Isocyanate Alternatives: Exploring Bio-Based Options

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Isocyanate Alternatives: Background and Objectives

Isocyanates have long been a cornerstone in the production of polyurethanes, widely used in various industries due to their versatile properties. However, growing concerns over their toxicity and environmental impact have sparked a global search for sustainable alternatives. The exploration of bio-based alternatives to isocyanates represents a significant shift towards more eco-friendly and safer materials in the chemical industry.

The development of isocyanates dates back to the 1930s, with their commercial production beginning in the 1950s. Since then, they have become integral to the manufacture of foams, coatings, adhesives, and elastomers. The global polyurethane market, heavily reliant on isocyanates, was valued at approximately $70 billion in 2020 and is projected to grow substantially in the coming years.

However, the health and environmental risks associated with isocyanates have become increasingly apparent. Exposure to these chemicals can cause respiratory issues, skin irritation, and in some cases, severe allergic reactions. Moreover, the production of isocyanates often involves the use of fossil fuel-based raw materials, contributing to carbon emissions and environmental degradation.

In response to these challenges, researchers and industry leaders have intensified efforts to develop bio-based alternatives. These alternatives aim to maintain or improve upon the performance characteristics of traditional isocyanates while mitigating their negative impacts. The primary objectives of this technological shift include reducing dependency on petroleum-based resources, lowering the carbon footprint of polyurethane production, and enhancing worker safety in manufacturing processes.

Bio-based alternatives to isocyanates are derived from renewable resources such as vegetable oils, sugars, and lignin. These materials offer the potential for biodegradability and reduced toxicity, aligning with the principles of green chemistry and sustainable development. The evolution of these alternatives is closely tied to advancements in biotechnology, polymer science, and process engineering.

The pursuit of bio-based isocyanate alternatives is driven by a combination of regulatory pressures, consumer demand for sustainable products, and corporate sustainability initiatives. As global environmental regulations become more stringent, industries are compelled to seek out greener alternatives to traditional chemical processes. This technological transition represents not only a challenge but also an opportunity for innovation and market differentiation in the polymer and materials science sectors.

The development of isocyanates dates back to the 1930s, with their commercial production beginning in the 1950s. Since then, they have become integral to the manufacture of foams, coatings, adhesives, and elastomers. The global polyurethane market, heavily reliant on isocyanates, was valued at approximately $70 billion in 2020 and is projected to grow substantially in the coming years.

However, the health and environmental risks associated with isocyanates have become increasingly apparent. Exposure to these chemicals can cause respiratory issues, skin irritation, and in some cases, severe allergic reactions. Moreover, the production of isocyanates often involves the use of fossil fuel-based raw materials, contributing to carbon emissions and environmental degradation.

In response to these challenges, researchers and industry leaders have intensified efforts to develop bio-based alternatives. These alternatives aim to maintain or improve upon the performance characteristics of traditional isocyanates while mitigating their negative impacts. The primary objectives of this technological shift include reducing dependency on petroleum-based resources, lowering the carbon footprint of polyurethane production, and enhancing worker safety in manufacturing processes.

Bio-based alternatives to isocyanates are derived from renewable resources such as vegetable oils, sugars, and lignin. These materials offer the potential for biodegradability and reduced toxicity, aligning with the principles of green chemistry and sustainable development. The evolution of these alternatives is closely tied to advancements in biotechnology, polymer science, and process engineering.

The pursuit of bio-based isocyanate alternatives is driven by a combination of regulatory pressures, consumer demand for sustainable products, and corporate sustainability initiatives. As global environmental regulations become more stringent, industries are compelled to seek out greener alternatives to traditional chemical processes. This technological transition represents not only a challenge but also an opportunity for innovation and market differentiation in the polymer and materials science sectors.

Market Demand Analysis for Sustainable Polyurethanes

The market demand for sustainable polyurethanes has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations on conventional isocyanate-based polyurethanes. This shift is particularly evident in industries such as construction, automotive, and furniture manufacturing, where there is a pressing need for eco-friendly alternatives.

Consumer awareness regarding the environmental impact of products has led to a surge in demand for bio-based materials. Sustainable polyurethanes, derived from renewable resources, are gaining traction as they offer reduced carbon footprint and lower toxicity compared to their petroleum-based counterparts. This trend is further reinforced by government initiatives and corporate sustainability goals, which are pushing industries to adopt greener alternatives.

The construction sector represents a significant market for sustainable polyurethanes, with applications in insulation, sealants, and coatings. The global green building market is projected to continue its robust growth, creating substantial opportunities for bio-based polyurethane products. Similarly, the automotive industry is increasingly incorporating sustainable materials to reduce vehicle weight and improve fuel efficiency, presenting another key market for these innovative materials.

Furniture and bedding manufacturers are also turning to sustainable polyurethanes to meet consumer demands for eco-friendly products. The growing popularity of "green" furniture and the emphasis on indoor air quality have created a niche market for bio-based foams and adhesives.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sustainable polyurethanes market. This is attributed to rapid industrialization, increasing disposable income, and stringent environmental regulations in countries like China and India. North America and Europe continue to be significant markets, driven by established environmental policies and consumer preferences for sustainable products.

Despite the positive outlook, challenges remain in the widespread adoption of sustainable polyurethanes. These include higher production costs compared to conventional polyurethanes and the need for further technological advancements to match the performance characteristics of isocyanate-based products. However, ongoing research and development efforts are addressing these issues, potentially leading to more cost-effective and high-performance bio-based alternatives.

The market for sustainable polyurethanes is expected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in double digits. This growth is underpinned by the increasing focus on circular economy principles and the push towards reducing dependence on fossil-based raw materials across various industries.

Consumer awareness regarding the environmental impact of products has led to a surge in demand for bio-based materials. Sustainable polyurethanes, derived from renewable resources, are gaining traction as they offer reduced carbon footprint and lower toxicity compared to their petroleum-based counterparts. This trend is further reinforced by government initiatives and corporate sustainability goals, which are pushing industries to adopt greener alternatives.

The construction sector represents a significant market for sustainable polyurethanes, with applications in insulation, sealants, and coatings. The global green building market is projected to continue its robust growth, creating substantial opportunities for bio-based polyurethane products. Similarly, the automotive industry is increasingly incorporating sustainable materials to reduce vehicle weight and improve fuel efficiency, presenting another key market for these innovative materials.

Furniture and bedding manufacturers are also turning to sustainable polyurethanes to meet consumer demands for eco-friendly products. The growing popularity of "green" furniture and the emphasis on indoor air quality have created a niche market for bio-based foams and adhesives.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the sustainable polyurethanes market. This is attributed to rapid industrialization, increasing disposable income, and stringent environmental regulations in countries like China and India. North America and Europe continue to be significant markets, driven by established environmental policies and consumer preferences for sustainable products.

Despite the positive outlook, challenges remain in the widespread adoption of sustainable polyurethanes. These include higher production costs compared to conventional polyurethanes and the need for further technological advancements to match the performance characteristics of isocyanate-based products. However, ongoing research and development efforts are addressing these issues, potentially leading to more cost-effective and high-performance bio-based alternatives.

The market for sustainable polyurethanes is expected to grow substantially in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) in double digits. This growth is underpinned by the increasing focus on circular economy principles and the push towards reducing dependence on fossil-based raw materials across various industries.

Current State and Challenges in Bio-based Isocyanate Substitutes

The current state of bio-based alternatives to isocyanates is characterized by significant progress, yet substantial challenges remain. Researchers and industry players have made considerable strides in developing sustainable substitutes, driven by increasing environmental concerns and regulatory pressures surrounding traditional isocyanates.

One of the primary advancements in this field is the development of bio-based polyols, which serve as key components in polyurethane production. These polyols, derived from renewable sources such as vegetable oils, have shown promising results in terms of performance and sustainability. However, their widespread adoption faces challenges related to cost-effectiveness and scalability.

Another area of focus has been the exploration of non-isocyanate polyurethanes (NIPUs). These materials, synthesized through alternative chemical pathways, offer the potential to eliminate the use of isocyanates entirely. While NIPUs have demonstrated favorable properties in certain applications, they still struggle to match the versatility and performance of traditional isocyanate-based polyurethanes across all use cases.

The development of bio-based crosslinkers and chain extenders represents another significant advancement. These components, derived from natural sources, aim to replace petrochemical-based alternatives in polyurethane formulations. However, achieving consistent quality and performance comparable to conventional materials remains a challenge.

A major hurdle in the widespread adoption of bio-based isocyanate substitutes is the need for extensive reformulation and process modifications in existing manufacturing setups. This requirement often leads to hesitation among industry players due to the associated costs and potential disruptions to established production lines.

Furthermore, the variability in the quality and composition of bio-based raw materials poses challenges in maintaining consistent product performance. This issue is particularly pronounced when scaling up production from laboratory to industrial levels.

Regulatory frameworks and standards for bio-based alternatives are still evolving, creating uncertainty for manufacturers and potentially slowing down market adoption. The lack of standardized testing methods and performance criteria specific to these new materials further complicates their integration into existing supply chains and applications.

Despite these challenges, ongoing research and development efforts continue to push the boundaries of bio-based isocyanate substitutes. Collaborations between academic institutions and industry partners are driving innovation in this field, with a focus on improving material properties, reducing costs, and enhancing overall sustainability profiles.

One of the primary advancements in this field is the development of bio-based polyols, which serve as key components in polyurethane production. These polyols, derived from renewable sources such as vegetable oils, have shown promising results in terms of performance and sustainability. However, their widespread adoption faces challenges related to cost-effectiveness and scalability.

Another area of focus has been the exploration of non-isocyanate polyurethanes (NIPUs). These materials, synthesized through alternative chemical pathways, offer the potential to eliminate the use of isocyanates entirely. While NIPUs have demonstrated favorable properties in certain applications, they still struggle to match the versatility and performance of traditional isocyanate-based polyurethanes across all use cases.

The development of bio-based crosslinkers and chain extenders represents another significant advancement. These components, derived from natural sources, aim to replace petrochemical-based alternatives in polyurethane formulations. However, achieving consistent quality and performance comparable to conventional materials remains a challenge.

A major hurdle in the widespread adoption of bio-based isocyanate substitutes is the need for extensive reformulation and process modifications in existing manufacturing setups. This requirement often leads to hesitation among industry players due to the associated costs and potential disruptions to established production lines.

Furthermore, the variability in the quality and composition of bio-based raw materials poses challenges in maintaining consistent product performance. This issue is particularly pronounced when scaling up production from laboratory to industrial levels.

Regulatory frameworks and standards for bio-based alternatives are still evolving, creating uncertainty for manufacturers and potentially slowing down market adoption. The lack of standardized testing methods and performance criteria specific to these new materials further complicates their integration into existing supply chains and applications.

Despite these challenges, ongoing research and development efforts continue to push the boundaries of bio-based isocyanate substitutes. Collaborations between academic institutions and industry partners are driving innovation in this field, with a focus on improving material properties, reducing costs, and enhancing overall sustainability profiles.

Existing Bio-based Isocyanate-free Solutions

01 Non-isocyanate polyurethane alternatives

Development of non-isocyanate polyurethane (NIPU) alternatives that offer similar properties to traditional polyurethanes without the use of isocyanates. These alternatives often involve the reaction of cyclic carbonates with amines or the use of bio-based materials to create polyurethane-like polymers.- Non-isocyanate polyurethane alternatives: Development of non-isocyanate polyurethane (NIPU) technologies as alternatives to traditional isocyanate-based polyurethanes. These alternatives often involve the use of cyclic carbonates and amines, offering improved safety and environmental profiles while maintaining desirable material properties.

- Bio-based alternatives to isocyanates: Exploration of bio-based materials as substitutes for isocyanates in various applications. These alternatives often utilize renewable resources such as plant-derived oils or carbohydrates, offering more sustainable and environmentally friendly options for polyurethane production.

- Isocyanate-free adhesive and coating systems: Development of adhesive and coating formulations that do not rely on isocyanates. These alternatives may include epoxy-based systems, silane-terminated polymers, or other chemistries that provide similar performance characteristics without the associated health and safety concerns of isocyanates.

- Low-VOC and low-toxicity isocyanate replacements: Research into alternative compounds and formulations that offer low volatile organic compound (VOC) emissions and reduced toxicity compared to traditional isocyanates. These alternatives aim to address environmental and health concerns while maintaining the desired performance in various applications.

- Isocyanate alternatives in foam production: Investigation of alternative blowing agents and chemical systems for foam production that do not rely on isocyanates. These alternatives may include physical blowing agents, water-blown systems, or novel chemical reactions that produce foam structures without the use of isocyanates.

02 Epoxy-based alternatives

Utilization of epoxy-based systems as alternatives to isocyanate-containing formulations. These systems can provide similar performance characteristics while avoiding the health and environmental concerns associated with isocyanates.Expand Specific Solutions03 Silane-terminated polymers

Development of silane-terminated polymers as isocyanate alternatives. These polymers can offer comparable adhesive and sealant properties while being less reactive and potentially safer to handle than isocyanate-based systems.Expand Specific Solutions04 Bio-based alternatives

Exploration of bio-based materials and renewable resources to create isocyanate-free polymers. This approach focuses on developing sustainable alternatives that can replace traditional isocyanate-based products in various applications.Expand Specific Solutions05 Hybrid systems

Development of hybrid systems that combine different chemistries to achieve properties similar to isocyanate-based products. These systems may incorporate a combination of alternative technologies to meet specific performance requirements while avoiding the use of isocyanates.Expand Specific Solutions

Key Players in Bio-based Polyurethane Industry

The exploration of bio-based alternatives to isocyanates is in a transitional phase, with the market showing significant growth potential. The global push for sustainable and environmentally friendly materials is driving research and development in this field. Companies like Gevo, Inc., DuPont de Nemours, Inc., and Covestro Deutschland AG are at the forefront of this technology, leveraging their expertise in renewable chemicals and materials science. The market size is expanding, fueled by increasing demand in various industries, including automotive, construction, and consumer goods. While the technology is advancing rapidly, it is not yet fully mature, with ongoing efforts to improve performance, cost-effectiveness, and scalability. Collaboration between academic institutions like Rutgers State University and industry leaders is accelerating progress in this area.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed bio-based alternatives to isocyanates using renewable resources. Their approach involves the synthesis of non-isocyanate polyurethanes (NIPUs) from vegetable oils and other bio-based feedstocks. The company has patented a process for producing polyurethanes from bio-based cyclic carbonates and diamines, which react to form urethane linkages without the use of isocyanates[1]. This technology allows for the production of polyurethanes with comparable properties to traditional isocyanate-based materials while reducing environmental impact and improving worker safety[2]. DuPont's bio-based alternatives have found applications in coatings, adhesives, and elastomers, demonstrating performance characteristics similar to conventional polyurethanes[3].

Strengths: Renewable feedstocks, reduced environmental impact, improved worker safety. Weaknesses: Potentially higher production costs, limited commercial scale production experience.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant strides in developing bio-based alternatives to isocyanates, focusing on sustainable polyurethane technologies. The company has introduced a series of bio-based polyols derived from natural oils and agricultural by-products, which serve as key components in their eco-friendly polyurethane systems[10]. Wanhua's approach includes the development of non-isocyanate polyurethanes (NIPUs) using cyclic carbonates and bio-based amines, resulting in materials with reduced environmental impact and improved safety profiles[11]. Their bio-based alternatives have found applications in various sectors, including construction, automotive, and furniture industries, offering comparable performance to traditional isocyanate-based polyurethanes while meeting increasingly stringent environmental regulations[12].

Strengths: Diverse application range, compliance with environmental regulations, utilization of agricultural by-products. Weaknesses: Potential challenges in achieving cost parity with traditional isocyanates, need for market education on new technologies.

Core Innovations in Non-isocyanate Polyurethanes

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

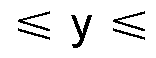

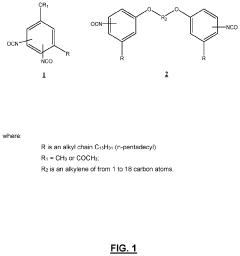

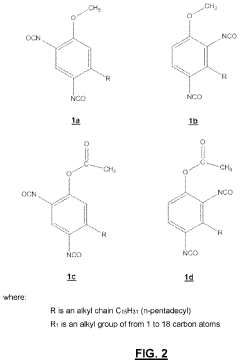

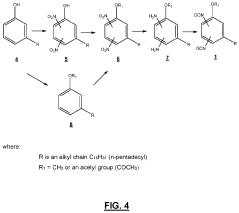

Biobased diisocyanates, and process for preparation of same

PatentInactiveUS20220356150A1

Innovation

- Development of biobased diisocyanates derived from Cardanol or Hydrogenated Cardanol, which are analogous in structure to TDI and MDI, using a process involving nitration, reduction, and phosgenation steps, with additional steps for protecting phenolic groups through methylation, acetylation, or etherification to produce aromatic and bis-aromatic diisocyanates.

Environmental Impact and Life Cycle Assessment

The environmental impact and life cycle assessment of bio-based alternatives to isocyanates is a critical aspect of their development and potential adoption. These assessments provide valuable insights into the sustainability and ecological footprint of these alternatives throughout their entire lifecycle, from raw material extraction to end-of-life disposal.

Bio-based alternatives to isocyanates generally demonstrate a lower environmental impact compared to their petrochemical counterparts. The primary reason for this is the renewable nature of their feedstocks, which often include plant-based materials such as vegetable oils, lignin, or cellulose. These raw materials have the potential to reduce greenhouse gas emissions and decrease dependence on fossil resources.

Life cycle assessments (LCAs) of bio-based alternatives typically show reduced carbon footprints and lower energy consumption during production. For instance, studies have indicated that some bio-based polyurethanes can achieve up to 30-50% reduction in carbon dioxide emissions compared to conventional isocyanate-based polyurethanes. This reduction is primarily attributed to the carbon sequestration that occurs during the growth of the biomass used as feedstock.

However, it is essential to consider the entire life cycle of these alternatives, including agricultural practices, land use changes, and potential competition with food crops. Sustainable sourcing of bio-based raw materials is crucial to ensure that the environmental benefits are not offset by negative impacts on biodiversity or food security. Additionally, the use of genetically modified crops or intensive farming practices may raise concerns about long-term ecological effects.

Water consumption and eutrophication potential are other important factors to consider in the environmental assessment of bio-based alternatives. While some bio-based processes may require less water than petrochemical routes, others might have higher water demands, particularly if irrigation is necessary for feedstock cultivation. Careful management of water resources and implementation of efficient agricultural practices are essential to mitigate these impacts.

End-of-life considerations also play a significant role in the overall environmental impact of bio-based alternatives. Many bio-based materials offer improved biodegradability or compostability compared to traditional isocyanate-based products. This characteristic can lead to reduced waste accumulation and lower environmental persistence of the materials after disposal.

It is important to note that the environmental benefits of bio-based alternatives can vary significantly depending on the specific feedstock, production process, and end-use application. Comprehensive LCAs that consider regional factors, such as local energy mixes and agricultural practices, are necessary to accurately assess the environmental performance of these alternatives in different contexts.

Bio-based alternatives to isocyanates generally demonstrate a lower environmental impact compared to their petrochemical counterparts. The primary reason for this is the renewable nature of their feedstocks, which often include plant-based materials such as vegetable oils, lignin, or cellulose. These raw materials have the potential to reduce greenhouse gas emissions and decrease dependence on fossil resources.

Life cycle assessments (LCAs) of bio-based alternatives typically show reduced carbon footprints and lower energy consumption during production. For instance, studies have indicated that some bio-based polyurethanes can achieve up to 30-50% reduction in carbon dioxide emissions compared to conventional isocyanate-based polyurethanes. This reduction is primarily attributed to the carbon sequestration that occurs during the growth of the biomass used as feedstock.

However, it is essential to consider the entire life cycle of these alternatives, including agricultural practices, land use changes, and potential competition with food crops. Sustainable sourcing of bio-based raw materials is crucial to ensure that the environmental benefits are not offset by negative impacts on biodiversity or food security. Additionally, the use of genetically modified crops or intensive farming practices may raise concerns about long-term ecological effects.

Water consumption and eutrophication potential are other important factors to consider in the environmental assessment of bio-based alternatives. While some bio-based processes may require less water than petrochemical routes, others might have higher water demands, particularly if irrigation is necessary for feedstock cultivation. Careful management of water resources and implementation of efficient agricultural practices are essential to mitigate these impacts.

End-of-life considerations also play a significant role in the overall environmental impact of bio-based alternatives. Many bio-based materials offer improved biodegradability or compostability compared to traditional isocyanate-based products. This characteristic can lead to reduced waste accumulation and lower environmental persistence of the materials after disposal.

It is important to note that the environmental benefits of bio-based alternatives can vary significantly depending on the specific feedstock, production process, and end-use application. Comprehensive LCAs that consider regional factors, such as local energy mixes and agricultural practices, are necessary to accurately assess the environmental performance of these alternatives in different contexts.

Regulatory Framework for Bio-based Materials

The regulatory framework for bio-based materials plays a crucial role in shaping the development and adoption of alternatives to isocyanates. As the global push for sustainability intensifies, governments and regulatory bodies are increasingly focusing on promoting bio-based materials and reducing reliance on petrochemical-derived products.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical safety and environmental protection. Under REACH, bio-based alternatives to isocyanates may benefit from a more favorable regulatory environment, as they are often considered less hazardous and more environmentally friendly. The EU's Bioeconomy Strategy further supports the development and commercialization of bio-based materials, providing incentives for research and innovation in this field.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). The EPA has shown increased interest in promoting safer alternatives to traditional chemicals, which could potentially benefit bio-based isocyanate replacements. Additionally, the USDA BioPreferred Program encourages the purchase and use of bio-based products, potentially creating market opportunities for bio-based alternatives to isocyanates.

Many countries have implemented or are developing regulations to reduce volatile organic compound (VOC) emissions, which could indirectly promote the adoption of bio-based alternatives to isocyanates in various applications, such as coatings and adhesives. These regulations often set limits on VOC content and emissions, encouraging manufacturers to seek more environmentally friendly options.

The regulatory landscape also includes standards and certifications for bio-based materials. For instance, the European Committee for Standardization (CEN) has developed standards for bio-based products, including methods for determining bio-based content. These standards provide a framework for assessing and verifying the environmental claims of bio-based alternatives to isocyanates.

As the field of bio-based materials continues to evolve, regulatory frameworks are likely to adapt and expand. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and circular economy principles, potentially creating additional incentives for the development and adoption of bio-based alternatives to isocyanates. However, manufacturers and researchers must remain vigilant in ensuring that new bio-based materials meet or exceed the performance and safety standards of their petrochemical counterparts to gain regulatory approval and market acceptance.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical safety and environmental protection. Under REACH, bio-based alternatives to isocyanates may benefit from a more favorable regulatory environment, as they are often considered less hazardous and more environmentally friendly. The EU's Bioeconomy Strategy further supports the development and commercialization of bio-based materials, providing incentives for research and innovation in this field.

In the United States, the Environmental Protection Agency (EPA) regulates chemicals under the Toxic Substances Control Act (TSCA). The EPA has shown increased interest in promoting safer alternatives to traditional chemicals, which could potentially benefit bio-based isocyanate replacements. Additionally, the USDA BioPreferred Program encourages the purchase and use of bio-based products, potentially creating market opportunities for bio-based alternatives to isocyanates.

Many countries have implemented or are developing regulations to reduce volatile organic compound (VOC) emissions, which could indirectly promote the adoption of bio-based alternatives to isocyanates in various applications, such as coatings and adhesives. These regulations often set limits on VOC content and emissions, encouraging manufacturers to seek more environmentally friendly options.

The regulatory landscape also includes standards and certifications for bio-based materials. For instance, the European Committee for Standardization (CEN) has developed standards for bio-based products, including methods for determining bio-based content. These standards provide a framework for assessing and verifying the environmental claims of bio-based alternatives to isocyanates.

As the field of bio-based materials continues to evolve, regulatory frameworks are likely to adapt and expand. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and circular economy principles, potentially creating additional incentives for the development and adoption of bio-based alternatives to isocyanates. However, manufacturers and researchers must remain vigilant in ensuring that new bio-based materials meet or exceed the performance and safety standards of their petrochemical counterparts to gain regulatory approval and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!