Environmental Impact of PETG Recycling Processes

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PETG Recycling Evolution

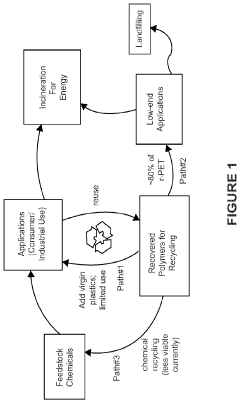

The recycling of PETG (Polyethylene Terephthalate Glycol-modified) has undergone significant evolution since its introduction to the market. Initially, PETG was considered difficult to recycle due to its unique chemical structure, which differs from traditional PET. However, as environmental concerns grew and technological advancements emerged, the recycling processes for PETG have seen substantial improvements.

In the early stages, PETG recycling was limited to mechanical recycling methods, which involved grinding the material into flakes and reprocessing it into new products. This approach, while simple, often resulted in degraded material properties and limited applications for the recycled PETG. The recycled material was primarily used in low-value products, such as packaging fillers or non-food-grade containers.

As technology progressed, more sophisticated recycling techniques were developed. Chemical recycling methods, such as glycolysis and methanolysis, began to gain traction in the mid-2000s. These processes break down PETG into its chemical building blocks, allowing for the production of virgin-quality material. This breakthrough significantly expanded the potential applications for recycled PETG, including its use in food-grade packaging.

The late 2010s saw the emergence of advanced sorting technologies, utilizing near-infrared (NIR) spectroscopy and artificial intelligence. These innovations greatly improved the efficiency of PETG separation from mixed plastic waste streams, addressing one of the major challenges in PETG recycling. Consequently, the purity of recycled PETG increased, leading to higher-quality end products.

In recent years, there has been a growing focus on closed-loop recycling systems for PETG. This approach aims to create a circular economy where PETG products are continuously recycled and reused within the same product category. Several major manufacturers have implemented pilot programs to collect and recycle their PETG products, demonstrating the feasibility of this concept.

The environmental impact of PETG recycling processes has also been a key driver in their evolution. Early recycling methods were energy-intensive and often involved the use of harmful chemicals. However, recent advancements have led to more eco-friendly processes, including the development of bio-based catalysts for chemical recycling and the optimization of mechanical recycling to reduce energy consumption.

Looking ahead, the evolution of PETG recycling is expected to continue, with a focus on improving energy efficiency, reducing water usage, and minimizing chemical waste. Emerging technologies, such as enzymatic recycling and microwave-assisted pyrolysis, show promise in further enhancing the environmental sustainability of PETG recycling processes.

In the early stages, PETG recycling was limited to mechanical recycling methods, which involved grinding the material into flakes and reprocessing it into new products. This approach, while simple, often resulted in degraded material properties and limited applications for the recycled PETG. The recycled material was primarily used in low-value products, such as packaging fillers or non-food-grade containers.

As technology progressed, more sophisticated recycling techniques were developed. Chemical recycling methods, such as glycolysis and methanolysis, began to gain traction in the mid-2000s. These processes break down PETG into its chemical building blocks, allowing for the production of virgin-quality material. This breakthrough significantly expanded the potential applications for recycled PETG, including its use in food-grade packaging.

The late 2010s saw the emergence of advanced sorting technologies, utilizing near-infrared (NIR) spectroscopy and artificial intelligence. These innovations greatly improved the efficiency of PETG separation from mixed plastic waste streams, addressing one of the major challenges in PETG recycling. Consequently, the purity of recycled PETG increased, leading to higher-quality end products.

In recent years, there has been a growing focus on closed-loop recycling systems for PETG. This approach aims to create a circular economy where PETG products are continuously recycled and reused within the same product category. Several major manufacturers have implemented pilot programs to collect and recycle their PETG products, demonstrating the feasibility of this concept.

The environmental impact of PETG recycling processes has also been a key driver in their evolution. Early recycling methods were energy-intensive and often involved the use of harmful chemicals. However, recent advancements have led to more eco-friendly processes, including the development of bio-based catalysts for chemical recycling and the optimization of mechanical recycling to reduce energy consumption.

Looking ahead, the evolution of PETG recycling is expected to continue, with a focus on improving energy efficiency, reducing water usage, and minimizing chemical waste. Emerging technologies, such as enzymatic recycling and microwave-assisted pyrolysis, show promise in further enhancing the environmental sustainability of PETG recycling processes.

Market Demand Analysis

The market demand for PETG recycling processes has been steadily increasing due to growing environmental concerns and regulatory pressures. As consumers become more environmentally conscious, there is a rising demand for sustainable packaging solutions, which has led to an increased focus on recycling PETG (Polyethylene Terephthalate Glycol-modified) materials.

The global PETG market is experiencing significant growth, driven by its widespread use in various industries such as packaging, electronics, and consumer goods. This growth has consequently increased the need for effective recycling processes to manage PETG waste. The packaging industry, in particular, has seen a surge in demand for PETG recycling solutions, as it is one of the largest consumers of this material.

Regulatory bodies worldwide are implementing stricter policies on plastic waste management, which has further boosted the market demand for PETG recycling processes. Many countries have set ambitious targets for plastic recycling rates, creating a favorable environment for the development and adoption of advanced recycling technologies.

The circular economy concept has gained traction in recent years, prompting businesses to seek more sustainable practices. This shift has led to an increased interest in closed-loop recycling systems for PETG, where the material can be recycled multiple times without significant loss of quality. As a result, there is a growing market for recycled PETG resin, which can be used in various applications, including food packaging and beverage bottles.

The automotive and construction industries are also contributing to the rising demand for PETG recycling processes. These sectors are increasingly using PETG in their products due to its durability and lightweight properties. As these industries strive to improve their sustainability credentials, they are actively seeking recycling solutions for PETG components.

The market for PETG recycling equipment and technologies is expanding, with companies investing in research and development to improve recycling efficiency and reduce environmental impact. There is a particular focus on developing processes that can handle mixed plastic waste streams, as this remains a significant challenge in the recycling industry.

Despite the growing demand, there are still barriers to widespread adoption of PETG recycling processes. These include the high costs associated with setting up recycling facilities, the need for advanced sorting technologies, and the challenge of maintaining the quality of recycled PETG. Overcoming these obstacles presents significant market opportunities for innovative companies in the recycling sector.

The global PETG market is experiencing significant growth, driven by its widespread use in various industries such as packaging, electronics, and consumer goods. This growth has consequently increased the need for effective recycling processes to manage PETG waste. The packaging industry, in particular, has seen a surge in demand for PETG recycling solutions, as it is one of the largest consumers of this material.

Regulatory bodies worldwide are implementing stricter policies on plastic waste management, which has further boosted the market demand for PETG recycling processes. Many countries have set ambitious targets for plastic recycling rates, creating a favorable environment for the development and adoption of advanced recycling technologies.

The circular economy concept has gained traction in recent years, prompting businesses to seek more sustainable practices. This shift has led to an increased interest in closed-loop recycling systems for PETG, where the material can be recycled multiple times without significant loss of quality. As a result, there is a growing market for recycled PETG resin, which can be used in various applications, including food packaging and beverage bottles.

The automotive and construction industries are also contributing to the rising demand for PETG recycling processes. These sectors are increasingly using PETG in their products due to its durability and lightweight properties. As these industries strive to improve their sustainability credentials, they are actively seeking recycling solutions for PETG components.

The market for PETG recycling equipment and technologies is expanding, with companies investing in research and development to improve recycling efficiency and reduce environmental impact. There is a particular focus on developing processes that can handle mixed plastic waste streams, as this remains a significant challenge in the recycling industry.

Despite the growing demand, there are still barriers to widespread adoption of PETG recycling processes. These include the high costs associated with setting up recycling facilities, the need for advanced sorting technologies, and the challenge of maintaining the quality of recycled PETG. Overcoming these obstacles presents significant market opportunities for innovative companies in the recycling sector.

Technical Challenges

The recycling of PETG (Polyethylene Terephthalate Glycol-modified) presents several technical challenges that impact its environmental footprint. One of the primary issues is the contamination of PETG waste streams. Unlike PET, PETG often contains additives and modifiers that can complicate the recycling process and potentially introduce harmful substances into the environment if not properly managed.

The separation of PETG from other plastics poses another significant challenge. Due to its similar appearance and properties to PET, PETG can be mistakenly mixed with PET in recycling streams. This contamination can lead to processing difficulties and reduced quality of recycled materials, potentially increasing the environmental burden of the recycling process.

Energy consumption during the recycling process is a notable concern. PETG typically requires higher processing temperatures compared to PET, resulting in increased energy usage and associated greenhouse gas emissions. This higher energy demand can offset some of the environmental benefits gained from recycling.

The degradation of PETG during recycling cycles is another technical hurdle. Each time PETG is recycled, its molecular structure can be compromised, leading to a decrease in mechanical properties and overall quality. This degradation limits the number of times PETG can be effectively recycled, potentially increasing the need for virgin material production and its associated environmental impacts.

Chemical recycling of PETG, while promising, faces its own set of challenges. The process often involves the use of solvents or catalysts that can be environmentally harmful if not properly managed. Ensuring the complete removal of these chemicals from the final recycled product is crucial to prevent environmental contamination.

The production of recycled PETG with consistent quality and properties comparable to virgin material is also challenging. Variations in feedstock quality and the potential presence of contaminants can lead to inconsistencies in the recycled product, limiting its applications and potentially increasing waste if the material does not meet required specifications.

Lastly, the scale-up of PETG recycling processes presents logistical and economic challenges. Developing efficient collection and sorting systems, as well as establishing economically viable recycling facilities, requires significant investment and infrastructure development. These factors can impact the overall environmental benefits of PETG recycling if not carefully managed and optimized.

The separation of PETG from other plastics poses another significant challenge. Due to its similar appearance and properties to PET, PETG can be mistakenly mixed with PET in recycling streams. This contamination can lead to processing difficulties and reduced quality of recycled materials, potentially increasing the environmental burden of the recycling process.

Energy consumption during the recycling process is a notable concern. PETG typically requires higher processing temperatures compared to PET, resulting in increased energy usage and associated greenhouse gas emissions. This higher energy demand can offset some of the environmental benefits gained from recycling.

The degradation of PETG during recycling cycles is another technical hurdle. Each time PETG is recycled, its molecular structure can be compromised, leading to a decrease in mechanical properties and overall quality. This degradation limits the number of times PETG can be effectively recycled, potentially increasing the need for virgin material production and its associated environmental impacts.

Chemical recycling of PETG, while promising, faces its own set of challenges. The process often involves the use of solvents or catalysts that can be environmentally harmful if not properly managed. Ensuring the complete removal of these chemicals from the final recycled product is crucial to prevent environmental contamination.

The production of recycled PETG with consistent quality and properties comparable to virgin material is also challenging. Variations in feedstock quality and the potential presence of contaminants can lead to inconsistencies in the recycled product, limiting its applications and potentially increasing waste if the material does not meet required specifications.

Lastly, the scale-up of PETG recycling processes presents logistical and economic challenges. Developing efficient collection and sorting systems, as well as establishing economically viable recycling facilities, requires significant investment and infrastructure development. These factors can impact the overall environmental benefits of PETG recycling if not carefully managed and optimized.

Current Recycling Methods

01 Chemical recycling processes for PETG

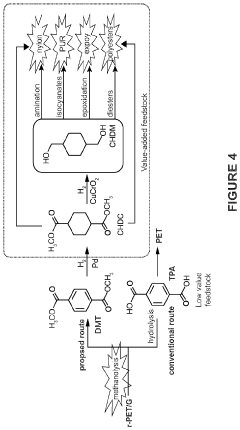

Chemical recycling processes for PETG involve breaking down the polymer into its monomers or other chemical components. These processes can include depolymerization, glycolysis, or solvolysis. The resulting products can be used to create new PETG or other materials, reducing the environmental impact of plastic waste.- Chemical recycling processes for PETG: Chemical recycling processes for PETG involve breaking down the polymer into its monomers or other chemical components. These methods can include depolymerization, solvolysis, or glycolysis. The resulting products can be used to create new PETG or other materials, potentially reducing the environmental impact of plastic waste.

- Mechanical recycling of PETG: Mechanical recycling processes for PETG involve sorting, cleaning, grinding, and reprocessing the material into new products. This method can help reduce the amount of virgin plastic needed and decrease the environmental impact of plastic production. However, the quality of the recycled material may degrade over multiple recycling cycles.

- Energy recovery from PETG waste: Energy recovery processes involve using PETG waste as a fuel source in industrial processes or for electricity generation. While this method can help reduce landfill waste, it may have environmental impacts related to emissions and does not conserve the material resources in the plastic.

- Life cycle assessment of PETG recycling: Life cycle assessments evaluate the environmental impacts of PETG recycling processes from raw material extraction to end-of-life disposal. These studies consider factors such as energy consumption, greenhouse gas emissions, and resource depletion to determine the overall environmental benefits and drawbacks of different recycling methods.

- Innovations in PETG recycling technology: New technologies and innovations are being developed to improve the efficiency and environmental performance of PETG recycling processes. These may include advanced sorting techniques, novel chemical recycling methods, or the integration of recycling processes with other industrial systems to minimize waste and energy consumption.

02 Mechanical recycling of PETG

Mechanical recycling processes for PETG involve shredding, washing, and melting the plastic to create recycled pellets. This method is less energy-intensive than chemical recycling but may result in lower quality recycled material. The environmental impact is reduced through the conservation of raw materials and energy savings compared to virgin PETG production.Expand Specific Solutions03 Energy recovery from PETG waste

Energy recovery processes involve incinerating PETG waste to generate electricity or heat. While this method reduces landfill waste, it has environmental concerns due to emissions. Advanced incineration technologies and proper filtration systems can mitigate some of these impacts, making it a viable option for non-recyclable PETG waste.Expand Specific Solutions04 Life cycle assessment of PETG recycling

Life cycle assessments evaluate the environmental impact of PETG recycling processes from production to disposal. These studies consider factors such as energy consumption, greenhouse gas emissions, and resource depletion. The results help in comparing different recycling methods and optimizing processes to minimize environmental impact.Expand Specific Solutions05 Innovations in PETG recycling technology

Emerging technologies aim to improve the efficiency and environmental performance of PETG recycling. These innovations include advanced sorting techniques, novel chemical recycling catalysts, and bio-based alternatives to traditional PETG. Such advancements can potentially reduce energy consumption, increase recycling rates, and minimize the overall environmental footprint of PETG recycling processes.Expand Specific Solutions

Key Industry Players

The environmental impact of PETG recycling processes is an emerging field with growing market potential. The industry is in its early stages of development, with increasing focus on sustainable solutions. Market size is expanding as more companies and research institutions invest in this area. Technological maturity varies, with some players like revalyu Resources GmbH commercializing breakthrough chemical recycling technologies, while others like Eastman Chemical Co. and Jiangsu Hengli Chemical Fiber Co., Ltd. are leveraging their expertise in chemical manufacturing to develop innovative PETG recycling processes. Academic institutions such as Zhejiang University and the University of North Carolina at Chapel Hill are also contributing to advancements in this field through research collaborations and technological innovations.

revalyu Resources GmbH

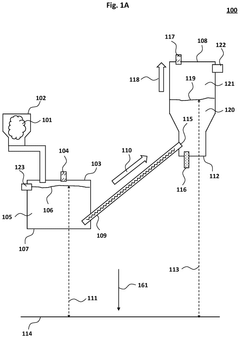

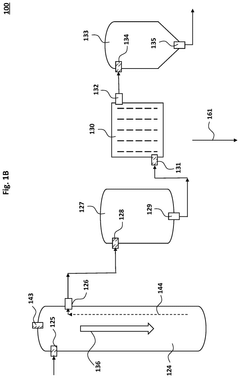

Technical Solution: revalyu Resources GmbH has developed a proprietary chemical recycling process for PET and PETG called "revalyu process". This technology uses a glycolysis-based method to depolymerize PETG into its monomers, primarily bis(2-hydroxyethyl) terephthalate (BHET). The process operates at lower temperatures compared to traditional mechanical recycling, typically around 180-220°C[4]. revalyu's method can handle post-consumer PETG waste, including colored and contaminated materials. The resulting monomers are purified and can be used to produce new PETG or PET with properties equivalent to virgin materials[5]. The company claims that their process reduces CO2 emissions by up to 75% compared to virgin PET production[6].

Strengths: Lower operating temperatures, can handle contaminated PETG, significant CO2 emission reduction. Weaknesses: May require pre-sorting of waste streams, potential challenges in scaling up the technology.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has developed a molecular recycling technology for PETG called "polyester renewal technology" (PRT). This process breaks down PETG into its basic molecular building blocks, which can then be used to create new, virgin-quality materials. The PRT process can handle mixed plastic waste streams, including those containing PETG, PET, and other polyesters[1]. The technology uses methanol to depolymerize the plastic waste at high temperatures and pressures, resulting in raw materials that can be used to produce new plastics with no loss in quality[2]. Eastman claims that this process reduces greenhouse gas emissions by 20-50% compared to processes using fossil feedstocks[3].

Strengths: Can handle mixed plastic waste streams, produces virgin-quality materials, reduces greenhouse gas emissions. Weaknesses: High energy requirements for the depolymerization process, potential methanol recovery and recycling challenges.

Innovative Technologies

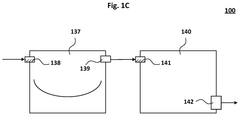

Methods for chemical recycling of condensation polymers

PatentPendingUS20240182665A1

Innovation

- A method involving melt-processing a condensation polymer with an internal catalyst to increase its amorphous content, followed by depolymerization in a reactive solvent, which enhances the efficiency and rate of the depolymerization process, allowing for the production of monomers that can be reused as chemical feedstocks.

Process for recycling polyethylene terephthalate using porous particulated filter material

PatentPendingUS20250171611A1

Innovation

- A method for producing PET oligomers from PET flakes, involving steps such as contacting PET with an organic compound to reduce the weight average molar mass, using particulated material for filtration, and optimizing conditions like temperature and pressure to enhance purity and throughput.

Environmental Regulations

Environmental regulations play a crucial role in shaping the landscape of PETG recycling processes and their environmental impact. These regulations are designed to minimize the negative effects of recycling activities on the environment while promoting sustainable practices in the industry.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal sets guidelines for the management of plastic waste, including PETG. This convention aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries. It also establishes a framework for environmentally sound management of plastic waste.

In the European Union, the Waste Framework Directive (2008/98/EC) provides a comprehensive approach to waste management, including plastic recycling. This directive emphasizes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. The EU Plastics Strategy, introduced in 2018, further reinforces the commitment to circular economy principles in plastic management, setting targets for recycling and promoting the use of recycled plastics.

The United States Environmental Protection Agency (EPA) regulates plastic recycling under the Resource Conservation and Recovery Act (RCRA). This act establishes standards for the management of hazardous and non-hazardous solid waste, including plastic materials like PETG. Additionally, individual states may have their own regulations that complement or exceed federal standards.

In Asia, countries like China and Japan have implemented stringent regulations on plastic waste imports and recycling. China's National Sword policy, introduced in 2018, significantly restricted the import of plastic waste, forcing many countries to reassess their recycling strategies and invest in domestic recycling infrastructure.

Environmental regulations also address specific aspects of the PETG recycling process. For instance, air quality regulations control emissions from recycling facilities, while water quality standards govern the discharge of wastewater from cleaning and processing operations. Occupational health and safety regulations ensure that workers in recycling facilities are protected from potential hazards associated with the recycling process.

As the environmental impact of plastic waste becomes increasingly apparent, many jurisdictions are implementing Extended Producer Responsibility (EPR) programs. These programs shift the responsibility for the entire lifecycle of plastic products, including their recycling and disposal, onto manufacturers. This approach incentivizes the development of more easily recyclable products and the establishment of efficient recycling systems.

The evolving nature of environmental regulations reflects the growing awareness of the environmental challenges posed by plastic waste. As research continues to reveal the complexities of PETG recycling and its environmental impact, it is likely that regulations will become more stringent and comprehensive, driving innovation in recycling technologies and promoting more sustainable practices in the plastic industry.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal sets guidelines for the management of plastic waste, including PETG. This convention aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries. It also establishes a framework for environmentally sound management of plastic waste.

In the European Union, the Waste Framework Directive (2008/98/EC) provides a comprehensive approach to waste management, including plastic recycling. This directive emphasizes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. The EU Plastics Strategy, introduced in 2018, further reinforces the commitment to circular economy principles in plastic management, setting targets for recycling and promoting the use of recycled plastics.

The United States Environmental Protection Agency (EPA) regulates plastic recycling under the Resource Conservation and Recovery Act (RCRA). This act establishes standards for the management of hazardous and non-hazardous solid waste, including plastic materials like PETG. Additionally, individual states may have their own regulations that complement or exceed federal standards.

In Asia, countries like China and Japan have implemented stringent regulations on plastic waste imports and recycling. China's National Sword policy, introduced in 2018, significantly restricted the import of plastic waste, forcing many countries to reassess their recycling strategies and invest in domestic recycling infrastructure.

Environmental regulations also address specific aspects of the PETG recycling process. For instance, air quality regulations control emissions from recycling facilities, while water quality standards govern the discharge of wastewater from cleaning and processing operations. Occupational health and safety regulations ensure that workers in recycling facilities are protected from potential hazards associated with the recycling process.

As the environmental impact of plastic waste becomes increasingly apparent, many jurisdictions are implementing Extended Producer Responsibility (EPR) programs. These programs shift the responsibility for the entire lifecycle of plastic products, including their recycling and disposal, onto manufacturers. This approach incentivizes the development of more easily recyclable products and the establishment of efficient recycling systems.

The evolving nature of environmental regulations reflects the growing awareness of the environmental challenges posed by plastic waste. As research continues to reveal the complexities of PETG recycling and its environmental impact, it is likely that regulations will become more stringent and comprehensive, driving innovation in recycling technologies and promoting more sustainable practices in the plastic industry.

Life Cycle Assessment

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of PETG recycling processes. This comprehensive approach examines the entire lifecycle of PETG products, from raw material extraction to final disposal or recycling. The assessment typically includes four main stages: raw material acquisition, manufacturing, use, and end-of-life.

In the context of PETG recycling, the LCA focuses primarily on the end-of-life stage and the potential for creating new products from recycled materials. The process begins with the collection and sorting of PETG waste, followed by cleaning, grinding, and reprocessing into new products or materials. Each step in this process has associated environmental impacts, including energy consumption, water usage, and emissions.

One of the key benefits of PETG recycling is the reduction in virgin material production. By reusing existing PETG, the demand for new petroleum-based raw materials decreases, leading to lower energy consumption and greenhouse gas emissions associated with extraction and processing. However, the recycling process itself requires energy and resources, which must be factored into the overall environmental impact assessment.

Water usage is another critical factor in the LCA of PETG recycling. The cleaning and processing stages often require significant amounts of water, which can strain local water resources. Additionally, the potential for water pollution from cleaning agents and contaminants removed from the PETG waste must be considered and mitigated.

Emissions from the recycling process, including air pollutants and greenhouse gases, are also important components of the LCA. These emissions can result from transportation of waste materials, energy use in processing facilities, and any chemical treatments applied during the recycling process. Comparing these emissions to those generated in the production of virgin PETG is essential for determining the net environmental benefit of recycling.

The LCA also considers the quality and usability of recycled PETG compared to virgin material. In some cases, recycled PETG may have reduced mechanical properties or aesthetic qualities, potentially limiting its applications. This could lead to a shorter lifespan for products made from recycled PETG, which would impact the overall environmental assessment.

Finally, the LCA must account for the potential for multiple recycling cycles. PETG can typically be recycled several times before its quality degrades significantly, but each cycle may require additional energy and resources. Understanding the optimal number of recycling cycles and the cumulative environmental impact over multiple uses is crucial for a comprehensive assessment of PETG recycling processes.

In the context of PETG recycling, the LCA focuses primarily on the end-of-life stage and the potential for creating new products from recycled materials. The process begins with the collection and sorting of PETG waste, followed by cleaning, grinding, and reprocessing into new products or materials. Each step in this process has associated environmental impacts, including energy consumption, water usage, and emissions.

One of the key benefits of PETG recycling is the reduction in virgin material production. By reusing existing PETG, the demand for new petroleum-based raw materials decreases, leading to lower energy consumption and greenhouse gas emissions associated with extraction and processing. However, the recycling process itself requires energy and resources, which must be factored into the overall environmental impact assessment.

Water usage is another critical factor in the LCA of PETG recycling. The cleaning and processing stages often require significant amounts of water, which can strain local water resources. Additionally, the potential for water pollution from cleaning agents and contaminants removed from the PETG waste must be considered and mitigated.

Emissions from the recycling process, including air pollutants and greenhouse gases, are also important components of the LCA. These emissions can result from transportation of waste materials, energy use in processing facilities, and any chemical treatments applied during the recycling process. Comparing these emissions to those generated in the production of virgin PETG is essential for determining the net environmental benefit of recycling.

The LCA also considers the quality and usability of recycled PETG compared to virgin material. In some cases, recycled PETG may have reduced mechanical properties or aesthetic qualities, potentially limiting its applications. This could lead to a shorter lifespan for products made from recycled PETG, which would impact the overall environmental assessment.

Finally, the LCA must account for the potential for multiple recycling cycles. PETG can typically be recycled several times before its quality degrades significantly, but each cycle may require additional energy and resources. Understanding the optimal number of recycling cycles and the cumulative environmental impact over multiple uses is crucial for a comprehensive assessment of PETG recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!