Cellulose Acetate: Enhancing Electronics with Sustainable Materials

Cellulose Acetate in Electronics: Background and Objectives

Cellulose acetate, a versatile and sustainable material, has been gaining significant attention in the electronics industry. This biodegradable polymer, derived from natural cellulose, offers a promising alternative to conventional petroleum-based plastics. The evolution of cellulose acetate in electronics can be traced back to its initial applications in photographic films and fibers, gradually expanding into various electronic components and devices.

The technological trajectory of cellulose acetate in electronics has been driven by the growing demand for eco-friendly materials that can meet the stringent performance requirements of modern electronic devices. As environmental concerns and sustainability initiatives gain momentum, the electronics industry is actively seeking alternatives to reduce its carbon footprint and minimize electronic waste.

The primary objective of incorporating cellulose acetate into electronics is to develop sustainable, high-performance components that can replace traditional materials without compromising functionality. This includes applications in flexible displays, electronic packaging, and substrate materials for printed circuit boards. The unique properties of cellulose acetate, such as its transparency, flexibility, and thermal stability, make it an attractive candidate for these applications.

Recent advancements in cellulose acetate technology have focused on enhancing its electrical and mechanical properties to meet the demands of electronic devices. Researchers are exploring various modification techniques, including nanocomposite formulations and surface treatments, to improve conductivity, dielectric properties, and durability. These efforts aim to position cellulose acetate as a viable alternative to conventional plastics in a wide range of electronic applications.

The integration of cellulose acetate into electronics aligns with the broader trend of green electronics, which seeks to minimize the environmental impact of electronic devices throughout their lifecycle. This includes not only the use of sustainable materials but also the development of recyclable and biodegradable electronic components. As such, cellulose acetate represents a key element in the transition towards more sustainable electronic products.

Looking ahead, the development of cellulose acetate in electronics is expected to focus on scaling up production, optimizing material properties, and expanding its application range. Collaborative efforts between material scientists, electronic engineers, and sustainability experts will be crucial in realizing the full potential of this material. The ultimate goal is to create a new generation of electronic devices that combine high performance with environmental responsibility, paving the way for a more sustainable future in the electronics industry.

Market Demand for Sustainable Electronic Materials

The market demand for sustainable electronic materials has been steadily increasing in recent years, driven by growing environmental concerns and regulatory pressures. Cellulose acetate, a biodegradable and renewable material derived from wood pulp or cotton fibers, has emerged as a promising candidate for enhancing electronics with sustainable alternatives.

Consumer electronics manufacturers are actively seeking eco-friendly materials to reduce their carbon footprint and appeal to environmentally conscious consumers. This shift is evident in the rising demand for products with recyclable or biodegradable components. Market research indicates that consumers are willing to pay a premium for electronics made with sustainable materials, creating a significant opportunity for cellulose acetate-based products.

The global market for sustainable electronic materials is projected to experience substantial growth over the next decade. This expansion is fueled by stringent environmental regulations in key markets such as the European Union, where the Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive have set high standards for electronic waste management and material sustainability.

Cellulose acetate's potential applications in electronics are diverse, ranging from flexible displays and circuit boards to packaging materials and device casings. The material's unique properties, including its transparency, flexibility, and biodegradability, make it particularly attractive for use in wearable technology and disposable electronic devices.

The automotive industry is another significant driver of demand for sustainable electronic materials. As vehicles become increasingly electrified and connected, there is a growing need for eco-friendly components in automotive electronics. Cellulose acetate's heat resistance and durability make it a suitable candidate for various automotive applications, including interior displays and sensor housings.

Despite the promising outlook, challenges remain in scaling up production and optimizing the performance of cellulose acetate for electronic applications. Investments in research and development are crucial to overcome these hurdles and fully capitalize on the market potential. Companies that successfully integrate cellulose acetate into their product lines stand to gain a competitive edge in the rapidly evolving sustainable electronics market.

As consumer awareness of environmental issues continues to grow, the demand for sustainable electronic materials is expected to accelerate. This trend presents a significant opportunity for cellulose acetate to establish itself as a key player in the green electronics revolution, potentially reshaping the industry's approach to material selection and product design.

Current State and Challenges of Cellulose Acetate in Electronics

Cellulose acetate has emerged as a promising sustainable material in the electronics industry, offering potential solutions to environmental concerns associated with traditional synthetic polymers. Currently, the application of cellulose acetate in electronics is primarily focused on flexible and biodegradable electronic components, such as substrates for printed circuit boards, dielectric layers, and packaging materials.

The development of cellulose acetate-based electronics has seen significant progress in recent years, with researchers successfully demonstrating its use in various electronic devices. These include flexible displays, sensors, and energy storage devices. The material's inherent flexibility, transparency, and biodegradability make it particularly attractive for wearable electronics and disposable electronic applications.

However, despite these advancements, several challenges remain in the widespread adoption of cellulose acetate in electronics. One of the primary obstacles is the material's relatively low electrical conductivity compared to traditional electronic materials. This limitation necessitates the development of innovative approaches to enhance its conductivity, such as incorporating conductive fillers or surface modifications.

Another significant challenge is the moisture sensitivity of cellulose acetate. When exposed to humid environments, the material can absorb water, leading to dimensional instability and potential degradation of electronic components. Researchers are actively working on developing moisture-resistant coatings and treatments to mitigate this issue.

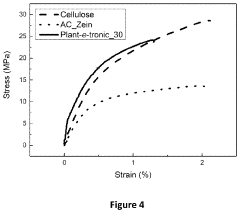

The mechanical properties of cellulose acetate also present challenges in certain electronic applications. While its flexibility is advantageous in some contexts, it may not provide sufficient rigidity for certain structural components. Efforts are underway to develop composite materials that combine cellulose acetate with other materials to achieve a balance between flexibility and structural integrity.

Furthermore, the processing and manufacturing of cellulose acetate-based electronic components require optimization to achieve consistency and scalability. Current production methods often involve complex processes and may not be easily adaptable to existing electronic manufacturing infrastructure.

From a geographical perspective, research and development in cellulose acetate electronics are distributed globally, with significant contributions from academic institutions and research centers in North America, Europe, and Asia. Japan, in particular, has been at the forefront of cellulose-based electronics research, leveraging its expertise in both electronics and cellulose-derived materials.

In conclusion, while cellulose acetate shows great promise in enhancing electronics with sustainable materials, several technical challenges must be addressed to fully realize its potential. Overcoming these obstacles will require continued research and development efforts, as well as collaboration between material scientists, electronic engineers, and manufacturing experts.

Existing Solutions for Cellulose Acetate Integration

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications, including textiles, filters, and composite materials. The properties of these fibers can be tailored for specific uses through modifications in the production process or post-treatment methods.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are presented, focusing on improved formulations and manufacturing techniques. These developments enhance the performance of cellulose acetate in applications such as separation processes and packaging materials.

- Cellulose acetate modifications and derivatives: Research on modifying cellulose acetate and creating new derivatives is discussed. These modifications aim to enhance properties such as biodegradability, thermal stability, and compatibility with other materials for various industrial applications.

- Cellulose acetate in pharmaceutical and biomedical applications: The use of cellulose acetate in pharmaceutical and biomedical fields is explored, including drug delivery systems, tissue engineering scaffolds, and medical devices. The biocompatibility and versatility of cellulose acetate make it suitable for these advanced applications.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications, including textiles, filters, and composite materials. The properties of these fibers can be tailored for specific uses through modifications in the production process or post-treatment methods.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology focus on improving properties such as permeability, selectivity, and durability. These developments are particularly relevant for applications in separation processes, packaging, and biomedical fields.Expand Specific Solutions04 Cellulose acetate blends and composites

Research on cellulose acetate blends and composites aims to enhance material properties by combining cellulose acetate with other polymers or additives. This approach allows for the creation of materials with improved mechanical, thermal, or functional characteristics.Expand Specific Solutions05 Biodegradable and sustainable cellulose acetate products

Development of biodegradable and sustainable cellulose acetate products focuses on improving environmental compatibility while maintaining desired material properties. This includes research on modified cellulose acetates and their applications in eco-friendly consumer goods and packaging materials.Expand Specific Solutions

Key Players in Cellulose Acetate and Electronics Industry

The cellulose acetate market for electronics is in a growth phase, driven by increasing demand for sustainable materials in the industry. The market size is expanding, with potential applications in flexible displays, sensors, and electronic components. Technologically, cellulose acetate is advancing from traditional uses to more sophisticated electronic applications. Companies like FUJIFILM Corp., Eastman Chemical Co., and Toray Industries, Inc. are at the forefront of this development, leveraging their expertise in materials science. Research institutions such as Nanyang Technological University and Tohoku University are contributing to technological advancements. The involvement of diverse players, including chemical companies, electronics manufacturers, and academic institutions, indicates a competitive and innovative landscape with significant potential for further growth and technological maturation in the electronics sector.

Daicel Corp.

Eastman Chemical Co.

Core Innovations in Cellulose Acetate for Electronics

- A resin composition incorporating a cellulose acetate ether compound with a specific atomic group introduced via an ether group, combined with a stabilizer like a phosphite or hindered phenol compound, and a glycidyl group-containing polymer compound to enhance thermal stability and impact resistance.

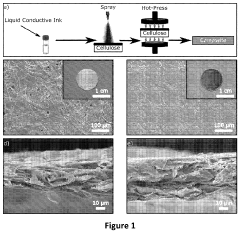

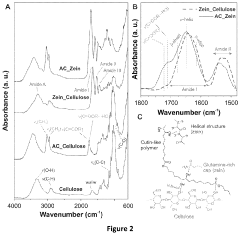

- A cellulose-based composite material is developed by dissolving plant-derived proteins and aleuritic acid, dispersing conductive materials like graphene nanoplatelets, and hot-pressing the mixture onto a cellulose substrate to create a flexible, conductive ink-impregnated composite suitable for various electronic applications.

Environmental Impact and Life Cycle Assessment

The environmental impact and life cycle assessment of cellulose acetate in electronics applications reveal both promising sustainability aspects and areas for improvement. Cellulose acetate, derived from renewable sources such as wood pulp or cotton linters, offers a more environmentally friendly alternative to traditional petroleum-based plastics. Its biodegradability and potential for recycling contribute to reduced waste accumulation and lower environmental persistence compared to conventional electronic materials.

Life cycle assessments of cellulose acetate in electronics demonstrate lower carbon footprints and reduced energy consumption during production compared to many synthetic polymers. The material's renewable nature helps mitigate resource depletion concerns associated with fossil fuel-based alternatives. Additionally, the production process for cellulose acetate typically involves fewer toxic chemicals and generates less hazardous waste, further enhancing its environmental profile.

However, the environmental benefits of cellulose acetate are not without challenges. The cultivation and harvesting of raw materials for cellulose production can lead to land use changes and potential impacts on biodiversity. Water consumption during the manufacturing process is also a concern, particularly in water-stressed regions. Furthermore, while cellulose acetate is biodegradable, the rate of decomposition can vary significantly depending on environmental conditions, potentially leading to accumulation in certain ecosystems.

The end-of-life management of cellulose acetate in electronics presents both opportunities and challenges. While the material can be recycled, the current infrastructure for recycling electronic components made from cellulose acetate is limited. Improving recycling technologies and establishing effective collection systems are crucial steps in maximizing the material's circular economy potential.

When considering the overall environmental impact, it is essential to evaluate the trade-offs between the benefits of using a renewable, biodegradable material and the potential drawbacks associated with its production and disposal. Life cycle assessments should account for regional variations in energy sources, manufacturing practices, and waste management systems to provide a comprehensive understanding of cellulose acetate's environmental performance in different contexts.

As the electronics industry continues to prioritize sustainability, ongoing research and development efforts are focused on optimizing the production processes for cellulose acetate, enhancing its durability in electronic applications, and improving end-of-life management strategies. These advancements will be crucial in further reducing the environmental footprint of cellulose acetate and solidifying its position as a sustainable material for the electronics sector.

Regulatory Framework for Bio-based Electronic Materials

The regulatory framework for bio-based electronic materials, particularly cellulose acetate, is evolving to address the unique challenges and opportunities presented by sustainable materials in electronics. As governments and international bodies recognize the potential of these materials to reduce environmental impact, new regulations and standards are being developed to ensure their safe and effective use.

In the European Union, the Eco-design Directive has been expanded to include requirements for the use of sustainable materials in electronic products. This directive now encourages manufacturers to incorporate bio-based materials like cellulose acetate into their designs, provided they meet performance and safety standards. The EU has also introduced the Circular Economy Action Plan, which promotes the use of renewable and recyclable materials in electronics, further supporting the adoption of cellulose acetate.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the use of bio-based materials in electronics through its Sustainable Materials Management program. These guidelines provide a framework for assessing the environmental impact of materials throughout their lifecycle, including production, use, and disposal. The EPA also offers incentives for companies that incorporate sustainable materials into their products, encouraging innovation in this field.

Japan has implemented the Green Purchasing Law, which mandates government agencies to prioritize the procurement of environmentally friendly products, including electronics made with sustainable materials. This law has indirectly stimulated the development and use of bio-based materials like cellulose acetate in the electronics industry.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), are developing new standards specific to bio-based electronic materials. These standards aim to establish consistent quality and performance criteria for materials like cellulose acetate, ensuring their reliability and safety in electronic applications.

The regulatory landscape also includes restrictions on hazardous substances in electronics, such as the Restriction of Hazardous Substances (RoHS) directive in the EU. As cellulose acetate and other bio-based materials often contain fewer hazardous substances than traditional materials, they are well-positioned to meet these stringent requirements.

As the field of bio-based electronic materials continues to advance, regulatory bodies are working to balance innovation with safety and environmental protection. This evolving framework is expected to play a crucial role in shaping the future of sustainable electronics, providing both guidance and incentives for the continued development and adoption of materials like cellulose acetate.