How to Achieve High-Performance Filters with Cellulose Acetate?

Cellulose Acetate Filter Technology Overview

Cellulose acetate has emerged as a versatile and sustainable material for high-performance filter applications. This natural polymer, derived from cellulose, offers a unique combination of properties that make it particularly suitable for filtration purposes. Its biodegradability and eco-friendly nature align with the growing demand for sustainable solutions in various industries.

The development of cellulose acetate filters dates back to the early 20th century, with significant advancements occurring in recent decades. Initially used in cigarette filters, the technology has since expanded to encompass a wide range of applications, including water purification, air filtration, and biomedical separations. The evolution of cellulose acetate filter technology has been driven by the need for improved efficiency, selectivity, and durability in filtration processes.

One of the key advantages of cellulose acetate in filter applications is its ability to form porous structures with controlled pore sizes. This characteristic allows for the creation of filters with precise selectivity, capable of removing specific contaminants or particles from fluids or gases. Additionally, cellulose acetate filters exhibit good chemical resistance, thermal stability, and mechanical strength, making them suitable for diverse operating conditions.

Recent technological advancements have focused on enhancing the performance of cellulose acetate filters through various strategies. These include the development of composite materials, surface modifications, and the incorporation of functional additives. For instance, blending cellulose acetate with other polymers or nanoparticles has led to filters with improved mechanical properties and filtration efficiency.

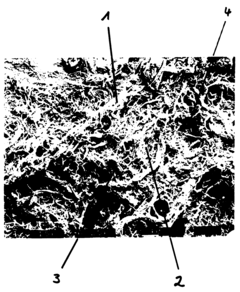

The ongoing research in cellulose acetate filter technology aims to address several challenges, such as fouling resistance, flux enhancement, and long-term stability. Scientists and engineers are exploring novel fabrication techniques, including electrospinning and phase inversion, to create filters with optimized structures and properties. These efforts are driven by the increasing demand for high-performance filters in critical applications such as healthcare, environmental protection, and industrial processes.

As environmental concerns continue to grow, the biodegradability of cellulose acetate presents a significant advantage over synthetic polymer-based filters. This aspect has sparked interest in developing fully bio-based and compostable filter materials, aligning with circular economy principles and sustainability goals. The potential for recycling and reusing cellulose acetate filters is also being investigated to further reduce their environmental impact.

In conclusion, cellulose acetate filter technology represents a promising field with substantial potential for innovation and improvement. The ongoing research and development efforts are focused on pushing the boundaries of filter performance while maintaining the material's inherent sustainability. As the demand for high-performance, environmentally friendly filtration solutions continues to rise, cellulose acetate is poised to play a crucial role in shaping the future of filter technology.

Market Analysis for High-Performance Filters

The market for high-performance filters utilizing cellulose acetate is experiencing significant growth, driven by increasing demand across various industries. The global filtration market, which includes cellulose acetate-based filters, is projected to reach substantial value in the coming years. This growth is primarily attributed to the rising awareness of air and water pollution, stringent environmental regulations, and the need for efficient filtration solutions in industrial processes.

Cellulose acetate filters are gaining traction in multiple sectors, including water treatment, air purification, automotive, and healthcare. In the water treatment industry, these filters are increasingly used for desalination processes and wastewater treatment, addressing the growing global water scarcity concerns. The air purification sector is witnessing a surge in demand for high-performance filters, particularly in regions with severe air pollution problems.

The automotive industry represents another significant market for cellulose acetate filters. With the implementation of stricter emission norms worldwide, there is a growing need for advanced filtration systems in vehicles. Cellulose acetate filters are being adopted for cabin air filtration and engine air intake systems, contributing to improved air quality inside vehicles and enhanced engine performance.

In the healthcare sector, cellulose acetate filters are finding applications in medical devices, pharmaceutical manufacturing, and laboratory equipment. The ongoing COVID-19 pandemic has further accelerated the demand for high-performance filtration solutions in healthcare settings, driving market growth.

The Asia-Pacific region is emerging as a key market for high-performance filters, fueled by rapid industrialization, urbanization, and increasing environmental concerns. Countries like China and India are investing heavily in water treatment infrastructure and air quality improvement initiatives, creating substantial opportunities for cellulose acetate filter manufacturers.

However, the market faces challenges such as the availability of alternative filter materials and the need for continuous innovation to meet evolving industry requirements. Manufacturers are focusing on developing advanced cellulose acetate filter technologies with enhanced performance characteristics, including improved filtration efficiency, durability, and sustainability.

The competitive landscape of the high-performance filter market is characterized by the presence of both established players and new entrants. Key market players are investing in research and development to introduce innovative products and expand their market share. Strategic partnerships, mergers, and acquisitions are also prevalent as companies seek to strengthen their position in this growing market.

Current Challenges in Cellulose Acetate Filtration

Cellulose acetate filtration technology, while widely used, faces several significant challenges that hinder its performance and limit its applications. One of the primary issues is the trade-off between filtration efficiency and flow rate. As filter pores become smaller to capture more particles, the resistance to fluid flow increases, reducing the overall throughput of the filtration system.

Another challenge is the susceptibility of cellulose acetate filters to fouling and clogging. Over time, trapped particles accumulate on the filter surface and within its pores, leading to decreased performance and shortened filter lifespan. This necessitates frequent replacements, increasing operational costs and downtime in industrial applications.

The mechanical strength of cellulose acetate filters is also a concern, particularly in high-pressure filtration systems. The material can deform or rupture under excessive pressure, compromising the integrity of the filtration process and potentially contaminating the filtered product.

Chemical compatibility presents another hurdle for cellulose acetate filters. They exhibit limited resistance to certain solvents, acids, and bases, restricting their use in various chemical processes and potentially causing filter degradation when exposed to incompatible substances.

Environmental factors such as temperature and humidity can significantly impact the performance of cellulose acetate filters. High temperatures can cause softening and deformation of the filter material, while excessive humidity may lead to swelling and altered pore sizes, both of which affect filtration efficiency.

The uniformity of pore size distribution in cellulose acetate filters is another area of concern. Inconsistent pore sizes can result in variable filtration performance across the filter surface, leading to unpredictable retention rates and potentially allowing larger particles to pass through in some areas.

Achieving high flux rates while maintaining selectivity remains a significant challenge. The inherent structure of cellulose acetate often limits the ability to create filters with high porosity without sacrificing particle retention capabilities.

Lastly, the biodegradability of cellulose acetate, while generally considered an environmental advantage, can be problematic in certain applications where long-term stability is required. The gradual breakdown of the filter material over time can lead to decreased performance and potential contamination of the filtered product.

Addressing these challenges is crucial for advancing cellulose acetate filtration technology and expanding its applications in high-performance filtering systems. Innovations in material science, manufacturing processes, and filter design are necessary to overcome these limitations and unlock the full potential of cellulose acetate as a filtration medium.

Existing High-Performance Cellulose Acetate Filter Solutions

01 Filtration efficiency and pressure drop

Cellulose acetate filters are evaluated based on their filtration efficiency and pressure drop characteristics. These parameters are crucial for determining the overall performance of the filter in removing particles while maintaining airflow. Researchers focus on optimizing the balance between high filtration efficiency and low pressure drop to create effective filters for various applications.- Filtration efficiency and performance: Cellulose acetate filters are known for their high filtration efficiency and performance in various applications. These filters can effectively remove particles and impurities from fluids or gases, making them suitable for use in cigarettes, air purification systems, and industrial processes. The performance of cellulose acetate filters can be enhanced by modifying their structure, porosity, and surface properties.

- Biodegradability and environmental impact: Cellulose acetate filters offer improved biodegradability compared to some synthetic alternatives, addressing environmental concerns. Research focuses on developing more eco-friendly cellulose acetate filter materials that can decompose faster in natural environments while maintaining their filtration performance. This aspect is particularly important in reducing the environmental impact of discarded cigarette filters.

- Modifications for enhanced performance: Various modifications can be applied to cellulose acetate filters to enhance their performance. These include surface treatments, incorporation of additives, and structural modifications. Such enhancements can improve filtration efficiency, selectivity, and durability of the filters. Researchers are exploring novel techniques to optimize cellulose acetate filter properties for specific applications.

- Application in cigarette filters: Cellulose acetate is widely used in cigarette filters due to its excellent filtration properties and ability to reduce harmful components in cigarette smoke. Ongoing research focuses on improving the design and composition of cellulose acetate cigarette filters to further reduce the health risks associated with smoking while maintaining the desired smoking experience.

- Manufacturing processes and quality control: The performance of cellulose acetate filters is closely tied to their manufacturing processes and quality control measures. Advanced manufacturing techniques, such as precision extrusion and controlled coagulation, are employed to produce filters with consistent properties. Quality control methods ensure that the filters meet specific performance criteria, including particle retention, pressure drop, and mechanical strength.

02 Additives and surface modifications

The performance of cellulose acetate filters can be enhanced through the incorporation of additives or surface modifications. These improvements may include the addition of activated carbon, nanoparticles, or chemical treatments to increase adsorption capacity, improve mechanical strength, or enhance specific filtering properties. Such modifications can lead to better overall filter performance and expanded application possibilities.Expand Specific Solutions03 Biodegradability and environmental impact

As environmental concerns grow, the biodegradability of cellulose acetate filters has become an important aspect of their performance evaluation. Research is focused on developing filters that maintain high filtration efficiency while also being environmentally friendly. This includes studying the degradation rates of cellulose acetate in various conditions and exploring potential alternatives or modifications to improve biodegradability.Expand Specific Solutions04 Structure and design optimization

The performance of cellulose acetate filters is significantly influenced by their structure and design. This includes factors such as fiber diameter, pore size distribution, filter thickness, and overall geometry. Researchers are continuously working on optimizing these parameters to achieve better filtration performance, increased durability, and improved user experience in various applications, from cigarette filters to industrial air purification systems.Expand Specific Solutions05 Performance in specific applications

Cellulose acetate filters are used in a wide range of applications, each with its own set of performance requirements. These applications include cigarette filters, water purification systems, and air filtration units. Research is ongoing to tailor the properties of cellulose acetate filters to meet the specific needs of each application, such as selective filtration of certain compounds, resistance to specific chemicals, or performance under varying environmental conditions.Expand Specific Solutions

Key Players in High-Performance Filter Industry

The high-performance filter market using cellulose acetate is in a mature stage, with a growing global market size driven by increasing environmental concerns and industrial applications. The technology's maturity is evident from the involvement of established players like Daicel Corp., Japan Tobacco, Inc., and Cerdia Produktions GmbH. These companies, along with others such as Kolon Industries, Inc. and FUJIFILM Corp., are continuously innovating to improve filter performance. The competitive landscape is diverse, including tobacco companies, chemical manufacturers, and research institutions, indicating a broad range of applications and ongoing R&D efforts to enhance cellulose acetate filter technology.

Daicel Corp.

Japan Tobacco, Inc.

Innovations in Cellulose Acetate Filter Design

- A filter material composed of microcrystalline and microfine cellulose, combined with cellulose acetate fibers, which are processed to achieve a homogeneous distribution and improved mobility, enhancing separation efficiency while being biodegradable and environmentally friendly.

- A high-performance cigarette filter with a fiber weight/draw resistance ratio greater than 0.7, residual crimp of 1.45, and maximum fiber weight of 10 mg/mm filter length, utilizing thermoplastic cellulose ester fibers or non-thermoplastic cellulose ester with evenly distributed plasticizers to enhance hardness and disintegrability, while maintaining improved retention properties.

Environmental Impact of Cellulose Acetate Filters

The environmental impact of cellulose acetate filters is a critical consideration in the development and use of high-performance filtration systems. Cellulose acetate, a biodegradable material derived from natural cellulose, offers several environmental advantages over synthetic alternatives. However, its production and disposal still present challenges that require careful management.

One of the primary environmental benefits of cellulose acetate filters is their biodegradability. Unlike many synthetic filter materials, cellulose acetate can decompose naturally over time, reducing long-term environmental accumulation. This characteristic is particularly important in single-use applications, where filters may be disposed of after a short period of use. The biodegradation process, however, can take several months to years, depending on environmental conditions.

The production of cellulose acetate filters also has environmental implications. The manufacturing process involves the use of acetic acid and other chemicals, which can contribute to air and water pollution if not properly managed. However, advancements in production technologies have led to more efficient and cleaner manufacturing processes, reducing the overall environmental footprint.

Water consumption is another significant factor in the production of cellulose acetate filters. The manufacturing process requires substantial amounts of water, which can strain local water resources in areas of production. Implementing water recycling and conservation measures in production facilities can help mitigate this impact.

Energy use in the production of cellulose acetate filters is also a consideration. The energy-intensive nature of the manufacturing process contributes to greenhouse gas emissions. However, compared to some synthetic alternatives, cellulose acetate production generally requires less energy, potentially resulting in a lower carbon footprint.

The disposal of used cellulose acetate filters presents both challenges and opportunities. While biodegradable, improper disposal can still lead to environmental issues. Encouraging proper recycling or composting of used filters can significantly reduce their environmental impact. Some innovative approaches include the development of collection and recycling programs specifically for cellulose acetate filters.

In terms of raw material sourcing, cellulose acetate offers advantages as it is derived from renewable resources, primarily wood pulp or cotton linters. This reduces dependence on fossil fuel-based materials. However, sustainable forestry practices must be ensured to prevent deforestation and maintain the ecological balance.

As research continues, efforts are being made to enhance the environmental performance of cellulose acetate filters. This includes developing filters with faster biodegradation rates, improving the efficiency of the production process, and exploring bio-based alternatives for the acetylation process. These advancements aim to further reduce the environmental impact while maintaining or improving filtration performance.

Regulatory Framework for Filter Materials

The regulatory framework for filter materials plays a crucial role in ensuring the safety, efficacy, and environmental sustainability of high-performance filters made with cellulose acetate. Various governmental agencies and international organizations have established guidelines and standards that manufacturers must adhere to when developing and producing these filters.

In the United States, the Food and Drug Administration (FDA) regulates filter materials used in food and beverage applications, medical devices, and pharmaceutical processes. The FDA's Center for Devices and Radiological Health (CDRH) oversees the safety and effectiveness of medical filters, while the Center for Food Safety and Applied Nutrition (CFSAN) regulates food-contact materials, including cellulose acetate filters used in food processing.

The Environmental Protection Agency (EPA) also plays a significant role in regulating filter materials, particularly those used in air and water filtration systems. The EPA's Clean Air Act and Clean Water Act set standards for air and water quality, which directly impact the design and performance requirements of filters used in these applications.

Internationally, the European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation affects the production and use of cellulose acetate filters. REACH aims to protect human health and the environment from the risks posed by chemicals, including those used in filter materials.

The International Organization for Standardization (ISO) has developed several standards relevant to filter materials, such as ISO 16890 for air filter testing and classification, and ISO 29463 for high-efficiency filters and filter media for removing particles from air. These standards provide a framework for evaluating filter performance and ensuring consistency across different manufacturers and applications.

In the context of cellulose acetate filters, specific regulations address the use of plasticizers, additives, and potential contaminants. For instance, the European Union's Directive 2011/65/EU on the Restriction of Hazardous Substances (RoHS) limits the use of certain hazardous substances in electrical and electronic equipment, which may include filters used in such devices.

Manufacturers of high-performance cellulose acetate filters must also consider regulations related to waste management and recycling. The EU's Waste Framework Directive and similar regulations in other countries promote the recycling and proper disposal of filter materials, encouraging the development of more sustainable and environmentally friendly filter designs.

As the demand for high-performance filters continues to grow, regulatory bodies are likely to update and refine their guidelines to address emerging concerns and technological advancements. This dynamic regulatory landscape necessitates ongoing vigilance and adaptability from filter manufacturers to ensure compliance and maintain product quality.