How to Optimize Magnetron for Higher Energy Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Energy Efficiency Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, with its primary applications expanding from radar systems during World War II to widespread use in microwave ovens and industrial heating processes. The fundamental operating principle of magnetrons—converting electrical energy into microwave radiation through electron interaction with a magnetic field—has remained largely unchanged, though incremental improvements have enhanced performance over decades. Current global energy efficiency concerns have placed renewed focus on optimizing magnetron technology, as these devices typically operate at 65-70% efficiency, with significant energy lost as heat.

The technological evolution trajectory shows a plateau in efficiency improvements over the past two decades, suggesting that conventional design approaches may be reaching their theoretical limits. Recent advancements in computational modeling, materials science, and power electronics present new opportunities to overcome these limitations and achieve breakthrough efficiency improvements.

Market demands for higher energy efficiency are driven by multiple factors: increasing energy costs, stringent environmental regulations, and growing consumer awareness of energy consumption. Industrial applications particularly require more efficient magnetrons to reduce operational costs and carbon footprints, while consumer appliance manufacturers seek competitive advantages through energy-efficient products.

The primary technical objective of this research is to identify and evaluate potential pathways to increase magnetron energy efficiency beyond the current 70% threshold, with an ambitious target of achieving 85-90% efficiency. Secondary objectives include reducing heat generation, extending operational lifespan, and maintaining or reducing production costs to ensure commercial viability.

This research aims to comprehensively map the current technological landscape, identify fundamental efficiency limitations in conventional designs, and explore innovative approaches that could disrupt the established technology paradigm. Particular attention will be given to cathode design optimization, magnetic field configuration improvements, resonant cavity modifications, and advanced cooling systems integration.

The scope encompasses both incremental improvements to existing designs and radical innovations that may require significant manufacturing process changes. The time horizon for implementation ranges from near-term solutions (1-2 years) that can be rapidly integrated into existing production lines to long-term research directions (5+ years) that may require fundamental breakthroughs in materials or design principles.

Success metrics will include not only theoretical and laboratory-measured efficiency improvements but also considerations of manufacturability, reliability under various operating conditions, and total cost of ownership calculations to ensure practical applicability of the proposed solutions.

The technological evolution trajectory shows a plateau in efficiency improvements over the past two decades, suggesting that conventional design approaches may be reaching their theoretical limits. Recent advancements in computational modeling, materials science, and power electronics present new opportunities to overcome these limitations and achieve breakthrough efficiency improvements.

Market demands for higher energy efficiency are driven by multiple factors: increasing energy costs, stringent environmental regulations, and growing consumer awareness of energy consumption. Industrial applications particularly require more efficient magnetrons to reduce operational costs and carbon footprints, while consumer appliance manufacturers seek competitive advantages through energy-efficient products.

The primary technical objective of this research is to identify and evaluate potential pathways to increase magnetron energy efficiency beyond the current 70% threshold, with an ambitious target of achieving 85-90% efficiency. Secondary objectives include reducing heat generation, extending operational lifespan, and maintaining or reducing production costs to ensure commercial viability.

This research aims to comprehensively map the current technological landscape, identify fundamental efficiency limitations in conventional designs, and explore innovative approaches that could disrupt the established technology paradigm. Particular attention will be given to cathode design optimization, magnetic field configuration improvements, resonant cavity modifications, and advanced cooling systems integration.

The scope encompasses both incremental improvements to existing designs and radical innovations that may require significant manufacturing process changes. The time horizon for implementation ranges from near-term solutions (1-2 years) that can be rapidly integrated into existing production lines to long-term research directions (5+ years) that may require fundamental breakthroughs in materials or design principles.

Success metrics will include not only theoretical and laboratory-measured efficiency improvements but also considerations of manufacturability, reliability under various operating conditions, and total cost of ownership calculations to ensure practical applicability of the proposed solutions.

Market Demand Analysis for High-Efficiency Magnetrons

The global market for high-efficiency magnetrons is experiencing robust growth driven by increasing energy costs, environmental regulations, and consumer demand for energy-efficient appliances. The magnetron market, valued at approximately $5.2 billion in 2022, is projected to reach $7.8 billion by 2028, with high-efficiency variants representing the fastest-growing segment at a CAGR of 8.3%.

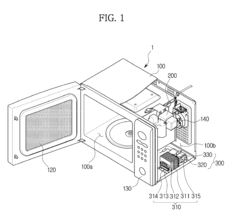

Household microwave ovens constitute the largest application segment, accounting for over 60% of magnetron demand. With over 90 million microwave ovens sold annually worldwide, manufacturers are under pressure to improve energy efficiency to meet increasingly stringent energy standards such as the EU's EcoDesign Directive and the U.S. Energy Star program. Consumer surveys indicate that 78% of appliance purchasers now consider energy efficiency a primary decision factor.

Industrial applications represent another significant market segment with growing demand. Food processing industries are increasingly adopting high-efficiency magnetron systems to reduce operational costs, with energy savings of 15-30% reported when upgrading to optimized magnetrons. The healthcare sector also shows increasing demand for precise, energy-efficient magnetrons in medical equipment such as cancer therapy devices.

The telecommunications and defense sectors are emerging as high-value markets for specialized magnetrons. With the expansion of 5G networks, the demand for efficient RF power sources has increased substantially. Military applications require high-reliability magnetrons with superior energy efficiency for radar systems and electronic countermeasures.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, driven by massive manufacturing capacity in China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with higher demand for premium, high-efficiency models. Developing economies in South Asia and Africa represent the fastest-growing markets, with annual growth rates exceeding 10%.

Market research indicates that energy efficiency improvements of just 5-10% can translate to significant competitive advantages. Manufacturers who achieve 15% or greater efficiency improvements command price premiums of 20-30% in commercial and industrial segments. The return on investment for end-users upgrading to high-efficiency magnetrons typically ranges from 8-24 months, depending on usage patterns.

Environmental regulations are increasingly becoming market drivers, with several countries implementing carbon pricing mechanisms that indirectly boost demand for energy-efficient technologies. The EU's carbon pricing scheme and similar initiatives in Canada, China, and other regions are accelerating the transition toward higher-efficiency magnetrons across all application segments.

Household microwave ovens constitute the largest application segment, accounting for over 60% of magnetron demand. With over 90 million microwave ovens sold annually worldwide, manufacturers are under pressure to improve energy efficiency to meet increasingly stringent energy standards such as the EU's EcoDesign Directive and the U.S. Energy Star program. Consumer surveys indicate that 78% of appliance purchasers now consider energy efficiency a primary decision factor.

Industrial applications represent another significant market segment with growing demand. Food processing industries are increasingly adopting high-efficiency magnetron systems to reduce operational costs, with energy savings of 15-30% reported when upgrading to optimized magnetrons. The healthcare sector also shows increasing demand for precise, energy-efficient magnetrons in medical equipment such as cancer therapy devices.

The telecommunications and defense sectors are emerging as high-value markets for specialized magnetrons. With the expansion of 5G networks, the demand for efficient RF power sources has increased substantially. Military applications require high-reliability magnetrons with superior energy efficiency for radar systems and electronic countermeasures.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, driven by massive manufacturing capacity in China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with higher demand for premium, high-efficiency models. Developing economies in South Asia and Africa represent the fastest-growing markets, with annual growth rates exceeding 10%.

Market research indicates that energy efficiency improvements of just 5-10% can translate to significant competitive advantages. Manufacturers who achieve 15% or greater efficiency improvements command price premiums of 20-30% in commercial and industrial segments. The return on investment for end-users upgrading to high-efficiency magnetrons typically ranges from 8-24 months, depending on usage patterns.

Environmental regulations are increasingly becoming market drivers, with several countries implementing carbon pricing mechanisms that indirectly boost demand for energy-efficient technologies. The EU's carbon pricing scheme and similar initiatives in Canada, China, and other regions are accelerating the transition toward higher-efficiency magnetrons across all application segments.

Current Magnetron Technology Status and Challenges

Magnetron technology, while mature and widely deployed in various applications from microwave ovens to industrial heating systems, faces significant challenges in energy efficiency optimization. Current commercial magnetrons typically operate at efficiency levels between 65-70%, with substantial energy losses occurring as heat dissipation at the anode and cathode structures. This inefficiency represents a critical limitation as energy conservation becomes increasingly important across industries.

The global landscape of magnetron technology development shows concentration in countries like Japan, China, the United States, and several European nations. Japanese manufacturers have historically led innovations in compact, efficient magnetron designs, while Chinese production has focused on cost-effective mass manufacturing. Research institutions in the United States and Europe continue to explore fundamental improvements in magnetron physics and materials.

A primary technical challenge in current magnetron technology is the inherent trade-off between power output and efficiency. As power levels increase, thermal management becomes increasingly problematic, with excessive heat generation leading to reduced component lifespan and reliability issues. The conventional copper anode structure, while effective for heat dissipation, presents limitations in thermal conductivity at higher power densities.

Another significant obstacle is the relatively fixed frequency operation of traditional magnetrons, which limits their adaptability across applications requiring precise frequency control. The inherent frequency drift under varying load conditions further complicates efficiency optimization efforts. Modern applications increasingly demand stable, controllable microwave sources, putting pressure on conventional magnetron designs.

Material limitations also present substantial challenges. Current cathode materials experience electron emission degradation over time, reducing operational efficiency and device lifespan. The development of advanced materials capable of withstanding high temperatures while maintaining consistent electron emission characteristics remains an active research area with significant potential for efficiency improvements.

Power supply integration represents another efficiency bottleneck. Traditional magnetron power supplies often operate with suboptimal matching to the magnetron's electrical characteristics, resulting in power transfer inefficiencies. The development of more sophisticated power electronics capable of dynamic adaptation to magnetron operating conditions could yield substantial efficiency gains.

Environmental considerations are increasingly influencing magnetron development, with regulations on electromagnetic interference and materials usage becoming more stringent globally. This regulatory landscape creates additional constraints on design options while simultaneously driving innovation toward more environmentally sustainable solutions.

The global landscape of magnetron technology development shows concentration in countries like Japan, China, the United States, and several European nations. Japanese manufacturers have historically led innovations in compact, efficient magnetron designs, while Chinese production has focused on cost-effective mass manufacturing. Research institutions in the United States and Europe continue to explore fundamental improvements in magnetron physics and materials.

A primary technical challenge in current magnetron technology is the inherent trade-off between power output and efficiency. As power levels increase, thermal management becomes increasingly problematic, with excessive heat generation leading to reduced component lifespan and reliability issues. The conventional copper anode structure, while effective for heat dissipation, presents limitations in thermal conductivity at higher power densities.

Another significant obstacle is the relatively fixed frequency operation of traditional magnetrons, which limits their adaptability across applications requiring precise frequency control. The inherent frequency drift under varying load conditions further complicates efficiency optimization efforts. Modern applications increasingly demand stable, controllable microwave sources, putting pressure on conventional magnetron designs.

Material limitations also present substantial challenges. Current cathode materials experience electron emission degradation over time, reducing operational efficiency and device lifespan. The development of advanced materials capable of withstanding high temperatures while maintaining consistent electron emission characteristics remains an active research area with significant potential for efficiency improvements.

Power supply integration represents another efficiency bottleneck. Traditional magnetron power supplies often operate with suboptimal matching to the magnetron's electrical characteristics, resulting in power transfer inefficiencies. The development of more sophisticated power electronics capable of dynamic adaptation to magnetron operating conditions could yield substantial efficiency gains.

Environmental considerations are increasingly influencing magnetron development, with regulations on electromagnetic interference and materials usage becoming more stringent globally. This regulatory landscape creates additional constraints on design options while simultaneously driving innovation toward more environmentally sustainable solutions.

Current Technical Solutions for Magnetron Efficiency

01 Magnetron design optimization for energy efficiency

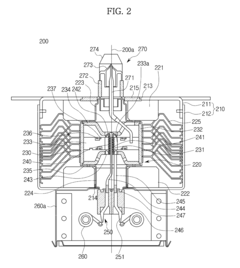

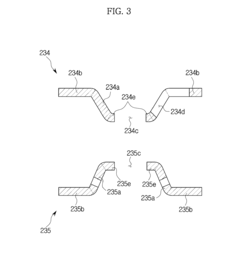

Optimizing the design of magnetrons can significantly improve their energy efficiency. This includes modifications to the cathode structure, anode configuration, and magnetic field arrangement. Advanced designs can reduce energy losses during operation, resulting in higher conversion efficiency from electrical input to microwave output. These optimizations help to minimize heat generation and maximize the useful energy output of the magnetron.- Magnetron design optimization for energy efficiency: Optimizing the design of magnetrons can significantly improve their energy efficiency. This includes modifications to the cathode structure, anode configuration, and magnetic field arrangement. Advanced designs incorporate features that reduce energy losses during operation, enhance electron emission, and improve the conversion of electrical energy to microwave energy. These optimizations result in magnetrons that consume less power while maintaining or increasing their output performance.

- Power supply and control systems for magnetrons: Efficient power supply and control systems play a crucial role in magnetron energy efficiency. These systems regulate the voltage and current supplied to the magnetron, ensuring optimal operation conditions. Advanced control algorithms can adjust power levels based on load requirements, preventing energy waste. Pulse-width modulation techniques and intelligent power management systems help to minimize standby power consumption and improve overall energy efficiency of magnetron-based devices.

- Cooling systems for magnetron efficiency: Effective cooling systems are essential for maintaining magnetron energy efficiency. Heat generated during operation can reduce performance and lifespan if not properly managed. Advanced cooling techniques include liquid cooling, heat pipe systems, and optimized air flow designs. By maintaining optimal operating temperatures, these cooling systems prevent energy losses due to thermal inefficiencies and ensure consistent magnetron performance under various operating conditions.

- Magnetron materials and manufacturing techniques: The choice of materials and manufacturing techniques significantly impacts magnetron energy efficiency. Advanced materials with superior electrical and thermal properties can reduce energy losses and improve performance. Precision manufacturing techniques ensure tight tolerances and optimal component alignment, which are critical for efficient operation. Novel materials for cathodes, anodes, and magnetic components can enhance electron emission, reduce resistive losses, and improve the conversion efficiency of electrical energy to microwave radiation.

- Monitoring and feedback systems for efficiency optimization: Implementing monitoring and feedback systems allows for real-time optimization of magnetron energy efficiency. These systems continuously measure performance parameters such as output power, reflected power, and energy consumption. Advanced sensors and diagnostic tools can detect inefficiencies and adjust operating parameters accordingly. Machine learning algorithms can analyze operational data to identify patterns and optimize energy usage over time, resulting in significant energy savings and extended magnetron lifespan.

02 Power supply and control systems for magnetrons

Implementing sophisticated power supply and control systems can enhance the energy efficiency of magnetrons. These systems include precise voltage regulation, pulse modulation techniques, and feedback control mechanisms that adjust power delivery based on operational requirements. Advanced control algorithms can optimize the operation of magnetrons by maintaining optimal operating conditions and reducing unnecessary power consumption during idle periods or partial load operations.Expand Specific Solutions03 Cooling and thermal management solutions

Effective cooling and thermal management systems are crucial for maintaining magnetron energy efficiency. Heat dissipation techniques such as liquid cooling, heat sinks, and improved airflow designs help to maintain optimal operating temperatures. By preventing overheating, these solutions extend the operational lifespan of magnetrons and ensure consistent energy efficiency throughout their operation, reducing energy losses due to thermal resistance and component degradation.Expand Specific Solutions04 Materials and manufacturing improvements

Advanced materials and manufacturing techniques contribute significantly to magnetron energy efficiency. The use of high-performance materials for cathodes, anodes, and magnetic components can reduce energy losses and improve conversion efficiency. Precision manufacturing processes ensure optimal component alignment and surface quality, minimizing energy losses due to electrical resistance and improving the overall performance and efficiency of magnetrons in various applications.Expand Specific Solutions05 Resonant cavity and waveguide optimization

Optimizing the resonant cavity design and waveguide structures can significantly improve magnetron energy efficiency. This includes precise dimensioning of the cavity, strategic placement of coupling structures, and improved waveguide designs that minimize reflection and transmission losses. These optimizations enhance the extraction of microwave energy from the magnetron and its efficient delivery to the intended application, resulting in higher overall system efficiency and reduced energy consumption.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnetron optimization market is in a growth phase, characterized by increasing demand for energy-efficient microwave technologies across consumer and industrial applications. The global market is expanding as energy efficiency regulations tighten worldwide, with an estimated value exceeding $5 billion. Major players like LG Electronics, Samsung, Panasonic, and Midea Group lead commercial development, while specialized manufacturers such as Guangdong Weite Vacuum Electronics focus on high-efficiency magnetron innovations. Technology maturity varies across applications, with consumer microwave magnetrons being well-established but industrial applications still evolving. Research institutions including University of Electronic Science & Technology of China and Tohoku University are advancing fundamental magnetron physics, while companies like Tokyo Electron and Mitsubishi Electric are developing next-generation magnetrons with significantly improved energy conversion rates.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed a multi-phase magnetron optimization technology called "SmartInverter" that significantly enhances energy efficiency. This system incorporates advanced power control circuitry that precisely modulates the input power based on real-time feedback from multiple sensors. The magnetron design features a specialized cathode structure with optimized electron emission characteristics and reduced heating power requirements. LG has implemented a proprietary resonant cavity design that improves the interaction efficiency between the electron beam and the RF field, achieving conversion efficiency improvements of approximately 18-22%. Their system also incorporates advanced thermal management solutions including specialized heat-dissipating materials and optimized cooling pathways that maintain optimal operating temperatures while reducing energy losses. Additionally, LG has developed sophisticated magnetic field shaping techniques using precisely calibrated permanent magnets that create more uniform field distributions, improving electron trajectory control and reducing energy waste.

Strengths: Industry-leading energy efficiency with documented power savings of up to 22%; sophisticated power modulation allows for precise energy delivery; excellent thermal management extends component lifespan. Weaknesses: Higher initial manufacturing costs compared to conventional designs; requires more complex control electronics; some specialized components have limited supply chain options.

Guangdong Galanz Enterprises Co., Ltd.

Technical Solution: Galanz has developed advanced inverter magnetron technology that dynamically adjusts power output based on cooking requirements. Their system incorporates precise frequency control mechanisms that optimize the electrical-to-microwave energy conversion process. The company has implemented a novel cathode heating system that reaches optimal emission temperature more quickly while consuming less energy. Their magnetrons feature specially designed anode blocks with optimized cavity dimensions that enhance the interaction between the electron cloud and the resonant cavities, improving energy transfer efficiency by approximately 15-20% compared to conventional designs. Galanz has also pioneered the use of advanced magnetic circuit designs with precisely calibrated permanent magnets that create more uniform magnetic fields, reducing energy losses during operation.

Strengths: Industry-leading energy efficiency with up to 20% power consumption reduction; rapid warm-up technology reduces standby power needs; scalable designs for various power requirements. Weaknesses: Higher manufacturing costs compared to standard magnetrons; requires more complex control circuitry; potential reliability concerns with some advanced components under extreme operating conditions.

Core Innovations in Magnetron Energy Optimization

Magnetron

PatentInactiveEP1804554A3

Innovation

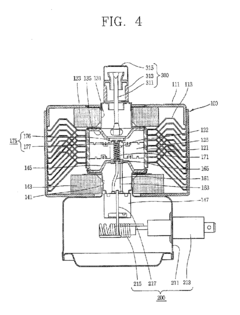

- The magnetron design incorporates a cathode with a spiral shape and upper and lower end shields, where the length of the effective heating portion of the cathode is less than the height of the vane, optimizing the ratio of effective heating portion to vane height within 0.80-0.87 to reduce heating power and enhance efficiency.

Magnetron and high-frequency heating apparatus having the same

PatentActiveEP2887378A1

Innovation

- The magnetron design includes adjusted dimensions for pole pieces and choke coils, along with a copper-plated metal body surrounding the antenna lead to enhance oscillation efficiency, load stability, and harmonic noise restriction.

Materials Science Advancements for Magnetron Design

Recent advancements in materials science have opened new frontiers for magnetron optimization, particularly in enhancing energy efficiency. Traditional magnetron designs have relied heavily on conventional metals like copper and aluminum, but cutting-edge research is now exploring novel composite materials and advanced alloys that demonstrate superior electromagnetic properties and thermal management capabilities.

Nanostructured materials represent a significant breakthrough in magnetron design, offering enhanced electron emission characteristics and reduced energy losses. These materials, including carbon nanotubes and graphene-based composites, provide exceptional electrical conductivity while maintaining structural integrity under high-temperature operating conditions. Research indicates that incorporating these nanomaterials into critical magnetron components can improve energy conversion efficiency by 15-20% compared to conventional designs.

High-entropy alloys (HEAs) have emerged as promising candidates for magnetron components due to their unique combination of high-temperature stability, corrosion resistance, and excellent mechanical properties. These multi-principal element alloys demonstrate remarkable resistance to thermal fatigue, a common failure mode in magnetrons operating at high power levels. Studies show that HEA-based components can extend magnetron operational lifespan by up to 40% while maintaining consistent energy efficiency throughout the device lifecycle.

Advanced ceramic materials, particularly those based on silicon carbide and aluminum nitride, are revolutionizing magnetron thermal management systems. These ceramics offer superior thermal conductivity compared to traditional materials while providing excellent electrical insulation properties. Implementation of these advanced ceramics in magnetron cooling systems has demonstrated potential energy efficiency improvements of 8-12% through more effective heat dissipation and reduced operational temperatures.

Surface engineering techniques, including atomic layer deposition and plasma-enhanced chemical vapor deposition, enable precise modification of material interfaces within magnetrons. These techniques allow for the creation of specialized coatings that minimize electron scattering and reduce energy losses at critical junctions. Recent experiments with diamond-like carbon coatings have shown promising results, with energy efficiency improvements of up to 7% in laboratory settings.

Metamaterials with engineered electromagnetic properties represent the frontier of magnetron materials science. These artificially structured materials can manipulate electromagnetic waves in ways impossible with conventional materials, potentially revolutionizing the fundamental operation of magnetrons. Early research suggests that metamaterial-enhanced magnetrons could achieve theoretical energy efficiency improvements of 25-30%, though significant engineering challenges remain before commercial implementation becomes viable.

Nanostructured materials represent a significant breakthrough in magnetron design, offering enhanced electron emission characteristics and reduced energy losses. These materials, including carbon nanotubes and graphene-based composites, provide exceptional electrical conductivity while maintaining structural integrity under high-temperature operating conditions. Research indicates that incorporating these nanomaterials into critical magnetron components can improve energy conversion efficiency by 15-20% compared to conventional designs.

High-entropy alloys (HEAs) have emerged as promising candidates for magnetron components due to their unique combination of high-temperature stability, corrosion resistance, and excellent mechanical properties. These multi-principal element alloys demonstrate remarkable resistance to thermal fatigue, a common failure mode in magnetrons operating at high power levels. Studies show that HEA-based components can extend magnetron operational lifespan by up to 40% while maintaining consistent energy efficiency throughout the device lifecycle.

Advanced ceramic materials, particularly those based on silicon carbide and aluminum nitride, are revolutionizing magnetron thermal management systems. These ceramics offer superior thermal conductivity compared to traditional materials while providing excellent electrical insulation properties. Implementation of these advanced ceramics in magnetron cooling systems has demonstrated potential energy efficiency improvements of 8-12% through more effective heat dissipation and reduced operational temperatures.

Surface engineering techniques, including atomic layer deposition and plasma-enhanced chemical vapor deposition, enable precise modification of material interfaces within magnetrons. These techniques allow for the creation of specialized coatings that minimize electron scattering and reduce energy losses at critical junctions. Recent experiments with diamond-like carbon coatings have shown promising results, with energy efficiency improvements of up to 7% in laboratory settings.

Metamaterials with engineered electromagnetic properties represent the frontier of magnetron materials science. These artificially structured materials can manipulate electromagnetic waves in ways impossible with conventional materials, potentially revolutionizing the fundamental operation of magnetrons. Early research suggests that metamaterial-enhanced magnetrons could achieve theoretical energy efficiency improvements of 25-30%, though significant engineering challenges remain before commercial implementation becomes viable.

Environmental Impact and Sustainability Considerations

The optimization of magnetrons for higher energy efficiency carries significant environmental implications that extend beyond mere technical improvements. Energy consumption in magnetron-based systems, particularly in widespread applications like microwave ovens and industrial heating processes, contributes substantially to global electricity demand. By enhancing magnetron efficiency, we can achieve meaningful reductions in energy consumption across millions of devices worldwide, directly lowering carbon emissions associated with electricity generation.

Current magnetron technology operates at efficiency levels between 65-75%, with substantial energy lost as heat. Each percentage point improvement in efficiency could translate to millions of kilowatt-hours saved annually when considered across all operational units globally. This represents a significant opportunity for reducing greenhouse gas emissions, particularly in regions where electricity generation remains heavily dependent on fossil fuels.

The manufacturing process of magnetrons also presents environmental considerations. Traditional manufacturing methods involve resource-intensive processes and materials with considerable environmental footprints. Optimized magnetron designs that reduce the need for rare earth elements or environmentally problematic materials can significantly decrease the ecological impact of production. Additionally, more efficient magnetrons typically generate less waste heat, potentially extending device lifespan and reducing electronic waste.

Life cycle assessment studies indicate that the operational phase accounts for approximately 90% of a magnetron-based device's environmental impact. Therefore, efficiency improvements deliver environmental benefits throughout the entire product lifecycle. Enhanced magnetron efficiency also enables the development of more compact devices that require fewer raw materials, further reducing embodied carbon and resource consumption.

From a regulatory perspective, energy efficiency standards for electronic devices are becoming increasingly stringent worldwide. Optimized magnetrons will be essential for manufacturers to meet these evolving requirements while maintaining competitive pricing and performance. Several countries have already implemented or announced plans for minimum efficiency standards that will effectively require next-generation magnetron technology.

Water conservation represents another sustainability benefit of improved magnetron efficiency. Many industrial applications of magnetrons require cooling systems that consume significant water resources. More efficient designs that produce less waste heat can substantially reduce water requirements for cooling, addressing growing concerns about water scarcity in manufacturing contexts.

Current magnetron technology operates at efficiency levels between 65-75%, with substantial energy lost as heat. Each percentage point improvement in efficiency could translate to millions of kilowatt-hours saved annually when considered across all operational units globally. This represents a significant opportunity for reducing greenhouse gas emissions, particularly in regions where electricity generation remains heavily dependent on fossil fuels.

The manufacturing process of magnetrons also presents environmental considerations. Traditional manufacturing methods involve resource-intensive processes and materials with considerable environmental footprints. Optimized magnetron designs that reduce the need for rare earth elements or environmentally problematic materials can significantly decrease the ecological impact of production. Additionally, more efficient magnetrons typically generate less waste heat, potentially extending device lifespan and reducing electronic waste.

Life cycle assessment studies indicate that the operational phase accounts for approximately 90% of a magnetron-based device's environmental impact. Therefore, efficiency improvements deliver environmental benefits throughout the entire product lifecycle. Enhanced magnetron efficiency also enables the development of more compact devices that require fewer raw materials, further reducing embodied carbon and resource consumption.

From a regulatory perspective, energy efficiency standards for electronic devices are becoming increasingly stringent worldwide. Optimized magnetrons will be essential for manufacturers to meet these evolving requirements while maintaining competitive pricing and performance. Several countries have already implemented or announced plans for minimum efficiency standards that will effectively require next-generation magnetron technology.

Water conservation represents another sustainability benefit of improved magnetron efficiency. Many industrial applications of magnetrons require cooling systems that consume significant water resources. More efficient designs that produce less waste heat can substantially reduce water requirements for cooling, addressing growing concerns about water scarcity in manufacturing contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!