Cellulose Acetate for Advanced Optical Applications

Cellulose Acetate Optics: Background and Objectives

Cellulose acetate has emerged as a promising material for advanced optical applications, with its roots tracing back to the early 20th century. Initially developed as a substitute for celluloid in photographic films, cellulose acetate has since evolved to find applications in various optical domains. The journey of cellulose acetate in optics has been marked by continuous improvements in its properties and processing techniques, driven by the growing demand for sustainable and high-performance optical materials.

The evolution of cellulose acetate in optical applications has been closely tied to advancements in polymer science and materials engineering. Over the decades, researchers have focused on enhancing its optical clarity, mechanical strength, and thermal stability to meet the stringent requirements of modern optical systems. The material's inherent biodegradability and renewability have positioned it as an environmentally friendly alternative to petroleum-based polymers, aligning with the global push towards sustainable technologies.

In recent years, the optical industry has witnessed a surge in demand for materials that can deliver superior performance while minimizing environmental impact. This trend has reignited interest in cellulose acetate, prompting researchers and manufacturers to explore its potential in cutting-edge optical applications. The material's unique combination of optical properties, including high transparency, low birefringence, and tunable refractive index, has made it an attractive candidate for various optical components and devices.

The primary objective of research on cellulose acetate for advanced optical applications is to unlock its full potential and overcome existing limitations. This includes improving its optical and mechanical properties, enhancing its processability, and expanding its range of applications. Researchers aim to develop novel formulations and processing techniques that can tailor cellulose acetate's properties to meet specific optical requirements, such as high-resolution displays, advanced lenses, and photonic devices.

Another crucial goal is to establish cellulose acetate as a viable alternative to traditional optical materials in terms of performance, cost-effectiveness, and sustainability. This involves comprehensive studies on its long-term stability, resistance to environmental factors, and compatibility with existing manufacturing processes. Additionally, researchers are exploring ways to integrate cellulose acetate with other materials and technologies to create hybrid optical systems with enhanced functionalities.

The research landscape for cellulose acetate in optics is characterized by interdisciplinary collaborations between material scientists, optical engineers, and industry partners. These efforts are driven by the vision of creating next-generation optical products that combine exceptional performance with environmental sustainability. As the field progresses, it is expected to contribute significantly to the development of eco-friendly optical technologies, potentially revolutionizing sectors such as consumer electronics, medical imaging, and telecommunications.

Market Analysis for Advanced Optical Materials

The advanced optical materials market is experiencing significant growth, driven by increasing demand for high-performance optical components in various industries. Cellulose acetate, a versatile biopolymer, is emerging as a promising material for advanced optical applications due to its unique properties and environmental sustainability.

The global market for advanced optical materials is projected to expand at a robust rate in the coming years, with a particular focus on materials that offer improved optical performance, durability, and eco-friendliness. Cellulose acetate fits well into this trend, as it provides excellent optical clarity, high light transmission, and good impact resistance while being derived from renewable resources.

Key market segments driving the demand for advanced optical materials include consumer electronics, automotive, aerospace, and medical devices. In the consumer electronics sector, there is a growing need for high-quality display materials and camera lenses, where cellulose acetate can potentially replace traditional petroleum-based plastics. The automotive industry is increasingly incorporating advanced optical materials in heads-up displays, sensors, and lighting systems, presenting opportunities for cellulose acetate applications.

The medical device industry is another significant market for advanced optical materials, with applications in diagnostic equipment, surgical instruments, and wearable devices. Cellulose acetate's biocompatibility and optical properties make it an attractive option for these applications. Additionally, the aerospace sector requires high-performance optical materials for cockpit displays, sensors, and communication systems, where cellulose acetate's lightweight nature and optical clarity could provide advantages.

Geographically, North America and Europe are currently the largest markets for advanced optical materials, with Asia-Pacific expected to show the fastest growth. This growth is attributed to the rapid industrialization, increasing consumer electronics production, and rising investments in research and development in countries like China, Japan, and South Korea.

The market is also influenced by regulatory trends promoting sustainable and biodegradable materials. As governments worldwide implement stricter environmental regulations, the demand for bio-based materials like cellulose acetate is expected to increase. This shift towards eco-friendly alternatives is likely to create new opportunities for cellulose acetate in the advanced optical materials market.

However, challenges such as the need for consistent quality, scalability of production, and competition from established synthetic materials must be addressed. Ongoing research and development efforts are focused on enhancing the optical and mechanical properties of cellulose acetate to meet the stringent requirements of advanced optical applications.

Current Challenges in Cellulose Acetate Optics

Cellulose acetate, despite its long history in optical applications, faces several significant challenges in meeting the demands of advanced optical systems. One of the primary issues is the material's inherent birefringence, which can cause unwanted light scattering and distortion in high-precision optical components. This characteristic limits its use in applications requiring exceptional optical clarity and uniformity.

Another challenge lies in the thermal and dimensional stability of cellulose acetate. When exposed to varying environmental conditions, particularly changes in temperature and humidity, the material can undergo subtle dimensional changes. These alterations, while minor, can be critical in advanced optical systems where nanometer-scale precision is often required. The resulting optical path variations can lead to performance degradation over time.

The mechanical properties of cellulose acetate also present challenges for certain optical applications. While the material offers good impact resistance, its relatively low stiffness compared to inorganic optical materials like glass can lead to deformation under stress. This characteristic makes it less suitable for large-scale optical components or those subjected to significant mechanical loads.

Durability and long-term stability remain concerns in advanced optical applications. Cellulose acetate is susceptible to degradation when exposed to UV radiation and certain chemicals, which can alter its optical properties over time. This degradation can manifest as yellowing, crazing, or changes in refractive index, all of which are detrimental to optical performance.

The processing of cellulose acetate for high-precision optical components also presents technical hurdles. Achieving the necessary surface quality and form accuracy for advanced optics requires specialized manufacturing techniques. The material's sensitivity to solvents and heat during processing can lead to residual stresses or surface imperfections that affect optical quality.

Lastly, the limited refractive index range of cellulose acetate constrains its versatility in optical design. While it offers advantages in certain applications, its inability to achieve very high or very low refractive indices restricts its use in complex optical systems that require a wide range of optical properties. This limitation often necessitates the use of alternative materials or complex multi-material designs to achieve desired optical performance.

Existing Cellulose Acetate Optical Solutions

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Production methods for cellulose acetate: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fibers and films: Techniques for manufacturing cellulose acetate fibers and films are detailed, covering aspects such as spinning processes, film formation, and modification of properties. These innovations contribute to the development of improved cellulose acetate-based materials for textiles, packaging, and other industries.

- Cellulose acetate composites and blends: Development of cellulose acetate composites and blends with other materials to enhance properties such as strength, flexibility, or biodegradability. These innovations expand the range of applications for cellulose acetate in various industries.

- Modification and functionalization of cellulose acetate: Methods for modifying and functionalizing cellulose acetate to impart specific properties or introduce new functionalities. These techniques allow for the tailoring of cellulose acetate for specialized applications in areas such as filtration, drug delivery, or smart materials.

- Applications of cellulose acetate in various industries: Exploration of novel applications for cellulose acetate in diverse industries, including but not limited to textiles, packaging, filtration, and biomedical fields. These innovations showcase the versatility and potential of cellulose acetate as a sustainable and functional material.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications, including textiles, filters, and composite materials. The properties of these fibers can be tailored for specific uses through modifications in the production process or post-treatment methods.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology are presented, focusing on improved formulations and manufacturing techniques. These developments enhance the performance of cellulose acetate in applications such as separation processes and packaging materials.Expand Specific Solutions04 Cellulose acetate modifications and derivatives

Various modifications and derivatives of cellulose acetate are explored to enhance its properties or create new materials. These include chemical modifications, blending with other polymers, and the development of novel cellulose acetate-based composites.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable applications

Research into the use of cellulose acetate in environmentally friendly and biodegradable products is presented. This includes the development of sustainable packaging materials, biodegradable plastics, and other eco-friendly applications leveraging the natural origin of cellulose acetate.Expand Specific Solutions

Key Players in Cellulose Acetate Optical Industry

The research on cellulose acetate for advanced optical applications is in a growth phase, with increasing market size and technological advancements. The global market for cellulose acetate in optical applications is expanding, driven by demand in sectors like displays, photographic films, and optical filters. Technologically, the field is progressing rapidly, with companies like Daicel Corp., FUJIFILM Corp., and Eastman Chemical Co. leading innovation. These firms, along with others like SK Innovation Co., Ltd. and Konica Minolta, Inc., are developing advanced formulations and manufacturing processes to enhance optical properties. The involvement of research institutions such as the Chinese Academy of Sciences indicates ongoing fundamental research, suggesting potential for further technological breakthroughs in this field.

Daicel Corp.

FUJIFILM Corp.

Core Innovations in Cellulose Acetate Optics

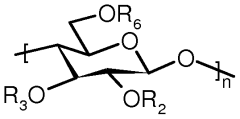

- Regioselectively substituted cellulose esters with a combination of alkyl-acyl and aryl-acyl substituents are used to create optical films that can be employed as compensation films in LCDs, these films have specific refractive index profiles and retardation values to minimize light leakage and improve optical performance.

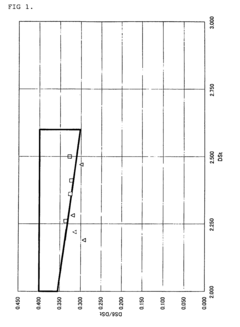

- A process involving the hydrolysis of cellulose triacetate with controlled amounts of acetic acid and an acetylation catalyst at specific temperatures to produce a 6-position highly acetylated cellulose diacetate with a total degree of acetyl substitution between 2.0 and 2.6, allowing for a high degree of acetyl substitution at the 6-position and sufficient margin for other acyl group introduction at the 2- and 3-positions.

Environmental Impact of Cellulose Acetate Optics

The environmental impact of cellulose acetate optics is a critical consideration in the development and application of advanced optical technologies. Cellulose acetate, derived from natural cellulose fibers, offers several environmental advantages over traditional petroleum-based plastics used in optical applications.

One of the primary benefits of cellulose acetate is its biodegradability. Unlike synthetic polymers, cellulose acetate can decompose naturally in the environment, reducing long-term pollution and waste accumulation. This characteristic is particularly important in the context of disposable optical products, such as single-use lenses or filters, which may otherwise contribute to plastic pollution.

However, the biodegradation process of cellulose acetate is relatively slow compared to some other bio-based materials. It can take several months to years for complete decomposition, depending on environmental conditions. This slower degradation rate may still pose challenges in waste management and environmental protection.

The production of cellulose acetate for optical applications generally has a lower carbon footprint compared to the manufacture of petroleum-based optical plastics. The raw material, cellulose, is renewable and can be sourced from sustainably managed forests or agricultural byproducts. This reduces dependency on fossil fuels and helps mitigate greenhouse gas emissions associated with material production.

In terms of energy consumption, the processing of cellulose acetate for optical applications typically requires less energy than the production of synthetic polymers. This energy efficiency translates to reduced environmental impact throughout the manufacturing lifecycle. Additionally, the production process generates fewer toxic byproducts, further minimizing environmental risks.

Cellulose acetate optics also offer advantages in terms of recyclability. While not as easily recyclable as some other materials, cellulose acetate can be reprocessed and repurposed, potentially reducing the overall waste generated by optical products. However, the recycling infrastructure for cellulose acetate is not as well-established as for more common plastics, which may limit its practical recyclability in some regions.

The use of cellulose acetate in optical applications can contribute to improved air and water quality. Unlike some synthetic materials, cellulose acetate does not release harmful volatile organic compounds (VOCs) during use or degradation. This characteristic is particularly important for indoor air quality in environments where optical devices are frequently used.

Despite these environmental benefits, it is important to consider the potential drawbacks of cellulose acetate optics. The material's sensitivity to moisture and temperature fluctuations may lead to a shorter lifespan for some optical products, potentially increasing replacement frequency and overall resource consumption. Balancing durability with environmental impact remains a challenge for researchers and manufacturers in this field.

Intellectual Property Landscape

The intellectual property landscape for cellulose acetate in advanced optical applications is characterized by a diverse array of patents and innovations. Major players in this field include established chemical companies, optical equipment manufacturers, and research institutions. These entities have been actively filing patents related to cellulose acetate formulations, processing techniques, and novel applications in optics.

A significant portion of the patents focus on improving the optical properties of cellulose acetate films. This includes enhancing transparency, reducing haze, and optimizing refractive indices. Companies like Eastman Chemical Company and Daicel Corporation have been particularly active in this area, with patents covering modified cellulose acetate compositions that exhibit superior optical clarity and durability.

Another prominent trend in the patent landscape is the development of cellulose acetate-based optical films with specialized functionalities. These include anti-reflective coatings, polarizing films, and light-diffusing materials. Firms such as 3M and Nitto Denko Corporation have made substantial contributions in this domain, with patents describing innovative layered structures and surface treatments to achieve desired optical effects.

The use of cellulose acetate in advanced display technologies has also garnered significant attention. Patents in this area often relate to the application of cellulose acetate films in flexible displays, organic light-emitting diodes (OLEDs), and other next-generation display technologies. Companies like LG Display and Samsung have been at the forefront of these developments, with patents covering the integration of cellulose acetate into various display components.

Emerging areas of patent activity include the incorporation of nanoparticles or other additives into cellulose acetate matrices to enhance optical performance. These innovations aim to create materials with unique optical properties, such as selective light transmission or enhanced UV protection. Academic institutions and smaller specialty chemical companies have been particularly active in exploring these novel approaches.

The geographical distribution of patents reveals a concentration of activity in East Asia, particularly Japan and South Korea, followed by the United States and Europe. This distribution reflects the strong presence of electronics and optical industries in these regions, as well as their focus on advanced materials research.

Recent patent trends indicate a growing interest in sustainable and bio-based alternatives to traditional petroleum-derived optical materials. This has led to an increase in patents related to the modification and optimization of cellulose acetate derived from renewable sources, aligning with broader industry trends towards environmentally friendly materials.