How to Integrate Cellulose Acetate in Textile Manufacturing?

Cellulose Acetate in Textiles: Background and Objectives

Cellulose acetate, a versatile and sustainable material, has been a subject of interest in the textile industry for decades. Its journey in textile manufacturing began in the early 20th century when it was first introduced as a fiber-forming substance. Since then, the technology has evolved significantly, driven by the growing demand for eco-friendly and performance-enhanced textiles.

The development of cellulose acetate in textiles has been marked by continuous improvements in production processes, fiber properties, and application techniques. Initially used primarily for apparel, cellulose acetate has expanded its reach to various textile sectors, including home furnishings, industrial fabrics, and technical textiles. This expansion has been fueled by advancements in acetylation methods, spinning technologies, and finishing treatments.

Recent years have witnessed a renewed interest in cellulose acetate due to its potential as a sustainable alternative to petroleum-based synthetic fibers. The global shift towards environmentally responsible manufacturing practices has positioned cellulose acetate as a promising material for the future of textile production. Its biodegradability and renewable source make it an attractive option for brands and consumers alike who are increasingly conscious of their environmental footprint.

The integration of cellulose acetate in textile manufacturing faces several challenges and opportunities. On one hand, there are technical hurdles related to fiber strength, moisture absorption, and dyeability that need to be addressed. On the other hand, there is significant potential for innovation in areas such as blending with other fibers, developing novel finishes, and creating advanced composite materials.

The primary objective of this technical research is to explore and evaluate methods for effectively integrating cellulose acetate into modern textile manufacturing processes. This involves investigating current production techniques, identifying bottlenecks, and proposing innovative solutions to enhance the material's performance and versatility. Additionally, the research aims to assess the economic viability and environmental impact of increased cellulose acetate usage in the textile industry.

Furthermore, this study seeks to analyze the potential of cellulose acetate in emerging textile applications, such as smart textiles and wearable technology. By examining the material's compatibility with electronic components and its ability to be functionalized, we aim to uncover new avenues for cellulose acetate in high-value textile products.

Market Analysis for Cellulose Acetate Textiles

The market for cellulose acetate textiles has shown significant growth potential in recent years, driven by increasing consumer demand for sustainable and eco-friendly fabric alternatives. As environmental concerns continue to shape consumer preferences, cellulose acetate has emerged as a promising material in the textile industry due to its biodegradability and renewable sourcing.

The global cellulose acetate market size was valued at approximately $3.5 billion in 2020, with the textile segment accounting for a substantial portion of this value. Industry analysts project a compound annual growth rate (CAGR) of around 4% for cellulose acetate in textiles over the next five years, indicating steady market expansion.

One of the key drivers for this growth is the rising awareness of environmental issues associated with synthetic fibers. Cellulose acetate, being derived from natural sources such as wood pulp or cotton linters, offers a more sustainable alternative to petroleum-based synthetic fibers. This aligns well with the growing trend of eco-conscious consumerism, particularly among younger demographics.

The fashion industry, in particular, has shown increased interest in cellulose acetate textiles. Major clothing brands and retailers are incorporating these materials into their product lines to meet consumer demand for sustainable fashion. This trend is expected to continue, potentially leading to a wider adoption of cellulose acetate in mainstream textile manufacturing.

Geographically, Asia-Pacific dominates the cellulose acetate textile market, with China and India being the largest producers and consumers. However, North America and Europe are also significant markets, driven by stringent environmental regulations and a growing emphasis on sustainable materials in these regions.

Despite the positive outlook, challenges remain in the cellulose acetate textile market. The relatively higher production costs compared to conventional synthetic fibers can be a barrier to widespread adoption. Additionally, the limited availability of raw materials and the complex manufacturing process pose challenges to scaling up production to meet increasing demand.

Competition from other sustainable materials, such as recycled polyester and organic cotton, also impacts the market dynamics for cellulose acetate textiles. Manufacturers and brands are continuously evaluating the performance, cost-effectiveness, and environmental impact of various materials to make informed decisions about their product offerings.

In conclusion, the market analysis for cellulose acetate textiles reveals a promising growth trajectory, underpinned by increasing environmental awareness and demand for sustainable materials. As technology advances and production processes improve, cellulose acetate is likely to play an increasingly important role in the future of textile manufacturing.

Current Challenges in Cellulose Acetate Integration

The integration of cellulose acetate in textile manufacturing faces several significant challenges that hinder its widespread adoption. One of the primary obstacles is the complex processing requirements for cellulose acetate fibers. Unlike traditional synthetic fibers, cellulose acetate demands specific temperature and humidity controls during production, which necessitates specialized equipment and expertise. This complexity often leads to increased production costs and potential quality inconsistencies, deterring many manufacturers from incorporating it into their existing production lines.

Another major challenge lies in the material's inherent properties. Cellulose acetate fibers are known for their low moisture regain and limited strength, particularly when wet. These characteristics can result in fabrics that are less comfortable and durable compared to other synthetic or natural fibers. Addressing these limitations often requires additional treatments or blending with other fibers, further complicating the manufacturing process and potentially increasing costs.

The environmental impact of cellulose acetate production also presents a significant hurdle. While the material is derived from natural sources, the acetylation process involves the use of acetic acid and other chemicals, raising concerns about waste management and environmental sustainability. Manufacturers must invest in advanced waste treatment systems and sustainable production methods to mitigate these environmental risks, which can be a substantial financial burden.

Scalability remains a critical challenge in the integration of cellulose acetate. Current production methods are often limited in their capacity to meet the high-volume demands of the textile industry. Scaling up production while maintaining consistent quality and cost-effectiveness is a complex task that requires significant research and development efforts. This scalability issue can lead to supply chain uncertainties and hesitation among larger textile manufacturers to commit to cellulose acetate integration.

Furthermore, the textile industry faces a knowledge gap when it comes to working with cellulose acetate. Many textile professionals are more familiar with traditional fibers and may lack the expertise to effectively handle and process cellulose acetate. This knowledge deficit extends to the design and marketing of cellulose acetate-based products, as the unique properties of the material may require different approaches to fabric design and consumer education.

Lastly, market acceptance poses a challenge to cellulose acetate integration. Despite its potential benefits, cellulose acetate still struggles to compete with well-established synthetic fibers in terms of cost and performance. Convincing manufacturers, designers, and consumers to embrace cellulose acetate-based textiles requires extensive marketing efforts and clear demonstrations of the material's advantages over existing alternatives. Overcoming these market perceptions and establishing a strong value proposition for cellulose acetate in textiles remains a significant hurdle in its widespread adoption.

Existing Integration Methods for Cellulose Acetate

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.- Cellulose acetate production methods: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.

- Cellulose acetate fiber applications: Cellulose acetate fibers are utilized in diverse applications, such as textiles, filters, and packaging materials. The properties of these fibers can be tailored through modifications in the production process or post-treatment to suit specific end-use requirements.

- Cellulose acetate film and membrane technology: Advancements in cellulose acetate film and membrane technology are presented, focusing on improved formulations and manufacturing techniques. These developments enhance the performance of cellulose acetate in applications such as separation processes and packaging.

- Cellulose acetate modifications and derivatives: Research on modifying cellulose acetate or creating new derivatives is discussed. These modifications aim to enhance properties such as biodegradability, thermal stability, or compatibility with other materials for various industrial applications.

- Cellulose acetate in composite materials: The use of cellulose acetate in composite materials is explored, including its incorporation into polymer blends and nanocomposites. These composites often exhibit improved mechanical, thermal, or barrier properties compared to the individual components.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in a wide range of applications, including textiles, filters, and personal care products. The unique properties of these fibers, such as biodegradability and moisture absorption, make them suitable for various industrial and consumer goods.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing techniques and novel applications. These developments enhance the performance of cellulose acetate in areas such as separation processes, packaging, and optical films.Expand Specific Solutions04 Cellulose acetate modifications and blends

Research on modifying cellulose acetate and creating blends with other materials is discussed. These modifications aim to enhance properties such as thermal stability, mechanical strength, and compatibility with other polymers, expanding the potential applications of cellulose acetate-based materials.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable products

The use of cellulose acetate in developing sustainable and biodegradable products is explored. This includes applications in packaging, disposable items, and eco-friendly alternatives to conventional plastics, leveraging the material's inherent biodegradability and renewable sourcing.Expand Specific Solutions

Key Players in Cellulose Acetate Textile Industry

The integration of cellulose acetate in textile manufacturing is in a growth phase, with increasing market size due to rising demand for sustainable and biodegradable materials. The global cellulose acetate market is projected to expand significantly in the coming years. Technologically, the field is moderately mature, with established players like Eastman Chemical Co. and Daicel Corp. leading in production. However, there's ongoing innovation, particularly in application techniques and eco-friendly processing methods. Companies such as Mitsubishi Rayon Textile Co., Ltd. and Toray Industries, Inc. are advancing the technology's integration into textiles. Research institutions like the Institute of Process Engineering, Chinese Academy of Sciences, are contributing to further technological developments, indicating potential for future breakthroughs in this sector.

Daicel Corp.

Eastman Chemical Co.

Innovative Techniques in Cellulose Acetate Processing

- A method involving the reaction of cellulose with acetic anhydride in the presence of an acid catalyst and acetic acid solvent, followed by hydrolysis to adjust the acetylation degree to 52-59%, precipitation in water, and dispersion in a mixed solvent with specific solubility parameters to form cellulose acetate flakes, reducing low-molecular-weight components and enhancing transparency.

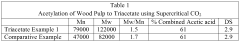

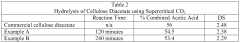

- A two-step process using densified gases, such as supercritical or near-supercritical carbon dioxide, to esterify and de-esterify cellulose in the presence of alternative catalysts like trifluoroacetic acid, eliminating the need for sulfuric acid and reducing sulfate content in the final product.

Environmental Impact of Cellulose Acetate Textiles

The integration of cellulose acetate in textile manufacturing has significant environmental implications that warrant careful consideration. Cellulose acetate, derived from natural cellulose fibers, offers a potentially more sustainable alternative to traditional synthetic materials. However, its environmental impact is complex and multifaceted.

One of the primary environmental advantages of cellulose acetate textiles is their biodegradability. Unlike many synthetic fibers that persist in the environment for centuries, cellulose acetate can decompose within months to years under proper conditions. This characteristic reduces the long-term accumulation of textile waste in landfills and marine environments, potentially mitigating the growing problem of microfiber pollution.

The production process of cellulose acetate also presents both benefits and challenges from an environmental perspective. On the positive side, cellulose acetate is derived from renewable resources, primarily wood pulp or cotton linters. This reduces dependence on petroleum-based raw materials, which are finite and associated with significant environmental impacts during extraction and processing.

However, the manufacturing of cellulose acetate involves the use of chemical solvents, particularly acetic acid and acetone. These chemicals can pose environmental risks if not properly managed. Emissions from the production process may contribute to air and water pollution if adequate control measures are not implemented. Additionally, the energy requirements for cellulose acetate production are considerable, potentially leading to increased carbon emissions depending on the energy sources used.

Water consumption is another critical environmental factor to consider. While cellulose acetate production generally requires less water than cotton cultivation, it still has a significant water footprint. The textile manufacturing process, including dyeing and finishing of cellulose acetate fabrics, can also contribute to water pollution if effluents are not properly treated.

End-of-life considerations for cellulose acetate textiles present both opportunities and challenges. While biodegradability is a key advantage, it is important to note that optimal decomposition often requires specific conditions that may not be present in typical disposal environments. Improper disposal or inadequate waste management systems can limit the potential environmental benefits of biodegradability.

Furthermore, the durability and longevity of cellulose acetate textiles play a role in their overall environmental impact. If these textiles prove less durable than synthetic alternatives, it could lead to increased consumption and waste generation, potentially offsetting some of the environmental benefits.

In conclusion, while cellulose acetate offers promising environmental advantages in textile manufacturing, its integration must be approached holistically. Manufacturers and policymakers need to consider the entire lifecycle of cellulose acetate textiles, from raw material sourcing to end-of-life management, to maximize environmental benefits and mitigate potential negative impacts.

Regulatory Framework for Cellulose Acetate in Textiles

The regulatory framework for cellulose acetate in textiles is a complex and evolving landscape that manufacturers must navigate to ensure compliance and product safety. At the global level, organizations such as the International Organization for Standardization (ISO) and the World Trade Organization (WTO) provide guidelines and standards that influence national regulations. These international bodies often focus on harmonizing standards to facilitate trade while maintaining safety and quality benchmarks.

In the United States, the Consumer Product Safety Commission (CPSC) oversees the safety of textile products, including those containing cellulose acetate. The Federal Trade Commission (FTC) regulates labeling and advertising claims related to textile fibers. The Environmental Protection Agency (EPA) also plays a role in regulating the chemical processes involved in cellulose acetate production and disposal.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of cellulose acetate in textiles. REACH requires manufacturers to register chemicals used in production and provide safety data. Additionally, the EU's General Product Safety Directive (GPSD) sets overarching safety requirements for consumer products, including textiles.

In Asia, countries like China and Japan have their own regulatory bodies and standards. China's GB (Guobiao) standards cover various aspects of textile production and safety, while Japan's Ministry of Health, Labour and Welfare enforces the Japan Industrial Standards (JIS) for textiles.

Environmental regulations are becoming increasingly stringent worldwide, affecting cellulose acetate production and disposal. Many countries are implementing circular economy principles, encouraging the recycling and sustainable use of textile materials. This trend is likely to impact future regulations on cellulose acetate in textiles.

Certification systems, such as OEKO-TEX and GOTS (Global Organic Textile Standard), provide voluntary standards that often exceed regulatory requirements. These certifications are becoming increasingly important in the global textile market, influencing both regulations and consumer expectations.

As sustainability concerns grow, regulations are likely to evolve to address the entire lifecycle of cellulose acetate in textiles, from raw material sourcing to end-of-life management. Manufacturers integrating cellulose acetate into textile production must stay informed about these regulatory developments and adapt their processes accordingly to ensure compliance and market access.