Exploring Magnetron Life Expectancy Through Aged Testing

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1920s by Albert Hull at General Electric Research Laboratory. Initially developed as a high-power vacuum tube for generating microwaves, magnetrons gained prominence during World War II when they were crucial components in radar systems. The technology has since transitioned into commercial applications, with microwave ovens representing the most widespread consumer use since the 1970s. Today, magnetrons are essential components in various industrial heating processes, medical equipment, and scientific research instruments.

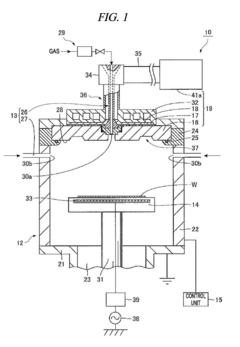

The fundamental operating principle of magnetrons involves electrons moving in a magnetic field to generate microwave radiation. This process occurs within a vacuum chamber where electrons emitted from a heated cathode are influenced by perpendicular electric and magnetic fields, causing them to follow a spiral path and produce microwave frequency oscillations. This elegant physical mechanism has remained largely unchanged, though manufacturing techniques and materials have advanced considerably.

Current technological trends in magnetron development focus on enhancing energy efficiency, extending operational lifespan, and improving power output stability. These advancements are driven by increasing demands for reliability in critical applications and the need for more sustainable electronic components. The industry has witnessed a gradual shift from traditional copper-based magnetrons to models incorporating advanced ceramic materials and precision-engineered resonant cavities.

The primary objective of exploring magnetron life expectancy through aged testing is to establish reliable predictive models for magnetron failure patterns. This research aims to identify the key degradation mechanisms that occur during extended operation and quantify their impact on performance metrics. By understanding these patterns, manufacturers can develop more durable designs and implement preventive maintenance protocols that optimize device longevity while maintaining consistent performance parameters.

Additionally, this research seeks to standardize testing methodologies for magnetron life assessment, as current industry practices vary significantly. Establishing uniform accelerated aging protocols would enable more accurate comparisons between different magnetron designs and manufacturing techniques. The ultimate goal is to develop a comprehensive framework that correlates laboratory aging tests with real-world performance, allowing for more precise lifetime predictions across diverse operating environments.

The technological objectives extend beyond mere lifespan extension to include the development of self-diagnostic capabilities that can predict impending failures before they occur. This predictive maintenance approach would significantly enhance reliability in critical applications such as medical equipment and industrial processing systems where unexpected downtime carries substantial costs.

The fundamental operating principle of magnetrons involves electrons moving in a magnetic field to generate microwave radiation. This process occurs within a vacuum chamber where electrons emitted from a heated cathode are influenced by perpendicular electric and magnetic fields, causing them to follow a spiral path and produce microwave frequency oscillations. This elegant physical mechanism has remained largely unchanged, though manufacturing techniques and materials have advanced considerably.

Current technological trends in magnetron development focus on enhancing energy efficiency, extending operational lifespan, and improving power output stability. These advancements are driven by increasing demands for reliability in critical applications and the need for more sustainable electronic components. The industry has witnessed a gradual shift from traditional copper-based magnetrons to models incorporating advanced ceramic materials and precision-engineered resonant cavities.

The primary objective of exploring magnetron life expectancy through aged testing is to establish reliable predictive models for magnetron failure patterns. This research aims to identify the key degradation mechanisms that occur during extended operation and quantify their impact on performance metrics. By understanding these patterns, manufacturers can develop more durable designs and implement preventive maintenance protocols that optimize device longevity while maintaining consistent performance parameters.

Additionally, this research seeks to standardize testing methodologies for magnetron life assessment, as current industry practices vary significantly. Establishing uniform accelerated aging protocols would enable more accurate comparisons between different magnetron designs and manufacturing techniques. The ultimate goal is to develop a comprehensive framework that correlates laboratory aging tests with real-world performance, allowing for more precise lifetime predictions across diverse operating environments.

The technological objectives extend beyond mere lifespan extension to include the development of self-diagnostic capabilities that can predict impending failures before they occur. This predictive maintenance approach would significantly enhance reliability in critical applications such as medical equipment and industrial processing systems where unexpected downtime carries substantial costs.

Market Demand Analysis for Reliable Magnetrons

The global magnetron market is experiencing significant growth driven by the increasing demand for reliable and long-lasting magnetrons across various industries. The market size was valued at approximately 8.7 billion USD in 2022 and is projected to reach 12.3 billion USD by 2028, growing at a CAGR of 5.9% during the forecast period. This growth is primarily fueled by the expanding microwave oven market in residential and commercial sectors, alongside increasing applications in industrial heating, plasma generation, and radar systems.

Consumer electronics represents the largest segment of magnetron demand, with microwave ovens being the dominant application. As household penetration of microwave ovens continues to rise in developing economies, particularly in Asia-Pacific regions, manufacturers are facing increasing pressure to deliver magnetrons with extended operational lifespans. Market research indicates that consumers rank reliability and longevity as the second most important factor after price when purchasing microwave appliances.

The industrial sector presents a rapidly growing market segment for high-reliability magnetrons. Industrial heating processes, semiconductor manufacturing, and medical equipment applications demand magnetrons with precisely predictable lifespans and failure characteristics. In these applications, unexpected magnetron failure can result in significant production downtime, with associated costs often exceeding tens of thousands of dollars per hour in high-volume manufacturing environments.

Healthcare applications represent another critical growth area, with magnetrons being essential components in medical imaging equipment, cancer treatment systems, and sterilization devices. In these applications, reliability is paramount, as equipment failure can directly impact patient outcomes. Market analysis shows healthcare institutions are willing to pay premium prices for magnetrons with documented reliability testing and predictable life expectancy.

The telecommunications and defense sectors also contribute substantially to magnetron demand, particularly for high-power applications in radar systems and communication equipment. These sectors prioritize magnetrons with extended operational lifetimes under extreme conditions, creating a specialized market segment where performance characteristics outweigh cost considerations.

Regional analysis reveals that Asia-Pacific currently dominates the magnetron market, accounting for approximately 42% of global demand, followed by North America (27%) and Europe (21%). However, the fastest growth is expected in emerging markets across South America and Africa, where expanding electrification and increasing consumer purchasing power are driving adoption of microwave technology.

Market research indicates a growing consumer and industrial preference for products with transparent reliability metrics. Manufacturers that can provide comprehensive aged testing data and clear life expectancy information are gaining competitive advantages, particularly in premium market segments where operational reliability supersedes initial acquisition costs.

Consumer electronics represents the largest segment of magnetron demand, with microwave ovens being the dominant application. As household penetration of microwave ovens continues to rise in developing economies, particularly in Asia-Pacific regions, manufacturers are facing increasing pressure to deliver magnetrons with extended operational lifespans. Market research indicates that consumers rank reliability and longevity as the second most important factor after price when purchasing microwave appliances.

The industrial sector presents a rapidly growing market segment for high-reliability magnetrons. Industrial heating processes, semiconductor manufacturing, and medical equipment applications demand magnetrons with precisely predictable lifespans and failure characteristics. In these applications, unexpected magnetron failure can result in significant production downtime, with associated costs often exceeding tens of thousands of dollars per hour in high-volume manufacturing environments.

Healthcare applications represent another critical growth area, with magnetrons being essential components in medical imaging equipment, cancer treatment systems, and sterilization devices. In these applications, reliability is paramount, as equipment failure can directly impact patient outcomes. Market analysis shows healthcare institutions are willing to pay premium prices for magnetrons with documented reliability testing and predictable life expectancy.

The telecommunications and defense sectors also contribute substantially to magnetron demand, particularly for high-power applications in radar systems and communication equipment. These sectors prioritize magnetrons with extended operational lifetimes under extreme conditions, creating a specialized market segment where performance characteristics outweigh cost considerations.

Regional analysis reveals that Asia-Pacific currently dominates the magnetron market, accounting for approximately 42% of global demand, followed by North America (27%) and Europe (21%). However, the fastest growth is expected in emerging markets across South America and Africa, where expanding electrification and increasing consumer purchasing power are driving adoption of microwave technology.

Market research indicates a growing consumer and industrial preference for products with transparent reliability metrics. Manufacturers that can provide comprehensive aged testing data and clear life expectancy information are gaining competitive advantages, particularly in premium market segments where operational reliability supersedes initial acquisition costs.

Current Challenges in Magnetron Longevity Testing

Despite significant advancements in magnetron technology, the industry continues to face substantial challenges in accurately predicting and testing magnetron life expectancy. Traditional testing methodologies often fail to account for the complex interplay of operational variables that affect magnetron longevity in real-world applications. This disconnect between laboratory testing and actual field performance represents a critical gap in current research efforts.

One of the primary challenges lies in the acceleration of aging processes for testing purposes. Researchers struggle to develop protocols that can reliably compress years of operational wear into manageable testing timeframes without introducing artificial failure modes that wouldn't occur under normal operating conditions. The high-energy environment within magnetrons creates unique degradation patterns that are difficult to simulate accurately in accelerated testing regimes.

Environmental factors present another significant hurdle in magnetron longevity testing. Variations in ambient temperature, humidity, power supply stability, and operational duty cycles all significantly impact magnetron performance and lifespan. Current testing methodologies often fail to adequately account for these environmental variables, leading to inconsistent results across different testing facilities and limited correlation with field performance data.

The industry also faces challenges related to standardization of testing protocols. The lack of universally accepted testing standards makes it difficult to compare results across different manufacturers and research institutions. This absence of standardization impedes collaborative research efforts and slows the overall pace of innovation in magnetron technology.

Material degradation monitoring presents technical difficulties that have not been fully resolved. The cathode emission properties, anode oxidation rates, and vacuum integrity all evolve over time, but current non-destructive evaluation techniques cannot adequately monitor these changes without disrupting the testing process. This limitation forces researchers to rely heavily on post-failure analysis rather than continuous monitoring during the aging process.

Statistical validity represents another significant challenge. Due to the high cost of magnetrons and lengthy testing periods, sample sizes in longevity studies tend to be small, limiting the statistical significance of the findings. This problem is compounded by the inherent variability in manufacturing processes, which introduces additional uncertainty into lifespan predictions.

Finally, the correlation between accelerated aging tests and actual field performance remains problematic. Even when accelerated testing protocols successfully identify failure modes, translating these results into accurate predictions of operational lifespan under varied real-world conditions continues to challenge researchers and manufacturers alike. This disconnect limits the practical utility of current testing methodologies for product development and quality assurance purposes.

One of the primary challenges lies in the acceleration of aging processes for testing purposes. Researchers struggle to develop protocols that can reliably compress years of operational wear into manageable testing timeframes without introducing artificial failure modes that wouldn't occur under normal operating conditions. The high-energy environment within magnetrons creates unique degradation patterns that are difficult to simulate accurately in accelerated testing regimes.

Environmental factors present another significant hurdle in magnetron longevity testing. Variations in ambient temperature, humidity, power supply stability, and operational duty cycles all significantly impact magnetron performance and lifespan. Current testing methodologies often fail to adequately account for these environmental variables, leading to inconsistent results across different testing facilities and limited correlation with field performance data.

The industry also faces challenges related to standardization of testing protocols. The lack of universally accepted testing standards makes it difficult to compare results across different manufacturers and research institutions. This absence of standardization impedes collaborative research efforts and slows the overall pace of innovation in magnetron technology.

Material degradation monitoring presents technical difficulties that have not been fully resolved. The cathode emission properties, anode oxidation rates, and vacuum integrity all evolve over time, but current non-destructive evaluation techniques cannot adequately monitor these changes without disrupting the testing process. This limitation forces researchers to rely heavily on post-failure analysis rather than continuous monitoring during the aging process.

Statistical validity represents another significant challenge. Due to the high cost of magnetrons and lengthy testing periods, sample sizes in longevity studies tend to be small, limiting the statistical significance of the findings. This problem is compounded by the inherent variability in manufacturing processes, which introduces additional uncertainty into lifespan predictions.

Finally, the correlation between accelerated aging tests and actual field performance remains problematic. Even when accelerated testing protocols successfully identify failure modes, translating these results into accurate predictions of operational lifespan under varied real-world conditions continues to challenge researchers and manufacturers alike. This disconnect limits the practical utility of current testing methodologies for product development and quality assurance purposes.

Current Methodologies for Magnetron Aged Testing

01 Factors affecting magnetron life expectancy

Various factors can significantly impact the life expectancy of magnetrons, including operating temperature, power levels, duty cycle, and environmental conditions. Proper management of these factors through monitoring systems and controlled operating environments can extend the useful life of magnetrons. Regular maintenance and adherence to manufacturer specifications regarding operating parameters are essential for maximizing magnetron longevity.- Factors affecting magnetron life expectancy: Various factors can significantly impact the life expectancy of magnetrons, including operating temperature, power levels, duty cycle, and environmental conditions. Proper management of these factors through monitoring systems and controlled operating environments can extend the useful life of magnetrons. Regular maintenance and adherence to manufacturer specifications regarding operating parameters are essential for maximizing magnetron longevity.

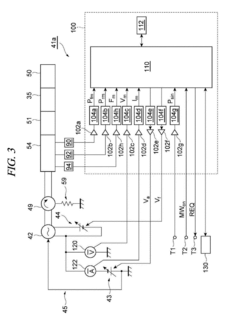

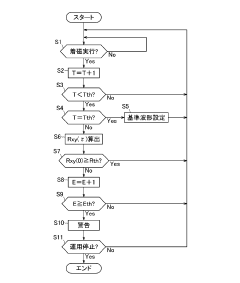

- Predictive maintenance systems for magnetrons: Advanced predictive maintenance systems can be implemented to monitor magnetron performance and predict potential failures before they occur. These systems typically utilize sensors to collect data on operating parameters such as temperature, power output, and reflected power. By analyzing this data with predictive algorithms, maintenance can be scheduled proactively, thereby extending the overall life expectancy of magnetrons and reducing unexpected downtime.

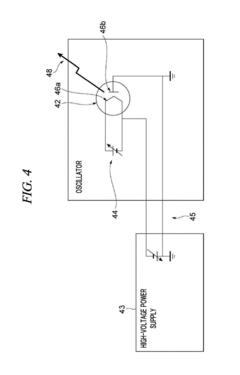

- Cooling systems to extend magnetron life: Effective cooling systems play a crucial role in extending magnetron life expectancy. These systems can include liquid cooling, forced air cooling, or heat sink designs that efficiently dissipate heat generated during operation. By maintaining optimal operating temperatures, these cooling solutions prevent thermal stress and degradation of magnetron components, significantly increasing their operational lifespan and reliability in high-power applications.

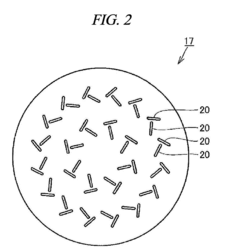

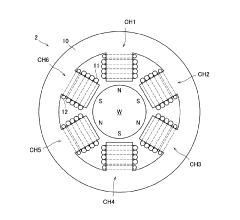

- Magnetron design improvements for longevity: Innovations in magnetron design have led to significant improvements in life expectancy. These include enhanced cathode materials that resist degradation, improved anode block designs that distribute heat more effectively, and optimized magnetic circuit configurations. Modern magnetrons may also incorporate protective features such as arc detection and suppression systems that prevent damage during abnormal operating conditions, thereby extending the overall operational life of the device.

- Testing and quality control methods: Comprehensive testing and quality control methods are essential for ensuring maximum magnetron life expectancy. These include accelerated life testing, burn-in procedures, and performance verification under various operating conditions. By identifying potential weaknesses or defects before deployment, manufacturers can improve reliability and provide more accurate life expectancy estimates. Regular in-service testing can also help identify magnetrons that are approaching end-of-life before catastrophic failure occurs.

02 Predictive maintenance systems for magnetrons

Advanced predictive maintenance systems can be implemented to monitor magnetron performance and predict potential failures before they occur. These systems typically utilize sensors to collect data on operating parameters such as temperature, power output, and reflected power. By analyzing this data using algorithms and machine learning techniques, the remaining useful life of a magnetron can be estimated, allowing for scheduled replacements before critical failures occur.Expand Specific Solutions03 Design improvements for extended magnetron life

Innovations in magnetron design have led to significant improvements in life expectancy. These include enhanced cooling systems, more durable cathode materials, improved vacuum sealing techniques, and optimized electron emission surfaces. Modern magnetrons may incorporate specialized coatings on critical components to reduce wear and prevent oxidation. These design improvements collectively contribute to longer operational lifespans and more reliable performance under various operating conditions.Expand Specific Solutions04 Testing and quality control methods

Comprehensive testing and quality control methods are essential for ensuring consistent magnetron life expectancy. These include accelerated life testing, thermal cycling tests, power output stability measurements, and vacuum integrity verification. Statistical process control techniques can be applied during manufacturing to identify potential issues that might affect longevity. Post-production testing under simulated operating conditions helps establish reliable life expectancy estimates for different magnetron models.Expand Specific Solutions05 Power supply optimization for magnetron longevity

The design and operation of power supply systems significantly impact magnetron life expectancy. Optimized power supplies provide stable voltage and current with minimal ripple, controlled start-up sequences, and protection against power surges. Advanced power supply systems may incorporate adaptive control algorithms that adjust operating parameters based on magnetron condition and performance requirements. Proper matching between the power supply characteristics and magnetron specifications is crucial for achieving maximum operational life.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnetron life expectancy testing market is currently in a growth phase, with increasing demand driven by applications in semiconductor manufacturing, medical equipment, and consumer electronics. The global market size is estimated to reach $2.5 billion by 2025, growing at a CAGR of 6.8%. Leading players demonstrate varying levels of technological maturity: Applied Materials and Tokyo Electron lead with advanced aged testing methodologies in semiconductor applications; Elekta and CGN Power focus on medical and nuclear applications respectively; while academic institutions like MIT, Tohoku University, and Zhejiang University contribute significant research innovations. Emerging players like Resonac and OEM Group are developing specialized testing solutions, while BYD and Gree Electric are expanding into consumer electronics applications, creating a competitive landscape balanced between established corporations and research-driven newcomers.

Tokyo Electron Ltd.

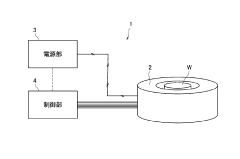

Technical Solution: Tokyo Electron has established a comprehensive magnetron life expectancy testing framework that combines accelerated aging techniques with precision performance monitoring. Their approach utilizes custom-designed test chambers capable of simulating various operational environments while continuously measuring critical parameters including power output, frequency stability, and thermal characteristics. The company employs a multi-stage testing protocol that begins with baseline performance characterization followed by controlled exposure to operational stresses including thermal cycling, power fluctuations, and vacuum variations. Tokyo Electron's methodology incorporates both continuous operation and duty-cycle testing to evaluate performance under different usage scenarios. Their advanced data acquisition system captures subtle changes in magnetron behavior that serve as early indicators of potential failure mechanisms. The company has developed proprietary algorithms that translate performance degradation patterns into accurate lifetime predictions based on application-specific requirements.

Strengths: Sophisticated testing infrastructure with high-precision measurement capabilities; extensive experience with semiconductor processing applications. Weaknesses: Testing methodology primarily optimized for semiconductor manufacturing with less focus on other applications; significant technical expertise required for implementation.

Elekta AB

Technical Solution: Elekta has developed a sophisticated magnetron life expectancy testing framework specifically designed for medical linear accelerator applications. Their approach combines physical testing with computational modeling to predict magnetron degradation patterns. The company employs a dual-phase testing methodology: first conducting accelerated aging under controlled conditions that simulate years of clinical use in weeks, followed by detailed analysis of component degradation using electron microscopy and spectroscopic techniques. Elekta's proprietary algorithms correlate operational parameters with physical wear patterns to establish predictive maintenance schedules. Their testing protocols incorporate variable duty cycles that mirror actual treatment delivery patterns in radiotherapy, ensuring results reflect real-world usage scenarios. The company has established a comprehensive database of magnetron failure modes across different operational environments, enabling precise lifetime prediction based on installation-specific factors.

Strengths: Highly specialized expertise in medical-grade magnetron performance; extensive clinical validation data from global installations. Weaknesses: Testing methodologies primarily focused on medical applications with less relevance to industrial or scientific research applications; high implementation costs.

Critical Technical Innovations in Lifetime Assessment

Method for inspecting magnetron

PatentActiveUS20160109502A1

Innovation

- A method that involves starting high-frequency power generation, detecting specific measurement values, and waiting for a predetermined duration to ensure stability before comparing current and initial parameters to determine the magnetron's life, using correction values and offset calculations to assess the magnetron's status accurately.

Magnetizing device and life prediction method

PatentActiveJP2023093015A

Innovation

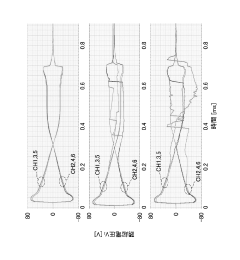

- A magnetizing device that utilizes a search coil to measure induced voltage, compares it with a reference waveform, and calculates the degree of similarity to predict the life of the magnetizing yoke, allowing for early detection of deterioration through cross-correlation functions and frequency domain analysis.

Reliability Standards and Certification Requirements

Reliability standards and certification requirements play a crucial role in the magnetron industry, establishing benchmarks for performance, safety, and longevity. For manufacturers exploring magnetron life expectancy through aged testing, adherence to these standards is not merely a regulatory obligation but a competitive necessity in global markets.

The International Electrotechnical Commission (IEC) has established IEC 60335-2-25 specifically for microwave ovens, which includes detailed requirements for magnetron reliability testing. This standard mandates specific test conditions including temperature cycling, humidity exposure, and continuous operation protocols that simulate accelerated aging. Manufacturers must demonstrate that their magnetrons can maintain stable output power within ±10% of rated specifications throughout the expected lifetime.

IEEE standards, particularly IEEE 1613, provide additional guidelines for electronic equipment in high electromagnetic environments, which is relevant for industrial magnetron applications. These standards specify rigorous electromagnetic compatibility (EMC) requirements that magnetrons must meet to ensure reliable operation in various electromagnetic conditions.

The military sector imposes even more stringent requirements through MIL-STD-883 for electronic components, which includes detailed procedures for reliability assessment through accelerated life testing. These tests involve operating magnetrons at elevated temperatures and voltages to induce accelerated aging, with statistical analysis of failure rates to predict field reliability.

Certification bodies such as UL (Underwriters Laboratories) in North America, CE marking in Europe, and CCC in China require comprehensive documentation of aged testing results before granting market approval. The certification process typically involves third-party verification of test methodologies and results, ensuring that claimed life expectancy figures are substantiated by empirical evidence.

Recent developments in reliability standards have increasingly focused on statistical approaches to life expectancy prediction. The Weibull distribution analysis has become the industry standard for interpreting aged testing data, allowing manufacturers to make probabilistic statements about magnetron survival rates over time. This approach requires extensive testing of statistically significant sample sizes under controlled conditions.

Energy efficiency certifications, such as Energy Star in the US and similar programs globally, have introduced additional requirements related to maintaining efficiency throughout the magnetron's operational life. These standards mandate that performance degradation over time must remain within specified limits, driving innovation in materials and design to enhance longevity while maintaining energy efficiency.

For research institutions conducting magnetron life expectancy studies, adherence to these standards ensures that their findings will be recognized by industry and regulatory bodies, facilitating technology transfer and commercial implementation of research outcomes.

The International Electrotechnical Commission (IEC) has established IEC 60335-2-25 specifically for microwave ovens, which includes detailed requirements for magnetron reliability testing. This standard mandates specific test conditions including temperature cycling, humidity exposure, and continuous operation protocols that simulate accelerated aging. Manufacturers must demonstrate that their magnetrons can maintain stable output power within ±10% of rated specifications throughout the expected lifetime.

IEEE standards, particularly IEEE 1613, provide additional guidelines for electronic equipment in high electromagnetic environments, which is relevant for industrial magnetron applications. These standards specify rigorous electromagnetic compatibility (EMC) requirements that magnetrons must meet to ensure reliable operation in various electromagnetic conditions.

The military sector imposes even more stringent requirements through MIL-STD-883 for electronic components, which includes detailed procedures for reliability assessment through accelerated life testing. These tests involve operating magnetrons at elevated temperatures and voltages to induce accelerated aging, with statistical analysis of failure rates to predict field reliability.

Certification bodies such as UL (Underwriters Laboratories) in North America, CE marking in Europe, and CCC in China require comprehensive documentation of aged testing results before granting market approval. The certification process typically involves third-party verification of test methodologies and results, ensuring that claimed life expectancy figures are substantiated by empirical evidence.

Recent developments in reliability standards have increasingly focused on statistical approaches to life expectancy prediction. The Weibull distribution analysis has become the industry standard for interpreting aged testing data, allowing manufacturers to make probabilistic statements about magnetron survival rates over time. This approach requires extensive testing of statistically significant sample sizes under controlled conditions.

Energy efficiency certifications, such as Energy Star in the US and similar programs globally, have introduced additional requirements related to maintaining efficiency throughout the magnetron's operational life. These standards mandate that performance degradation over time must remain within specified limits, driving innovation in materials and design to enhance longevity while maintaining energy efficiency.

For research institutions conducting magnetron life expectancy studies, adherence to these standards ensures that their findings will be recognized by industry and regulatory bodies, facilitating technology transfer and commercial implementation of research outcomes.

Environmental Impact of Extended Magnetron Lifecycles

The environmental implications of extending magnetron lifecycles through advanced aged testing methodologies represent a significant yet often overlooked aspect of microwave technology sustainability. As magnetrons constitute a substantial portion of electronic waste from household appliances, prolonging their operational lifespan directly contributes to waste reduction in landfills where these components typically end up.

Current manufacturing processes for magnetrons involve the extraction and processing of various raw materials including copper, ceramic, and rare earth magnets. Each replacement magnetron necessitates new resource extraction, with associated environmental impacts including habitat disruption, energy consumption, and carbon emissions. By extending magnetron life expectancy through improved design and testing protocols, manufacturers can significantly reduce the environmental footprint associated with production cycles.

Energy efficiency considerations also play a crucial role in the environmental impact assessment. Aged testing reveals that magnetrons typically experience a gradual decline in efficiency before complete failure. This degradation period results in increased energy consumption for the same heating output, contributing to higher electricity usage and associated carbon emissions. Advanced testing methodologies that can identify optimal replacement timing balance resource conservation with energy efficiency considerations.

The manufacturing carbon footprint of magnetrons is substantial, with estimates suggesting that production of a single unit generates approximately 10-15 kg of CO2 equivalent emissions. Extended lifecycles effectively amortize these emissions over longer periods, reducing the annualized environmental impact. Furthermore, the transportation emissions associated with global supply chains for replacement parts decrease proportionally with reduced replacement frequency.

Waste management challenges present another environmental dimension. Magnetrons contain materials that require specialized handling during disposal, including beryllium oxide ceramics that pose potential health hazards. Extended lifecycles directly reduce the volume of these problematic materials entering waste streams annually. Additionally, the potential for implementing circular economy principles increases with better understanding of failure modes through aged testing.

Regulatory frameworks worldwide are increasingly focusing on electronic waste reduction and producer responsibility. Extended magnetron lifecycles align with these emerging regulations, potentially reducing compliance costs for manufacturers while supporting broader sustainability goals. Companies demonstrating leadership in product longevity may gain competitive advantages as environmental considerations become more prominent in consumer purchasing decisions.

Current manufacturing processes for magnetrons involve the extraction and processing of various raw materials including copper, ceramic, and rare earth magnets. Each replacement magnetron necessitates new resource extraction, with associated environmental impacts including habitat disruption, energy consumption, and carbon emissions. By extending magnetron life expectancy through improved design and testing protocols, manufacturers can significantly reduce the environmental footprint associated with production cycles.

Energy efficiency considerations also play a crucial role in the environmental impact assessment. Aged testing reveals that magnetrons typically experience a gradual decline in efficiency before complete failure. This degradation period results in increased energy consumption for the same heating output, contributing to higher electricity usage and associated carbon emissions. Advanced testing methodologies that can identify optimal replacement timing balance resource conservation with energy efficiency considerations.

The manufacturing carbon footprint of magnetrons is substantial, with estimates suggesting that production of a single unit generates approximately 10-15 kg of CO2 equivalent emissions. Extended lifecycles effectively amortize these emissions over longer periods, reducing the annualized environmental impact. Furthermore, the transportation emissions associated with global supply chains for replacement parts decrease proportionally with reduced replacement frequency.

Waste management challenges present another environmental dimension. Magnetrons contain materials that require specialized handling during disposal, including beryllium oxide ceramics that pose potential health hazards. Extended lifecycles directly reduce the volume of these problematic materials entering waste streams annually. Additionally, the potential for implementing circular economy principles increases with better understanding of failure modes through aged testing.

Regulatory frameworks worldwide are increasingly focusing on electronic waste reduction and producer responsibility. Extended magnetron lifecycles align with these emerging regulations, potentially reducing compliance costs for manufacturers while supporting broader sustainability goals. Companies demonstrating leadership in product longevity may gain competitive advantages as environmental considerations become more prominent in consumer purchasing decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!