How to Advance Waste Management with Cellulose Acetate Innovation?

Cellulose Acetate in Waste Management: Background and Objectives

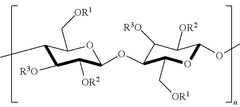

Cellulose acetate, a versatile biopolymer derived from cellulose, has emerged as a promising material in the field of waste management. Its unique properties and biodegradability make it an attractive alternative to conventional plastics, offering potential solutions to the growing global waste crisis. The evolution of cellulose acetate technology has been driven by the increasing need for sustainable materials and the urgent demand for effective waste management strategies.

The development of cellulose acetate can be traced back to the late 19th century, with its initial applications primarily in the textile and film industries. However, in recent decades, researchers and industry professionals have recognized its potential in addressing environmental challenges, particularly in waste management. This shift in focus has led to a surge in research and development efforts aimed at exploring innovative applications of cellulose acetate in waste reduction, recycling, and biodegradation processes.

The primary objective of advancing waste management through cellulose acetate innovation is to create sustainable, eco-friendly solutions that can effectively replace harmful materials and improve waste treatment processes. This includes developing biodegradable packaging materials, enhancing waste filtration systems, and creating novel composting methods that leverage the unique properties of cellulose acetate.

One of the key goals is to reduce the environmental impact of single-use plastics by replacing them with cellulose acetate-based alternatives. This involves not only creating products with similar functionality but also ensuring their compatibility with existing recycling and waste management infrastructure. Additionally, researchers aim to optimize the biodegradation process of cellulose acetate, making it a viable option for composting and reducing the burden on landfills.

Another important objective is to explore the potential of cellulose acetate in advanced waste treatment technologies. This includes its application in water purification systems, where cellulose acetate membranes can be used for efficient filtration of contaminants. Furthermore, there is growing interest in utilizing cellulose acetate in the development of smart packaging solutions that can extend the shelf life of products and reduce food waste.

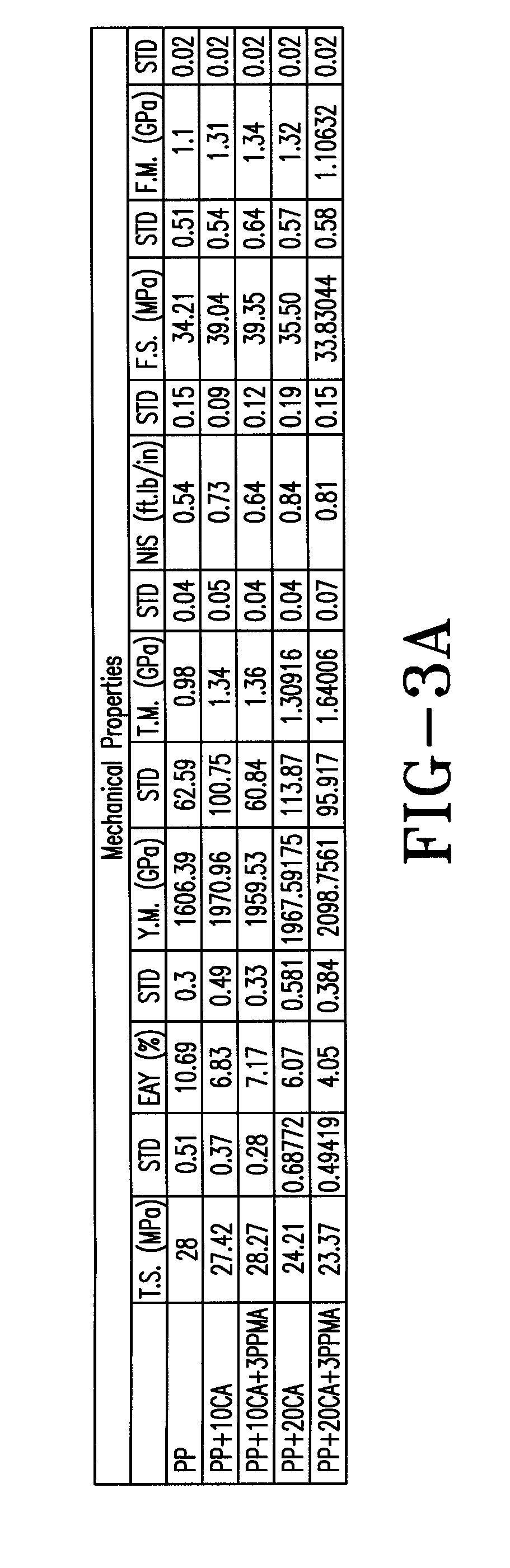

The technological evolution in this field is driven by the need to address several challenges, such as improving the mechanical properties of cellulose acetate-based materials, enhancing their resistance to environmental factors, and optimizing their production processes to make them economically viable alternatives to traditional plastics. Researchers are also focusing on developing new formulations and composites that combine cellulose acetate with other biodegradable materials to create products with enhanced performance characteristics.

As the waste management industry continues to evolve, the role of cellulose acetate is expected to grow significantly. The ongoing research and development efforts aim to unlock its full potential, paving the way for innovative solutions that can revolutionize waste management practices and contribute to a more sustainable future.

Market Analysis for Sustainable Waste Solutions

The global market for sustainable waste management solutions is experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and a growing emphasis on circular economy principles. The cellulose acetate innovation sector, in particular, presents a promising opportunity within this market landscape. As governments and industries worldwide seek more eco-friendly alternatives to traditional waste management practices, the demand for biodegradable and recyclable materials like cellulose acetate is on the rise.

Current market trends indicate a shift towards sustainable packaging solutions, with cellulose acetate emerging as a viable alternative to conventional plastics. The packaging industry, which accounts for a substantial portion of global waste, is actively seeking materials that can reduce environmental impact while maintaining functionality. Cellulose acetate, derived from renewable sources such as wood pulp or cotton linters, offers a biodegradable option that aligns with these sustainability goals.

The market potential for cellulose acetate in waste management extends beyond packaging. Its versatility allows for applications in various sectors, including textiles, electronics, and consumer goods. As consumers become more environmentally conscious, there is a growing demand for products made from sustainable materials, creating new market opportunities for cellulose acetate-based solutions.

Geographically, developed regions such as North America and Europe are currently leading the adoption of sustainable waste management practices, including the use of cellulose acetate innovations. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in this market as they grapple with increasing waste generation and environmental challenges.

The market is characterized by a mix of established players and innovative startups. Large chemical companies are investing in research and development to improve the properties and production efficiency of cellulose acetate, while smaller firms are focusing on niche applications and novel processing techniques. This dynamic ecosystem is driving innovation and expanding the potential applications of cellulose acetate in waste management.

Challenges in the market include the need for cost-effective production methods to compete with traditional materials, as well as the development of efficient recycling and composting infrastructure for cellulose acetate products. Overcoming these hurdles will be crucial for widespread adoption and market growth.

Looking ahead, the market for cellulose acetate in sustainable waste management is poised for substantial expansion. Factors such as increasing environmental regulations, corporate sustainability initiatives, and consumer preferences for eco-friendly products are expected to drive demand. The development of advanced cellulose acetate formulations with enhanced properties and the exploration of new application areas will further contribute to market growth and diversification in the coming years.

Current Challenges in Cellulose Acetate Waste Management

Cellulose acetate, a versatile biopolymer, faces significant challenges in waste management due to its widespread use and complex disposal requirements. The primary obstacle lies in its slow biodegradation rate, which can take several decades under natural conditions. This prolonged decomposition period contributes to the accumulation of cellulose acetate waste in landfills and marine environments, exacerbating environmental concerns.

Another major challenge is the lack of efficient recycling infrastructure for cellulose acetate products. Unlike other common plastics, cellulose acetate requires specialized recycling processes, which are not widely available. This limitation often results in cellulose acetate waste being incinerated or sent to landfills, leading to increased carbon emissions and resource wastage.

The presence of additives and plasticizers in cellulose acetate products further complicates their disposal. These additives, while enhancing product performance, can leach into the environment during decomposition, potentially causing harm to ecosystems and human health. Developing safe and effective methods to separate and neutralize these additives remains a significant technical challenge.

Moreover, the inconsistent composition of cellulose acetate waste streams poses difficulties in implementing standardized recycling processes. Variations in the degree of acetylation and the presence of different additives across products necessitate tailored recycling approaches, making large-scale recycling economically challenging.

The current regulatory landscape also presents hurdles for cellulose acetate waste management. Many regions lack specific guidelines for the disposal and recycling of cellulose acetate, leading to inconsistent practices and missed opportunities for sustainable management. This regulatory gap hinders the development and adoption of innovative waste management solutions.

Additionally, there is a notable lack of consumer awareness regarding the proper disposal of cellulose acetate products. Many users are unaware of the material's environmental impact and appropriate disposal methods, leading to improper disposal and contamination of recycling streams.

Lastly, the economic viability of cellulose acetate recycling remains a significant challenge. The costs associated with collecting, sorting, and processing cellulose acetate waste often outweigh the value of recovered materials, discouraging investment in recycling infrastructure and technologies. Overcoming these economic barriers is crucial for establishing a sustainable cellulose acetate waste management system.

Existing Cellulose Acetate Waste Management Solutions

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

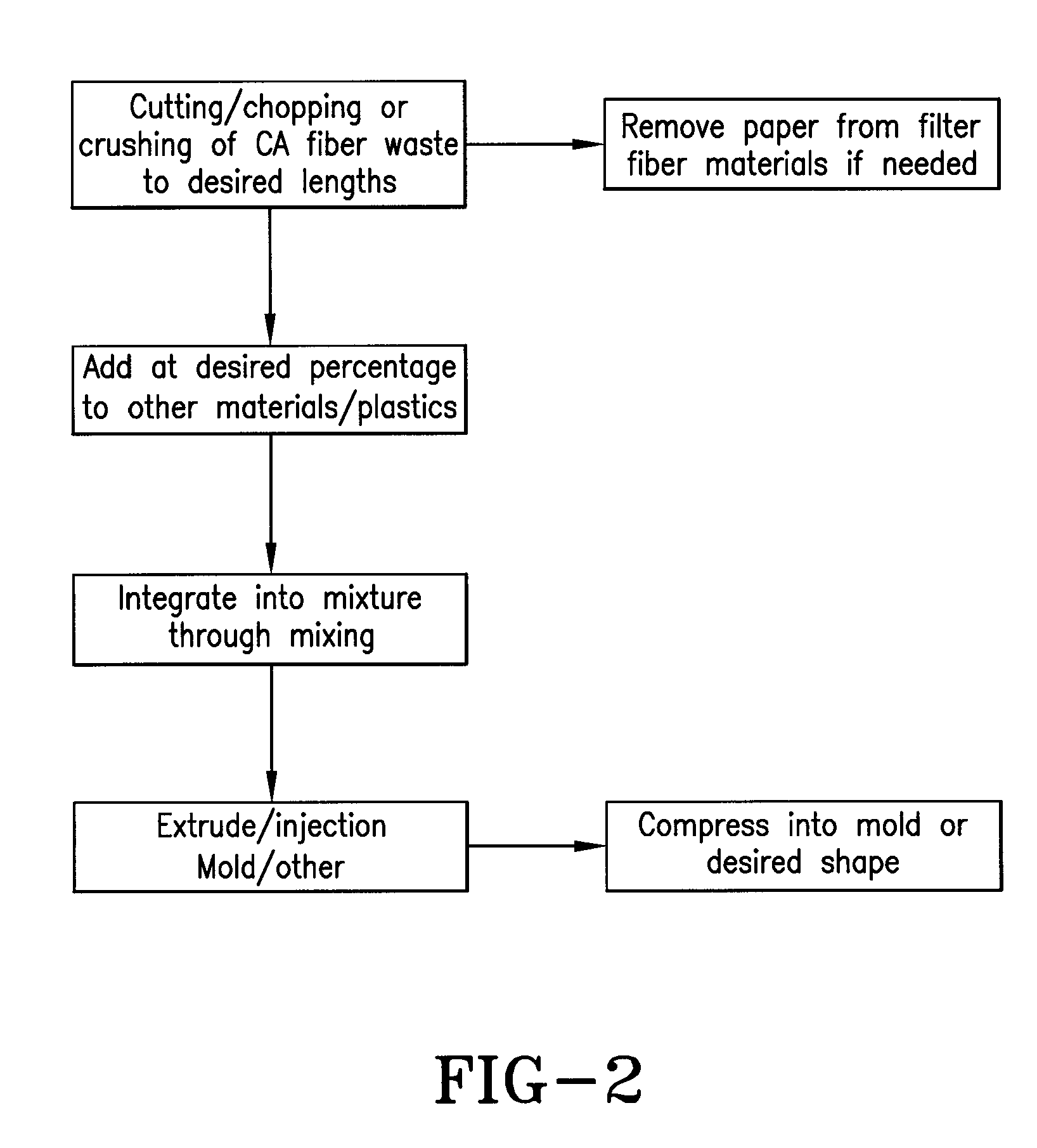

- Cellulose acetate fibers and films: Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane industries.

- Cellulose acetate composites and blends: Development of cellulose acetate-based composites and blends with other materials to enhance specific properties or create new functionalities. These innovations aim to expand the application range of cellulose acetate in various industries.

- Cellulose acetate modification and derivatization: Methods for modifying cellulose acetate through chemical treatments or derivatization to impart new properties or improve existing ones. These modifications can lead to enhanced performance in specific applications or enable new uses for cellulose acetate.

- Cellulose acetate in filtration and separation: Applications of cellulose acetate in filtration and separation processes, including membrane technology and filter materials. Innovations focus on improving selectivity, permeability, and durability of cellulose acetate-based filtration systems.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films with improved properties are presented. These include methods for enhancing strength, durability, and other physical characteristics of cellulose acetate-based materials for use in textiles, packaging, and other industries.Expand Specific Solutions03 Cellulose acetate composites and blends

Innovations in creating cellulose acetate composites and blends with other materials are discussed. These developments aim to enhance the performance and expand the applications of cellulose acetate in various fields, including biodegradable plastics and advanced materials.Expand Specific Solutions04 Cellulose acetate modification and functionalization

Methods for modifying and functionalizing cellulose acetate to impart new properties or improve existing ones are outlined. These include chemical treatments, surface modifications, and the incorporation of additives to enhance the material's functionality for specific applications.Expand Specific Solutions05 Cellulose acetate in membrane technology

Applications of cellulose acetate in membrane technology are explored, including its use in filtration, separation, and purification processes. Techniques for improving membrane performance, selectivity, and durability are discussed, along with novel membrane structures and compositions.Expand Specific Solutions

Key Players in Cellulose Acetate Industry and Recycling

The waste management industry is evolving rapidly, with cellulose acetate innovation playing a crucial role. The market is in a growth phase, driven by increasing environmental concerns and stringent regulations. The global cellulose acetate market size is projected to expand significantly, with key players like Daicel Corp., Eastman Chemical Co., and Nantong Cellulose Fibers Co. Ltd. leading the way. Technological maturity varies, with established companies like Eastman Chemical Co. and Daicel Corp. demonstrating advanced capabilities. Emerging players such as Zhuhai Cellulose Fibers Co. Ltd. and Kunming Acetate Fiber Co. Ltd. are also making strides in developing innovative solutions. Research institutions like the Institute of Process Engineering, Chinese Academy of Sciences, and Jiangnan University are contributing to technological advancements, fostering a competitive and dynamic landscape in cellulose acetate-based waste management solutions.

Daicel Corp.

Eastman Chemical Co.

Innovative Approaches in Cellulose Acetate Recycling

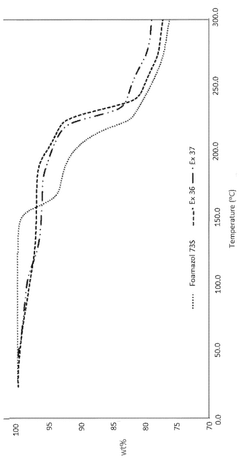

- A foamable composition comprising cellulose acetate with a specific degree of substitution, combined with plasticizers, nucleating agents, blowing agents, and natural fibers, which is melt-processable, thermoformable, and biodegradable, offering performance and aesthetic characteristics comparable to traditional plastics while being environmentally friendly.

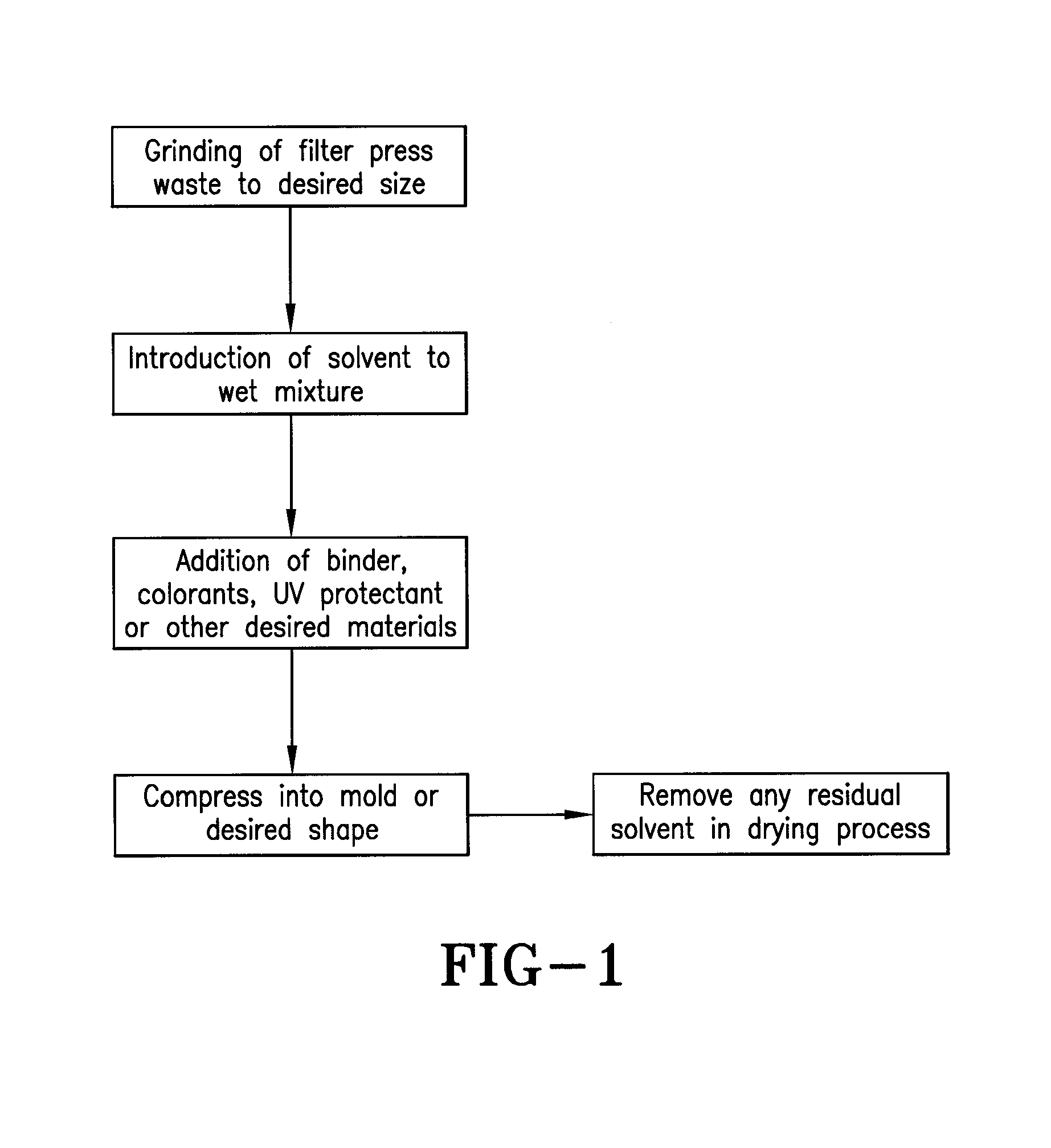

- A process involving grinding and wetting cellulose acetate waste with acetone, followed by molding and possible addition of colorants or UV protection, to create strong and lightweight materials suitable for insulation, reinforcement in plastics, and decorative items, leveraging the fibers' strength and insulating properties.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate innovation in waste management reveals both positive and negative implications. On the positive side, cellulose acetate-based materials offer a biodegradable alternative to traditional plastics, potentially reducing the accumulation of non-degradable waste in landfills and oceans. When properly disposed of, these materials can decompose within months to years, depending on environmental conditions, significantly faster than conventional plastics that may persist for centuries.

Furthermore, the production of cellulose acetate from renewable sources such as wood pulp or cotton linters can lead to a reduced carbon footprint compared to petroleum-based plastics. This shift towards bio-based materials aligns with circular economy principles, promoting the use of renewable resources and minimizing environmental impact throughout the product lifecycle.

However, the environmental benefits of cellulose acetate are not without challenges. The production process involves the use of acetic acid and other chemicals, which, if not properly managed, can lead to air and water pollution. Proper waste treatment and emission control systems are crucial to mitigate these risks. Additionally, while cellulose acetate is biodegradable, it may still persist in the environment for extended periods under certain conditions, particularly in marine environments where degradation rates can be slower.

The end-of-life management of cellulose acetate products also presents environmental considerations. While biodegradable, these materials require specific conditions to break down efficiently. Improper disposal in conventional landfills may not provide the optimal environment for biodegradation, potentially leading to prolonged persistence. Implementing dedicated composting or biodegradation facilities is essential to maximize the environmental benefits of these materials.

Moreover, the increased use of cellulose acetate in waste management solutions may impact land use and forestry practices. As demand for cellulose-based materials grows, there is a potential for increased pressure on forest resources, necessitating sustainable forest management practices to prevent deforestation and maintain biodiversity.

In terms of energy consumption, the production of cellulose acetate can be more energy-intensive compared to some conventional plastics. However, ongoing research and technological advancements aim to improve energy efficiency in the manufacturing process, potentially reducing the overall environmental impact over time.

Lastly, the environmental impact of cellulose acetate innovation extends to water usage. The production process requires significant amounts of water, which can strain local water resources in areas of manufacturing. Implementing water recycling and conservation measures in production facilities is crucial to mitigate this impact and ensure sustainable water management practices.

Regulatory Framework for Cellulose Acetate Disposal

The regulatory framework for cellulose acetate disposal is a critical aspect of advancing waste management through innovation. As governments worldwide increasingly focus on environmental protection and sustainable practices, the disposal of cellulose acetate products has come under scrutiny. The current regulatory landscape varies significantly across different regions, with some countries implementing strict guidelines while others are still in the process of developing comprehensive policies.

In the European Union, the Waste Framework Directive (2008/98/EC) provides the overarching legislation for waste management, including cellulose acetate products. This directive emphasizes waste prevention, reuse, and recycling, with disposal as a last resort. Member states are required to implement national laws that align with these principles, leading to variations in specific regulations across EU countries. For instance, some nations have introduced extended producer responsibility (EPR) schemes for cellulose acetate products, placing the onus on manufacturers to manage the entire lifecycle of their products.

The United States approaches cellulose acetate disposal primarily through the Resource Conservation and Recovery Act (RCRA). While cellulose acetate is not classified as hazardous waste under federal regulations, individual states may impose additional requirements. Some states have implemented landfill bans on certain cellulose acetate products, encouraging recycling and alternative disposal methods. The Environmental Protection Agency (EPA) also provides guidelines for the proper disposal of cellulose acetate-containing items, though these are often non-binding recommendations rather than strict regulations.

In Asia, the regulatory landscape is diverse and rapidly evolving. Japan, for example, has implemented the Law for Promotion of Effective Utilization of Resources, which includes provisions for cellulose acetate recycling. China's recent revisions to its Solid Waste Law have tightened restrictions on waste imports and disposal, potentially affecting cellulose acetate waste management practices. Other countries in the region are at various stages of developing and implementing waste management regulations, with a growing trend towards more stringent environmental protection measures.

Globally, international agreements such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal influence the regulatory framework for cellulose acetate disposal. While cellulose acetate is not explicitly listed as hazardous waste, the convention's principles of environmentally sound management apply to its disposal, particularly in cross-border scenarios.

As innovation in cellulose acetate waste management advances, regulatory frameworks are likely to evolve. Emerging technologies and circular economy principles are influencing policy development, with a growing emphasis on biodegradability, recyclability, and sustainable disposal methods. Future regulations may focus on incentivizing the development of eco-friendly alternatives, promoting closed-loop recycling systems, and implementing more stringent disposal standards to minimize environmental impact.