Cellulose Acetate Future in Bioengineering: Challenges and Opportunities

Cellulose Acetate Evolution and Bioengineering Goals

Cellulose acetate, a versatile biopolymer, has been a subject of interest in the field of bioengineering for decades. Its journey from a simple textile fiber to a multifaceted material with diverse applications in biomedical and environmental sectors exemplifies the dynamic nature of biomaterial research. The evolution of cellulose acetate technology has been marked by significant milestones, each contributing to its expanding potential in bioengineering.

Initially developed as an alternative to cellulose nitrate in the early 20th century, cellulose acetate quickly found applications in photographic films and fibers. However, its biocompatibility and biodegradability soon attracted the attention of bioengineers, leading to a new era of research and development. The 1960s and 1970s saw the first explorations of cellulose acetate in biomedical applications, particularly in controlled drug delivery systems.

As environmental concerns grew in the late 20th century, the biodegradable nature of cellulose acetate became a focal point for researchers. This led to increased efforts in developing eco-friendly applications, such as biodegradable packaging materials and filters. The turn of the millennium brought about a renewed interest in cellulose acetate as a sustainable alternative to petroleum-based plastics, aligning with global sustainability goals.

In recent years, advancements in nanotechnology have opened new avenues for cellulose acetate in bioengineering. The development of cellulose acetate nanofibers and nanocomposites has expanded its potential in tissue engineering, wound healing, and advanced drug delivery systems. These innovations have set the stage for the next phase of cellulose acetate evolution in bioengineering.

Looking ahead, the goals for cellulose acetate in bioengineering are ambitious and multifaceted. One primary objective is to enhance its mechanical properties and stability in biological environments, making it more suitable for long-term implantable devices. Researchers are also focusing on improving its processability to enable more complex 3D structures for tissue engineering scaffolds.

Another crucial goal is to develop cellulose acetate-based materials with enhanced bioactivity. This includes incorporating growth factors, antimicrobial agents, or other bioactive molecules into the cellulose acetate matrix to create smart, responsive biomaterials. Such advancements could revolutionize wound healing and tissue regeneration applications.

Furthermore, there is a growing emphasis on exploring the potential of cellulose acetate in emerging fields such as biosensors and bioelectronics. The aim is to leverage its unique properties to create flexible, biocompatible electronic devices for medical diagnostics and monitoring. This intersection of bioengineering and electronics represents a promising frontier for cellulose acetate innovation.

Market Demand Analysis for Bioengineered Cellulose Acetate

The market demand for bioengineered cellulose acetate is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable materials across various industries. Cellulose acetate, derived from natural cellulose sources, offers a biodegradable and renewable alternative to traditional petroleum-based plastics. This has led to a surge in interest from sectors such as packaging, textiles, and consumer goods.

In the packaging industry, there is a growing demand for eco-friendly materials that can replace single-use plastics. Bioengineered cellulose acetate films and coatings are being explored for food packaging applications, offering improved barrier properties and biodegradability. The textile sector is also showing increased interest in cellulose acetate fibers as a sustainable alternative to synthetic fibers, particularly in the production of clothing and home textiles.

The consumer goods market is another area where bioengineered cellulose acetate is gaining traction. Products such as disposable cutlery, straws, and personal care items are being developed using this material to meet the rising consumer demand for environmentally friendly options. Additionally, the automotive industry is exploring cellulose acetate composites for interior components, aiming to reduce vehicle weight and improve fuel efficiency.

The healthcare sector presents a promising market for bioengineered cellulose acetate, with applications in drug delivery systems, wound dressings, and tissue engineering scaffolds. The material's biocompatibility and ability to be tailored for specific medical applications are driving its adoption in this field.

Market analysts project that the global cellulose acetate market, including bioengineered variants, will continue to grow at a steady rate over the next decade. This growth is attributed to the increasing awareness of environmental issues, stringent regulations on plastic use, and the shift towards circular economy models.

However, challenges remain in scaling up production and reducing costs to compete with traditional materials. The development of more efficient bioengineering processes and the optimization of cellulose acetate properties for specific applications are key areas of focus for industry players. As research and development efforts intensify, it is expected that the market for bioengineered cellulose acetate will expand further, offering new opportunities for innovation and sustainable product development across multiple sectors.

Current Challenges in Cellulose Acetate Bioengineering

Cellulose acetate bioengineering faces several significant challenges that hinder its widespread adoption and full potential realization in various applications. One of the primary obstacles is the complexity of cellulose acetate's molecular structure, which makes it difficult to manipulate and modify for specific bioengineering purposes. The intricate network of hydrogen bonds within cellulose acetate molecules presents a formidable barrier to efficient enzymatic degradation and chemical modification.

Another major challenge lies in the production process of cellulose acetate. Current manufacturing methods often involve the use of environmentally harmful chemicals and energy-intensive processes. This not only raises sustainability concerns but also increases production costs, making cellulose acetate less competitive compared to other biomaterials. The development of greener and more cost-effective production techniques remains a critical area of research.

Biocompatibility issues also pose significant challenges in cellulose acetate bioengineering. While cellulose acetate is generally considered non-toxic, its interaction with living tissues and biological systems can sometimes lead to unexpected reactions or limited functionality. Improving the material's biocompatibility without compromising its desirable properties is a delicate balancing act that researchers continue to grapple with.

The biodegradability of cellulose acetate presents another complex challenge. Although it is derived from natural sources, the acetylation process can significantly alter its degradation properties. Achieving a controlled and predictable biodegradation rate in various environments is crucial for many bioengineering applications, particularly in fields such as tissue engineering and drug delivery systems.

Furthermore, the mechanical properties of cellulose acetate often fall short of requirements for certain bioengineering applications. Enhancing its strength, flexibility, and durability without sacrificing other beneficial characteristics remains a significant challenge. This is particularly important in applications such as biomedical implants or tissue scaffolds, where mechanical integrity is paramount.

Lastly, the scalability of cellulose acetate production and processing for bioengineering applications presents considerable challenges. Transitioning from laboratory-scale successes to industrial-scale production often encounters unforeseen obstacles, including issues with consistency, quality control, and cost-effectiveness. Developing robust and scalable manufacturing processes that maintain the material's desired properties is essential for the widespread adoption of cellulose acetate in bioengineering.

Current Bioengineering Approaches for Cellulose Acetate

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications such as textiles, filters, and composite materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment methods to suit specific end-use requirements.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing techniques, enhanced properties, and novel applications in areas such as separation processes, packaging, and optical films.

- Cellulose acetate modifications and derivatives: Research on modifying cellulose acetate or creating new derivatives is discussed, aiming to enhance properties such as biodegradability, thermal stability, or compatibility with other materials for various industrial and consumer applications.

- Cellulose acetate in sustainable and biodegradable products: The use of cellulose acetate in developing sustainable and biodegradable products is explored, including its application in eco-friendly packaging, disposable items, and as a replacement for conventional plastics in various consumer goods.

02 Cellulose acetate fibers and films

Innovations in the production and properties of cellulose acetate fibers and films are presented. These developments focus on improving the mechanical strength, flexibility, and other physical characteristics of cellulose acetate-based materials for use in textiles, packaging, and other industries.Expand Specific Solutions03 Cellulose acetate composites and blends

Research on cellulose acetate composites and blends with other materials is discussed. These innovations aim to create new materials with enhanced properties, such as improved biodegradability, strength, or functionality, by combining cellulose acetate with other polymers or additives.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Techniques for modifying and functionalizing cellulose acetate are explored. These methods involve chemical treatments or additions to alter the properties of cellulose acetate, such as improving its solubility, reactivity, or compatibility with other materials for specific applications.Expand Specific Solutions05 Applications of cellulose acetate in various industries

Diverse applications of cellulose acetate across multiple industries are presented. These include its use in textiles, packaging, filters, membranes, and other specialized products. The focus is on leveraging the unique properties of cellulose acetate to develop innovative solutions for different sectors.Expand Specific Solutions

Key Players in Cellulose Acetate Bioengineering

The cellulose acetate market in bioengineering is in a growth phase, driven by increasing demand for sustainable materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, cellulose acetate is mature but evolving, with companies like Daicel Corp., Eastman Chemical Co., and Nantong Cellulose Fibers Co. Ltd. leading innovation. Research institutions such as the Chinese Academy of Sciences and Virginia Tech are advancing applications in bioengineering. Challenges include improving biodegradability and enhancing performance for specialized applications. Opportunities lie in developing novel biomedical and environmental applications, with companies like DSM IP Assets BV and Cytiva BioProcess R&D AB exploring new frontiers in this field.

Daicel Corp.

Eastman Chemical Co.

Innovative Cellulose Acetate Bioengineering Patents

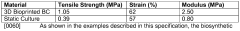

- A microfluidic medium administration system is used to control the rate and volume of culture media, allowing for the production of biosynthetic cellulose with predetermined shape and porosity, enabling the creation of three-dimensional structures with enhanced strength and cellular support.

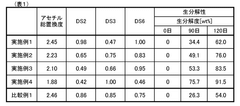

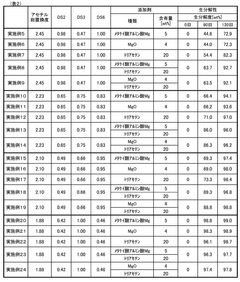

- Introducing acetyl groups heterogeneously into the 2nd, 3rd, and 6th carbon atoms of the glucose ring in cellulose acetate with a total degree of acetyl substitution between 1.75 and 2.55, and at least one position having a degree of acetyl substitution of 0.7 or less, combined with additives like magnesium oxide and triacetin to enhance biodegradability in seawater.

Environmental Impact of Bioengineered Cellulose Acetate

The environmental impact of bioengineered cellulose acetate is a critical consideration in the development and application of this versatile material. As a biodegradable polymer derived from renewable resources, cellulose acetate offers significant potential for reducing the environmental footprint of various products and processes.

One of the primary environmental benefits of bioengineered cellulose acetate is its ability to replace petroleum-based plastics in many applications. This substitution can lead to a substantial reduction in greenhouse gas emissions associated with the production and disposal of traditional plastics. Additionally, the biodegradability of cellulose acetate helps mitigate the persistent pollution issues caused by conventional plastics in terrestrial and aquatic ecosystems.

However, the environmental impact of bioengineered cellulose acetate is not without challenges. The production process, while more sustainable than that of petroleum-based plastics, still requires energy and resources. Optimizing these processes to minimize energy consumption and waste generation remains an ongoing area of research and development.

Water usage in the production of cellulose acetate is another environmental concern. The manufacturing process typically involves significant water consumption, which can strain local water resources. Implementing water recycling systems and developing more water-efficient production methods are crucial steps in improving the overall environmental profile of bioengineered cellulose acetate.

The end-of-life management of cellulose acetate products also presents both opportunities and challenges. While the material is biodegradable, the rate of degradation can vary depending on environmental conditions. Ensuring proper disposal and composting infrastructure is essential to fully realize the environmental benefits of this material.

Furthermore, the sourcing of raw materials for cellulose acetate production must be carefully managed to prevent deforestation or competition with food crops. Sustainable forestry practices and the use of agricultural waste as feedstock can help address these concerns and enhance the material's environmental credentials.

As research in bioengineering advances, there is potential for further improvements in the environmental performance of cellulose acetate. Genetic modification of source plants to enhance cellulose content or modify its structure could lead to more efficient production processes and improved material properties, potentially reducing the overall environmental impact.

In conclusion, while bioengineered cellulose acetate offers significant environmental advantages over traditional plastics, ongoing research and development are necessary to fully optimize its production, use, and disposal. By addressing these challenges, cellulose acetate can play a crucial role in the transition towards more sustainable and environmentally friendly materials in various industries.

Regulatory Framework for Bioengineered Materials

The regulatory framework for bioengineered materials, including cellulose acetate, is a complex and evolving landscape that plays a crucial role in shaping the future of bioengineering. As cellulose acetate gains prominence in bioengineering applications, it is essential to understand the current regulatory environment and anticipate future developments.

In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing bioengineered materials. The FDA's approach to regulating these materials is based on their intended use and potential risks. For cellulose acetate in bioengineering, this may involve evaluations under the medical device, drug, or food contact material regulations, depending on the specific application.

The European Union has established a comprehensive regulatory framework for bioengineered materials through the European Medicines Agency (EMA) and the European Food Safety Authority (EFSA). These agencies have developed guidelines for the assessment and approval of bioengineered products, including those incorporating cellulose acetate.

In recent years, there has been a growing emphasis on sustainability and environmental impact in regulatory considerations. This trend is particularly relevant for cellulose acetate, given its biodegradable properties. Regulatory bodies are increasingly requiring manufacturers to demonstrate the environmental safety and sustainability of their bioengineered materials.

One of the key challenges in the regulatory landscape is the rapid pace of technological advancement in bioengineering. Regulators must continually adapt their frameworks to address novel applications and potential risks associated with emerging technologies. This dynamic environment creates both opportunities and challenges for cellulose acetate in bioengineering.

International harmonization of regulatory standards is another important aspect of the framework for bioengineered materials. Initiatives such as the International Medical Device Regulators Forum (IMDRF) aim to promote global convergence of regulatory requirements, which could streamline the approval process for cellulose acetate-based products across different markets.

As the field of bioengineering continues to evolve, it is likely that regulatory frameworks will become more sophisticated and tailored to specific applications. This may include the development of new testing methodologies, risk assessment models, and post-market surveillance strategies specifically designed for bioengineered materials like cellulose acetate.

In conclusion, the regulatory framework for bioengineered materials is a critical factor in determining the future of cellulose acetate in bioengineering. As regulations continue to evolve, stakeholders must stay informed and engaged to navigate the complex landscape and capitalize on the opportunities presented by this versatile material.