How to Utilize Cellulose Acetate in Novel Coating Technologies?

Cellulose Acetate Coating Evolution and Objectives

Cellulose acetate has been a cornerstone in coating technologies since its introduction in the early 20th century. Initially developed as a substitute for celluloid, it quickly found applications in various industries due to its unique properties. The evolution of cellulose acetate coatings has been driven by the need for more sustainable, versatile, and high-performance materials in an increasingly environmentally conscious world.

The journey of cellulose acetate in coating technologies began with its use in photographic films and continued to expand into diverse sectors such as textiles, packaging, and electronics. Over the decades, researchers and industry professionals have continuously refined the production processes and formulations to enhance its properties and broaden its applicability.

In recent years, the focus has shifted towards developing novel coating technologies that leverage the biodegradability and renewability of cellulose acetate. This aligns with the global push for more sustainable materials and processes in various industries. The current objectives in cellulose acetate coating research are multifaceted, aiming to address both environmental concerns and performance requirements.

One primary goal is to improve the barrier properties of cellulose acetate coatings, particularly in packaging applications. Researchers are exploring ways to enhance moisture resistance and gas impermeability while maintaining the material's biodegradability. This involves investigating various additives and modification techniques that can be incorporated into cellulose acetate formulations.

Another significant objective is to develop cellulose acetate coatings with advanced functionalities. This includes creating smart coatings that can respond to environmental stimuli, such as temperature or pH changes, opening up new possibilities in fields like food packaging and biomedical applications. Additionally, there is a growing interest in incorporating antimicrobial properties into cellulose acetate coatings, addressing hygiene concerns in various sectors.

The pursuit of more efficient and eco-friendly production methods for cellulose acetate coatings is also a key focus. Researchers are exploring green solvents and sustainable processing techniques to reduce the environmental impact of manufacturing. This aligns with the broader industry trend towards circular economy principles and lifecycle assessment considerations.

As we look to the future, the objectives for cellulose acetate in novel coating technologies are likely to expand further. There is potential for integrating cellulose acetate with other advanced materials, such as nanoparticles or conductive polymers, to create hybrid coatings with enhanced properties. The development of these next-generation coatings could open up new applications in electronics, energy storage, and beyond, solidifying cellulose acetate's position as a versatile and sustainable coating material for the 21st century.

Market Analysis for Cellulose Acetate Coatings

The global market for cellulose acetate coatings is experiencing significant growth, driven by increasing demand across various industries. The versatility and eco-friendly nature of cellulose acetate make it an attractive option for coating applications in sectors such as packaging, textiles, automotive, and electronics.

In the packaging industry, cellulose acetate coatings are gaining traction due to their excellent barrier properties and biodegradability. As consumers become more environmentally conscious, there is a growing preference for sustainable packaging solutions. This trend is expected to fuel the demand for cellulose acetate coatings in food packaging, cosmetics, and pharmaceutical industries.

The textile sector is another key market for cellulose acetate coatings. These coatings provide fabric with enhanced durability, water resistance, and aesthetic appeal. With the rising demand for high-performance textiles in sportswear and outdoor apparel, the market for cellulose acetate coatings in this sector is projected to expand significantly.

In the automotive industry, cellulose acetate coatings are finding applications in interior components and exterior finishes. The ability of these coatings to provide a glossy finish, scratch resistance, and UV protection makes them suitable for various automotive parts. As the automotive industry continues to focus on lightweight and sustainable materials, the demand for cellulose acetate coatings is expected to increase.

The electronics sector is also emerging as a promising market for cellulose acetate coatings. These coatings can be used to protect electronic components from moisture, dust, and other environmental factors. With the rapid growth of the electronics industry and the increasing miniaturization of devices, the demand for protective coatings is on the rise.

Geographically, Asia-Pacific is expected to be the fastest-growing market for cellulose acetate coatings, driven by the rapid industrialization and increasing adoption of sustainable technologies in countries like China and India. North America and Europe are also significant markets, with a strong focus on eco-friendly products and stringent regulations promoting the use of biodegradable materials.

However, the market for cellulose acetate coatings faces challenges such as competition from synthetic alternatives and the need for continuous innovation to improve performance characteristics. To address these challenges, manufacturers are investing in research and development to enhance the properties of cellulose acetate coatings and expand their applications in novel areas.

Current Challenges in Cellulose Acetate Coating Technology

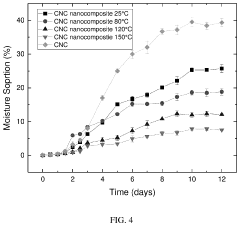

Cellulose acetate coating technology, while promising, faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the material's inherent sensitivity to moisture. Cellulose acetate tends to absorb water from the environment, which can lead to dimensional instability and compromised mechanical properties of the coating. This hygroscopic nature not only affects the coating's durability but also impacts its barrier properties, potentially limiting its effectiveness in applications requiring moisture resistance.

Another challenge lies in the coating's thermal stability. Cellulose acetate has a relatively low glass transition temperature, which can cause problems in high-temperature applications or during processing. This limitation restricts its use in certain industrial settings where heat resistance is crucial. Additionally, the material's thermal degradation at elevated temperatures can result in the release of acetic acid, potentially affecting the coating's integrity and the surrounding environment.

The compatibility of cellulose acetate with other materials in multi-layer coating systems presents another hurdle. Achieving strong adhesion between cellulose acetate and substrates or other coating layers can be challenging, often requiring the use of specialized adhesion promoters or surface treatments. This compatibility issue not only complicates the coating process but also affects the overall performance and longevity of the coated product.

Furthermore, the processability of cellulose acetate in coating applications poses technical difficulties. The material's solution viscosity can be high, making it challenging to achieve uniform and thin coatings. This characteristic can lead to inconsistencies in coating thickness and quality, potentially impacting the final product's performance and appearance. Additionally, the solvent systems used for cellulose acetate coatings often involve volatile organic compounds (VOCs), raising environmental and health concerns that need to be addressed.

The biodegradability of cellulose acetate, while generally considered an advantage, can also present challenges in certain applications. In environments where long-term stability is required, the material's susceptibility to biodegradation may limit its use. Balancing the benefits of biodegradability with the need for durability remains a complex issue in coating technology.

Lastly, the cost-effectiveness of cellulose acetate coatings compared to alternative materials is an ongoing challenge. While cellulose acetate offers unique properties, its production and processing costs can be higher than those of some synthetic polymers. This economic factor can influence its adoption in cost-sensitive industries, necessitating ongoing research to improve production efficiency and reduce overall costs.

Existing Cellulose Acetate Coating Methodologies

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in a wide range of applications, including textiles, filters, and personal care products. The unique properties of these fibers, such as biodegradability and moisture absorption, make them suitable for various industrial and consumer goods.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, packaging, and optical films.

- Modification and blending of cellulose acetate: Research on modifying cellulose acetate through chemical treatments or blending with other polymers aims to enhance its properties and expand its applications. This includes improving thermal stability, mechanical strength, and compatibility with other materials.

- Cellulose acetate in sustainable and biodegradable products: The use of cellulose acetate in environmentally friendly and biodegradable products is a growing area of interest. This includes the development of sustainable packaging materials, disposable items, and other eco-friendly alternatives to conventional plastics.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane industries.Expand Specific Solutions03 Cellulose acetate composites and blends

Development of cellulose acetate-based composites and blends with other materials to enhance specific properties or create new functionalities. These innovations aim to expand the application range of cellulose acetate in various industries.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate to impart new properties or improve existing ones. These techniques include chemical modifications, surface treatments, and incorporation of additives to enhance performance in specific applications.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable applications

Utilization of cellulose acetate in environmentally friendly and biodegradable products, focusing on reducing environmental impact and developing sustainable alternatives to conventional plastics. This includes research on improving biodegradability and exploring new eco-friendly applications.Expand Specific Solutions

Key Industry Players in Cellulose Acetate Coatings

The utilization of cellulose acetate in novel coating technologies is in a growth phase, with increasing market size and technological advancements. The global market for cellulose acetate-based coatings is expanding, driven by demand for sustainable and high-performance materials. Technologically, the field is progressing rapidly, with companies like Daicel Corp., Eastman Chemical Co., and FUJIFILM Corp. leading innovation. These firms are developing advanced formulations and application methods, improving coating properties such as durability, flexibility, and environmental friendliness. Emerging players like Wanhua Chemical Group and Kansai Paint Co., Ltd. are also contributing to the technological maturity, focusing on specialized applications and eco-friendly solutions. The competitive landscape is characterized by a mix of established chemical companies and innovative startups, fostering a dynamic environment for research and development in cellulose acetate coating technologies.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Coating Patents

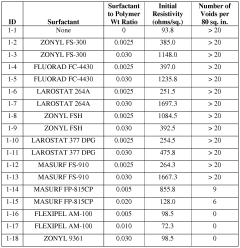

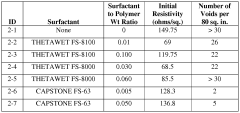

- A coating composition comprising a cellulosic polymer, silver nanowires, and specific surfactants like FLEXIPEL™ AM-101, ZONYL® 9361, or CAPSTONE® FS-63, which wet out silver nanowires without compromising conductivity, achieving resistivities less than 150 ohms per square and low void densities.

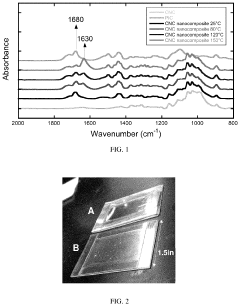

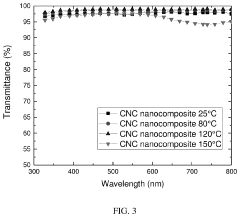

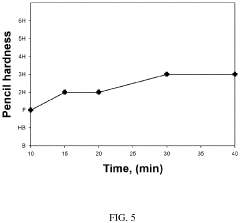

- A novel cellulose nanomaterial-based waterborne polyurethane coating is developed using pristine cellulose nanocrystals or nanofibrils combined with water-dispersible blocked polyisocyanates, where the cellulose nanomaterials contribute 40-90 wt% of the coating, and are crosslinked at elevated temperatures to enhance water resistance and mechanical properties.

Environmental Impact of Cellulose Acetate Coatings

The environmental impact of cellulose acetate coatings is a critical consideration in the development and application of novel coating technologies. Cellulose acetate, derived from natural cellulose, offers several environmental advantages over traditional petroleum-based coatings. Its biodegradability and renewable source material contribute to reduced environmental footprint throughout its lifecycle.

One of the primary environmental benefits of cellulose acetate coatings is their potential for biodegradation. Unlike many synthetic polymers, cellulose acetate can be broken down by microorganisms in natural environments, reducing long-term accumulation in ecosystems. This characteristic is particularly important in addressing concerns related to plastic pollution and microplastic contamination in aquatic environments.

The production process of cellulose acetate coatings also presents opportunities for environmental improvement. Compared to conventional coating materials, cellulose acetate can be manufactured using less energy-intensive methods, potentially reducing greenhouse gas emissions associated with production. Additionally, the use of renewable cellulose sources, such as wood pulp or cotton linters, supports sustainable resource management practices.

However, it is essential to consider the full lifecycle impact of cellulose acetate coatings. While the raw material is renewable, the acetylation process involves chemical modifications that may have environmental implications. The use of acetic anhydride and other chemicals in production requires careful management to minimize potential environmental risks and ensure proper disposal of byproducts.

Water consumption and wastewater management are also important factors in assessing the environmental impact of cellulose acetate coating production. Implementing efficient water recycling systems and advanced wastewater treatment technologies can significantly reduce the water footprint associated with manufacturing processes.

The end-of-life phase of cellulose acetate coatings presents both challenges and opportunities. While biodegradable, the rate of decomposition can vary depending on environmental conditions. Proper disposal and recycling infrastructure are crucial to maximize the environmental benefits of these coatings. Research into enhancing the biodegradability of cellulose acetate under various conditions is ongoing, aiming to improve its environmental performance across different applications.

In terms of air quality, cellulose acetate coatings generally emit fewer volatile organic compounds (VOCs) compared to solvent-based alternatives. This characteristic contributes to improved indoor air quality and reduced atmospheric pollution, aligning with increasingly stringent environmental regulations in many regions.

As the adoption of cellulose acetate in novel coating technologies continues to grow, ongoing research and development efforts focus on further improving its environmental profile. This includes exploring bio-based plasticizers, optimizing production processes for energy efficiency, and developing advanced recycling techniques to close the material loop.

Regulatory Framework for Novel Coating Technologies

The regulatory framework for novel coating technologies utilizing cellulose acetate is a complex and evolving landscape. As these technologies continue to advance, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and product quality. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing coatings that may come into contact with food or pharmaceuticals. The FDA's regulations, particularly 21 CFR 175.300, provide specific guidelines for resinous and polymeric coatings, which would encompass cellulose acetate-based formulations.

The Environmental Protection Agency (EPA) also has a significant influence on coating regulations, especially concerning volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). As cellulose acetate-based coatings often involve solvents, manufacturers must adhere to EPA standards for emissions and waste management. The agency's Toxic Substances Control Act (TSCA) inventory is particularly relevant for novel coating materials, requiring new chemical substances to be registered and evaluated before commercialization.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those used in coatings. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide safety data. The EU's Restriction of Hazardous Substances (RoHS) directive also impacts coating technologies, limiting the use of certain hazardous materials in electronic and electrical equipment.

For applications in the packaging industry, particularly food packaging, the European Food Safety Authority (EFSA) sets guidelines for materials in contact with food. Cellulose acetate coatings intended for such applications must comply with these regulations to ensure consumer safety. Similarly, in Asia, countries like Japan and China have their own regulatory frameworks, such as Japan's Food Sanitation Law and China's GB standards for food contact materials.

Globally, the International Organization for Standardization (ISO) provides standards that influence coating technologies. ISO 8502, for instance, addresses the assessment of surface cleanliness before coating application, which is crucial for the effectiveness of cellulose acetate-based coatings. Additionally, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) impacts the labeling and safety data sheets for coating materials and their components.

As sustainability becomes increasingly important, regulations are evolving to promote eco-friendly coating solutions. This trend favors cellulose acetate as a biodegradable alternative to synthetic polymers. However, it also necessitates compliance with emerging standards for bio-based materials and end-of-life considerations, such as the EU's Circular Economy Action Plan.