natural habitats. Sustainable forestry practices and responsible sourcing are crucial to mitigate these concerns and ensure the long-term viability of cellulose acetate as a sustainable material.

In conclusion, while cellulose acetate offers several environmental advantages over conventional plastics, a comprehensive life cycle assessment is necessary to fully understand its impact. Ongoing research and development in production processes, material properties, and end-of-life management are key to enhancing its environmental performance and solidifying its role in sustainable development.

Regulatory Framework for Sustainable Cellulose Acetate

The regulatory framework for sustainable cellulose acetate is evolving rapidly to address environmental concerns and promote sustainable development. Governments and international organizations are implementing stricter regulations to ensure the responsible production and use of cellulose acetate materials.

One of the key areas of focus is the reduction of environmental impact throughout the lifecycle of cellulose acetate products. Regulations are being introduced to limit the use of harmful chemicals in the production process, with a particular emphasis on reducing the use of acetic anhydride and sulfuric acid. These regulations aim to minimize pollution and protect worker health and safety.

Waste management and disposal of cellulose acetate products are also subject to increasing regulatory scrutiny. Many countries are implementing extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including collection and recycling at the end of use.

The European Union has been at the forefront of sustainable cellulose acetate regulations. The EU's Circular Economy Action Plan includes specific measures to promote the recyclability and biodegradability of cellulose acetate products. This includes setting targets for recycled content in new products and establishing standards for biodegradability.

In the United States, the Environmental Protection Agency (EPA) has introduced guidelines for the sustainable production of cellulose acetate. These guidelines focus on reducing energy consumption, minimizing water usage, and promoting the use of renewable energy sources in manufacturing processes.

International standards organizations, such as ISO, are developing new standards for sustainable cellulose acetate production. These standards aim to provide a globally recognized framework for assessing the environmental impact of cellulose acetate products and promoting best practices in sustainable manufacturing.

Emerging regulations are also addressing the issue of microplastic pollution from cellulose acetate products, particularly in the context of cigarette filters. Several countries have introduced or are considering bans on single-use plastic products, including cellulose acetate-based items, to reduce environmental pollution.

As the regulatory landscape continues to evolve, companies in the cellulose acetate industry are being encouraged to invest in research and development of more sustainable alternatives. This includes exploring bio-based feedstocks, improving recycling technologies, and developing fully biodegradable cellulose acetate formulations.

The regulatory framework is also promoting transparency and traceability in the cellulose acetate supply chain. Companies are increasingly required to disclose information about their sourcing practices, manufacturing processes, and environmental impact assessments to ensure compliance with sustainability regulations.