Cellulose Acetate: A Game-Changer in Biodegradable Material Use

Cellulose Acetate Evolution

Cellulose acetate has undergone a remarkable evolution since its inception in the late 19th century. Initially developed as a photographic film base, this versatile material has transformed into a key player in the realm of biodegradable materials. The journey of cellulose acetate began with its discovery by Paul Schützenberger in 1865, but it wasn't until the early 1900s that large-scale production methods were developed.

The 1920s marked a significant milestone in cellulose acetate's evolution with the introduction of cellulose acetate fibers, commonly known as acetate silk. This development revolutionized the textile industry, offering a more affordable and versatile alternative to natural silk. As the material's potential became apparent, research efforts intensified, leading to improvements in production techniques and expanding its applications.

The mid-20th century saw cellulose acetate gain prominence in the plastics industry. Its unique properties, including transparency, toughness, and moldability, made it an ideal material for a wide range of products, from eyeglass frames to tool handles. This period also witnessed advancements in the material's formulation, enhancing its durability and resistance to environmental factors.

In the latter half of the 20th century, environmental concerns began to shape the trajectory of cellulose acetate's evolution. As awareness of plastic pollution grew, researchers focused on improving the material's biodegradability. This shift in focus led to the development of modified cellulose acetate formulations with enhanced degradation properties, positioning it as a potential solution to the global plastic waste problem.

The 21st century has ushered in a new era for cellulose acetate, with a renewed emphasis on sustainability and eco-friendly materials. Recent advancements have focused on optimizing the material's biodegradation rate and expanding its applications in various industries. Researchers have explored novel production methods using renewable resources and green chemistry principles, further enhancing cellulose acetate's environmental credentials.

Today, cellulose acetate stands at the forefront of biodegradable material research. Its evolution continues as scientists and engineers work to improve its properties, reduce production costs, and expand its applications. From its humble beginnings as a photographic film base to its current status as a promising solution for sustainable packaging and consumer goods, cellulose acetate's journey exemplifies the dynamic nature of materials science and the ongoing quest for more environmentally friendly alternatives to traditional plastics.

Biodegradable Market Demand

The market demand for biodegradable materials has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. Cellulose acetate, as a biodegradable alternative to traditional plastics, is poised to play a crucial role in meeting this rising demand across various industries.

In the packaging sector, which accounts for a substantial portion of plastic waste, there is a growing shift towards sustainable solutions. Cellulose acetate offers an attractive option for food packaging, disposable cutlery, and other single-use items. Its biodegradability and compatibility with food contact make it particularly appealing to environmentally conscious consumers and businesses alike.

The textile industry is another key market for cellulose acetate. As consumers become more aware of the environmental impact of synthetic fibers, there is a rising demand for biodegradable alternatives in clothing and home textiles. Cellulose acetate's versatility in fiber production positions it as a potential game-changer in this sector.

In the automotive industry, there is an increasing focus on reducing the environmental footprint of vehicles. Cellulose acetate can be used in interior components, contributing to the overall sustainability of car manufacturing. This aligns with the industry's push towards more eco-friendly practices and materials.

The personal care and cosmetics industry is also showing a strong interest in biodegradable materials. Cellulose acetate's potential applications in this sector include packaging for beauty products and even as a base material for certain cosmetic formulations. This trend is driven by consumer demand for more sustainable beauty options.

The medical and pharmaceutical sectors present another significant market opportunity for cellulose acetate. Its biocompatibility and biodegradability make it suitable for various medical applications, including drug delivery systems and disposable medical devices. As healthcare providers increasingly prioritize sustainability, the demand for biodegradable materials in this sector is expected to grow.

Electronic waste is a growing environmental concern, and the electronics industry is under pressure to adopt more sustainable practices. Cellulose acetate's potential use in biodegradable electronic components and packaging could help address this issue, opening up new market opportunities in this sector.

As governments worldwide implement stricter regulations on single-use plastics and waste management, industries are actively seeking biodegradable alternatives. This regulatory landscape is expected to further boost the demand for materials like cellulose acetate across multiple sectors.

Cellulose Acetate Challenges

Despite the promising potential of cellulose acetate as a biodegradable material, several significant challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the material's limited biodegradability in natural environments. While cellulose acetate can degrade under specific conditions, its decomposition rate in typical disposal scenarios is often slower than desired, potentially contributing to environmental pollution if not properly managed.

The production process of cellulose acetate presents another set of challenges. The current manufacturing methods rely heavily on the use of acetic anhydride and other chemical solvents, which can have negative environmental impacts. These processes are often energy-intensive and generate chemical waste, contradicting the material's eco-friendly image. Developing more sustainable and efficient production techniques remains a critical area for improvement.

Mechanical properties pose another hurdle for cellulose acetate. While the material offers certain advantages, it often falls short in terms of strength, durability, and flexibility compared to conventional plastics. This limitation restricts its application in products that require high structural integrity or resistance to environmental stresses, such as packaging for certain foods or beverages.

Moisture sensitivity is a significant concern for cellulose acetate-based products. The material tends to absorb moisture from the environment, which can lead to dimensional instability, warping, and degradation of mechanical properties. This characteristic limits its use in applications where moisture resistance is crucial, such as outdoor products or long-term storage solutions.

Cost-effectiveness remains a challenge in scaling up cellulose acetate production. The raw materials and processing costs are often higher than those of traditional petroleum-based plastics, making it less economically viable for mass-market applications. This price differential creates a barrier to widespread adoption, particularly in price-sensitive industries.

Compatibility with existing manufacturing and recycling infrastructure is another obstacle. Many current plastic processing and recycling systems are not optimized for cellulose acetate, requiring significant investments in new equipment and processes. This incompatibility can lead to difficulties in integrating cellulose acetate into established production lines and waste management systems.

Lastly, there is a need for standardization and regulatory clarity regarding the use and disposal of cellulose acetate products. The lack of uniform guidelines and certifications for biodegradability claims can lead to confusion among consumers and businesses, potentially undermining confidence in the material's environmental benefits.

Current Cellulose Acetate Tech

01 Enzymatic degradation of cellulose acetate

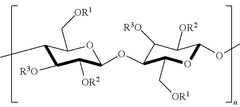

Cellulose acetate biodegradability can be enhanced through enzymatic degradation. This process involves the use of specific enzymes that can break down the cellulose acetate structure, making it more susceptible to microbial decomposition. The enzymatic treatment can be optimized for different types of cellulose acetate materials, improving their overall biodegradability in various environmental conditions.- Biodegradable cellulose acetate compositions: Development of cellulose acetate compositions with enhanced biodegradability. These compositions may include additives or modifications to the cellulose acetate structure to promote faster decomposition in natural environments. The focus is on creating materials that maintain the desirable properties of cellulose acetate while improving its environmental impact.

- Enzymatic degradation of cellulose acetate: Utilization of specific enzymes to accelerate the biodegradation of cellulose acetate. This approach involves identifying and applying enzymes capable of breaking down the acetyl groups and cellulose backbone, potentially in combination with other treatments to enhance the overall biodegradation process.

- Microbial degradation of cellulose acetate: Research into microbial strains capable of degrading cellulose acetate. This includes the identification and cultivation of bacteria and fungi that can effectively break down cellulose acetate under various environmental conditions. The goal is to develop more efficient biodegradation processes for cellulose acetate-based products.

- Chemical modifications for improved biodegradability: Chemical treatments and modifications of cellulose acetate to enhance its susceptibility to biodegradation. This may involve partial deacetylation, incorporation of biodegradable plasticizers, or grafting with other biodegradable polymers to create composite materials that degrade more readily in the environment.

- Biodegradable cellulose acetate blends and composites: Development of blends and composites combining cellulose acetate with other biodegradable materials. These formulations aim to improve the overall biodegradability of the resulting products while maintaining or enhancing their functional properties. The approach often involves mixing cellulose acetate with natural fibers or other biodegradable polymers.

02 Blending with biodegradable polymers

Improving the biodegradability of cellulose acetate can be achieved by blending it with other biodegradable polymers. This approach creates composite materials that combine the desirable properties of cellulose acetate with enhanced biodegradability. The blending process can be tailored to achieve specific degradation rates and mechanical properties, making the resulting materials suitable for various applications while ensuring better environmental compatibility.Expand Specific Solutions03 Chemical modification for improved biodegradability

Chemical modification techniques can be applied to cellulose acetate to enhance its biodegradability. These modifications may involve altering the degree of substitution, introducing new functional groups, or creating more easily degradable linkages within the polymer structure. Such chemical treatments can make cellulose acetate more susceptible to natural degradation processes while maintaining its useful properties for various applications.Expand Specific Solutions04 Microbial degradation strategies

Developing and optimizing microbial degradation strategies can significantly improve the biodegradability of cellulose acetate. This involves identifying and cultivating specific microorganisms capable of efficiently breaking down cellulose acetate. Research in this area focuses on understanding the metabolic pathways involved in cellulose acetate degradation and creating conditions that promote microbial activity, thereby accelerating the biodegradation process in natural environments.Expand Specific Solutions05 Environmental factors affecting biodegradation

Understanding and controlling environmental factors that influence cellulose acetate biodegradation is crucial for improving its overall biodegradability. Factors such as temperature, humidity, pH, and the presence of specific microorganisms can significantly impact the rate of degradation. Research in this area aims to identify optimal environmental conditions for cellulose acetate biodegradation and develop strategies to enhance its breakdown in various ecosystems.Expand Specific Solutions

Key Cellulose Acetate Players

The cellulose acetate market is in a growth phase, driven by increasing demand for biodegradable materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, cellulose acetate is mature but evolving, with companies like Eastman Chemical Co., Daicel Corp., and BASF Corp. leading innovation. These firms, along with others such as Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd., are advancing applications in various sectors. Research institutions like the Chinese Academy of Sciences and universities are contributing to technological advancements, focusing on improving biodegradability and expanding potential uses. The competitive landscape is characterized by a mix of established chemical companies and specialized manufacturers, with ongoing research driving product development and market expansion.

Eastman Chemical Co.

Daicel Corp.

Cellulose Acetate Innovations

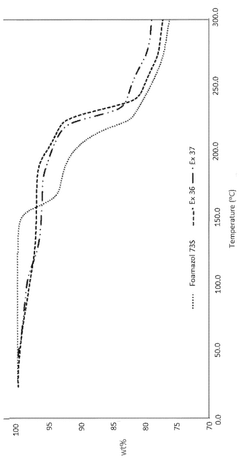

- A foamable composition comprising cellulose acetate with a specific degree of substitution, combined with plasticizers, nucleating agents, blowing agents, and natural fibers, which is melt-processable, thermoformable, and biodegradable, offering performance and aesthetic characteristics comparable to traditional plastics while being environmentally friendly.

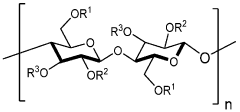

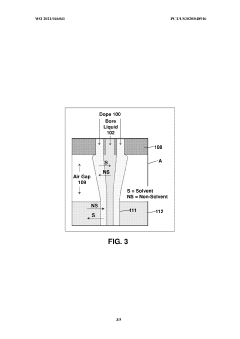

- Development of biodegradable products, specifically elongated tubular members made from cellulose esters with controlled porosity and acetyl degree of substitution, which are compostable under industrial and home conditions, and suitable for applications like drinking straws and packaging, using a solvent casting or extrusion process.

Environmental Impact Analysis

Cellulose acetate, a biodegradable material derived from natural cellulose, has garnered significant attention due to its potential to revolutionize sustainable product manufacturing. As we delve into the environmental impact analysis of this innovative material, it is crucial to consider both its positive contributions and potential drawbacks.

One of the primary environmental benefits of cellulose acetate lies in its biodegradability. Unlike traditional petroleum-based plastics that persist in the environment for hundreds of years, cellulose acetate can decompose within months to a few years under proper conditions. This characteristic significantly reduces the long-term accumulation of waste in landfills and natural ecosystems, mitigating the detrimental effects of plastic pollution on wildlife and marine environments.

Furthermore, the production of cellulose acetate from renewable resources, such as wood pulp or cotton linters, presents a more sustainable alternative to fossil fuel-based materials. This shift in raw material sourcing helps reduce the carbon footprint associated with plastic production and aligns with global efforts to transition towards a circular economy.

However, it is essential to acknowledge that the environmental impact of cellulose acetate is not entirely benign. The manufacturing process involves the use of chemical solvents and additives, which can potentially lead to air and water pollution if not properly managed. Additionally, the energy consumption required for production and the associated greenhouse gas emissions must be carefully considered when evaluating the overall environmental footprint of cellulose acetate products.

Another aspect to consider is the end-of-life management of cellulose acetate products. While biodegradable, these materials may still require specific conditions to decompose efficiently. Improper disposal or inadequate waste management infrastructure could lead to incomplete degradation, potentially resulting in microplastic pollution. Therefore, the development of appropriate recycling and composting systems is crucial to maximize the environmental benefits of cellulose acetate.

The use of cellulose acetate in various applications, such as textiles, packaging, and consumer goods, also presents opportunities for reducing environmental impact. For instance, in the textile industry, cellulose acetate fibers can replace synthetic fibers, potentially reducing microfiber pollution in water bodies. In packaging, cellulose acetate films can offer a biodegradable alternative to conventional plastic wraps, contributing to the reduction of single-use plastic waste.

In conclusion, while cellulose acetate shows promise as a more environmentally friendly material, its widespread adoption must be accompanied by comprehensive life cycle assessments and the development of appropriate waste management strategies. By addressing these challenges and optimizing production processes, cellulose acetate has the potential to play a significant role in reducing the environmental impact of material consumption and advancing sustainable manufacturing practices.

Regulatory Framework

The regulatory framework surrounding cellulose acetate as a biodegradable material is complex and evolving, reflecting the growing global emphasis on sustainable practices and environmental protection. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Trade Organization (WTO) have established guidelines and agreements that influence the production, use, and disposal of biodegradable materials, including cellulose acetate.

In the European Union, the regulatory landscape is particularly advanced, with the European Commission's Circular Economy Action Plan setting ambitious targets for reducing plastic waste and promoting biodegradable alternatives. The EU's Single-Use Plastics Directive, implemented in 2021, specifically addresses the use of certain plastic products and encourages the adoption of more sustainable materials like cellulose acetate.

The United States has a more fragmented approach, with regulations varying at federal, state, and local levels. The Environmental Protection Agency (EPA) oversees the broader aspects of environmental protection, while specific regulations on biodegradable materials are often implemented at the state level. California, for instance, has been at the forefront with its strict regulations on single-use plastics and promotion of biodegradable alternatives.

In Asia, countries like Japan and South Korea have implemented comprehensive recycling laws that indirectly promote the use of biodegradable materials. China's recent ban on certain types of plastic imports has also accelerated the search for sustainable alternatives, potentially boosting the adoption of cellulose acetate-based products.

Certification standards play a crucial role in the regulatory framework. Organizations such as the Biodegradable Products Institute (BPI) in North America and TÜV Austria in Europe provide certifications for compostable and biodegradable materials. These certifications are often referenced in regulations and help manufacturers demonstrate compliance with environmental standards.

The regulatory landscape also extends to labeling requirements. Many jurisdictions now mandate clear and accurate labeling of biodegradable products to prevent greenwashing and ensure consumer awareness. This has led to the development of standardized labels and symbols for biodegradable and compostable materials.

As the use of cellulose acetate in biodegradable applications grows, it is likely that more specific regulations will emerge. Current trends suggest a move towards harmonization of standards across different regions, which could facilitate the global adoption of cellulose acetate-based products. However, manufacturers and users of cellulose acetate must remain vigilant to the evolving regulatory landscape to ensure continued compliance and market access.