How to Engineer Cellulose Acetate for Enhanced Material Strength?

Cellulose Acetate Engineering Background and Objectives

Cellulose acetate, a versatile biopolymer derived from cellulose, has been a subject of extensive research and development since its discovery in the late 19th century. This semi-synthetic material has found applications across various industries, including textiles, films, and plastics, due to its unique properties such as biodegradability, transparency, and moldability. However, the quest for enhanced material strength has become increasingly crucial in expanding its potential applications and improving its performance in existing uses.

The evolution of cellulose acetate engineering has been driven by the growing demand for sustainable and high-performance materials in industries ranging from automotive to biomedical. As environmental concerns continue to shape material science, cellulose acetate has emerged as a promising alternative to petroleum-based polymers. Its renewable source and biodegradable nature align well with the global push towards more sustainable manufacturing practices and circular economy principles.

The primary objective in engineering cellulose acetate for enhanced material strength is to overcome its inherent limitations while preserving its desirable characteristics. These limitations include relatively low tensile strength, poor moisture resistance, and limited thermal stability compared to some synthetic polymers. By addressing these challenges, researchers aim to expand the material's applicability in high-performance applications such as automotive components, structural materials, and advanced packaging solutions.

Recent technological advancements have opened new avenues for cellulose acetate modification. Nanotechnology, in particular, has shown promise in enhancing the mechanical properties of cellulose acetate. The incorporation of nanofillers, such as cellulose nanocrystals or carbon nanotubes, has demonstrated significant improvements in tensile strength and modulus. Additionally, chemical modification techniques, including crosslinking and grafting, have been explored to tailor the material's properties for specific applications.

The ongoing research in cellulose acetate engineering is also focused on developing more efficient and environmentally friendly production processes. This includes optimizing acetylation reactions, exploring alternative solvents, and investigating novel catalysts to reduce energy consumption and minimize waste generation. These efforts aim not only to enhance the material's strength but also to improve its overall sustainability profile, making it more competitive against traditional petroleum-based polymers.

As we look towards the future, the engineering of cellulose acetate for enhanced material strength represents a convergence of material science, sustainability, and industrial innovation. The successful development of high-strength cellulose acetate composites could potentially revolutionize various sectors, offering a renewable and biodegradable alternative to conventional materials without compromising on performance. This technological pursuit aligns with broader global initiatives to transition towards a more sustainable and circular economy, positioning cellulose acetate as a key player in the next generation of advanced materials.

Market Demand Analysis for High-Strength Cellulose Acetate

The market demand for high-strength cellulose acetate has been steadily increasing across various industries due to its unique combination of properties and environmental benefits. This biodegradable material, derived from renewable sources, offers a sustainable alternative to petroleum-based plastics while providing excellent mechanical strength, optical clarity, and chemical resistance.

In the packaging industry, there is a growing need for robust, eco-friendly materials to replace traditional plastics. High-strength cellulose acetate meets these requirements, driving its adoption in food packaging, consumer goods packaging, and protective packaging for electronics. The global sustainable packaging market is expected to grow significantly in the coming years, with cellulose acetate playing a crucial role in this expansion.

The automotive sector represents another major market for high-strength cellulose acetate. As automakers strive to reduce vehicle weight and improve fuel efficiency, they are increasingly turning to lightweight, high-performance materials. Cellulose acetate composites offer an attractive solution for interior components, panels, and even structural elements, combining strength with reduced weight.

In the textile industry, there is a rising demand for durable, sustainable fibers. High-strength cellulose acetate fibers are gaining traction in the production of long-lasting, wrinkle-resistant fabrics for clothing and home textiles. The material's moisture-wicking properties and natural feel make it particularly appealing for sportswear and outdoor apparel.

The construction sector is also showing interest in high-strength cellulose acetate for applications such as insulation materials, window frames, and decorative panels. The material's durability, fire resistance, and thermal insulation properties make it an attractive option for sustainable building practices.

In the medical field, there is a growing need for biocompatible materials with enhanced strength for applications such as implants, surgical tools, and drug delivery systems. High-strength cellulose acetate's biocompatibility and customizable mechanical properties position it as a promising material for these applications.

The electronics industry is exploring the use of high-strength cellulose acetate in the production of flexible displays, wearable devices, and biodegradable electronic components. As the demand for sustainable electronics grows, cellulose acetate-based materials are expected to play an increasingly important role.

Overall, the market demand for high-strength cellulose acetate is driven by the global shift towards sustainable materials, stringent environmental regulations, and the need for advanced materials with superior mechanical properties. As research and development efforts continue to improve the material's strength and versatility, its market potential is expected to expand further across multiple industries.

Current Challenges in Cellulose Acetate Strength Enhancement

Despite significant advancements in cellulose acetate (CA) technology, several challenges persist in enhancing its material strength. One of the primary obstacles is the inherent brittleness of CA, which limits its applications in high-stress environments. This brittleness is attributed to the rigid molecular structure of cellulose and the presence of strong hydrogen bonding between polymer chains.

Another significant challenge is the moisture sensitivity of CA. The material tends to absorb water from the environment, leading to dimensional instability and reduced mechanical properties. This hygroscopic nature not only affects the strength but also impacts the long-term durability of CA-based products, particularly in humid conditions.

The plasticization process, crucial for improving flexibility, presents its own set of challenges. While plasticizers enhance the material's workability, they often compromise its strength and thermal stability. Finding the right balance between flexibility and strength remains a complex task, as excessive plasticization can lead to a significant reduction in tensile strength and modulus.

Furthermore, the degree of substitution (DS) in CA synthesis plays a critical role in determining its properties. Achieving precise control over the DS during production is challenging, yet crucial for optimizing strength characteristics. Variations in DS can lead to inconsistencies in material properties, making it difficult to maintain uniform strength across different batches.

The crystallinity of CA also poses a challenge in strength enhancement. While higher crystallinity generally correlates with increased strength, it can also lead to increased brittleness. Balancing the amorphous and crystalline regions to achieve optimal mechanical properties is a delicate process that requires fine-tuning of production parameters.

Additionally, the molecular weight distribution of CA significantly influences its mechanical properties. Achieving a narrow and controlled molecular weight distribution during synthesis is technically challenging but essential for consistent strength characteristics. Broad molecular weight distributions can result in heterogeneous material properties, compromising overall strength and performance.

Lastly, the environmental stability of CA remains a concern. Exposure to UV radiation and thermal stress can lead to degradation of the polymer chains, resulting in a gradual loss of strength over time. Developing effective stabilization techniques without compromising the material's core properties is an ongoing challenge in CA engineering.

Existing Methods for Improving Cellulose Acetate Strength

01 Modification of cellulose acetate structure

Altering the molecular structure of cellulose acetate through chemical treatments or processing methods can enhance its strength. This may involve adjusting the degree of substitution, crosslinking, or incorporating reinforcing agents to improve mechanical properties.- Fiber reinforcement for improved strength: Incorporating fibers into cellulose acetate materials can significantly enhance their strength and mechanical properties. This technique involves blending cellulose acetate with various types of fibers, such as natural or synthetic fibers, to create a composite material with improved tensile strength, impact resistance, and overall durability.

- Chemical modification of cellulose acetate: Chemical treatments and modifications can be applied to cellulose acetate to enhance its strength properties. These modifications may include crosslinking, grafting, or introducing functional groups that improve intermolecular bonding and structural integrity, resulting in a stronger and more resilient material.

- Nanocomposite formulations: Incorporating nanoparticles or nanomaterials into cellulose acetate can lead to significant improvements in material strength. These nanocomposites often exhibit enhanced mechanical properties, including increased tensile strength, modulus, and impact resistance, due to the unique interactions between the nanoparticles and the cellulose acetate matrix.

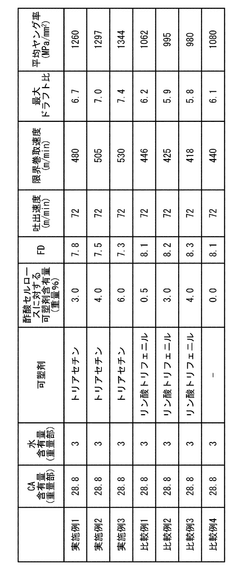

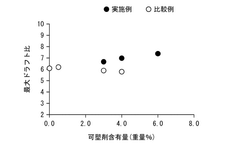

- Plasticizer optimization: Careful selection and optimization of plasticizers can significantly impact the strength of cellulose acetate materials. By adjusting the type and concentration of plasticizers, it is possible to achieve a balance between flexibility and strength, resulting in improved overall mechanical properties and durability of the material.

- Processing techniques for strength enhancement: Various processing techniques can be employed to improve the strength of cellulose acetate materials. These may include optimized extrusion or molding processes, heat treatments, or specialized forming methods that enhance molecular orientation and crystallinity, leading to improved mechanical properties and overall material strength.

02 Blending with other polymers

Combining cellulose acetate with other compatible polymers can create composite materials with improved strength characteristics. This approach allows for the synergistic combination of properties from different materials to enhance overall performance.Expand Specific Solutions03 Fiber reinforcement techniques

Incorporating fibers or nanofibers into cellulose acetate matrices can significantly increase material strength. Various types of fibers, such as natural or synthetic ones, can be used to create reinforced composites with enhanced mechanical properties.Expand Specific Solutions04 Surface treatment and coating

Applying surface treatments or coatings to cellulose acetate materials can improve their strength and durability. These treatments may include plasma modification, chemical grafting, or the application of protective layers to enhance resistance to environmental factors.Expand Specific Solutions05 Optimization of processing conditions

Adjusting manufacturing parameters such as temperature, pressure, and curing time during the production of cellulose acetate materials can significantly impact their strength. Optimizing these conditions can lead to improved molecular orientation and crystallinity, resulting in enhanced mechanical properties.Expand Specific Solutions

Key Players in Cellulose Acetate Industry

The engineering of cellulose acetate for enhanced material strength is currently in a growth phase, with increasing market demand driven by sustainability trends. The global cellulose acetate market is projected to reach $7.2 billion by 2027, growing at a CAGR of 4.5%. Technologically, the field is moderately mature but evolving rapidly. Companies like Daicel Corp., Eastman Chemical Co., and Asahi Kasei Corp. are leading innovation, focusing on improving mechanical properties and developing novel applications. Research institutions such as Hokkaido University and CNRS are contributing to fundamental advancements. Emerging players like Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd. are also making significant strides, particularly in eco-friendly production methods and high-performance variants.

Daicel Corp.

Nantong Cellulose Fibers Co. Ltd.

Core Innovations in Cellulose Acetate Reinforcement

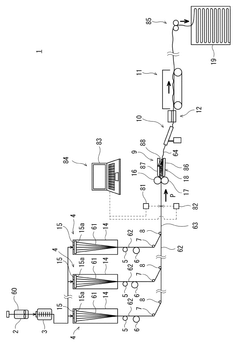

- A method involving the preparation of a spinning stock solution by dissolving cellulose acetate and a plasticizer in a solvent, where the plasticizer has a viscosity of 150,000 mPa·s or less at 25°C, and the content of the plasticizer is 0.5% by weight or more, allowing for high-speed spinning and improved strength of cellulose acetate fibers with a filament denier of less than 75 denier/9000 m.

- Development of a molded composite material using cellulose acetate as a binder with natural cellulose fibers, achieving a degree of substitution (DS) of 1.2 to 2.7 and a mass ratio of 10:90 to 90:10, allowing for biodegradability and high Vicat temperatures without the need for external plasticizers, utilizing processing conditions such as moisture content, temperature, and pressure to enhance mechanical and thermal properties.

Environmental Impact of Cellulose Acetate Production

The production of cellulose acetate, while offering numerous benefits in material science, carries significant environmental implications that warrant careful consideration. The manufacturing process involves the use of various chemicals and solvents, which can potentially lead to environmental pollution if not properly managed. One of the primary concerns is the release of volatile organic compounds (VOCs) during production, which contribute to air pollution and can have adverse effects on both human health and ecosystems.

Water pollution is another critical issue associated with cellulose acetate production. The process generates wastewater containing dissolved chemicals and suspended solids, which, if not adequately treated, can contaminate local water sources. This can lead to the degradation of aquatic ecosystems and pose risks to human health if the contaminated water enters the drinking water supply.

Energy consumption is a significant factor in the environmental impact of cellulose acetate production. The manufacturing process requires substantial amounts of energy, often derived from fossil fuels, contributing to greenhouse gas emissions and climate change. As the demand for cellulose acetate increases, the cumulative energy consumption and associated carbon footprint become increasingly concerning from an environmental perspective.

The sourcing of raw materials for cellulose acetate production, primarily wood pulp or cotton linters, raises questions about sustainable forestry practices and land use. Improper management of these resources can lead to deforestation, loss of biodiversity, and soil degradation. It is crucial for manufacturers to ensure that their raw materials are sourced from sustainably managed forests or agricultural practices to mitigate these environmental impacts.

Waste management is another critical aspect of the environmental impact of cellulose acetate production. The process generates various waste products, including chemical residues and off-specification materials. Proper disposal or recycling of these wastes is essential to prevent soil and water contamination. Additionally, the end-of-life disposal of cellulose acetate products presents challenges, as they are not readily biodegradable in natural environments.

To address these environmental concerns, the industry is increasingly focusing on developing more sustainable production methods. This includes the implementation of closed-loop systems to minimize waste and maximize resource efficiency, the adoption of renewable energy sources to reduce carbon emissions, and the exploration of bio-based alternatives to traditional chemical solvents. Furthermore, research into improving the biodegradability of cellulose acetate products is ongoing, aiming to reduce their long-term environmental impact.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of engineering cellulose acetate for enhanced material strength are crucial factors in determining its viability for large-scale industrial applications. The production process of cellulose acetate involves several steps, including the acetylation of cellulose, hydrolysis, and precipitation. Scaling up these processes presents both opportunities and challenges.

One of the primary advantages of cellulose acetate production is the abundance and renewability of its raw material, cellulose. This ensures a stable and potentially cost-effective supply chain, which is essential for scalability. However, the acetylation process, which is key to enhancing material strength, requires careful control of reaction conditions and the use of acetic anhydride, a relatively expensive reagent.

To improve scalability, continuous flow reactors have been explored as an alternative to batch processes. These systems offer better control over reaction parameters, reduced processing times, and improved product consistency. Additionally, they can be more easily scaled up by increasing the number of parallel reactors or extending reactor length, rather than redesigning entire batch systems.

Cost-effectiveness can be enhanced through process optimization and the development of more efficient catalysts. Recent research has focused on heterogeneous catalysts that can be easily separated and reused, reducing both material costs and environmental impact. Furthermore, the recovery and recycling of acetic acid, a byproduct of the acetylation process, can significantly improve the economic viability of large-scale production.

Energy consumption is another critical factor affecting both scalability and cost-effectiveness. The drying and solvent recovery stages are particularly energy-intensive. Implementing heat integration systems and exploring alternative drying technologies, such as supercritical CO2 drying, could lead to substantial energy savings and improved process economics.

The development of advanced process control systems and the implementation of Industry 4.0 technologies can further enhance scalability and cost-effectiveness. Real-time monitoring and adaptive control strategies can optimize reaction conditions, reduce waste, and improve product quality, all of which contribute to more efficient large-scale production.

Lastly, the potential for value-added applications of cellulose acetate with enhanced material strength opens up new market opportunities. This could justify higher production costs if the resulting materials command premium prices in specialized sectors such as aerospace, automotive, or high-performance textiles. Balancing production costs with market demand and pricing strategies will be crucial for long-term economic viability.