Transforming Waste with Cellulose Acetate Recycling Techniques

Cellulose Acetate Recycling: Background and Objectives

Cellulose acetate, a versatile and widely used synthetic polymer, has been a cornerstone material in various industries for over a century. Derived from cellulose, the most abundant organic polymer on Earth, cellulose acetate has found applications in textiles, films, cigarette filters, and numerous consumer products. However, the increasing global concern over plastic waste and environmental sustainability has brought the recycling of cellulose acetate into sharp focus.

The evolution of cellulose acetate technology can be traced back to its discovery in the 1860s, with commercial production beginning in the early 20th century. Initially prized for its durability and versatility, cellulose acetate quickly became a preferred material in many manufacturing processes. As environmental awareness grew in the latter half of the 20th century, so did the need to address the end-of-life issues associated with cellulose acetate products.

The current technological landscape surrounding cellulose acetate recycling is characterized by a mix of established methods and emerging innovations. Traditional recycling techniques have primarily focused on mechanical processes, which often result in downcycled products of lower quality. However, recent advancements in chemical recycling methods have opened new possibilities for more efficient and higher-quality recycling outcomes.

The primary objective of cellulose acetate recycling techniques is to transform waste materials back into valuable resources, thereby reducing environmental impact and creating a more circular economy. This goal aligns with broader sustainability initiatives and waste reduction targets set by governments and industries worldwide. Specifically, the aims include developing cost-effective recycling processes, improving the quality of recycled materials, and expanding the range of applications for recycled cellulose acetate.

Key technological trends in this field include the development of enzymatic deacetylation processes, which offer a more environmentally friendly alternative to chemical methods. Additionally, research into solvent-based recycling techniques shows promise for recovering high-purity cellulose from acetate waste. These advancements are driven by the need to address the limitations of current recycling methods, such as high energy consumption and the use of harsh chemicals.

As the demand for sustainable materials continues to grow, the cellulose acetate recycling industry faces both challenges and opportunities. The technical goals for the future include increasing recycling efficiency, reducing processing costs, and developing new applications for recycled cellulose acetate that can compete with virgin materials in terms of quality and performance. Achieving these objectives will require continued innovation, cross-industry collaboration, and supportive regulatory frameworks.

Market Analysis for Recycled Cellulose Acetate Products

The market for recycled cellulose acetate products is experiencing significant growth, driven by increasing environmental awareness and stringent regulations on plastic waste. Cellulose acetate, commonly used in textiles, cigarette filters, and packaging, has become a focal point for recycling efforts due to its biodegradable nature and potential for circular economy applications.

The global cellulose acetate market is projected to expand steadily, with a particular emphasis on recycled variants. Key sectors driving demand include textiles, where recycled cellulose acetate fibers are gaining traction in sustainable fashion lines. The packaging industry is also adopting recycled cellulose acetate for eco-friendly alternatives to traditional plastics, especially in food and cosmetics packaging.

Consumer electronics represent another promising market segment, with recycled cellulose acetate being utilized in the production of durable, bio-based casings and components. This trend aligns with the growing consumer preference for environmentally responsible products and the tech industry's push towards sustainability.

The automotive sector is exploring recycled cellulose acetate for interior components, aiming to reduce the carbon footprint of vehicles while meeting stringent quality and safety standards. This application showcases the material's versatility and potential to penetrate high-value markets.

Geographically, Europe and North America lead in the adoption of recycled cellulose acetate products, supported by advanced recycling infrastructure and favorable regulatory environments. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing industrialization and environmental concerns in countries like China and India.

Market challenges include the need for improved collection and sorting systems to ensure a steady supply of recyclable cellulose acetate. Additionally, the cost of recycling processes remains a barrier to widespread adoption, necessitating technological advancements and economies of scale to improve economic viability.

Despite these challenges, the market outlook for recycled cellulose acetate products remains positive. Collaborations between material scientists, manufacturers, and recycling companies are fostering innovations in recycling techniques and product applications. This synergy is expected to unlock new market opportunities and drive the transition towards a more circular economy for cellulose acetate-based products.

Current Challenges in Cellulose Acetate Recycling

Cellulose acetate recycling faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the complex chemical structure of cellulose acetate, which makes it resistant to natural degradation processes. This inherent stability, while beneficial for product longevity, complicates recycling efforts as it requires specialized techniques to break down the material effectively.

The contamination of cellulose acetate waste streams presents another major hurdle. Many products containing cellulose acetate, such as cigarette filters and textiles, often include additives, dyes, or other materials that can interfere with recycling processes. Separating these contaminants from the cellulose acetate is both technically challenging and economically demanding, reducing the overall efficiency and viability of recycling operations.

Energy consumption in the recycling process is a significant concern. Current methods for breaking down cellulose acetate often require high temperatures and pressures, leading to substantial energy expenditure. This not only increases the carbon footprint of recycling operations but also raises questions about the overall environmental benefits of recycling compared to other disposal methods.

The lack of standardized collection and sorting systems for cellulose acetate waste further complicates recycling efforts. Unlike more common plastics, there is no widespread infrastructure for the separate collection of cellulose acetate products, leading to contamination in general waste streams and reducing the potential for effective recycling.

Economic factors also play a crucial role in the challenges facing cellulose acetate recycling. The costs associated with collecting, sorting, and processing cellulose acetate waste often outweigh the value of the recycled material, making it difficult for recycling operations to be financially sustainable without significant subsidies or regulatory support.

Technical limitations in the quality of recycled cellulose acetate pose another challenge. Current recycling methods often result in degraded material properties, limiting the applications for recycled cellulose acetate. This quality reduction can make it less attractive for manufacturers to incorporate recycled content into new products, creating a barrier to closing the recycling loop.

Regulatory hurdles and a lack of standardized policies across regions create additional complications. The absence of unified guidelines for cellulose acetate recycling leads to inconsistent practices and hampers the development of large-scale, efficient recycling systems. This regulatory uncertainty also discourages investment in new recycling technologies and infrastructure.

Existing Cellulose Acetate Recycling Techniques

01 Chemical deacetylation and regeneration

This method involves chemically treating cellulose acetate to remove acetyl groups, converting it back to cellulose. The regenerated cellulose can then be used to produce new materials or products. This process often utilizes alkaline solutions to break down the acetate structure and recover the cellulose fibers.- Chemical deacetylation and regeneration: This method involves chemically treating cellulose acetate to remove acetyl groups, converting it back to cellulose. The regenerated cellulose can then be used to produce new materials or products. This process often utilizes alkaline solutions to break down the acetate groups and may involve additional steps to purify and process the resulting cellulose.

- Solvent-based recycling: Solvent-based recycling methods dissolve cellulose acetate in specific solvents, allowing for the separation of additives and impurities. The purified cellulose acetate solution can then be used to create new products through various forming processes. This approach often requires careful solvent selection and recovery to ensure economic and environmental viability.

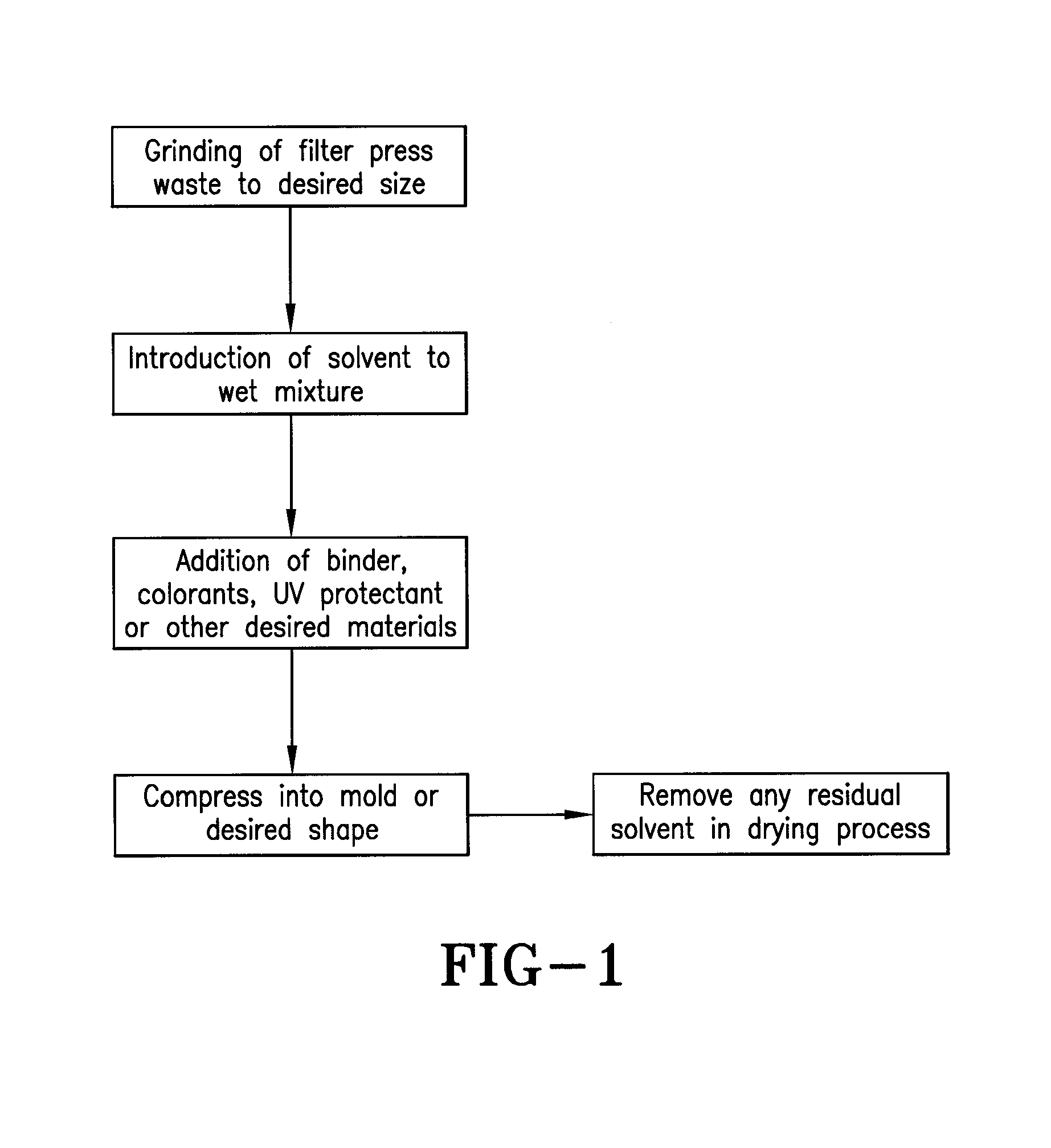

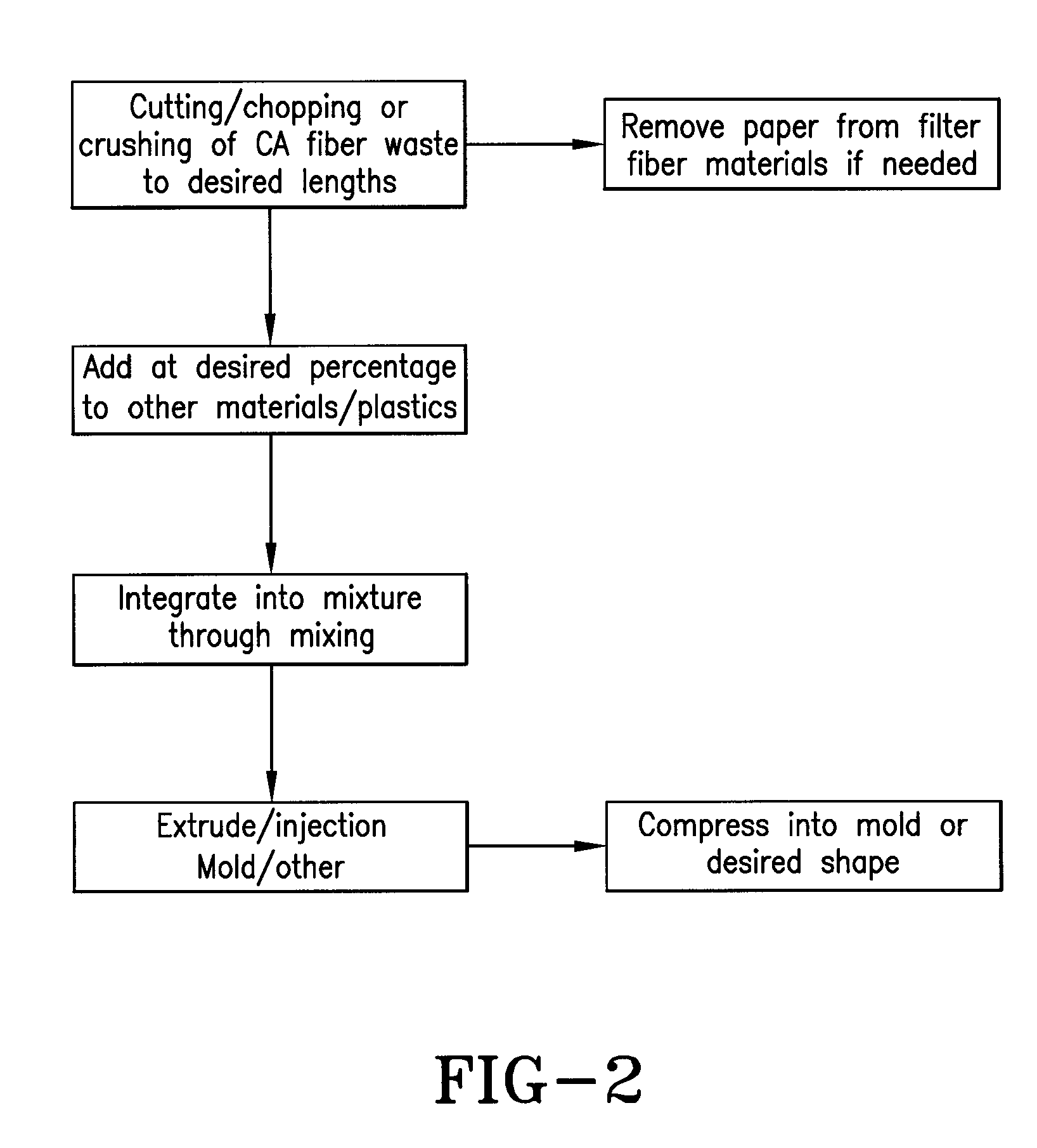

- Mechanical recycling and reprocessing: Mechanical recycling involves grinding or shredding cellulose acetate products into smaller particles, which can then be reprocessed into new materials. This method may include steps such as melting, extrusion, or compression molding to form new products. Additives or compatibilizers may be used to improve the properties of the recycled material.

- Enzymatic degradation and bio-based recycling: Enzymatic methods use specific enzymes to break down cellulose acetate into simpler compounds. These can then be used as feedstock for biological processes or further chemical conversions. This approach often involves the use of microorganisms or isolated enzymes to catalyze the deacetylation and degradation of cellulose acetate under controlled conditions.

- Thermal decomposition and pyrolysis: Thermal methods involve heating cellulose acetate under controlled conditions to break it down into valuable chemical components. This can include pyrolysis, where the material is heated in the absence of oxygen, or other thermal decomposition processes. The resulting products can be used as chemical feedstocks or fuels, providing an alternative to traditional recycling methods.

02 Solvent-based recycling

Solvent-based recycling methods dissolve cellulose acetate in specific solvents, allowing for the separation of additives and impurities. The purified cellulose acetate solution can then be used to create new products through various forming processes. This approach helps maintain the polymer structure and properties of the original material.Expand Specific Solutions03 Mechanical recycling and reprocessing

Mechanical recycling involves grinding or shredding cellulose acetate products into smaller particles, which can then be reprocessed into new materials. This method may include melting and reforming the material or using it as a filler in composite materials. It's a relatively simple process but may result in some degradation of material properties.Expand Specific Solutions04 Enzymatic degradation and recovery

Enzymatic methods use specific enzymes to break down cellulose acetate into its component parts. This bio-based approach allows for the recovery of cellulose and acetic acid, which can be used as raw materials for new products. The process is environmentally friendly and can be tailored to different types of cellulose acetate materials.Expand Specific Solutions05 Thermal decomposition and pyrolysis

This method involves heating cellulose acetate under controlled conditions to break it down into valuable chemical components. The process can yield a range of products including gases, oils, and char, which can be used as fuel or chemical feedstocks. Pyrolysis conditions can be optimized to maximize the yield of desired products.Expand Specific Solutions

Key Players in Cellulose Acetate Recycling Industry

The cellulose acetate recycling industry is in a growth phase, driven by increasing environmental concerns and circular economy initiatives. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Daicel Corp., Eastman Chemical Co., and Lenzing AG leading innovation. These firms are developing more efficient recycling processes and exploring novel applications for recycled cellulose acetate. Emerging players such as SmartFlow Technologies, Inc. and Acetek Momentum Co., Ltd. are introducing disruptive technologies, while research institutions like the Institute of Process Engineering, Chinese Academy of Sciences are contributing to fundamental advancements. The competitive landscape is characterized by a mix of established chemical companies and innovative startups, with collaboration between industry and academia accelerating technological progress.

Daicel Corp.

Eastman Chemical Co.

Innovative Approaches in Cellulose Acetate Recycling

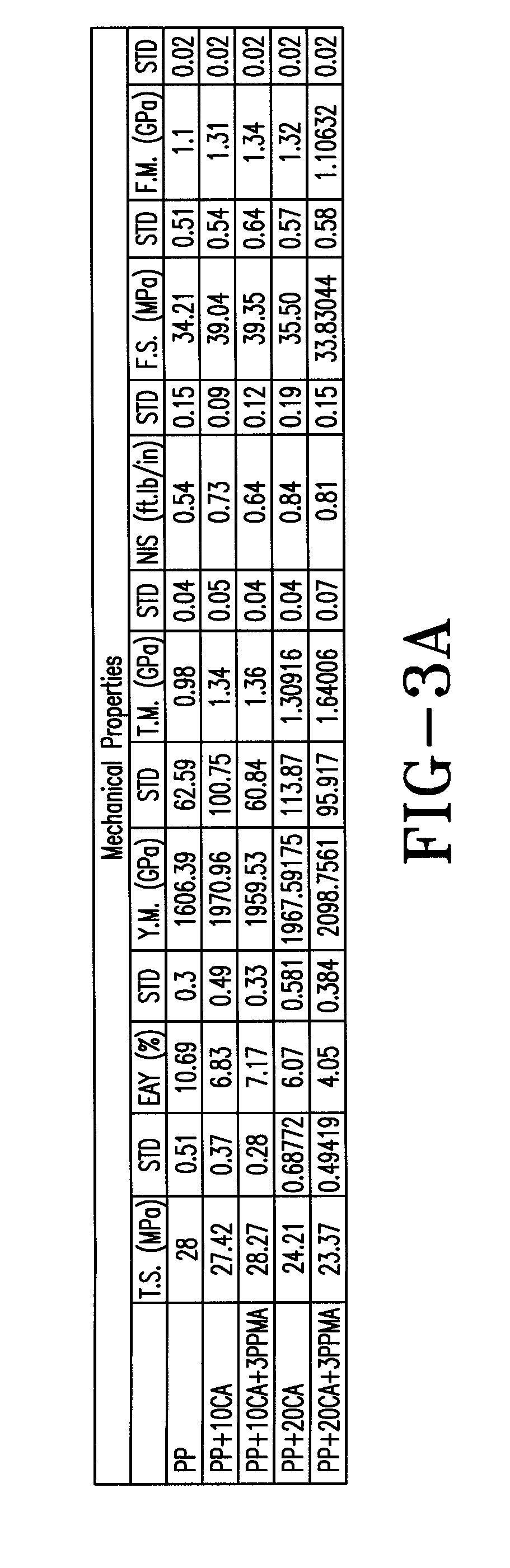

- A process involving grinding and wetting cellulose acetate waste with acetone, followed by molding and possible addition of colorants or UV protection, to create strong and lightweight materials suitable for insulation, reinforcement in plastics, and decorative items, leveraging the fibers' strength and insulating properties.

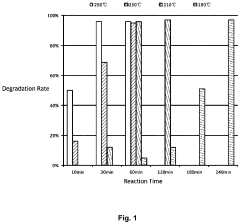

- A hydrothermal liquefaction process is developed to decompose cellulose acetate, operating at temperatures between 190-250°C with reaction times of 10-240 minutes, which produces acetic acid and diethyl phthalate by hydrolyzing ester bonds, using a micro-reactor with a cellulose acetate to water ratio of 1:5 to 1:10, followed by filtration and solvent extraction to separate and recover these valuable compounds.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate recycling techniques reveals both positive and negative effects on the ecosystem. On the positive side, these recycling methods significantly reduce the volume of waste entering landfills and incinerators. By diverting cellulose acetate products from traditional disposal methods, the techniques help mitigate greenhouse gas emissions associated with waste decomposition and incineration. Furthermore, the recycling process decreases the demand for virgin raw materials, thereby conserving natural resources and reducing the environmental footprint of cellulose acetate production.

However, the recycling techniques themselves are not without environmental concerns. The chemical processes involved in breaking down cellulose acetate often require solvents and energy-intensive operations. These processes can lead to the release of volatile organic compounds (VOCs) and other potentially harmful emissions if not properly controlled. Additionally, the water consumption and wastewater generation during the recycling process need careful management to prevent water pollution and strain on local water resources.

The life cycle assessment of cellulose acetate recycling techniques indicates a net positive environmental impact when compared to traditional disposal methods. The reduction in landfill space usage and the conservation of raw materials outweigh the environmental costs of the recycling process itself. However, the extent of this benefit varies depending on the specific recycling method employed and the efficiency of the recycling facilities.

Energy consumption is a critical factor in the environmental impact of these recycling techniques. While the energy required for recycling is generally less than that needed for producing new cellulose acetate from raw materials, it is still significant. The source of this energy plays a crucial role in determining the overall carbon footprint of the recycling process. Facilities powered by renewable energy sources can substantially reduce the environmental impact compared to those relying on fossil fuels.

Biodiversity impacts of cellulose acetate recycling are generally positive, as the reduction in waste accumulation in natural environments helps protect ecosystems and wildlife habitats. However, the potential for chemical leakage or improper disposal of recycling by-products poses risks that must be carefully managed to prevent localized environmental damage.

Economic Viability of Recycling Processes

The economic viability of cellulose acetate recycling processes is a critical factor in determining the feasibility and sustainability of transforming waste through these techniques. The cost-effectiveness of recycling cellulose acetate depends on several interconnected factors, including the availability and cost of raw materials, energy consumption, processing efficiency, and market demand for recycled products.

One of the primary economic advantages of cellulose acetate recycling is the potential reduction in raw material costs. By reclaiming and reprocessing cellulose acetate from waste streams, manufacturers can decrease their reliance on virgin materials, which often come with higher price tags and environmental impacts. This cost savings can be significant, especially in regions where raw material prices are volatile or subject to supply chain disruptions.

However, the economic viability is also heavily influenced by the efficiency of the recycling process itself. Advanced recycling techniques, such as chemical deacetylation and re-acetylation, require substantial energy inputs and specialized equipment. The initial capital investment for setting up these recycling facilities can be considerable, potentially creating a barrier to entry for smaller companies or those operating in developing economies.

Energy consumption is another crucial factor affecting the economic feasibility of cellulose acetate recycling. Processes that require high temperatures or extensive chemical treatments may incur significant operational costs. Innovations in energy-efficient recycling technologies, such as low-temperature solvent-based methods, are essential for improving the overall economic viability of these processes.

The market demand for recycled cellulose acetate products plays a pivotal role in determining the economic success of recycling initiatives. As consumer awareness of environmental issues grows, there is an increasing preference for products made from recycled materials. This trend can potentially drive up the value of recycled cellulose acetate, making the recycling process more economically attractive.

Furthermore, government policies and regulations can significantly impact the economic landscape of cellulose acetate recycling. Incentives such as tax breaks, subsidies, or mandatory recycling targets can improve the financial viability of recycling operations. Conversely, stringent environmental regulations may increase compliance costs, potentially offsetting some of the economic benefits.

The scale of recycling operations also influences their economic viability. Larger-scale facilities can often achieve economies of scale, reducing per-unit processing costs and improving overall profitability. However, this advantage must be balanced against the logistics and transportation costs associated with collecting and consolidating waste materials from diverse sources.

In conclusion, while cellulose acetate recycling techniques show promise for transforming waste, their economic viability is complex and multifaceted. Continued research and development in more efficient and cost-effective recycling methods, coupled with supportive policy frameworks and growing market demand, will be crucial in enhancing the economic attractiveness of these processes in the long term.