Cellulose Acetate for Eco-Friendly Fashion: A New Horizon

Cellulose Acetate Evolution and Objectives

Cellulose acetate, a versatile and eco-friendly material, has a rich history dating back to its discovery in the mid-19th century. Initially developed as a substitute for celluloid, it has since evolved into a key player in various industries, particularly in fashion and textiles. The journey of cellulose acetate from its inception to its current status as a sustainable alternative in fashion is marked by significant technological advancements and shifting market demands.

The evolution of cellulose acetate can be traced through several key phases. In its early days, it was primarily used in photographic films and fibers. As manufacturing processes improved, its applications expanded to include eyewear frames, buttons, and other small consumer goods. The mid-20th century saw a surge in its use for textile production, particularly in the form of acetate fibers for clothing.

Recent years have witnessed a renewed interest in cellulose acetate, driven by the growing demand for sustainable materials in the fashion industry. This resurgence is fueled by increasing environmental awareness and the need to reduce reliance on petroleum-based synthetic fibers. The material's biodegradability and its origin from renewable resources position it as a promising solution for eco-conscious fashion brands and consumers alike.

The current technological landscape surrounding cellulose acetate is focused on enhancing its properties and production efficiency. Research efforts are directed towards improving its durability, flexibility, and aesthetic qualities to meet the demanding standards of the fashion industry. Additionally, there is a strong emphasis on developing more sustainable production methods, aiming to reduce the environmental impact of the manufacturing process.

Looking ahead, the objectives for cellulose acetate in the context of eco-friendly fashion are multifaceted. One primary goal is to further optimize the material's biodegradability while maintaining its desirable physical properties. This involves fine-tuning the chemical composition and structure to achieve an ideal balance between performance and environmental impact.

Another key objective is to expand the range of applications for cellulose acetate in fashion. This includes exploring new textile forms, such as blends with other natural fibers, and developing innovative finishing techniques to enhance its versatility. The aim is to position cellulose acetate as a viable alternative to a wider array of synthetic materials currently dominating the fashion industry.

Furthermore, there is a concerted effort to scale up production capabilities to meet the growing demand for sustainable materials. This involves not only increasing manufacturing capacity but also ensuring a stable and sustainable supply chain for raw materials. The long-term vision is to establish cellulose acetate as a cornerstone of sustainable fashion, contributing to a more environmentally responsible and circular textile economy.

Sustainable Fashion Market Analysis

The sustainable fashion market has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and a growing demand for eco-friendly products. This trend has created a substantial opportunity for innovative materials like cellulose acetate in the fashion industry.

Market research indicates that the global sustainable fashion market was valued at approximately $6.35 billion in 2019 and is projected to reach $9.81 billion by 2025, growing at a compound annual growth rate (CAGR) of 9.1% during the forecast period. This growth is attributed to factors such as changing consumer preferences, increased focus on sustainability by fashion brands, and supportive government regulations promoting eco-friendly practices.

Consumer behavior studies reveal that a growing segment of shoppers, particularly millennials and Gen Z, are willing to pay a premium for sustainable fashion products. A survey conducted by McKinsey & Company found that 67% of consumers consider the use of sustainable materials as an important purchasing factor. This shift in consumer mindset presents a significant opportunity for cellulose acetate-based fashion products.

The market for sustainable textiles, including cellulose acetate, is expected to witness robust growth. The global market for bio-based textiles, which includes cellulose-derived materials, is projected to reach $39.3 billion by 2027, growing at a CAGR of 11.2% from 2020 to 2027. This growth is driven by the increasing adoption of sustainable materials in various fashion applications, including apparel, accessories, and footwear.

Geographically, Europe and North America currently lead the sustainable fashion market, with Asia-Pacific expected to emerge as the fastest-growing region. The European market, in particular, has shown strong interest in cellulose-based materials, with countries like Germany, France, and the United Kingdom at the forefront of sustainable fashion innovation.

Key market drivers for cellulose acetate in the fashion industry include its biodegradability, versatility, and potential to replace petroleum-based synthetic fibers. The material's ability to mimic the properties of traditional plastics while offering improved environmental performance aligns well with the industry's sustainability goals.

However, challenges remain in terms of scalability, cost-competitiveness, and consumer education. The sustainable fashion market is still in its early stages, and there is a need for increased awareness about the benefits of materials like cellulose acetate. Additionally, the industry must address issues related to supply chain transparency and certification to build consumer trust in sustainable fashion products.

In conclusion, the market analysis indicates a favorable environment for the adoption of cellulose acetate in eco-friendly fashion. The growing consumer demand for sustainable products, coupled with the material's unique properties, positions cellulose acetate as a promising solution for the fashion industry's sustainability challenges.

Cellulose Acetate Tech Challenges

Cellulose acetate, a versatile biopolymer derived from natural cellulose, has gained significant attention in the fashion industry as an eco-friendly alternative to traditional synthetic materials. However, its widespread adoption faces several technical challenges that need to be addressed to fully realize its potential in sustainable fashion.

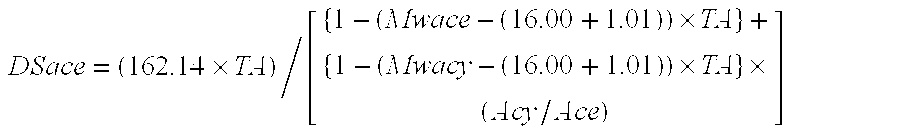

One of the primary obstacles is the optimization of the acetylation process. While cellulose acetate production has been established for decades, achieving consistent quality and properties at scale remains challenging. The degree of substitution (DS) in cellulose acetate significantly affects its physical and chemical properties, and controlling this parameter precisely during large-scale production is crucial for ensuring uniform product quality.

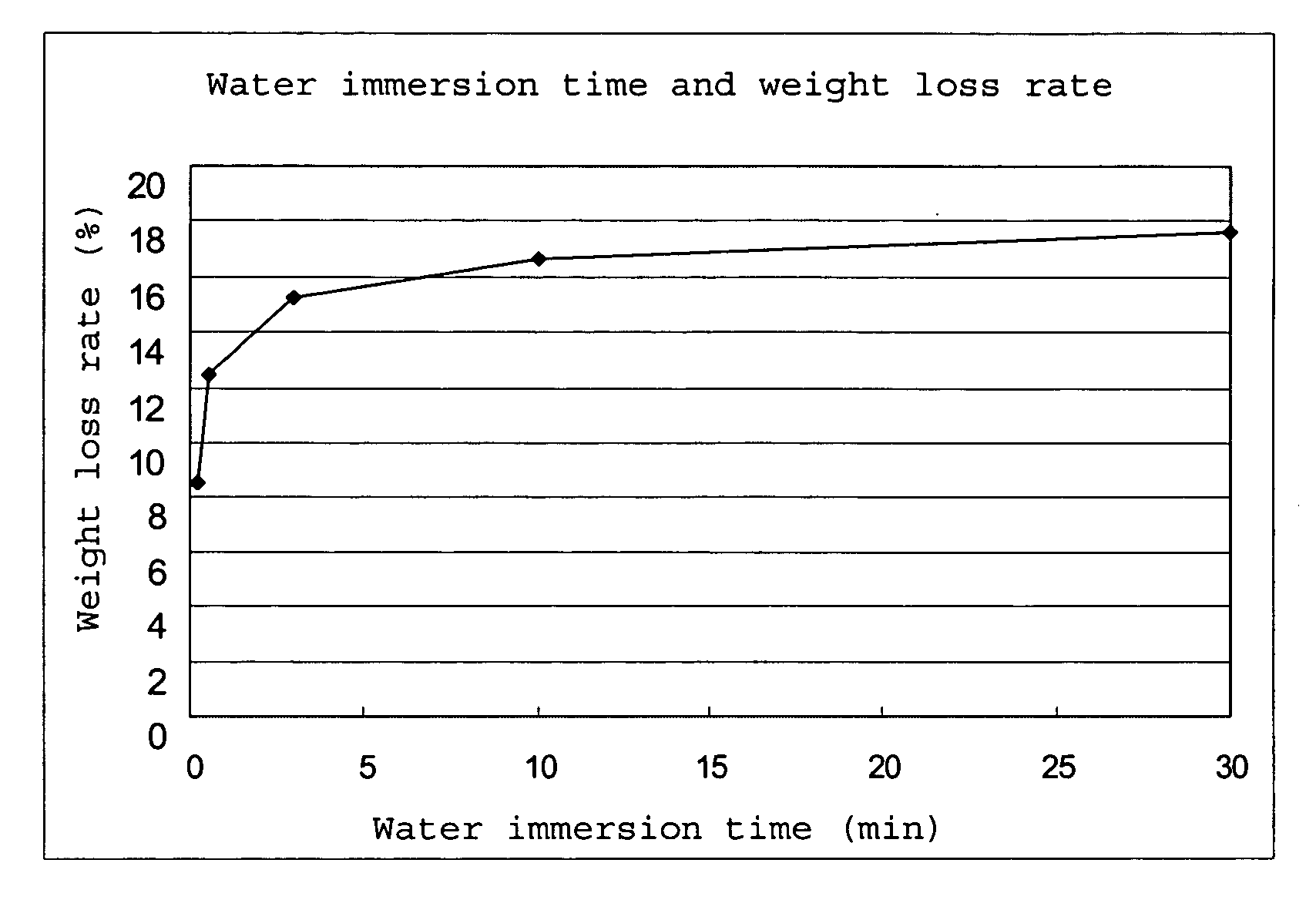

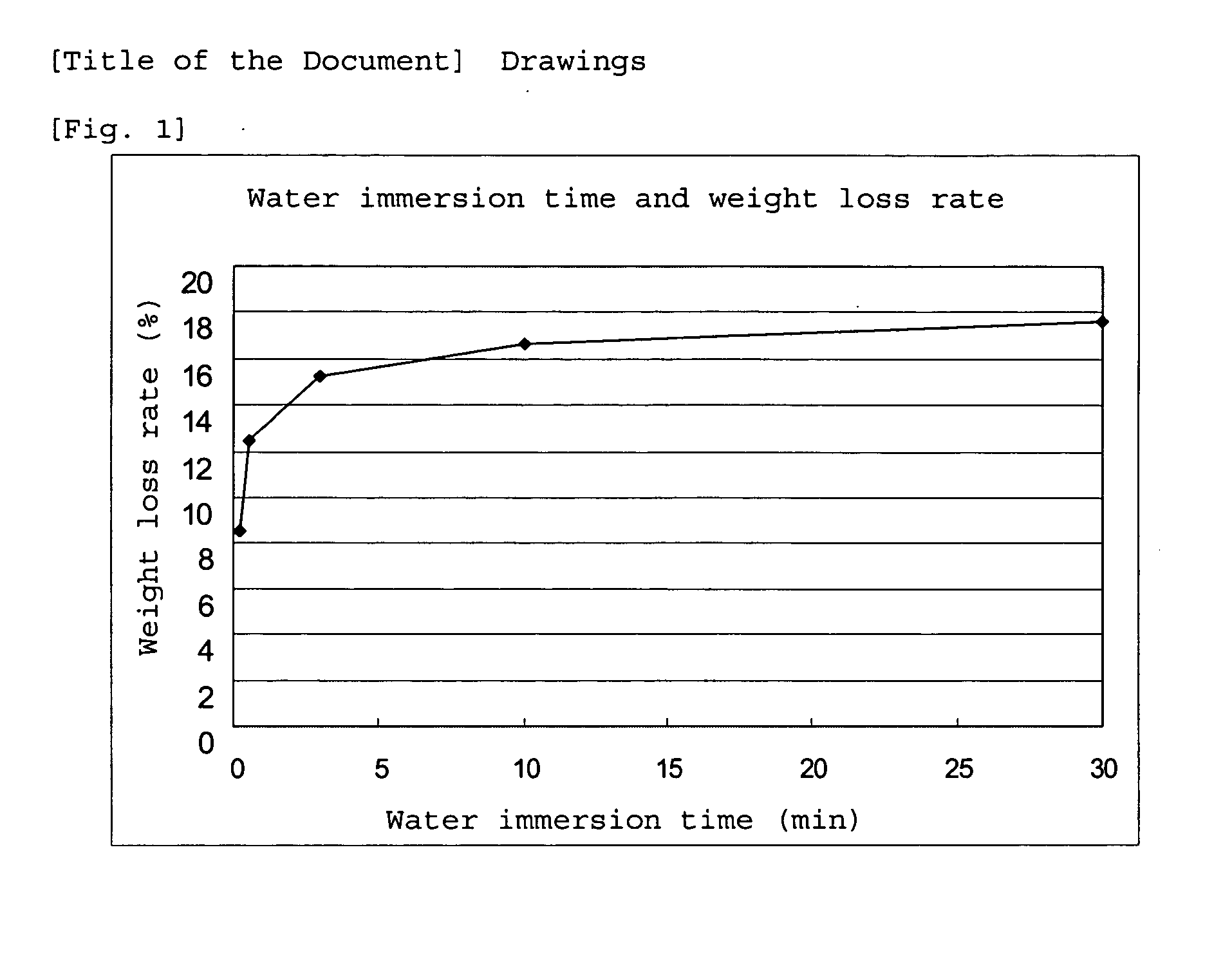

Another technical hurdle lies in improving the material's moisture resistance. Cellulose acetate is inherently hydrophilic, which can lead to dimensional instability and reduced durability in high-humidity environments. Developing effective moisture-resistant coatings or modifying the polymer structure to enhance hydrophobicity without compromising its biodegradability is an ongoing area of research.

The mechanical properties of cellulose acetate also present challenges for its application in fashion. While it offers good flexibility, its tensile strength and impact resistance are often lower compared to synthetic alternatives. Enhancing these properties through the development of novel composite materials or improved processing techniques is essential for expanding its use in a wider range of fashion applications.

Coloration and dyeing of cellulose acetate fabrics pose another set of technical challenges. The material's acetyl groups can interfere with dye uptake, leading to difficulties in achieving vibrant and long-lasting colors. Developing specialized dyes and dyeing processes that are compatible with cellulose acetate's chemical structure while maintaining eco-friendliness is crucial for its success in the fashion industry.

Biodegradability, while a key advantage of cellulose acetate, also presents challenges in terms of controlled degradation. Ensuring that the material maintains its integrity during use but degrades efficiently at the end of its lifecycle requires careful engineering of its molecular structure and additives.

Lastly, scaling up production to meet potential demand while maintaining cost-effectiveness is a significant challenge. Current production methods for high-quality cellulose acetate are often energy-intensive and rely on chemical processes that may not align with sustainability goals. Developing more efficient, environmentally friendly production techniques is essential for making cellulose acetate a viable alternative in the competitive fashion market.

Current Cellulose Acetate Applications

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in a wide range of applications, including textiles, filters, and composite materials. The patents discuss novel fiber compositions, manufacturing techniques, and treatments to enhance the performance and properties of cellulose acetate fibers for specific end-uses.

- Cellulose acetate film and membrane technology: Innovations in cellulose acetate film and membrane technology are presented, covering areas such as improved formulations, manufacturing processes, and surface modifications. These advancements aim to enhance the performance of cellulose acetate in applications like separation membranes, packaging materials, and optical films.

- Cellulose acetate biodegradability and sustainability: Research and development efforts focus on improving the biodegradability and sustainability of cellulose acetate materials. This includes modifications to the polymer structure, blending with other biodegradable materials, and developing eco-friendly production processes to address environmental concerns.

- Cellulose acetate in pharmaceutical and biomedical applications: Cellulose acetate is explored for various pharmaceutical and biomedical applications, including drug delivery systems, tissue engineering scaffolds, and biocompatible implants. The patents discuss formulations, processing techniques, and surface modifications to enhance the material's performance in these specialized fields.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and composite materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment methods to suit specific end-use requirements.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, packaging, and biomedical fields.Expand Specific Solutions04 Cellulose acetate blends and composites

Research on cellulose acetate blends and composites aims to enhance material properties by combining cellulose acetate with other polymers or additives. This approach allows for the development of materials with improved mechanical, thermal, or functional characteristics.Expand Specific Solutions05 Cellulose acetate modification and derivatives

Chemical modifications of cellulose acetate and the development of novel derivatives are explored to expand its range of applications. These modifications can alter properties such as solubility, biodegradability, and reactivity, opening up new possibilities for cellulose acetate-based materials.Expand Specific Solutions

Key Players in Eco-Friendly Textiles

The cellulose acetate market for eco-friendly fashion is in a growth phase, driven by increasing demand for sustainable materials. The market size is expanding rapidly, with major players like Daicel Corp., Eastman Chemical Co., and Toray Industries, Inc. leading the way. The technology is relatively mature, but ongoing innovations are pushing its boundaries. Companies such as Infinited Fiber Co. Oy and Newlight Technologies LLC are developing advanced processes to enhance the material's eco-friendly properties. Research institutions like the Institute of Process Engineering, Chinese Academy of Sciences, and universities are contributing to technological advancements. The competitive landscape is diverse, with established chemical companies, specialized fiber producers, and innovative startups all vying for market share in this promising sector.

Daicel Corp.

Eastman Chemical Co.

Innovations in Cellulose Acetate Production

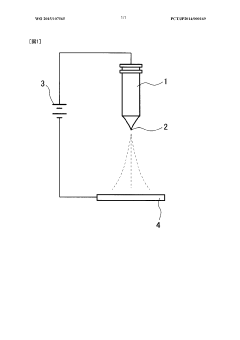

- Cellulose acetate fibers with a total degree of acetyl substitution of 0.4 to 1.3 and a composition distribution index of 2.0 or less, produced through electrospinning using a spinning dope dissolved in water or a water/mixed solvent, exhibit enhanced water solubility and biodegradability.

- A fabric comprising cellulose mixed ester fibers with a glass transition point of 160° C. or more and a strength range of 1.3 to 4 cN/dtex, produced through a melt-spinning process using a composition of 70 to 95 wt % cellulose mixed ester and 5 to 20 wt % water-soluble plasticizer, followed by aqueous treatment to remove the plasticizer, resulting in high heat resistance, strength, and uniformity.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate in eco-friendly fashion reveals a complex interplay of benefits and challenges. As a biodegradable material derived from natural sources, cellulose acetate offers significant advantages over traditional synthetic fibers in terms of sustainability and end-of-life management.

One of the primary environmental benefits of cellulose acetate is its reduced carbon footprint compared to petroleum-based synthetic fibers. The production process of cellulose acetate utilizes renewable resources, primarily wood pulp or cotton linters, which can be sustainably harvested. This results in lower greenhouse gas emissions and decreased reliance on fossil fuels throughout the material's lifecycle.

Furthermore, cellulose acetate's biodegradability addresses the growing concern of microfiber pollution in aquatic ecosystems. Unlike synthetic fibers that persist in the environment for centuries, cellulose acetate can decompose naturally under appropriate conditions, potentially mitigating the accumulation of microplastics in water bodies and soil.

However, the environmental impact of cellulose acetate production is not without its challenges. The manufacturing process involves the use of chemical solvents, particularly acetic acid and acetone, which can pose risks if not properly managed. Ensuring proper waste treatment and recycling of these chemicals is crucial to minimize environmental contamination and reduce the overall ecological footprint of production.

Water consumption is another significant factor to consider in the environmental assessment of cellulose acetate. The production process requires substantial amounts of water, particularly in the initial stages of cellulose extraction and during the acetylation process. Implementing water-efficient technologies and closed-loop systems can help mitigate this impact and improve the overall sustainability of cellulose acetate production.

Land use and biodiversity impacts associated with the sourcing of raw materials for cellulose acetate production must also be carefully evaluated. Sustainable forest management practices and responsible sourcing of cotton linters are essential to prevent deforestation and maintain ecosystem balance.

In terms of end-of-life management, cellulose acetate offers advantages over synthetic materials due to its biodegradability. However, the rate of decomposition can vary significantly depending on environmental conditions. While cellulose acetate will eventually break down in natural settings, it may persist for extended periods in landfills where conditions are less conducive to biodegradation.

To fully realize the environmental benefits of cellulose acetate in eco-friendly fashion, a holistic approach to lifecycle assessment is necessary. This includes optimizing production processes, implementing closed-loop recycling systems, and developing innovative disposal methods that accelerate biodegradation. Additionally, educating consumers about proper care and disposal of cellulose acetate products can further enhance its environmental performance.

Regulatory Framework for Sustainable Textiles

The regulatory framework for sustainable textiles plays a crucial role in shaping the adoption and implementation of eco-friendly materials like cellulose acetate in the fashion industry. As governments and international organizations increasingly recognize the environmental impact of textile production, a complex web of regulations, standards, and guidelines has emerged to promote sustainability.

At the forefront of this regulatory landscape is the European Union's Circular Economy Action Plan, which includes specific measures for textiles. This plan aims to ensure that textile products are designed for durability, reusability, and recyclability, aligning perfectly with the properties of cellulose acetate. The EU has also introduced the Product Environmental Footprint (PEF) methodology, which provides a standardized way to assess the environmental impact of products, including textiles.

In the United States, the Federal Trade Commission (FTC) has established Green Guides to prevent deceptive environmental marketing claims. These guidelines are particularly relevant for cellulose acetate, as manufacturers must accurately represent its eco-friendly attributes. Additionally, the California Textile and Fiber Products Law requires proper labeling of textile fiber content, which is essential for transparency in cellulose acetate-based products.

Globally, the United Nations Fashion Industry Charter for Climate Action sets ambitious targets for reducing greenhouse gas emissions in the fashion sector. This initiative encourages the use of sustainable materials like cellulose acetate and promotes circular economy principles. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are widely recognized certification systems that ensure textiles meet strict ecological and social criteria throughout their production chain.

Emerging regulations are focusing on microfiber pollution, an area where cellulose acetate shows promise due to its biodegradability. For instance, France has mandated that all new washing machines be equipped with microfiber filters by 2025, a move that could influence the choice of textile materials.

The regulatory landscape also extends to chemical management. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and similar laws in other jurisdictions impact the production and use of cellulose acetate by controlling the chemicals involved in its manufacturing process.

As the fashion industry moves towards greater sustainability, these regulatory frameworks are likely to evolve, potentially offering more incentives for the use of eco-friendly materials like cellulose acetate. Companies investing in this material should closely monitor regulatory developments to ensure compliance and capitalize on potential advantages in an increasingly environmentally conscious market.