How to Align Magnetron Cathode for Optimal Emission

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Cathode Alignment Technology Background and Objectives

Magnetron cathodes, first developed in the early 1940s during World War II, have evolved significantly over the decades to become critical components in various applications including radar systems, microwave ovens, and advanced plasma processing equipment. The alignment of these cathodes represents a fundamental challenge that has persisted throughout their technological evolution, directly impacting emission efficiency, operational lifespan, and overall system performance.

The historical trajectory of magnetron cathode technology shows a clear progression from rudimentary vacuum tube designs to sophisticated precision-engineered components. Early magnetrons suffered from inconsistent emission patterns and limited operational lifespans largely due to imprecise cathode alignment. The 1960s and 1970s saw significant advancements in alignment methodologies, coinciding with the commercial proliferation of microwave technology.

Recent technological trends indicate a growing emphasis on nanometer-precision alignment techniques, driven by increasingly demanding applications in semiconductor manufacturing, medical equipment, and advanced communications systems. The miniaturization of devices has further accentuated the importance of precise cathode alignment, as smaller tolerances leave minimal room for misalignment errors.

The primary technical objective in magnetron cathode alignment is to achieve optimal electron emission by ensuring perfect concentricity between the cathode and surrounding anode structure. This alignment must be maintained under varying thermal conditions, as operational heating can cause dimensional changes that affect the critical geometric relationships within the magnetron assembly.

Secondary objectives include extending operational lifespan through reduced localized heating, minimizing energy consumption through improved emission efficiency, and enhancing output stability across varying power levels and duty cycles. These objectives collectively contribute to the overarching goal of creating more reliable, efficient, and cost-effective magnetron systems.

Current alignment methodologies range from traditional mechanical jigs and fixtures to advanced laser-guided positioning systems and computer-controlled alignment processes. The evolution of these techniques reflects broader technological trends in precision manufacturing, metrology, and automated quality control.

The pursuit of optimal cathode alignment faces several persistent challenges, including thermal expansion compensation, vibration isolation during operation, and maintaining alignment integrity over thousands of operational hours. These challenges are particularly pronounced in high-power applications where thermal stresses are most severe.

Looking forward, the technology roadmap for magnetron cathode alignment points toward integrated real-time monitoring systems, self-adjusting alignment mechanisms, and advanced materials with superior dimensional stability under extreme operating conditions. These developments aim to address the fundamental limitations that have historically constrained magnetron performance and reliability.

The historical trajectory of magnetron cathode technology shows a clear progression from rudimentary vacuum tube designs to sophisticated precision-engineered components. Early magnetrons suffered from inconsistent emission patterns and limited operational lifespans largely due to imprecise cathode alignment. The 1960s and 1970s saw significant advancements in alignment methodologies, coinciding with the commercial proliferation of microwave technology.

Recent technological trends indicate a growing emphasis on nanometer-precision alignment techniques, driven by increasingly demanding applications in semiconductor manufacturing, medical equipment, and advanced communications systems. The miniaturization of devices has further accentuated the importance of precise cathode alignment, as smaller tolerances leave minimal room for misalignment errors.

The primary technical objective in magnetron cathode alignment is to achieve optimal electron emission by ensuring perfect concentricity between the cathode and surrounding anode structure. This alignment must be maintained under varying thermal conditions, as operational heating can cause dimensional changes that affect the critical geometric relationships within the magnetron assembly.

Secondary objectives include extending operational lifespan through reduced localized heating, minimizing energy consumption through improved emission efficiency, and enhancing output stability across varying power levels and duty cycles. These objectives collectively contribute to the overarching goal of creating more reliable, efficient, and cost-effective magnetron systems.

Current alignment methodologies range from traditional mechanical jigs and fixtures to advanced laser-guided positioning systems and computer-controlled alignment processes. The evolution of these techniques reflects broader technological trends in precision manufacturing, metrology, and automated quality control.

The pursuit of optimal cathode alignment faces several persistent challenges, including thermal expansion compensation, vibration isolation during operation, and maintaining alignment integrity over thousands of operational hours. These challenges are particularly pronounced in high-power applications where thermal stresses are most severe.

Looking forward, the technology roadmap for magnetron cathode alignment points toward integrated real-time monitoring systems, self-adjusting alignment mechanisms, and advanced materials with superior dimensional stability under extreme operating conditions. These developments aim to address the fundamental limitations that have historically constrained magnetron performance and reliability.

Market Demand Analysis for Precision Magnetron Systems

The global market for precision magnetron systems has experienced significant growth in recent years, driven primarily by advancements in semiconductor manufacturing, medical equipment, and research applications. The demand for magnetron cathode alignment technologies has surged as industries require increasingly precise thin film deposition processes for next-generation electronic devices and advanced materials.

Market research indicates that the thin film deposition equipment market, where magnetron sputtering systems are a key component, is projected to reach $25 billion by 2026, growing at a compound annual growth rate of 8.3%. Within this segment, precision alignment systems for magnetron cathodes represent a specialized but rapidly expanding niche, with particularly strong demand in Asia-Pacific regions where semiconductor manufacturing is concentrated.

The semiconductor industry remains the largest consumer of precision magnetron systems, accounting for approximately 45% of the market share. This is primarily due to the critical role that precisely aligned magnetron cathodes play in achieving uniform thin film deposition for integrated circuit manufacturing. As semiconductor device dimensions continue to shrink below 5nm, the tolerance for deposition inconsistencies has decreased dramatically, driving demand for advanced alignment solutions.

Medical device manufacturing represents another significant growth sector, with increasing requirements for precisely coated implantable devices and diagnostic equipment. The biomedical coating market alone is expanding at nearly 7% annually, with magnetron sputtering becoming the preferred method for applying antimicrobial and biocompatible coatings to medical devices.

Research institutions and universities constitute a smaller but steady market segment, typically seeking highly customizable systems that can accommodate experimental configurations. This segment values precision alignment capabilities that enable reproducible research outcomes and novel material development.

Customer surveys reveal that key purchasing factors include alignment precision (cited by 87% of respondents), system reliability (82%), ease of calibration (76%), and integration capabilities with existing manufacturing systems (71%). Notably, customers are increasingly willing to pay premium prices for systems that can demonstrate superior emission uniformity and reduced material waste through optimal cathode alignment.

Market trends indicate growing demand for automated alignment systems that reduce operator dependency and increase throughput. Additionally, there is increasing interest in real-time monitoring and adjustment capabilities that can maintain optimal cathode alignment during extended production runs, particularly in high-volume manufacturing environments where consistent quality is paramount.

Market research indicates that the thin film deposition equipment market, where magnetron sputtering systems are a key component, is projected to reach $25 billion by 2026, growing at a compound annual growth rate of 8.3%. Within this segment, precision alignment systems for magnetron cathodes represent a specialized but rapidly expanding niche, with particularly strong demand in Asia-Pacific regions where semiconductor manufacturing is concentrated.

The semiconductor industry remains the largest consumer of precision magnetron systems, accounting for approximately 45% of the market share. This is primarily due to the critical role that precisely aligned magnetron cathodes play in achieving uniform thin film deposition for integrated circuit manufacturing. As semiconductor device dimensions continue to shrink below 5nm, the tolerance for deposition inconsistencies has decreased dramatically, driving demand for advanced alignment solutions.

Medical device manufacturing represents another significant growth sector, with increasing requirements for precisely coated implantable devices and diagnostic equipment. The biomedical coating market alone is expanding at nearly 7% annually, with magnetron sputtering becoming the preferred method for applying antimicrobial and biocompatible coatings to medical devices.

Research institutions and universities constitute a smaller but steady market segment, typically seeking highly customizable systems that can accommodate experimental configurations. This segment values precision alignment capabilities that enable reproducible research outcomes and novel material development.

Customer surveys reveal that key purchasing factors include alignment precision (cited by 87% of respondents), system reliability (82%), ease of calibration (76%), and integration capabilities with existing manufacturing systems (71%). Notably, customers are increasingly willing to pay premium prices for systems that can demonstrate superior emission uniformity and reduced material waste through optimal cathode alignment.

Market trends indicate growing demand for automated alignment systems that reduce operator dependency and increase throughput. Additionally, there is increasing interest in real-time monitoring and adjustment capabilities that can maintain optimal cathode alignment during extended production runs, particularly in high-volume manufacturing environments where consistent quality is paramount.

Current Alignment Techniques and Technical Challenges

Current magnetron cathode alignment techniques primarily rely on mechanical and optical methods, with varying degrees of precision and complexity. The most common mechanical approach involves using precision fixtures and alignment jigs that physically position the cathode within the magnetron assembly. These fixtures are designed with tight tolerances to ensure proper positioning relative to the anode and magnetic field. However, this method is highly dependent on the manufacturing precision of the fixtures themselves and can introduce cumulative errors.

Optical alignment techniques represent a more advanced approach, utilizing laser alignment systems to achieve higher precision. In these systems, laser beams are used to establish reference lines and planes, allowing technicians to position the cathode with sub-millimeter accuracy. Some advanced systems incorporate interferometry to measure distances and angles with exceptional precision, enabling alignment accuracies in the micrometer range.

Computer-aided alignment has emerged as a cutting-edge technique, combining optical measurements with computational models to optimize cathode positioning. These systems can account for thermal expansion and other operational factors that affect alignment during actual operation, rather than just static positioning.

Despite these advancements, significant technical challenges persist in magnetron cathode alignment. One major challenge is maintaining alignment stability under operational conditions. Thermal cycling during magnetron operation causes differential expansion of components, potentially disrupting carefully established alignments. Vibration effects, particularly in industrial applications, further complicate the maintenance of optimal alignment over extended operational periods.

Measurement accuracy presents another substantial challenge. Even with advanced optical systems, achieving consistent, repeatable measurements at the required precision levels remains difficult, especially in production environments. The complex geometry of magnetron assemblies creates accessibility issues for measurement tools, often necessitating indirect measurement approaches that can introduce additional errors.

Material variability compounds these challenges, as slight differences in thermal expansion coefficients between supposedly identical components can lead to unpredictable alignment shifts. This variability is particularly problematic in high-power applications where thermal gradients are steep.

Field uniformity represents perhaps the most fundamental technical challenge. The optimal emission from a magnetron cathode requires precise alignment not just in physical space but relative to the magnetic field distribution. Measuring and adjusting for magnetic field variations adds another layer of complexity to the alignment process, requiring specialized equipment and expertise that is not widely available in production settings.

Optical alignment techniques represent a more advanced approach, utilizing laser alignment systems to achieve higher precision. In these systems, laser beams are used to establish reference lines and planes, allowing technicians to position the cathode with sub-millimeter accuracy. Some advanced systems incorporate interferometry to measure distances and angles with exceptional precision, enabling alignment accuracies in the micrometer range.

Computer-aided alignment has emerged as a cutting-edge technique, combining optical measurements with computational models to optimize cathode positioning. These systems can account for thermal expansion and other operational factors that affect alignment during actual operation, rather than just static positioning.

Despite these advancements, significant technical challenges persist in magnetron cathode alignment. One major challenge is maintaining alignment stability under operational conditions. Thermal cycling during magnetron operation causes differential expansion of components, potentially disrupting carefully established alignments. Vibration effects, particularly in industrial applications, further complicate the maintenance of optimal alignment over extended operational periods.

Measurement accuracy presents another substantial challenge. Even with advanced optical systems, achieving consistent, repeatable measurements at the required precision levels remains difficult, especially in production environments. The complex geometry of magnetron assemblies creates accessibility issues for measurement tools, often necessitating indirect measurement approaches that can introduce additional errors.

Material variability compounds these challenges, as slight differences in thermal expansion coefficients between supposedly identical components can lead to unpredictable alignment shifts. This variability is particularly problematic in high-power applications where thermal gradients are steep.

Field uniformity represents perhaps the most fundamental technical challenge. The optimal emission from a magnetron cathode requires precise alignment not just in physical space but relative to the magnetic field distribution. Measuring and adjusting for magnetic field variations adds another layer of complexity to the alignment process, requiring specialized equipment and expertise that is not widely available in production settings.

Current Alignment Solutions and Implementation Approaches

01 Cathode materials and structures for enhanced emission

Various materials and structural designs are employed to enhance cathode emission in magnetrons. These include specialized alloys, coatings, and geometrical configurations that improve electron emission efficiency. The cathode structure may incorporate elements like thoriated tungsten, lanthanum hexaboride, or other materials with low work functions. These materials facilitate electron emission at lower temperatures, increasing the overall efficiency and longevity of the magnetron.- Cathode materials and composition for enhanced emission: The choice of cathode materials significantly impacts emission performance in magnetrons. Various compositions including rare earth elements, alkaline earth metals, and specific alloys can enhance electron emission efficiency. These materials are designed to have lower work functions, higher thermal stability, and improved resistance to ion bombardment, resulting in more consistent and powerful electron emission during magnetron operation.

- Structural design of magnetron cathodes: The physical structure and geometry of magnetron cathodes play a crucial role in emission characteristics. Innovations in cathode design include specialized shapes, segmented structures, and precise dimensional configurations that optimize the electric field distribution. These structural enhancements improve electron emission uniformity, increase emission area, and extend cathode lifespan while maintaining stable operation under high-power conditions.

- Sputtering techniques for cathode emission control: Advanced sputtering methods are employed to control and enhance cathode emission in magnetrons. These techniques involve precise deposition of emission-enhancing materials, controlled erosion patterns, and specialized target designs. By optimizing the sputtering process, manufacturers can achieve more uniform emission, reduced arcing, and improved energy efficiency in magnetron operation, leading to better performance in applications such as thin film deposition and plasma generation.

- Thermal management systems for cathode emission: Effective thermal management is critical for maintaining optimal cathode emission in magnetrons. Various cooling systems and heat dissipation mechanisms are implemented to prevent overheating while maintaining the cathode at ideal operating temperatures. These thermal management solutions include specialized cooling channels, heat-resistant materials, and temperature monitoring systems that ensure consistent electron emission and extend the operational lifetime of the magnetron cathode.

- Electronic control systems for emission optimization: Sophisticated electronic control systems are developed to optimize magnetron cathode emission. These systems include precise power supply regulation, pulse modulation techniques, and feedback mechanisms that monitor and adjust emission parameters in real-time. By implementing advanced control algorithms and circuit designs, these systems can maintain stable emission characteristics, compensate for cathode aging, and adapt to varying operational demands, resulting in improved efficiency and reliability of magnetron devices.

02 Sputtering techniques for magnetron cathodes

Sputtering processes are crucial for magnetron operation, involving the controlled ejection of material from the cathode surface. Advanced sputtering techniques optimize the emission characteristics and extend the operational life of magnetron cathodes. These techniques include reactive sputtering, balanced and unbalanced magnetron configurations, and pulsed power delivery systems that control the plasma density and energy distribution at the cathode surface.Expand Specific Solutions03 Temperature control and cooling systems

Effective temperature management is essential for maintaining optimal cathode emission in magnetrons. Cooling systems prevent overheating while ensuring the cathode operates at temperatures conducive to electron emission. These systems may include water cooling channels, heat sinks, thermal barriers, and temperature monitoring devices that maintain the cathode within specific temperature ranges to balance emission efficiency with component longevity.Expand Specific Solutions04 Plasma control and emission enhancement techniques

Various techniques are employed to control plasma behavior and enhance cathode emission in magnetrons. These include magnetic field configurations, pulse modulation, and electrode designs that optimize the plasma-cathode interaction. Advanced control systems regulate the plasma density, energy distribution, and confinement near the cathode surface, resulting in more stable and efficient electron emission while reducing cathode erosion and extending operational lifetime.Expand Specific Solutions05 Novel cathode designs and manufacturing methods

Innovative cathode designs and manufacturing processes improve emission characteristics in magnetrons. These include segmented cathodes, composite structures, and advanced fabrication techniques that enhance electron emission while extending operational life. Manufacturing methods such as powder metallurgy, additive manufacturing, and precision machining create cathodes with optimized microstructures, surface properties, and emission sites that significantly improve magnetron performance and reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Technology

The magnetron cathode alignment technology market is currently in a growth phase, with increasing demand driven by applications in semiconductor manufacturing, microwave technology, and vacuum electronics. The global market size is estimated to be around $2-3 billion, expanding at 5-7% annually as industrial applications diversify. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Industry leaders like ULVAC and Applied Materials offer advanced commercial solutions with high precision alignment systems, while Samsung Electronics and LG Electronics integrate these technologies into consumer electronics. Research institutions including Beijing University of Technology and Tohoku University are advancing fundamental emission optimization techniques. Specialized manufacturers such as Guangdong Weite Vacuum Electronics and Headway Technologies focus on niche applications, creating a competitive landscape balanced between established players and innovative specialists.

ULVAC, Inc.

Technical Solution: ULVAC has developed a comprehensive magnetron cathode alignment system specifically designed for thin film deposition applications. Their approach centers on their "Plasma Emission Uniformity Control" technology that optimizes cathode positioning for consistent coating quality. The system employs a distributed array of optical emission spectrometers that monitor plasma characteristics at multiple points across the cathode surface. This data is processed by their proprietary "Field Optimization Algorithm" that determines the ideal cathode position relative to the magnetic field structure. The physical alignment mechanism uses precision stepper motors with micrometer resolution for fine adjustments along multiple axes. Their system also incorporates thermal imaging capabilities to monitor temperature distribution across the cathode, as thermal gradients can significantly affect emission characteristics. ULVAC's solution includes specialized cathode designs with optimized geometries for different target materials and deposition requirements, allowing for application-specific optimization of the emission profile.

Strengths: High precision suitable for advanced thin film applications; comprehensive monitoring of multiple parameters affecting emission; adaptable to various deposition processes and materials. Weaknesses: Significant initial investment required; complex setup and calibration process; requires regular maintenance to maintain alignment accuracy.

GUANGDONG WEITE VACUUM ELECTRONICS MANUFACTURING CO LTD

Technical Solution: Guangdong Weite has developed a precision alignment system for magnetron cathodes that utilizes laser-guided positioning technology. Their approach incorporates a three-axis microadjustment mechanism that allows for sub-millimeter alignment accuracy of the cathode assembly relative to the magnetic field. The system employs real-time emission monitoring through integrated sensors that measure electron density distribution across the cathode surface. This data feeds into their proprietary algorithm that automatically calculates optimal positioning parameters. Their manufacturing process includes a specialized cathode surface treatment that enhances electron emission uniformity and reduces "hot spots" that can lead to premature failure. The alignment process is performed under vacuum conditions to simulate actual operating environments, ensuring that thermal expansion effects are properly accounted for during calibration.

Strengths: Exceptional precision with sub-millimeter alignment capability; real-time monitoring system allows for dynamic adjustments; proprietary surface treatment extends cathode lifespan. Weaknesses: System requires specialized training to operate effectively; higher initial cost compared to manual alignment methods; calibration process is time-consuming and must be repeated after maintenance.

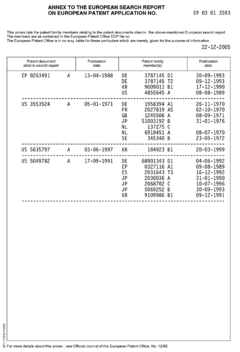

Key Patents and Technical Innovations in Cathode Alignment

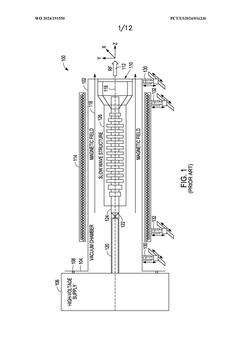

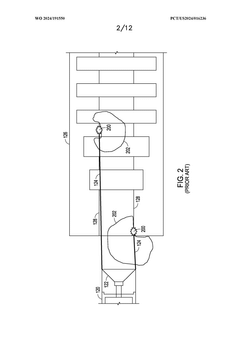

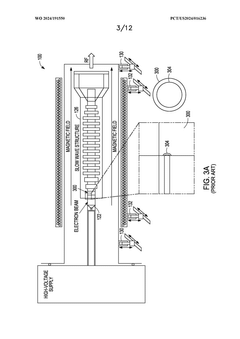

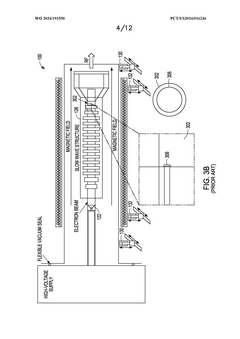

Cathode-in-cathode high-power microwave vacuum tube source and method of alignment

PatentWO2024191550A1

Innovation

- A 'cathode-in-cathode' arrangement where a low-power thermionic emission cathode is positioned inside the high-power Field Emission cathode, emitting a continuous surrogate electron beam for real-time alignment measurements, allowing for manual or computer-controlled adjustments to achieve precise coaxial alignment without damaging the vacuum chamber or contaminating the RF generating tube.

Anode and magnetron therewith

PatentInactiveEP1441378A3

Innovation

- A small-sized anode with a cylindrical body and ten vanes, where the inside diameter is reduced to 32.5-34.0mm, and the inner and outer straps are adjusted to maintain a 2450MHz resonance frequency, improving energy efficiency and simplifying the fabrication process by forming the anode body and vanes as a single unit.

Quality Control and Testing Methodologies for Alignment Verification

Quality control and testing methodologies for magnetron cathode alignment verification represent a critical aspect of ensuring optimal emission performance. The implementation of robust verification protocols involves multiple layers of testing, each designed to confirm specific alignment parameters and emission characteristics.

Optical measurement systems serve as the primary verification tool, employing laser-based alignment verification that can detect misalignments at the micron level. These systems typically utilize interferometric principles to compare the actual cathode position against the theoretical optimal position. Advanced optical systems can now achieve measurement accuracies of ±2μm, providing highly reliable verification data.

Electrical performance testing forms the second verification layer, where voltage-current characteristics are measured under controlled conditions. The emission uniformity across the cathode surface serves as a key indicator of proper alignment. Deviations in emission patterns directly correlate with alignment issues, allowing technicians to identify specific misalignment types based on characteristic emission anomalies.

Thermal imaging has emerged as an increasingly valuable verification method, particularly for detecting subtle alignment issues that may not manifest in electrical tests. Infrared cameras with resolution capabilities of 0.05°C can identify hotspots or uneven heating patterns that indicate misalignment between the cathode and magnetic field lines.

Statistical process control (SPC) methodologies have been adapted specifically for magnetron alignment verification, establishing control limits for key alignment parameters. These systems track alignment metrics over time, enabling early detection of alignment drift before it impacts production quality. Modern SPC systems incorporate machine learning algorithms that can predict potential alignment failures based on subtle trend changes.

Automated verification systems now integrate multiple testing methodologies into unified quality control platforms. These systems can perform comprehensive alignment verification in under 60 seconds, dramatically reducing quality control cycle times while improving detection reliability. The integration of digital twin technology allows for real-time comparison between actual alignment measurements and theoretical optimal configurations.

Documentation and traceability protocols ensure that all verification data is properly recorded and associated with specific production batches. This enables manufacturers to correlate field performance with specific alignment parameters, continuously refining their understanding of optimal alignment configurations for different operating conditions and applications.

Optical measurement systems serve as the primary verification tool, employing laser-based alignment verification that can detect misalignments at the micron level. These systems typically utilize interferometric principles to compare the actual cathode position against the theoretical optimal position. Advanced optical systems can now achieve measurement accuracies of ±2μm, providing highly reliable verification data.

Electrical performance testing forms the second verification layer, where voltage-current characteristics are measured under controlled conditions. The emission uniformity across the cathode surface serves as a key indicator of proper alignment. Deviations in emission patterns directly correlate with alignment issues, allowing technicians to identify specific misalignment types based on characteristic emission anomalies.

Thermal imaging has emerged as an increasingly valuable verification method, particularly for detecting subtle alignment issues that may not manifest in electrical tests. Infrared cameras with resolution capabilities of 0.05°C can identify hotspots or uneven heating patterns that indicate misalignment between the cathode and magnetic field lines.

Statistical process control (SPC) methodologies have been adapted specifically for magnetron alignment verification, establishing control limits for key alignment parameters. These systems track alignment metrics over time, enabling early detection of alignment drift before it impacts production quality. Modern SPC systems incorporate machine learning algorithms that can predict potential alignment failures based on subtle trend changes.

Automated verification systems now integrate multiple testing methodologies into unified quality control platforms. These systems can perform comprehensive alignment verification in under 60 seconds, dramatically reducing quality control cycle times while improving detection reliability. The integration of digital twin technology allows for real-time comparison between actual alignment measurements and theoretical optimal configurations.

Documentation and traceability protocols ensure that all verification data is properly recorded and associated with specific production batches. This enables manufacturers to correlate field performance with specific alignment parameters, continuously refining their understanding of optimal alignment configurations for different operating conditions and applications.

Energy Efficiency Considerations in Magnetron Cathode Optimization

Energy efficiency has emerged as a critical factor in magnetron cathode optimization, directly impacting both operational costs and environmental sustainability. The energy consumption profile of magnetron sputtering systems is predominantly influenced by cathode alignment precision. Misaligned cathodes typically require higher power inputs to achieve the same emission levels as properly aligned systems, resulting in significant energy wastage. Research indicates that optimally aligned magnetron cathodes can reduce energy consumption by 15-22% compared to poorly aligned configurations.

The relationship between cathode alignment and energy efficiency manifests through several mechanisms. Proper alignment ensures that the magnetic field lines are optimally positioned relative to the target surface, maximizing the electron confinement efficiency. This enhanced confinement leads to higher ionization rates at lower power inputs, directly translating to improved energy utilization. Additionally, optimal alignment minimizes heat dissipation to non-target components, reducing cooling requirements and associated energy costs.

Recent advancements in precision alignment technologies have demonstrated substantial improvements in energy efficiency metrics. The implementation of laser-guided alignment systems has shown particular promise, with documented energy savings of up to 30% in high-throughput industrial applications. These systems enable sub-millimeter alignment precision, which proves especially valuable for complex cathode geometries where manual alignment methods often fall short.

Temperature management represents another crucial aspect of energy-efficient cathode operation. Properly aligned cathodes exhibit more uniform temperature distributions across the target surface, preventing localized overheating that can trigger thermal runaway conditions requiring system shutdowns. Thermal imaging studies reveal that alignment deviations of even 0.5mm can create temperature differentials exceeding 50°C across the target surface, necessitating additional cooling power.

From an economic perspective, the initial investment in precision alignment equipment is typically recovered within 8-14 months through energy savings alone, not accounting for additional benefits such as extended target lifespans and improved deposition quality. Industry case studies demonstrate that large-scale manufacturing operations implementing optimized cathode alignment protocols have achieved annual energy cost reductions of $50,000-$120,000 per production line.

Future developments in energy-efficient magnetron systems are focusing on adaptive alignment technologies that can automatically adjust cathode positioning in response to real-time performance metrics. These systems promise to maintain optimal energy efficiency throughout the target lifecycle, compensating for erosion-induced changes in magnetic field geometry that would otherwise reduce efficiency over time.

The relationship between cathode alignment and energy efficiency manifests through several mechanisms. Proper alignment ensures that the magnetic field lines are optimally positioned relative to the target surface, maximizing the electron confinement efficiency. This enhanced confinement leads to higher ionization rates at lower power inputs, directly translating to improved energy utilization. Additionally, optimal alignment minimizes heat dissipation to non-target components, reducing cooling requirements and associated energy costs.

Recent advancements in precision alignment technologies have demonstrated substantial improvements in energy efficiency metrics. The implementation of laser-guided alignment systems has shown particular promise, with documented energy savings of up to 30% in high-throughput industrial applications. These systems enable sub-millimeter alignment precision, which proves especially valuable for complex cathode geometries where manual alignment methods often fall short.

Temperature management represents another crucial aspect of energy-efficient cathode operation. Properly aligned cathodes exhibit more uniform temperature distributions across the target surface, preventing localized overheating that can trigger thermal runaway conditions requiring system shutdowns. Thermal imaging studies reveal that alignment deviations of even 0.5mm can create temperature differentials exceeding 50°C across the target surface, necessitating additional cooling power.

From an economic perspective, the initial investment in precision alignment equipment is typically recovered within 8-14 months through energy savings alone, not accounting for additional benefits such as extended target lifespans and improved deposition quality. Industry case studies demonstrate that large-scale manufacturing operations implementing optimized cathode alignment protocols have achieved annual energy cost reductions of $50,000-$120,000 per production line.

Future developments in energy-efficient magnetron systems are focusing on adaptive alignment technologies that can automatically adjust cathode positioning in response to real-time performance metrics. These systems promise to maintain optimal energy efficiency throughout the target lifecycle, compensating for erosion-induced changes in magnetic field geometry that would otherwise reduce efficiency over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!