Future of Cellulose Acetate in Eco-Friendly Product Design

Cellulose Acetate Evolution and Objectives

Cellulose acetate, a versatile bioplastic, has a rich history dating back to its discovery in the 1860s. Initially developed as a substitute for celluloid, it has since evolved into a material with diverse applications across multiple industries. The evolution of cellulose acetate has been driven by the need for sustainable alternatives to petroleum-based plastics, aligning with global efforts to reduce environmental impact and promote eco-friendly product design.

Over the years, cellulose acetate has undergone significant improvements in its production processes and material properties. Early manufacturing methods were energy-intensive and relied on hazardous chemicals. However, advancements in green chemistry and biotechnology have led to more sustainable production techniques, reducing the environmental footprint of cellulose acetate manufacturing.

The primary objective in the future of cellulose acetate is to further enhance its eco-friendly credentials while maintaining or improving its desirable properties. This includes developing biodegradable variants that can decompose more rapidly in natural environments, without compromising the material's durability during its intended use. Researchers are also focusing on improving the material's resistance to moisture and heat, expanding its potential applications in various industries.

Another key goal is to optimize the sourcing of raw materials for cellulose acetate production. While traditionally derived from wood pulp, there is growing interest in exploring alternative cellulose sources, such as agricultural waste and fast-growing plants. This shift aims to reduce pressure on forest resources and create a more sustainable supply chain for cellulose acetate production.

In the context of eco-friendly product design, cellulose acetate is poised to play a crucial role in replacing conventional plastics in various consumer goods. The material's transparency, moldability, and potential for customization make it an attractive option for packaging, consumer electronics, and personal care products. As such, a significant objective is to develop cellulose acetate formulations that can meet the specific requirements of these diverse applications while maintaining their biodegradability and overall environmental benefits.

The future trajectory of cellulose acetate also involves exploring its potential in advanced applications, such as 3D printing and smart materials. Researchers are investigating ways to incorporate additional functionalities into cellulose acetate, such as conductivity or shape-memory properties, opening up new possibilities for innovative and sustainable product designs.

Eco-Friendly Product Market Analysis

The eco-friendly product market has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and a shift towards sustainable consumption. This trend has created a substantial opportunity for cellulose acetate, a biodegradable material derived from natural sources, to play a crucial role in eco-friendly product design.

The global market for eco-friendly products is projected to continue its upward trajectory, with estimates suggesting a compound annual growth rate (CAGR) of over 8% through 2025. This growth is particularly pronounced in sectors such as packaging, consumer goods, and textiles, where cellulose acetate has found numerous applications.

In the packaging industry, there is a growing demand for sustainable alternatives to traditional plastics. Cellulose acetate's biodegradability and versatility make it an attractive option for food packaging, disposable cutlery, and other single-use items. The market for biodegradable packaging materials is expected to expand rapidly, with some regions implementing regulations that favor such materials over conventional plastics.

The consumer goods sector, including personal care and household products, has also seen a surge in demand for eco-friendly alternatives. Cellulose acetate's potential in this market is significant, as it can be used in products ranging from toothbrushes to disposable razors. Consumers are increasingly willing to pay a premium for products that align with their environmental values, creating a favorable market environment for cellulose acetate-based goods.

In the textile industry, cellulose acetate fibers are gaining traction as a sustainable alternative to synthetic fibers. The growing interest in eco-friendly fashion and the push for circular economy principles in the apparel industry are driving the adoption of biodegradable materials like cellulose acetate.

Geographically, Europe and North America lead in the adoption of eco-friendly products, with stringent regulations and environmentally conscious consumers. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth in this sector, presenting new opportunities for cellulose acetate applications.

Despite the positive market outlook, challenges remain. The higher cost of eco-friendly materials compared to conventional alternatives can be a barrier to widespread adoption. Additionally, the need for consumer education about the benefits and proper disposal of biodegradable products is crucial for market expansion.

Current Challenges in Cellulose Acetate Applications

Cellulose acetate, despite its eco-friendly potential, faces several challenges in its current applications. One of the primary issues is its limited biodegradability in natural environments. While cellulose acetate is derived from natural sources, the acetylation process alters its structure, making it resistant to microbial breakdown. This results in prolonged decomposition times, which can span several years, particularly in landfill conditions.

Another significant challenge is the material's moisture sensitivity. Cellulose acetate tends to absorb water from its surroundings, leading to dimensional instability and potential degradation of its mechanical properties. This characteristic limits its use in certain applications where moisture resistance is crucial, such as outdoor products or packaging for liquids.

The production process of cellulose acetate also presents environmental concerns. The use of acetic anhydride and other chemicals in the acetylation process can generate harmful byproducts and emissions if not properly managed. This necessitates stringent environmental controls and waste management practices, which can increase production costs and complexity.

Furthermore, the recyclability of cellulose acetate products remains a challenge. While theoretically recyclable, the infrastructure for collecting and processing cellulose acetate waste is not widely established. This leads to most cellulose acetate products ending up in landfills or incineration facilities, rather than being recycled into new materials.

The material's thermal stability is another area of concern. Cellulose acetate has a relatively low heat deflection temperature, which limits its use in applications involving high temperatures or prolonged heat exposure. This thermal sensitivity can result in deformation or degradation of cellulose acetate products under certain conditions.

Lastly, the cost-effectiveness of cellulose acetate compared to synthetic polymers poses a challenge for widespread adoption. While prices have become more competitive in recent years, cellulose acetate still tends to be more expensive than many petroleum-based plastics. This cost differential can be a significant barrier, particularly in price-sensitive markets or applications where large volumes of material are required.

Existing Eco-Friendly Cellulose Acetate Solutions

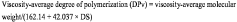

01 Production methods for cellulose acetate

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fibers and films: Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane industries.

- Cellulose acetate modifications and derivatives: Research on modifying cellulose acetate and creating new derivatives is discussed. These modifications aim to enhance specific properties or introduce new functionalities for various applications, including biomedical and industrial uses.

- Cellulose acetate in filtration and separation: Applications of cellulose acetate in filtration and separation processes are explored. This includes the development of membranes and filters for water treatment, gas separation, and other industrial processes.

- Cellulose acetate composites and blends: Innovations in creating cellulose acetate composites and blends with other materials are presented. These developments aim to combine the properties of cellulose acetate with other substances to create materials with enhanced characteristics for specific applications.

02 Cellulose acetate fibers and films

Techniques for manufacturing cellulose acetate fibers and films are presented, focusing on improving their properties such as strength, flexibility, and durability. These innovations are applicable in textile, packaging, and membrane industries.Expand Specific Solutions03 Cellulose acetate composites and blends

Development of cellulose acetate-based composites and blends with other materials to enhance performance characteristics. These innovations aim to create materials with improved mechanical, thermal, or barrier properties for various applications.Expand Specific Solutions04 Modification and functionalization of cellulose acetate

Methods for modifying and functionalizing cellulose acetate to impart specific properties or introduce new functionalities. These techniques can lead to the creation of advanced materials with tailored characteristics for specialized applications.Expand Specific Solutions05 Applications of cellulose acetate in various industries

Exploration of novel applications for cellulose acetate in diverse industries, including but not limited to filtration, biomedical, electronics, and environmental remediation. These innovations showcase the versatility and potential of cellulose acetate-based materials.Expand Specific Solutions

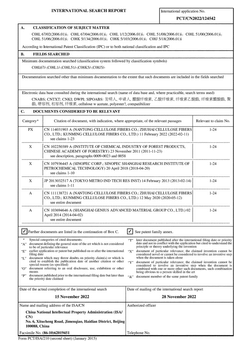

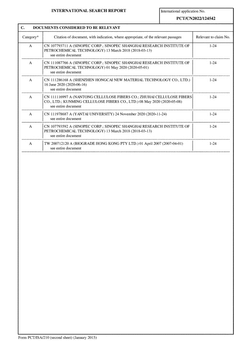

Key Industry Players and Competitors

The future of cellulose acetate in eco-friendly product design is entering a mature phase, with a growing market driven by sustainability trends. The global cellulose acetate market is expected to reach significant size, reflecting increased demand for biodegradable materials. Technologically, the field is advancing rapidly, with companies like Eastman Chemical Co. and Daicel Corp. leading innovation. China Petroleum & Chemical Corp. and its research institute are also making strides in developing eco-friendly cellulose acetate applications. Emerging players such as Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd. are contributing to the competitive landscape, while research institutions like the Chinese Academy of Sciences are pushing the boundaries of cellulose acetate technology for sustainable product design.

Eastman Chemical Co.

Daicel Corp.

Innovative Cellulose Acetate Formulations

- Cellulose acetate with a total degree of acetyl substitution between 1.75 and 2.55, and at least one degree of acetyl substitution at the 2- or 3-position being 0.7 or less, combined with additives such as magnesium oxide and triacetin, which promote hydrolysis and biodegradation in seawater.

- Incorporating a compatibilizer with active multifunctional groups, such as epoxy or maleic anhydride, to enhance the interfacial compatibility and mechanical properties of cellulose acetate and biodegradable polyester blends through reaction extrusion, allowing for improved thermal processing and film production.

Environmental Impact Assessment

The environmental impact assessment of cellulose acetate in eco-friendly product design reveals both positive and negative aspects. On the positive side, cellulose acetate is derived from renewable resources, primarily wood pulp and cotton linters, making it a more sustainable alternative to petroleum-based plastics. Its biodegradability, when properly disposed of, contributes to reduced long-term environmental pollution compared to conventional plastics.

However, the production process of cellulose acetate involves the use of acetic acid and other chemicals, which can have negative environmental implications if not managed properly. The manufacturing process also requires significant energy input, contributing to carbon emissions. Additionally, while cellulose acetate is biodegradable, it may take several years to decompose fully in natural environments, potentially causing short-term ecological disruptions.

In terms of waste management, cellulose acetate presents both opportunities and challenges. Its biodegradability offers an advantage in composting facilities, but it requires specific conditions to break down effectively. Improper disposal can lead to accumulation in landfills or marine environments, where it may persist for extended periods.

The use of cellulose acetate in eco-friendly product design has shown promise in reducing the environmental footprint of various consumer goods. For instance, in the textile industry, cellulose acetate fibers have been used as a more sustainable alternative to synthetic fibers. In packaging, it offers a biodegradable option for single-use items, potentially reducing plastic waste.

However, the overall environmental impact depends heavily on the entire lifecycle of cellulose acetate products. This includes raw material sourcing, production processes, transportation, use phase, and end-of-life management. Sustainable forestry practices are crucial to ensure the responsible sourcing of wood pulp, while efficient manufacturing processes can minimize energy consumption and chemical waste.

Looking forward, advancements in production technologies and waste management systems could further enhance the environmental profile of cellulose acetate. Research into more efficient biodegradation processes and the development of closed-loop recycling systems for cellulose acetate products could significantly reduce its environmental impact. Additionally, innovations in bio-based additives and processing methods may lead to cellulose acetate formulations with improved biodegradability and reduced chemical inputs.

Regulatory Framework for Bioplastics

The regulatory framework for bioplastics, including cellulose acetate, is evolving rapidly as governments and international organizations recognize the need for sustainable alternatives to conventional plastics. In the European Union, the Single-Use Plastics Directive (EU) 2019/904 has been a significant driver for the adoption of bioplastics, including cellulose acetate-based products. This directive aims to reduce the impact of certain plastic products on the environment, particularly marine ecosystems.

In the United States, the regulatory landscape is more fragmented, with individual states taking the lead in implementing bioplastic-friendly policies. California, for instance, has enacted the Sustainable Packaging for the State of California Act of 2018, which promotes the use of recyclable and compostable materials, including certain bioplastics. The FDA has also issued guidance on the use of bioplastics in food contact applications, ensuring their safety for consumers.

Globally, the United Nations Environment Programme (UNEP) has been instrumental in shaping international policies on bioplastics. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste, potentially affecting the trade and disposal of bioplastic products.

Certification systems play a crucial role in the regulatory framework for bioplastics. The European Standard EN 13432 and the American Standard ASTM D6400 set the criteria for compostable plastics. These standards are essential for cellulose acetate products marketed as biodegradable or compostable.

Emerging regulations are focusing on the entire lifecycle of bioplastic products. The EU's Circular Economy Action Plan, part of the European Green Deal, emphasizes the importance of sustainable product design and waste reduction. This approach is likely to influence future regulations on cellulose acetate and other bioplastics, promoting their use in eco-friendly product design.

Challenges in the regulatory framework include the need for standardized definitions of bioplastics and biodegradability across different jurisdictions. The lack of harmonized regulations can create barriers to trade and confusion among consumers. Additionally, there is ongoing debate about the environmental impact of bioplastics, including land use for feedstock production and end-of-life management.

As the market for cellulose acetate and other bioplastics grows, regulators are likely to focus on lifecycle assessments, carbon footprint calculations, and waste management infrastructure. Future regulations may also address the sourcing of raw materials for bioplastics, promoting sustainable forestry practices for cellulose-based products.