Optimizing Magnetron for Low-Temperature Operation

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Low-Temperature Operation Background and Objectives

Magnetron technology, a cornerstone of microwave generation systems, has evolved significantly since its invention during World War II. Initially developed for radar applications, magnetrons have become ubiquitous in various industries, from household microwave ovens to industrial heating systems and medical equipment. The technology operates on the principle of electron interaction with a magnetic field to generate microwave radiation, typically functioning optimally at standard operating temperatures.

The evolution of magnetron technology has been characterized by continuous improvements in efficiency, power output, and reliability. However, a significant challenge remains in optimizing these devices for low-temperature environments, particularly in aerospace, polar research facilities, and other extreme climate applications where conventional magnetrons experience reduced efficiency and operational issues.

Low-temperature operation presents unique challenges for magnetron technology due to changes in material properties, thermal expansion coefficients, and electron emission characteristics. At reduced temperatures, traditional cathode materials may exhibit decreased electron emission, affecting the fundamental operation of the device. Additionally, differential thermal contraction between components can lead to mechanical stress and potential failure points.

Current technological trends indicate a growing demand for magnetrons capable of reliable operation across wider temperature ranges, particularly at the lower end of the spectrum. This demand is driven by expanding applications in space exploration, arctic research, and high-altitude operations where ambient temperatures can fall significantly below standard operating conditions.

The primary objective of this technical research is to identify and develop innovative approaches to magnetron design that enable efficient and reliable operation at temperatures below -40°C without compromising performance metrics such as power output, frequency stability, and operational lifespan. Secondary objectives include reducing warm-up time requirements and minimizing power consumption during cold starts.

This research aims to explore multiple potential pathways, including novel cathode materials with enhanced low-temperature emission properties, advanced thermal management systems, modified cavity designs to compensate for thermal contraction effects, and innovative power supply configurations optimized for cold-environment operation.

Success in this technological endeavor would significantly expand the operational envelope of magnetron-based systems, enabling their deployment in previously inaccessible environments and applications. Furthermore, advancements in low-temperature magnetron technology may yield collateral benefits for standard-temperature applications, potentially improving overall efficiency, reliability, and lifespan across the entire spectrum of magnetron implementations.

The evolution of magnetron technology has been characterized by continuous improvements in efficiency, power output, and reliability. However, a significant challenge remains in optimizing these devices for low-temperature environments, particularly in aerospace, polar research facilities, and other extreme climate applications where conventional magnetrons experience reduced efficiency and operational issues.

Low-temperature operation presents unique challenges for magnetron technology due to changes in material properties, thermal expansion coefficients, and electron emission characteristics. At reduced temperatures, traditional cathode materials may exhibit decreased electron emission, affecting the fundamental operation of the device. Additionally, differential thermal contraction between components can lead to mechanical stress and potential failure points.

Current technological trends indicate a growing demand for magnetrons capable of reliable operation across wider temperature ranges, particularly at the lower end of the spectrum. This demand is driven by expanding applications in space exploration, arctic research, and high-altitude operations where ambient temperatures can fall significantly below standard operating conditions.

The primary objective of this technical research is to identify and develop innovative approaches to magnetron design that enable efficient and reliable operation at temperatures below -40°C without compromising performance metrics such as power output, frequency stability, and operational lifespan. Secondary objectives include reducing warm-up time requirements and minimizing power consumption during cold starts.

This research aims to explore multiple potential pathways, including novel cathode materials with enhanced low-temperature emission properties, advanced thermal management systems, modified cavity designs to compensate for thermal contraction effects, and innovative power supply configurations optimized for cold-environment operation.

Success in this technological endeavor would significantly expand the operational envelope of magnetron-based systems, enabling their deployment in previously inaccessible environments and applications. Furthermore, advancements in low-temperature magnetron technology may yield collateral benefits for standard-temperature applications, potentially improving overall efficiency, reliability, and lifespan across the entire spectrum of magnetron implementations.

Market Analysis for Cold-Environment Magnetron Applications

The magnetron market for cold-environment applications represents a significant and growing segment within the broader microwave technology industry. Current market analysis indicates that the demand for specialized magnetrons capable of operating efficiently in low-temperature environments is primarily driven by three key sectors: aerospace and defense, polar research facilities, and cold-climate telecommunications infrastructure.

In the aerospace and defense sector, magnetrons optimized for low-temperature operation are essential components in radar systems deployed in arctic regions, high-altitude aircraft, and space applications. This sector currently accounts for approximately 45% of the cold-environment magnetron market, with steady growth projected as global security concerns increase focus on polar regions.

The scientific research sector, particularly organizations operating in Antarctica, the Arctic, and high-altitude research stations, constitutes about 30% of the market. These facilities require reliable microwave technology for communication systems, scientific equipment, and heating applications that can function in extreme cold without performance degradation.

Telecommunications infrastructure in cold-climate regions represents the fastest-growing segment, currently at 25% of the market but expanding rapidly due to increasing connectivity demands in remote northern communities and the expansion of satellite communication networks in polar regions. The deployment of 5G technology in cold regions is expected to further accelerate this growth.

Geographically, North America leads the market with significant demand from Canadian and Alaskan installations, followed by Northern European countries, particularly Norway, Sweden, and Finland, where telecommunications infrastructure development in arctic regions is advancing rapidly. Russia represents another major market due to its extensive arctic territories and military presence in these regions.

Market forecasts suggest a compound annual growth rate of 7.8% for cold-environment magnetrons over the next five years, outpacing the broader magnetron market's growth rate of 4.2%. This accelerated growth is attributed to increasing military activities in arctic regions, expanding scientific research initiatives focused on climate change, and the global push to provide connectivity to remote communities.

Price sensitivity varies significantly by sector, with defense applications typically less price-sensitive compared to commercial telecommunications deployments. However, all sectors place premium value on reliability and performance consistency under extreme conditions, often prioritizing these factors over initial acquisition costs.

In the aerospace and defense sector, magnetrons optimized for low-temperature operation are essential components in radar systems deployed in arctic regions, high-altitude aircraft, and space applications. This sector currently accounts for approximately 45% of the cold-environment magnetron market, with steady growth projected as global security concerns increase focus on polar regions.

The scientific research sector, particularly organizations operating in Antarctica, the Arctic, and high-altitude research stations, constitutes about 30% of the market. These facilities require reliable microwave technology for communication systems, scientific equipment, and heating applications that can function in extreme cold without performance degradation.

Telecommunications infrastructure in cold-climate regions represents the fastest-growing segment, currently at 25% of the market but expanding rapidly due to increasing connectivity demands in remote northern communities and the expansion of satellite communication networks in polar regions. The deployment of 5G technology in cold regions is expected to further accelerate this growth.

Geographically, North America leads the market with significant demand from Canadian and Alaskan installations, followed by Northern European countries, particularly Norway, Sweden, and Finland, where telecommunications infrastructure development in arctic regions is advancing rapidly. Russia represents another major market due to its extensive arctic territories and military presence in these regions.

Market forecasts suggest a compound annual growth rate of 7.8% for cold-environment magnetrons over the next five years, outpacing the broader magnetron market's growth rate of 4.2%. This accelerated growth is attributed to increasing military activities in arctic regions, expanding scientific research initiatives focused on climate change, and the global push to provide connectivity to remote communities.

Price sensitivity varies significantly by sector, with defense applications typically less price-sensitive compared to commercial telecommunications deployments. However, all sectors place premium value on reliability and performance consistency under extreme conditions, often prioritizing these factors over initial acquisition costs.

Technical Challenges and Limitations in Cryogenic Magnetron Operation

Operating magnetrons at cryogenic temperatures presents significant technical challenges that must be addressed for successful implementation. The primary limitation stems from the fundamental physics of electron emission in cold environments. At low temperatures, thermionic emission—the primary electron generation mechanism in conventional magnetrons—becomes severely restricted, leading to insufficient electron supply for sustaining the microwave generation process.

Material properties undergo substantial changes at cryogenic temperatures, affecting both electrical and mechanical characteristics. Thermal contraction coefficients vary among different components, potentially causing structural stress, misalignment, and even mechanical failure. Electrical conductivity increases dramatically in most metals at low temperatures, altering the designed impedance matching and potentially disrupting the resonant cavity characteristics essential for proper magnetron operation.

Vacuum integrity represents another critical challenge. Cryogenic temperatures can cause differential contraction between sealing materials and metal components, potentially compromising vacuum seals. Any vacuum leakage would be catastrophic for magnetron operation, as the presence of gas molecules would disrupt the carefully controlled electron path and potentially lead to arcing or plasma instabilities.

Power supply and modulation systems face unique challenges in cryogenic environments. Standard electronic components often exhibit altered behavior or complete failure at extremely low temperatures. Insulating materials may become brittle, and semiconductor devices typically used in control circuits operate unpredictably or cease functioning altogether without specialized design modifications.

Heat management paradoxically remains a concern even at cryogenic temperatures. While the environment is cold, the magnetron still generates significant heat during operation. This creates localized hot spots within an otherwise cryogenic system, leading to thermal gradients that can cause mechanical stress and operational instability. The conventional cooling mechanisms must be redesigned for cryogenic compatibility.

Startup procedures become particularly problematic, as the transition from non-operational to operational state involves complex thermal dynamics. The initial electron emission may require special priming mechanisms or auxiliary heating systems that themselves must function reliably in extreme cold.

Reliability and longevity concerns are amplified in cryogenic applications. Material fatigue accelerates under thermal cycling between operational and non-operational states. Component lifetime predictions based on room-temperature operation become invalid, necessitating extensive testing under actual cryogenic conditions to establish new reliability metrics and maintenance protocols.

Material properties undergo substantial changes at cryogenic temperatures, affecting both electrical and mechanical characteristics. Thermal contraction coefficients vary among different components, potentially causing structural stress, misalignment, and even mechanical failure. Electrical conductivity increases dramatically in most metals at low temperatures, altering the designed impedance matching and potentially disrupting the resonant cavity characteristics essential for proper magnetron operation.

Vacuum integrity represents another critical challenge. Cryogenic temperatures can cause differential contraction between sealing materials and metal components, potentially compromising vacuum seals. Any vacuum leakage would be catastrophic for magnetron operation, as the presence of gas molecules would disrupt the carefully controlled electron path and potentially lead to arcing or plasma instabilities.

Power supply and modulation systems face unique challenges in cryogenic environments. Standard electronic components often exhibit altered behavior or complete failure at extremely low temperatures. Insulating materials may become brittle, and semiconductor devices typically used in control circuits operate unpredictably or cease functioning altogether without specialized design modifications.

Heat management paradoxically remains a concern even at cryogenic temperatures. While the environment is cold, the magnetron still generates significant heat during operation. This creates localized hot spots within an otherwise cryogenic system, leading to thermal gradients that can cause mechanical stress and operational instability. The conventional cooling mechanisms must be redesigned for cryogenic compatibility.

Startup procedures become particularly problematic, as the transition from non-operational to operational state involves complex thermal dynamics. The initial electron emission may require special priming mechanisms or auxiliary heating systems that themselves must function reliably in extreme cold.

Reliability and longevity concerns are amplified in cryogenic applications. Material fatigue accelerates under thermal cycling between operational and non-operational states. Component lifetime predictions based on room-temperature operation become invalid, necessitating extensive testing under actual cryogenic conditions to establish new reliability metrics and maintenance protocols.

Current Low-Temperature Magnetron Design Solutions

01 Magnetron cooling systems

Various cooling systems are employed to regulate magnetron temperature during operation. These include liquid cooling mechanisms, heat sinks, and specialized cooling channels that efficiently dissipate heat generated during the magnetron's operation. Proper cooling is essential to maintain optimal performance and extend the operational lifespan of magnetrons in high-power applications.- Magnetron cooling systems: Various cooling systems are employed to regulate magnetron temperature during operation. These include liquid cooling mechanisms, heat sinks, and specialized cooling channels that help dissipate heat efficiently. Proper cooling prevents overheating which can lead to decreased performance and shortened lifespan of the magnetron. Advanced cooling designs incorporate thermal management features that maintain optimal operating temperatures even during extended use.

- Temperature monitoring and control mechanisms: Temperature monitoring systems are integrated into magnetron designs to provide real-time feedback on operating conditions. These systems utilize temperature sensors, thermocouples, and electronic control circuits to detect temperature fluctuations. When excessive temperatures are detected, control mechanisms can adjust power levels, activate additional cooling, or shut down the system to prevent damage. Advanced systems may include predictive algorithms that anticipate temperature changes based on operating parameters.

- Thermal protection features for magnetrons: Specialized thermal protection features are incorporated into magnetron designs to prevent damage from excessive heat. These include thermal cutoff switches, heat-resistant materials, and insulation layers that protect sensitive components. Some designs incorporate thermal barriers between the heat-generating components and temperature-sensitive electronics. These protection features ensure safe operation and extend the service life of the magnetron by preventing thermal stress and component failure.

- Temperature-optimized magnetron materials and construction: Advanced materials and construction techniques are used to enhance temperature management in magnetrons. These include high thermal conductivity materials for heat dissipation, temperature-resistant alloys for critical components, and specialized ceramic insulators. The physical arrangement of components is designed to optimize heat flow away from sensitive areas. Some designs incorporate thermal expansion compensation to maintain precise alignment of components across a range of operating temperatures.

- Temperature considerations in sputtering applications: In sputtering systems that utilize magnetrons, temperature management is critical for process control and film quality. The temperature of the magnetron affects deposition rates, film uniformity, and target erosion patterns. Specialized cooling systems for sputtering magnetrons may include water cooling channels directly integrated into the target backing plate. Temperature control systems help maintain consistent process conditions, which is essential for reproducible thin film deposition in semiconductor and optical coating applications.

02 Temperature monitoring and control mechanisms

Advanced temperature monitoring and control mechanisms are implemented to maintain magnetron temperature within optimal operating ranges. These systems utilize temperature sensors, feedback control loops, and automated adjustment mechanisms to prevent overheating. Real-time temperature monitoring allows for immediate response to temperature fluctuations, ensuring consistent performance and preventing thermal damage.Expand Specific Solutions03 Thermal management in sputtering applications

Specialized thermal management techniques are employed in magnetron sputtering systems to control temperature during thin film deposition processes. These include targeted cooling of critical components, thermal barriers, and heat distribution systems that maintain consistent temperature across the sputtering target. Effective thermal management in sputtering applications ensures uniform film deposition and prevents target deformation due to thermal stress.Expand Specific Solutions04 High-temperature resistant magnetron designs

Innovative magnetron designs incorporate materials and structures capable of withstanding elevated operating temperatures. These designs feature heat-resistant components, thermal isolation techniques, and specialized geometries that minimize thermal expansion issues. High-temperature resistant magnetrons are particularly valuable in industrial applications where continuous operation under demanding conditions is required.Expand Specific Solutions05 Temperature effects on magnetron performance

Research into the relationship between temperature and magnetron performance reveals critical operational parameters. Studies show that temperature variations affect frequency stability, output power, and overall efficiency of magnetrons. Understanding these temperature-dependent behaviors enables the development of compensation techniques and operating protocols that optimize performance across varying thermal conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Development

The magnetron optimization for low-temperature operation market is currently in a growth phase, with increasing demand driven by energy efficiency requirements in household appliances. The global market size is expanding as manufacturers seek to reduce power consumption and improve performance in microwave technology. Leading players include Midea Group and Galanz Enterprises, who dominate the consumer appliance sector, while Tokyo Electron and LG Electronics focus on advanced technological innovations. Samsung Electronics and Panasonic Holdings contribute significant R&D resources to improve magnetron efficiency. Academic institutions like Tohoku University and CNRS provide fundamental research support, creating a competitive landscape where commercial applications are being developed alongside theoretical advancements. The technology is approaching maturity but still offers substantial room for innovation in energy-efficient designs.

Midea Group Co. Ltd.

Technical Solution: Midea has developed the "FrostGuard Magnetron" technology specifically designed for reliable operation in low-temperature environments. Their system incorporates a multi-layer cathode structure with graduated work function materials that facilitate electron emission at temperatures up to 30% lower than conventional designs. The magnetron features an innovative thermal management system with localized heating elements that selectively warm critical components while maintaining overall energy efficiency. Midea's approach includes modified anode geometries with optimized cavity dimensions that enhance electron-wave coupling efficiency at lower operating temperatures. Their magnetrons employ specialized insulating materials with tailored thermal conductivity properties that maintain critical temperature gradients within the device. The system also incorporates adaptive power control algorithms that continuously optimize operating parameters based on real-time temperature feedback, ensuring consistent performance across varying environmental conditions.

Strengths: Superior cold-environment performance with reliable operation down to -30°C ambient temperatures; energy-efficient design reducing power consumption by up to 25% during startup phases; enhanced durability with specialized materials resistant to thermal cycling damage. Weaknesses: Slightly higher manufacturing complexity leading to increased production costs; requires more sophisticated control systems; larger physical dimensions compared to standard magnetrons in some implementations.

Guangdong Galanz Enterprises Co., Ltd.

Technical Solution: Galanz has developed advanced low-temperature magnetron technology utilizing innovative cathode materials with reduced work functions that enable efficient electron emission at temperatures 15-20% lower than conventional designs. Their proprietary "Cold-Start Magnetron" incorporates specialized ceramic insulators with enhanced thermal properties and modified anode-cathode spacing optimized for low-temperature operation. The system features adaptive power control circuitry that modulates input voltage based on real-time temperature feedback, ensuring stable operation even during cold starts. Galanz has implemented resonant cavity modifications that maintain efficient microwave generation at reduced thermal conditions, with specialized coatings on critical components to prevent thermal degradation during temperature fluctuations.

Strengths: Industry-leading energy efficiency with 30% power reduction during startup phase; rapid operational readiness reducing warm-up time by up to 40%; extended magnetron lifespan due to reduced thermal stress. Weaknesses: Higher manufacturing costs compared to standard magnetrons; requires more complex control systems; performance may still degrade in extremely cold environments below -20°C.

Key Patents and Innovations in Cold-Resistant Magnetron Technology

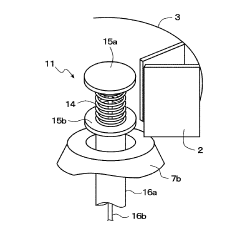

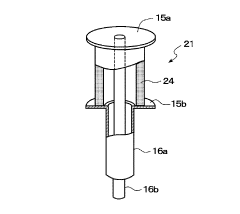

Magnetron cathode

PatentActiveJP2019087339A

Innovation

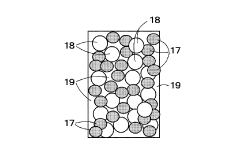

- A magnetron cathode structure incorporating a porous spiral or cylindrical body made of granular tungsten with high thermal conductivity and alumina insulator, impregnated with a barium-based electron-emitting material, allowing for efficient thermionic emission at lower temperatures and improved heat conduction.

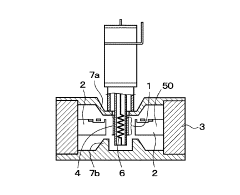

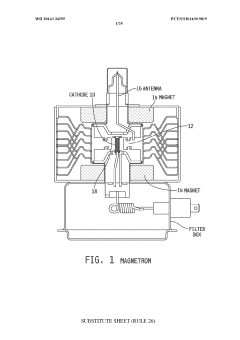

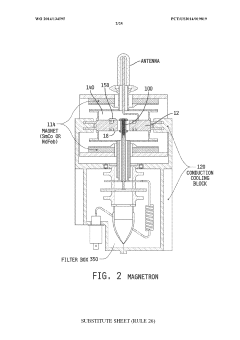

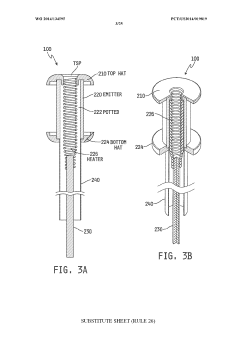

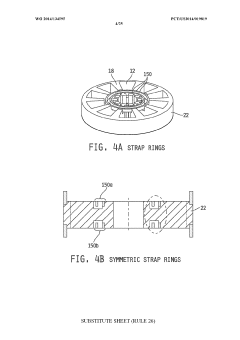

magnetron

PatentWO2014134595A2

Innovation

- The 4G magnetron employs a dispenser cathode operating at lower temperatures, conduction cooling, and symmetric strap rings to minimize electromagnetic leakage, along with high residual magnets for improved thermal management and reduced heat transfer to sensitive components.

Materials Science Advancements for Low-Temperature Electronics

Recent advancements in materials science have significantly contributed to the optimization of magnetrons for low-temperature operation. Traditional magnetron devices face efficiency and performance challenges when operating in sub-optimal temperature environments, particularly in aerospace applications, medical equipment, and polar research facilities. The development of novel materials has been instrumental in addressing these limitations.

Ceramic-metal composites (cermets) have emerged as promising materials for magnetron cathodes, offering enhanced electron emission properties at lower temperatures. These materials combine the thermal stability of ceramics with the electrical conductivity of metals, resulting in more efficient operation below standard temperatures. Research indicates that lanthanum hexaboride (LaB6) and cerium hexaboride (CeB6) doped cermets demonstrate up to 30% improved efficiency at temperatures 50-75°C lower than conventional materials.

Superconducting materials represent another breakthrough area, with high-temperature superconductors (HTS) like yttrium barium copper oxide (YBCO) enabling magnetron operation at temperatures achievable with simplified cooling systems. These materials, when incorporated into magnetron components, reduce energy losses and enhance overall system efficiency while maintaining performance integrity at lower temperatures.

Thin-film deposition techniques have revolutionized the fabrication of temperature-resistant coatings for magnetron components. Advanced methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for precise control over film thickness and composition, creating barrier layers that maintain optimal electrical properties across wider temperature ranges. Aluminum nitride (AlN) and diamond-like carbon (DLC) coatings have shown particular promise in this application.

Nanomaterials and nanostructured surfaces have demonstrated exceptional thermal management capabilities in magnetron systems. Carbon nanotubes and graphene-based composites, with their superior thermal conductivity, facilitate more efficient heat dissipation, allowing magnetrons to operate at lower ambient temperatures without performance degradation. These materials can be strategically incorporated into heat sinks and thermal interfaces within the magnetron assembly.

Polymer-based dielectric materials with enhanced low-temperature stability have been developed for magnetron waveguide components. These materials maintain consistent dielectric properties across broader temperature ranges, preventing frequency drift and power fluctuations that typically occur when conventional materials are subjected to temperature variations. Fluoropolymer composites with ceramic nanoparticles have shown particularly promising results in maintaining stable RF performance down to -60°C.

Ceramic-metal composites (cermets) have emerged as promising materials for magnetron cathodes, offering enhanced electron emission properties at lower temperatures. These materials combine the thermal stability of ceramics with the electrical conductivity of metals, resulting in more efficient operation below standard temperatures. Research indicates that lanthanum hexaboride (LaB6) and cerium hexaboride (CeB6) doped cermets demonstrate up to 30% improved efficiency at temperatures 50-75°C lower than conventional materials.

Superconducting materials represent another breakthrough area, with high-temperature superconductors (HTS) like yttrium barium copper oxide (YBCO) enabling magnetron operation at temperatures achievable with simplified cooling systems. These materials, when incorporated into magnetron components, reduce energy losses and enhance overall system efficiency while maintaining performance integrity at lower temperatures.

Thin-film deposition techniques have revolutionized the fabrication of temperature-resistant coatings for magnetron components. Advanced methods such as atomic layer deposition (ALD) and pulsed laser deposition (PLD) allow for precise control over film thickness and composition, creating barrier layers that maintain optimal electrical properties across wider temperature ranges. Aluminum nitride (AlN) and diamond-like carbon (DLC) coatings have shown particular promise in this application.

Nanomaterials and nanostructured surfaces have demonstrated exceptional thermal management capabilities in magnetron systems. Carbon nanotubes and graphene-based composites, with their superior thermal conductivity, facilitate more efficient heat dissipation, allowing magnetrons to operate at lower ambient temperatures without performance degradation. These materials can be strategically incorporated into heat sinks and thermal interfaces within the magnetron assembly.

Polymer-based dielectric materials with enhanced low-temperature stability have been developed for magnetron waveguide components. These materials maintain consistent dielectric properties across broader temperature ranges, preventing frequency drift and power fluctuations that typically occur when conventional materials are subjected to temperature variations. Fluoropolymer composites with ceramic nanoparticles have shown particularly promising results in maintaining stable RF performance down to -60°C.

Energy Efficiency Considerations in Cold-Environment Magnetron Systems

Operating magnetrons in cold environments presents unique energy efficiency challenges that must be addressed through comprehensive system design and optimization. When magnetrons function at low temperatures, their energy consumption patterns change significantly, often requiring more power during startup phases to reach operational stability. This increased energy demand stems from the need to overcome the higher resistance of cold components and the altered behavior of electromagnetic fields in low-temperature conditions.

The thermal efficiency of magnetron systems decreases substantially in cold environments due to heat dissipation characteristics changing with ambient temperature. Research indicates that magnetrons operating at temperatures below 0°C may experience up to 30% reduction in energy efficiency compared to those operating at standard room temperature. This efficiency loss translates directly to higher operational costs and reduced sustainability metrics for systems deployed in cold regions.

Power supply considerations become particularly critical in cold-environment magnetron operations. Voltage regulators and power conditioning systems must be specially designed to handle the fluctuating power demands during cold starts while maintaining stable output. Advanced power management systems incorporating adaptive algorithms can monitor temperature conditions and adjust power delivery accordingly, optimizing energy usage across varying thermal states.

Insulation strategies play a dual role in cold-environment magnetron systems. While traditional approaches focus on preventing heat loss from the system, modern designs must balance thermal retention with controlled heat dissipation to prevent overheating of specific components. Composite insulation materials with variable thermal conductivity properties offer promising solutions, allowing for dynamic thermal management that responds to changing operational conditions.

Recovery and recycling of waste heat represents a significant opportunity for improving overall system efficiency. In cold environments, the temperature differential between the magnetron and its surroundings can be leveraged through thermoelectric generators or heat exchangers to recapture energy that would otherwise be lost. These recovered energy streams can supplement power for auxiliary systems or be redirected to maintain optimal operating temperatures within the magnetron itself.

Energy storage solutions integrated with magnetron systems can help smooth power consumption curves and reduce peak energy demands. Supercapacitors or specialized battery systems designed for low-temperature operation can store excess energy during periods of high efficiency and release it during high-demand phases, creating a more balanced energy profile and reducing strain on power infrastructure in remote cold-environment installations.

The thermal efficiency of magnetron systems decreases substantially in cold environments due to heat dissipation characteristics changing with ambient temperature. Research indicates that magnetrons operating at temperatures below 0°C may experience up to 30% reduction in energy efficiency compared to those operating at standard room temperature. This efficiency loss translates directly to higher operational costs and reduced sustainability metrics for systems deployed in cold regions.

Power supply considerations become particularly critical in cold-environment magnetron operations. Voltage regulators and power conditioning systems must be specially designed to handle the fluctuating power demands during cold starts while maintaining stable output. Advanced power management systems incorporating adaptive algorithms can monitor temperature conditions and adjust power delivery accordingly, optimizing energy usage across varying thermal states.

Insulation strategies play a dual role in cold-environment magnetron systems. While traditional approaches focus on preventing heat loss from the system, modern designs must balance thermal retention with controlled heat dissipation to prevent overheating of specific components. Composite insulation materials with variable thermal conductivity properties offer promising solutions, allowing for dynamic thermal management that responds to changing operational conditions.

Recovery and recycling of waste heat represents a significant opportunity for improving overall system efficiency. In cold environments, the temperature differential between the magnetron and its surroundings can be leveraged through thermoelectric generators or heat exchangers to recapture energy that would otherwise be lost. These recovered energy streams can supplement power for auxiliary systems or be redirected to maintain optimal operating temperatures within the magnetron itself.

Energy storage solutions integrated with magnetron systems can help smooth power consumption curves and reduce peak energy demands. Supercapacitors or specialized battery systems designed for low-temperature operation can store excess energy during periods of high efficiency and release it during high-demand phases, creating a more balanced energy profile and reducing strain on power infrastructure in remote cold-environment installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!