How to Innovate Packaging with Cellulose Acetate Solutions?

Cellulose Acetate Packaging Evolution and Objectives

Cellulose acetate, a versatile biopolymer derived from natural cellulose, has been a cornerstone in packaging innovation for over a century. Its journey began in the early 1900s when it was first developed as a more stable alternative to celluloid. Initially used in photographic film and fibers, cellulose acetate quickly found its way into the packaging industry due to its unique properties.

The evolution of cellulose acetate packaging has been marked by continuous improvements in material properties and processing techniques. In the 1920s and 1930s, it gained popularity as a packaging material for food products, offering transparency and moisture resistance. The post-World War II era saw a surge in its use for consumer goods packaging, driven by the growing demand for convenient and attractive packaging solutions.

Recent decades have witnessed a renewed interest in cellulose acetate as a sustainable packaging option. With increasing environmental concerns, the biodegradability and renewability of cellulose acetate have become significant advantages. Researchers and industry players have focused on enhancing its barrier properties, improving its processability, and reducing production costs to compete with synthetic plastics.

The current objectives in cellulose acetate packaging innovation are multifaceted. Firstly, there is a push towards developing fully bio-based cellulose acetate, eliminating the need for petroleum-derived components. This aligns with the global trend towards sustainable and circular economy principles. Secondly, improving the material's barrier properties against oxygen, moisture, and UV light remains a key goal to expand its application in food and pharmaceutical packaging.

Another critical objective is to enhance the material's mechanical properties, making it suitable for a wider range of packaging applications. This includes improving its flexibility, strength, and impact resistance. Additionally, there is a focus on developing cellulose acetate composites and blends that combine the benefits of cellulose acetate with other materials to create high-performance packaging solutions.

The packaging industry is also exploring innovative processing techniques for cellulose acetate. This includes advancements in film extrusion, injection molding, and 3D printing technologies tailored for cellulose acetate-based materials. These efforts aim to broaden the range of packaging formats and designs achievable with cellulose acetate.

Lastly, a significant objective is to optimize the end-of-life management of cellulose acetate packaging. This involves improving its biodegradability in various environments, developing efficient recycling processes, and ensuring compatibility with existing waste management systems. The ultimate goal is to create a closed-loop system for cellulose acetate packaging, minimizing environmental impact and maximizing resource efficiency.

Market Demand for Sustainable Packaging Solutions

The global packaging industry is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and regulatory pressures. Cellulose acetate, a biodegradable and renewable material derived from wood pulp, has emerged as a promising alternative to traditional plastic packaging. The market demand for sustainable packaging solutions using cellulose acetate is growing rapidly across various sectors.

Consumer awareness and preferences are key drivers of this demand. A recent survey revealed that 73% of consumers are willing to pay more for products with environmentally friendly packaging. This shift in consumer behavior has prompted major brands to commit to sustainable packaging goals, creating a substantial market opportunity for cellulose acetate solutions.

The food and beverage industry, in particular, has shown strong interest in cellulose acetate packaging. With the global food packaging market projected to reach $456 billion by 2027, there is a significant potential for cellulose acetate to capture a substantial share. Restaurants and food delivery services are increasingly adopting biodegradable packaging options, further fueling the demand.

In the personal care and cosmetics sector, cellulose acetate packaging is gaining traction as brands seek to align with eco-conscious consumers. The global cosmetic packaging market, valued at $30.9 billion in 2020, is expected to grow at a CAGR of 4.3% from 2021 to 2028, with sustainable packaging solutions playing a crucial role in this growth.

The pharmaceutical industry is another key market for cellulose acetate packaging solutions. With stringent regulations on packaging materials and a growing emphasis on sustainability, pharmaceutical companies are exploring alternatives to traditional plastic packaging. The global pharmaceutical packaging market, projected to reach $153.93 billion by 2027, presents a significant opportunity for cellulose acetate innovations.

E-commerce, which has seen exponential growth in recent years, is driving demand for sustainable packaging solutions. As online retailers face pressure to reduce their environmental impact, cellulose acetate packaging offers a viable alternative to conventional materials. The e-commerce packaging market is expected to grow at a CAGR of 14.3% from 2021 to 2028, highlighting the potential for cellulose acetate solutions in this sector.

Regulatory initiatives worldwide are further propelling the market demand for sustainable packaging. Many countries have implemented or are considering bans on single-use plastics, creating a favorable environment for cellulose acetate alternatives. The European Union's Circular Economy Action Plan and similar initiatives in other regions are expected to accelerate the adoption of sustainable packaging solutions.

Current Challenges in Cellulose Acetate Packaging

Cellulose acetate packaging faces several significant challenges in the current market landscape. One of the primary issues is the material's limited barrier properties, particularly against moisture and gases. This limitation restricts its use in applications requiring high-performance barrier packaging, such as for certain food products or sensitive electronics.

The biodegradability of cellulose acetate, while generally considered an advantage, presents a challenge in terms of consistency and predictability. The rate of degradation can vary significantly depending on environmental conditions, making it difficult to guarantee a specific lifespan for packaging products. This variability can be problematic for industries that require precise control over packaging integrity and shelf life.

Cost-effectiveness remains a hurdle for widespread adoption of cellulose acetate packaging. While the raw material is derived from renewable sources, the processing and manufacturing costs can be higher compared to conventional plastics. This price differential can deter companies from switching to cellulose acetate, especially in price-sensitive markets or for low-margin products.

Another challenge lies in the mechanical properties of cellulose acetate. While it offers good clarity and gloss, it may not match the strength and flexibility of some synthetic polymers. This can limit its application in packaging that requires high impact resistance or flexibility, such as in certain types of food containers or flexible pouches.

The recyclability of cellulose acetate packaging also presents challenges. While the material is theoretically recyclable, the infrastructure and processes for large-scale recycling of cellulose acetate are not as well-established as those for more common plastics. This can lead to difficulties in implementing effective end-of-life solutions for cellulose acetate packaging products.

Regulatory compliance and standardization pose additional challenges. As a relatively newer material in the packaging industry, cellulose acetate may face hurdles in meeting established packaging regulations or standards that were primarily developed for traditional plastics. This can create barriers to entry in certain markets or applications.

Lastly, there are technical challenges in processing and manufacturing cellulose acetate packaging. The material can be sensitive to processing conditions, requiring careful control of temperature and other parameters during production. This can lead to increased complexity and potential quality control issues in manufacturing processes.

Existing Cellulose Acetate Packaging Solutions

01 Cellulose acetate solutions for packaging films

Cellulose acetate solutions are used to create packaging films with desirable properties such as transparency, strength, and flexibility. These solutions can be formulated with various additives to enhance specific characteristics of the resulting film, making them suitable for a wide range of packaging applications.- Cellulose acetate solutions for packaging films: Cellulose acetate solutions are used to create packaging films with desirable properties such as transparency, strength, and flexibility. These solutions can be formulated with various solvents and additives to achieve specific characteristics for different packaging applications.

- Improvements in cellulose acetate packaging materials: Advancements in cellulose acetate packaging materials focus on enhancing properties such as moisture resistance, barrier properties, and durability. These improvements may involve modifying the cellulose acetate structure or incorporating additional components into the solution.

- Cellulose acetate solutions for coating applications: Cellulose acetate solutions are utilized as coatings for various substrates, including paper, textiles, and other materials. These coatings can provide protection, improve appearance, or impart specific functionalities to the packaged products.

- Biodegradable packaging solutions using cellulose acetate: Cellulose acetate solutions are being developed and utilized to create biodegradable packaging materials. These environmentally friendly alternatives aim to reduce plastic waste while maintaining the necessary packaging properties.

- Cellulose acetate solutions for specialized packaging applications: Cellulose acetate solutions are formulated for specific packaging needs, such as food packaging, pharmaceutical packaging, or electronic component packaging. These specialized solutions may incorporate additional ingredients to meet industry-specific requirements and regulations.

02 Improved cellulose acetate formulations for packaging

Advanced formulations of cellulose acetate solutions have been developed to enhance the performance of packaging materials. These improvements may include better moisture resistance, increased durability, and improved barrier properties, addressing specific needs in the packaging industry.Expand Specific Solutions03 Cellulose acetate solutions for biodegradable packaging

Cellulose acetate solutions are being explored for the development of biodegradable packaging materials. These environmentally friendly solutions aim to reduce plastic waste while maintaining the necessary properties for effective packaging.Expand Specific Solutions04 Cellulose acetate blends for specialized packaging

Blending cellulose acetate solutions with other materials or polymers can create specialized packaging solutions. These blends may offer unique combinations of properties, such as improved heat resistance, enhanced printability, or specific barrier characteristics tailored to particular packaging requirements.Expand Specific Solutions05 Processing techniques for cellulose acetate packaging solutions

Various processing techniques have been developed to optimize the production of packaging materials from cellulose acetate solutions. These may include novel casting methods, drying processes, or surface treatments to enhance the final product's properties and performance in packaging applications.Expand Specific Solutions

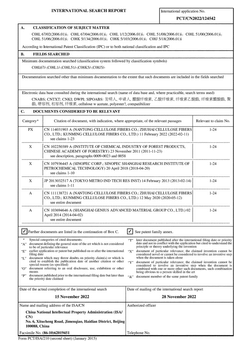

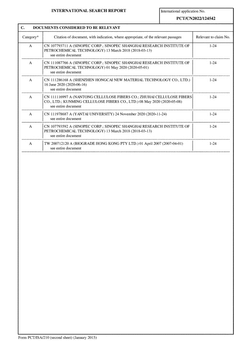

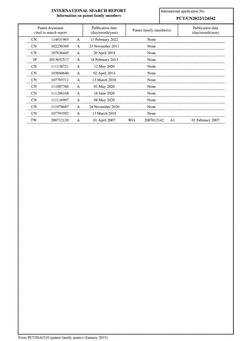

Key Players in Cellulose Acetate Packaging Industry

The innovation of packaging with cellulose acetate solutions is in a growth phase, driven by increasing demand for sustainable packaging alternatives. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Daicel Corp., Eastman Chemical Co., and BASF Corp. leading in research and development. These firms, along with others such as FUJIFILM Corp. and Cerdia International GmbH, are pushing the boundaries of cellulose acetate applications in packaging. The technology's maturity varies across different applications, with some areas well-established and others still emerging, indicating a dynamic and evolving landscape in this sector.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Formulations and Properties

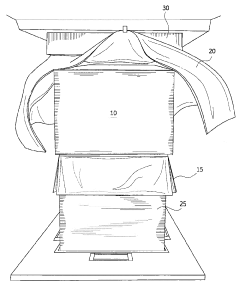

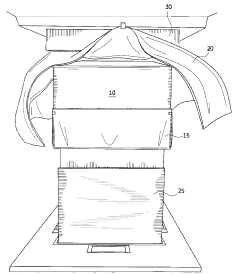

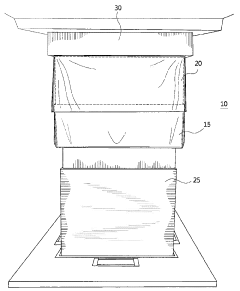

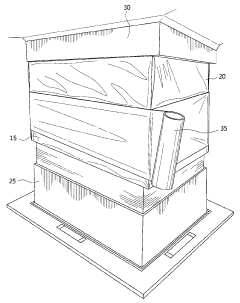

- A method involving positioning a fibrous material between a top and bottom sheet with overlapping edges, secured by a perimeter pass of tape with an adhesive layer, allowing for ambient temperature and pressure packaging without the need for heat sealing or vacuum sealing, using sheets and tape materials that can withstand the internal pressures.

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to enhance the interfacial compatibility and mechanical properties of cellulose acetate and biodegradable polyester blends through reaction extrusion, allowing for improved thermal processing and film production.

Environmental Impact and Regulations

The environmental impact of packaging materials has become a critical concern in recent years, with increasing focus on sustainability and regulatory compliance. Cellulose acetate, as a biodegradable and renewable material, offers significant potential for innovative packaging solutions that align with environmental goals and regulations.

Cellulose acetate packaging materials have a lower carbon footprint compared to traditional petroleum-based plastics. The production process of cellulose acetate requires less energy and generates fewer greenhouse gas emissions. Additionally, its biodegradability reduces the long-term environmental impact associated with plastic waste accumulation in landfills and oceans.

Regulations surrounding packaging materials have become increasingly stringent, with many countries implementing bans or restrictions on single-use plastics. The European Union's Single-Use Plastics Directive, for instance, aims to reduce the impact of certain plastic products on the environment. Cellulose acetate packaging solutions can help companies comply with these regulations while maintaining product integrity and consumer convenience.

The recyclability of cellulose acetate further enhances its environmental profile. Unlike many composite materials, cellulose acetate can be easily recycled through existing waste management systems. This characteristic aligns with circular economy principles and supports the development of closed-loop packaging systems.

However, it is important to note that the environmental benefits of cellulose acetate packaging are dependent on proper end-of-life management. While biodegradable, cellulose acetate requires specific conditions to break down efficiently. Educating consumers and establishing appropriate disposal infrastructure are crucial steps in maximizing the environmental advantages of this material.

Regulatory bodies are also considering the entire lifecycle of packaging materials, including production, use, and disposal. Cellulose acetate's renewable sourcing from wood pulp or cotton linters aligns with regulations promoting the use of sustainable raw materials. This aspect can provide companies with a competitive advantage in markets where sustainability credentials are increasingly valued.

As regulations continue to evolve, the adaptability of cellulose acetate in various packaging applications positions it as a versatile solution. Its compatibility with different manufacturing processes allows for the development of innovative packaging designs that meet both regulatory requirements and consumer expectations for eco-friendly products.

Cost-Benefit Analysis of Cellulose Acetate Packaging

The cost-benefit analysis of cellulose acetate packaging reveals a complex interplay of economic, environmental, and performance factors. Initial production costs for cellulose acetate packaging tend to be higher than traditional plastic alternatives due to the specialized manufacturing processes and raw material sourcing. However, these upfront expenses are often offset by long-term benefits and cost savings.

One significant advantage of cellulose acetate packaging is its biodegradability, which can lead to reduced waste management costs for businesses and municipalities. This characteristic aligns with growing consumer demand for sustainable packaging solutions, potentially increasing market share and brand loyalty. The material's versatility also allows for innovative designs that can enhance product visibility and appeal, potentially boosting sales and justifying premium pricing.

From a performance standpoint, cellulose acetate offers excellent clarity, rigidity, and printability, comparable to many conventional plastics. These properties ensure that products are well-protected and attractively presented, maintaining quality standards while potentially reducing breakage and returns. The material's natural antistatic properties can be particularly beneficial for electronics packaging, offering added value in specific market segments.

Environmental benefits, while not directly quantifiable in monetary terms, contribute significantly to the overall value proposition. Reduced carbon footprint, lower environmental impact, and alignment with circular economy principles can enhance corporate reputation and help meet increasingly stringent regulatory requirements. This proactive approach to sustainability can mitigate future costs associated with environmental compliance and potential penalties.

However, challenges exist in scaling up production and establishing efficient recycling infrastructure for cellulose acetate. These factors can impact the overall cost-effectiveness of the material in the short term. Additionally, the performance of cellulose acetate in certain high-moisture or high-temperature applications may require additional treatments or modifications, potentially increasing costs for specific use cases.

In conclusion, while the initial investment in cellulose acetate packaging may be higher, the long-term benefits in terms of sustainability, market positioning, and potential regulatory advantages present a compelling case for its adoption. As production scales and technologies improve, the cost-benefit ratio is likely to become increasingly favorable, making cellulose acetate a viable and attractive option for innovative packaging solutions.