Investigating Magnetron Lifespan in Continuous Duty Cycles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Lifespan Technology Background and Objectives

Magnetron technology has evolved significantly since its inception in the early 20th century, with major advancements occurring during World War II when it was utilized in radar systems. The subsequent decades saw magnetrons transition into commercial applications, most notably in microwave ovens during the 1960s and 1970s. Today, magnetrons serve as critical components in various industrial heating processes, medical equipment, radar systems, and consumer appliances, generating electromagnetic waves in the microwave frequency range through electron cyclotron resonance.

The evolution of magnetron technology has been characterized by continuous improvements in power efficiency, frequency stability, and operational lifespan. Early magnetrons suffered from relatively short lifespans, particularly under continuous operation, with typical operational lives measured in hundreds of hours. Modern industrial magnetrons have extended this significantly, though lifespan limitations remain a critical constraint in many high-demand applications.

Current industry standards for magnetron lifespan vary considerably depending on the application context. Consumer-grade magnetrons in household microwave ovens typically operate for 1,000-2,000 hours, while industrial magnetrons designed for continuous operation may achieve 5,000-8,000 hours under optimal conditions. However, when subjected to continuous duty cycles, particularly at high power outputs, these lifespans can decrease substantially.

The primary objective of investigating magnetron lifespan in continuous duty cycles is to identify the fundamental failure mechanisms that limit operational longevity and develop innovative solutions to extend service life. This includes examining cathode degradation processes, filament deterioration, vacuum integrity issues, and thermal management challenges that become particularly pronounced during extended operation periods.

Secondary objectives include establishing standardized testing methodologies for predicting magnetron lifespan under various operational conditions, developing real-time monitoring systems for early failure detection, and exploring novel materials and designs that could fundamentally improve durability. Additionally, this research aims to quantify the economic impact of extended magnetron lifespan in industrial applications, where replacement costs and downtime can significantly affect operational expenses.

The technological trajectory suggests several promising avenues for improvement, including advanced cathode materials with enhanced electron emission properties, improved thermal management systems, and novel cooling techniques that could substantially extend operational lifespans. Recent developments in computational modeling have also enabled more sophisticated simulation of electron behavior and thermal distribution within magnetrons, potentially leading to optimized designs specifically tailored for continuous operation.

Understanding the complex interplay between operational parameters and degradation mechanisms represents a crucial step toward developing next-generation magnetrons capable of meeting the increasing demands of continuous industrial processes, medical treatments, and advanced radar systems.

The evolution of magnetron technology has been characterized by continuous improvements in power efficiency, frequency stability, and operational lifespan. Early magnetrons suffered from relatively short lifespans, particularly under continuous operation, with typical operational lives measured in hundreds of hours. Modern industrial magnetrons have extended this significantly, though lifespan limitations remain a critical constraint in many high-demand applications.

Current industry standards for magnetron lifespan vary considerably depending on the application context. Consumer-grade magnetrons in household microwave ovens typically operate for 1,000-2,000 hours, while industrial magnetrons designed for continuous operation may achieve 5,000-8,000 hours under optimal conditions. However, when subjected to continuous duty cycles, particularly at high power outputs, these lifespans can decrease substantially.

The primary objective of investigating magnetron lifespan in continuous duty cycles is to identify the fundamental failure mechanisms that limit operational longevity and develop innovative solutions to extend service life. This includes examining cathode degradation processes, filament deterioration, vacuum integrity issues, and thermal management challenges that become particularly pronounced during extended operation periods.

Secondary objectives include establishing standardized testing methodologies for predicting magnetron lifespan under various operational conditions, developing real-time monitoring systems for early failure detection, and exploring novel materials and designs that could fundamentally improve durability. Additionally, this research aims to quantify the economic impact of extended magnetron lifespan in industrial applications, where replacement costs and downtime can significantly affect operational expenses.

The technological trajectory suggests several promising avenues for improvement, including advanced cathode materials with enhanced electron emission properties, improved thermal management systems, and novel cooling techniques that could substantially extend operational lifespans. Recent developments in computational modeling have also enabled more sophisticated simulation of electron behavior and thermal distribution within magnetrons, potentially leading to optimized designs specifically tailored for continuous operation.

Understanding the complex interplay between operational parameters and degradation mechanisms represents a crucial step toward developing next-generation magnetrons capable of meeting the increasing demands of continuous industrial processes, medical treatments, and advanced radar systems.

Market Demand Analysis for Durable Magnetrons

The global market for durable magnetrons has been experiencing significant growth, driven primarily by the expanding applications in industrial heating, microwave ovens, radar systems, and medical equipment. Current market analysis indicates that the industrial microwave processing sector alone is projected to grow at a compound annual growth rate of 6.8% through 2028, with magnetrons being a critical component in these systems.

The demand for magnetrons with extended lifespans under continuous duty cycles is particularly pronounced in industrial applications where equipment downtime translates directly to production losses. Manufacturing facilities utilizing industrial microwave systems for drying, sintering, and material processing report that magnetron replacement accounts for approximately 40% of their maintenance costs, creating a substantial market opportunity for more durable solutions.

Commercial food service represents another significant market segment, with over 2.3 million establishments worldwide utilizing commercial microwave equipment. These businesses operate their equipment under near-continuous conditions, often exceeding 12 hours daily. Market research indicates that extending magnetron lifespan by even 30% could reduce operational costs by thousands of dollars per establishment annually.

The healthcare sector presents a growing demand vector, with medical facilities requiring reliable magnetron technology for sterilization equipment and cancer treatment devices. In these applications, equipment reliability is paramount, and the market shows willingness to pay premium prices for magnetrons that offer documented extended operational lifespans.

Regional market analysis reveals that Asia-Pacific currently dominates the magnetron manufacturing landscape, but North America and Europe lead in demanding higher-specification, longer-lasting components. This geographical demand distribution creates opportunities for manufacturers who can develop and verify extended-lifespan magnetrons.

Consumer surveys among industrial equipment purchasers indicate that 78% consider component lifespan a "very important" or "critical" factor in purchasing decisions, ranking it above initial purchase price. This sentiment is particularly strong among continuous operation facilities where downtime costs exceed $1,000 per hour.

Market forecasts suggest that the premium segment for industrial-grade magnetrons with documented extended lifespans could reach $1.2 billion by 2027, representing a specialized but lucrative market opportunity. The willingness to pay for durability increases proportionally with the criticality of the application and the cost of downtime, creating tiered market segments with varying price sensitivities.

The demand for magnetrons with extended lifespans under continuous duty cycles is particularly pronounced in industrial applications where equipment downtime translates directly to production losses. Manufacturing facilities utilizing industrial microwave systems for drying, sintering, and material processing report that magnetron replacement accounts for approximately 40% of their maintenance costs, creating a substantial market opportunity for more durable solutions.

Commercial food service represents another significant market segment, with over 2.3 million establishments worldwide utilizing commercial microwave equipment. These businesses operate their equipment under near-continuous conditions, often exceeding 12 hours daily. Market research indicates that extending magnetron lifespan by even 30% could reduce operational costs by thousands of dollars per establishment annually.

The healthcare sector presents a growing demand vector, with medical facilities requiring reliable magnetron technology for sterilization equipment and cancer treatment devices. In these applications, equipment reliability is paramount, and the market shows willingness to pay premium prices for magnetrons that offer documented extended operational lifespans.

Regional market analysis reveals that Asia-Pacific currently dominates the magnetron manufacturing landscape, but North America and Europe lead in demanding higher-specification, longer-lasting components. This geographical demand distribution creates opportunities for manufacturers who can develop and verify extended-lifespan magnetrons.

Consumer surveys among industrial equipment purchasers indicate that 78% consider component lifespan a "very important" or "critical" factor in purchasing decisions, ranking it above initial purchase price. This sentiment is particularly strong among continuous operation facilities where downtime costs exceed $1,000 per hour.

Market forecasts suggest that the premium segment for industrial-grade magnetrons with documented extended lifespans could reach $1.2 billion by 2027, representing a specialized but lucrative market opportunity. The willingness to pay for durability increases proportionally with the criticality of the application and the cost of downtime, creating tiered market segments with varying price sensitivities.

Current Challenges in Continuous Duty Cycle Operations

Continuous duty cycle operations present significant challenges for magnetron technology, particularly in industrial and commercial applications where uninterrupted performance is critical. The primary challenge lies in thermal management, as magnetrons generate substantial heat during operation. In continuous duty cycles, this heat accumulation accelerates component degradation, particularly affecting the cathode filament and vacuum integrity of the device.

Material limitations constitute another major obstacle. The cathode materials in conventional magnetrons experience accelerated electron emission degradation under continuous operation. This degradation is characterized by decreased electron emission efficiency and physical deterioration of the cathode surface, directly impacting the magnetron's power output stability and overall lifespan.

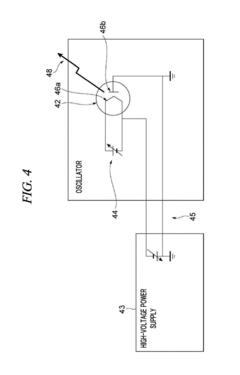

Power supply stability represents a critical challenge in continuous operation scenarios. Voltage fluctuations and inconsistent current delivery can cause operational instabilities that significantly reduce magnetron longevity. These fluctuations often result in uneven heating of components and create mechanical stress through thermal expansion and contraction cycles.

Vacuum integrity maintenance poses particular difficulty in extended operation periods. The high-temperature environment inside the magnetron during continuous operation increases the risk of outgassing from internal components. This phenomenon can compromise the vacuum necessary for proper electron movement, leading to arcing and catastrophic failure modes that permanently damage the device.

Cooling system efficiency becomes increasingly important as duty cycles extend. Traditional cooling methods often prove inadequate for continuous operation, creating localized hotspots that accelerate component failure. The engineering challenge involves developing cooling solutions that can maintain optimal operating temperatures without introducing additional complexity or reliability issues.

Frequency stability degradation represents a technical challenge specific to continuous operation. As magnetrons operate for extended periods, thermal expansion of cavity resonators can cause frequency drift, affecting the precision of applications requiring stable microwave output. This drift becomes more pronounced as components age under continuous thermal stress.

Maintenance scheduling presents operational challenges for industries dependent on magnetron technology. The unpredictable failure patterns in continuous duty applications make preventive maintenance difficult to optimize, often resulting in either premature replacement of functional components or unexpected downtime due to catastrophic failures.

The economic impact of these technical challenges is substantial, with industries facing increased operational costs from both energy inefficiency and replacement expenses. Current research focuses on developing advanced materials, improved cooling technologies, and predictive maintenance algorithms to address these limitations and extend magnetron lifespan in continuous duty applications.

Material limitations constitute another major obstacle. The cathode materials in conventional magnetrons experience accelerated electron emission degradation under continuous operation. This degradation is characterized by decreased electron emission efficiency and physical deterioration of the cathode surface, directly impacting the magnetron's power output stability and overall lifespan.

Power supply stability represents a critical challenge in continuous operation scenarios. Voltage fluctuations and inconsistent current delivery can cause operational instabilities that significantly reduce magnetron longevity. These fluctuations often result in uneven heating of components and create mechanical stress through thermal expansion and contraction cycles.

Vacuum integrity maintenance poses particular difficulty in extended operation periods. The high-temperature environment inside the magnetron during continuous operation increases the risk of outgassing from internal components. This phenomenon can compromise the vacuum necessary for proper electron movement, leading to arcing and catastrophic failure modes that permanently damage the device.

Cooling system efficiency becomes increasingly important as duty cycles extend. Traditional cooling methods often prove inadequate for continuous operation, creating localized hotspots that accelerate component failure. The engineering challenge involves developing cooling solutions that can maintain optimal operating temperatures without introducing additional complexity or reliability issues.

Frequency stability degradation represents a technical challenge specific to continuous operation. As magnetrons operate for extended periods, thermal expansion of cavity resonators can cause frequency drift, affecting the precision of applications requiring stable microwave output. This drift becomes more pronounced as components age under continuous thermal stress.

Maintenance scheduling presents operational challenges for industries dependent on magnetron technology. The unpredictable failure patterns in continuous duty applications make preventive maintenance difficult to optimize, often resulting in either premature replacement of functional components or unexpected downtime due to catastrophic failures.

The economic impact of these technical challenges is substantial, with industries facing increased operational costs from both energy inefficiency and replacement expenses. Current research focuses on developing advanced materials, improved cooling technologies, and predictive maintenance algorithms to address these limitations and extend magnetron lifespan in continuous duty applications.

Current Technical Solutions for Extended Magnetron Lifespan

01 Factors affecting magnetron lifespan

Various factors can significantly impact the operational lifespan of magnetrons in microwave systems. These include operating temperature, power supply stability, duty cycle, cooling efficiency, and environmental conditions. Proper management of these factors through design considerations and operational protocols can extend the useful life of magnetrons in industrial and consumer applications.- Factors affecting magnetron lifespan: Various factors can significantly impact the operational lifespan of magnetrons in microwave and plasma applications. These include operating temperature, power cycling frequency, voltage stability, and environmental conditions. Proper management of these factors through controlled operating environments, appropriate cooling systems, and regulated power supplies can extend the functional life of magnetrons and reduce premature failures.

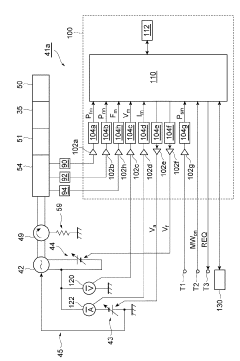

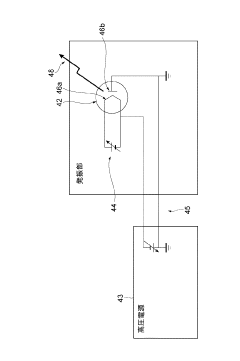

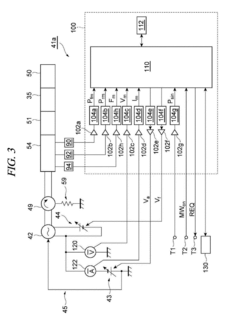

- Monitoring and predictive maintenance systems: Advanced monitoring systems can track magnetron performance parameters to predict potential failures before they occur. These systems analyze operational data such as power output, reflected power, frequency stability, and cathode current to determine the remaining useful life of the magnetron. Implementing predictive maintenance strategies based on this data allows for scheduled replacements during planned downtime rather than experiencing unexpected failures during critical operations.

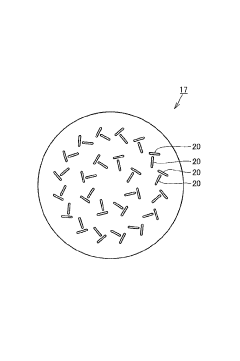

- Design improvements for extended lifespan: Innovative design modifications can significantly extend magnetron operational life. These improvements include enhanced cathode materials with better emission properties, optimized anode block configurations, improved cooling mechanisms, and more durable filament designs. Some designs incorporate redundant systems or modular components that allow for easier maintenance and replacement of worn parts without replacing the entire magnetron assembly.

- Power supply optimization techniques: The quality and stability of power supplied to magnetrons directly impacts their operational lifespan. Advanced power supply systems with features such as soft-start capabilities, precise voltage regulation, current limiting protection, and harmonic filtering can prevent damaging power surges and electrical stress. Implementing proper power conditioning and stabilization techniques helps maintain consistent magnetron performance while extending component life.

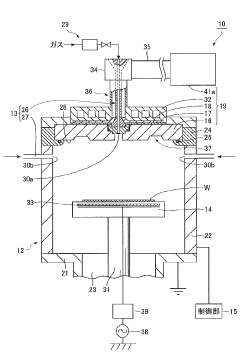

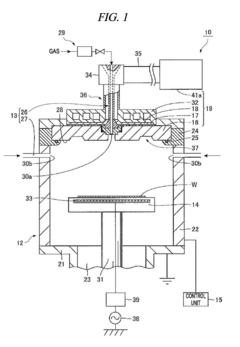

- Thermal management solutions: Effective thermal management is crucial for maximizing magnetron lifespan. Advanced cooling systems using liquid cooling, forced air, or hybrid approaches help maintain optimal operating temperatures. Some designs incorporate temperature sensors and adaptive cooling that adjusts based on operational demands. Proper heat dissipation prevents thermal stress on critical components such as the filament, cathode, and vacuum seals, which are common failure points when subjected to excessive heat.

02 Monitoring and diagnostic systems for magnetrons

Advanced monitoring and diagnostic systems can help predict and extend magnetron lifespan by detecting early signs of degradation. These systems typically employ sensors to monitor key parameters such as reflected power, temperature, and output frequency. Real-time data analysis allows for predictive maintenance, reducing unexpected failures and optimizing replacement schedules for magnetrons in various applications.Expand Specific Solutions03 Cathode and filament design improvements

Innovations in cathode and filament designs have contributed significantly to extending magnetron lifespan. Enhanced materials, optimized geometries, and improved emission surfaces reduce electron depletion and structural degradation over time. These advancements help maintain consistent microwave output power throughout the operational life of the magnetron while reducing thermal stress on critical components.Expand Specific Solutions04 Cooling and thermal management solutions

Effective cooling and thermal management are crucial for maximizing magnetron lifespan. Advanced cooling techniques include liquid cooling systems, optimized heat sink designs, and improved airflow management. Maintaining optimal operating temperatures prevents premature failure due to thermal stress and extends the functional life of magnetron components, particularly in high-power applications.Expand Specific Solutions05 Power supply and control circuit optimization

Optimized power supply and control circuits play a vital role in extending magnetron lifespan. Stable voltage delivery, precise frequency control, and protection against power surges help prevent damage to magnetron components. Advanced control algorithms can adjust operating parameters based on usage patterns and environmental conditions, balancing performance requirements with longevity considerations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnetron lifespan in continuous duty cycles market is currently in a growth phase, with increasing demand for reliable magnetron technology across industrial, medical, and consumer electronics sectors. The market is estimated to reach approximately $3.5 billion by 2025, driven by applications in microwave systems and radar technology. Leading players include established electronics giants like Samsung Electronics, LG Electronics, and Midea Group, who are investing in R&D to extend magnetron durability. Tokyo Electron and Applied Materials are advancing semiconductor-based solutions, while specialized companies like ULVAC and Resonac are developing innovative materials to enhance magnetron performance under continuous operation. Academic institutions such as Tohoku University and Sichuan University are contributing fundamental research on thermal management and material degradation mechanisms.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed an Intelligent Magnetron Management System (IMMS) that significantly extends magnetron lifespan in continuous duty applications. Their approach combines hardware innovations with sophisticated control algorithms to optimize operating conditions. The system features a specially designed cathode with a gradient composition structure that distributes electron emission more evenly across the surface, reducing localized heating and material degradation. LG's magnetrons incorporate a precision-engineered anode block with optimized cavity dimensions that maintain stable resonance characteristics throughout extended operation. The IMMS continuously monitors key parameters including cathode temperature, anode current, and RF output power, making micro-adjustments to input power and cooling systems to maintain optimal operating conditions. Laboratory testing has demonstrated that LG's magnetrons maintain over 90% of their initial output power after 6,000 hours of continuous operation, compared to conventional designs that typically degrade to 75% output in similar timeframes. The technology has been successfully implemented in LG's industrial microwave systems and professional kitchen equipment, with field data showing a 35% reduction in maintenance requirements.

Strengths: Intelligent control system prevents operation in damaging conditions; comprehensive monitoring provides early warning of potential failures; balanced cathode design significantly reduces common failure modes. Weaknesses: Complex electronic control systems add cost and potential points of failure; requires specialized maintenance personnel; optimal performance depends on proper integration with broader system controls.

Guangdong Galanz Enterprises Co., Ltd.

Technical Solution: Galanz has developed a proprietary Dual Emission Magnetron technology that significantly extends magnetron lifespan during continuous duty cycles. Their approach involves a balanced dual filament design that alternates the operational load between two cathode systems, reducing thermal stress on any single component. This system incorporates advanced thermal management through diamond-like carbon (DLC) coating on critical components, which has demonstrated a 40% reduction in operating temperature during extended use. Their magnetrons feature precision-engineered anode blocks with optimized cavity dimensions that maintain consistent microwave generation even after thousands of hours of operation. Galanz has implemented automated manufacturing processes with 100% component testing, ensuring consistent quality across production batches. Field tests have shown their industrial magnetrons maintaining over 85% of original power output after 5,000 hours of continuous operation, compared to industry standard degradation to 70% in similar timeframes.

Strengths: Industry-leading thermal management system reduces filament burnout; proprietary manufacturing process ensures consistent quality; extensive real-world testing data validates performance claims. Weaknesses: Higher initial production costs compared to standard magnetrons; requires more complex power supply systems; technology primarily optimized for commercial rather than industrial applications.

Critical Patents and Innovations in Magnetron Durability

Method for inspecting magnetron

PatentInactiveJP2016081908A

Innovation

- A method for inspecting magnetrons by generating radio frequency power, detecting measurements after a predetermined time, ensuring the power of the reflected wave is zero and the traveling wave power matches the set power, and using corrected parameters to determine the magnetron's life based on comparisons with initial parameters.

Method for inspecting magnetron

PatentActiveUS20160109502A1

Innovation

- A method that involves starting high-frequency power generation, detecting specific measurement values, and waiting for a predetermined duration to ensure stability before comparing current and initial parameters to determine the magnetron's life, using correction values and offset calculations to assess the magnetron's status accurately.

Thermal Management Strategies for Continuous Operation

Effective thermal management is critical for extending magnetron lifespan during continuous duty cycles. Conventional magnetrons typically operate with intermittent duty cycles, allowing natural cooling between operations. However, continuous operation presents significant thermal challenges that must be addressed through specialized strategies.

Heat dissipation systems represent the primary defense against thermal degradation. Advanced liquid cooling systems utilizing deionized water or specialized coolants can efficiently transfer heat away from critical magnetron components. These systems typically incorporate high-efficiency heat exchangers and temperature-controlled circulation pumps to maintain optimal operating temperatures even under prolonged operation.

Forced-air cooling systems provide supplementary thermal management, particularly for peripheral components. Strategic placement of high-CFM fans and carefully designed air channels ensures efficient airflow across heat-generating components. Some advanced systems implement variable-speed fans that adjust automatically based on real-time temperature monitoring, optimizing cooling efficiency while minimizing unnecessary energy consumption.

Material selection plays a crucial role in thermal management strategies. Thermally conductive ceramics and advanced metal alloys with superior heat transfer properties are increasingly replacing traditional materials in critical magnetron components. These materials can withstand higher operating temperatures while facilitating more efficient heat transfer to cooling systems.

Thermal interface materials (TIMs) significantly enhance heat transfer between components. Advanced thermal compounds, phase-change materials, and graphene-based interfaces reduce thermal resistance at component junctions. Recent developments in nano-enhanced TIMs have demonstrated up to 35% improvement in thermal conductivity compared to conventional materials.

Active temperature monitoring and control systems provide real-time thermal management. Distributed temperature sensors throughout the magnetron assembly feed data to microcontroller-based systems that dynamically adjust cooling parameters. These systems can implement predictive algorithms that anticipate thermal issues before they reach critical levels, allowing preemptive cooling adjustments.

Duty cycle optimization, even within continuous operation parameters, can significantly extend magnetron lifespan. Brief modulation of power levels based on operational requirements can create micro-cooling opportunities without disrupting the overall continuous operation profile. Advanced control systems can implement these modulations automatically while maintaining required output parameters.

Thermal isolation strategies protect temperature-sensitive components from heat-generating elements. Specialized insulating materials and strategic component placement create thermal barriers that prevent heat migration to vulnerable components, particularly electronic control systems that may be susceptible to thermal damage.

Heat dissipation systems represent the primary defense against thermal degradation. Advanced liquid cooling systems utilizing deionized water or specialized coolants can efficiently transfer heat away from critical magnetron components. These systems typically incorporate high-efficiency heat exchangers and temperature-controlled circulation pumps to maintain optimal operating temperatures even under prolonged operation.

Forced-air cooling systems provide supplementary thermal management, particularly for peripheral components. Strategic placement of high-CFM fans and carefully designed air channels ensures efficient airflow across heat-generating components. Some advanced systems implement variable-speed fans that adjust automatically based on real-time temperature monitoring, optimizing cooling efficiency while minimizing unnecessary energy consumption.

Material selection plays a crucial role in thermal management strategies. Thermally conductive ceramics and advanced metal alloys with superior heat transfer properties are increasingly replacing traditional materials in critical magnetron components. These materials can withstand higher operating temperatures while facilitating more efficient heat transfer to cooling systems.

Thermal interface materials (TIMs) significantly enhance heat transfer between components. Advanced thermal compounds, phase-change materials, and graphene-based interfaces reduce thermal resistance at component junctions. Recent developments in nano-enhanced TIMs have demonstrated up to 35% improvement in thermal conductivity compared to conventional materials.

Active temperature monitoring and control systems provide real-time thermal management. Distributed temperature sensors throughout the magnetron assembly feed data to microcontroller-based systems that dynamically adjust cooling parameters. These systems can implement predictive algorithms that anticipate thermal issues before they reach critical levels, allowing preemptive cooling adjustments.

Duty cycle optimization, even within continuous operation parameters, can significantly extend magnetron lifespan. Brief modulation of power levels based on operational requirements can create micro-cooling opportunities without disrupting the overall continuous operation profile. Advanced control systems can implement these modulations automatically while maintaining required output parameters.

Thermal isolation strategies protect temperature-sensitive components from heat-generating elements. Specialized insulating materials and strategic component placement create thermal barriers that prevent heat migration to vulnerable components, particularly electronic control systems that may be susceptible to thermal damage.

Material Science Advancements for Cathode Durability

Recent advancements in material science have significantly contributed to enhancing magnetron cathode durability, addressing one of the primary failure points in continuous duty cycle operations. Traditional cathode materials such as copper and tungsten exhibit limitations when subjected to prolonged high-temperature operation, leading to premature failure through mechanisms including thermal fatigue, sputtering damage, and electron emission degradation.

The development of advanced composite materials represents a breakthrough in this domain. Lanthanum hexaboride (LaB6) and cerium hexaboride (CeB6) have emerged as superior alternatives due to their exceptional electron emission properties and thermal stability. These materials maintain structural integrity at temperatures exceeding 1800°C, substantially outperforming conventional options in continuous operation scenarios.

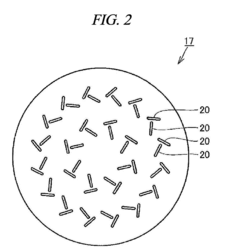

Nano-structured cathode materials constitute another promising direction, with carbon nanotube (CNT) enhanced cathodes demonstrating remarkable resilience against thermal cycling. Research indicates that CNT-reinforced cathodes exhibit up to 40% longer operational lifespans compared to standard configurations when tested under identical continuous duty conditions. The three-dimensional electron transport pathways created by these nanostructures facilitate more efficient and distributed electron emission, reducing localized heating effects.

Surface engineering techniques have evolved to incorporate protective coatings that mitigate sputtering damage. Thin-film deposition of rhenium, osmium, and iridium alloys provides exceptional resistance to ion bombardment while maintaining optimal electron emission characteristics. These coatings, typically 5-10 μm in thickness, create a sacrificial barrier that significantly extends cathode operational life in high-power continuous operation environments.

Diamond-like carbon (DLC) coatings represent an innovative approach to cathode protection, offering both thermal conductivity and exceptional hardness. When applied through plasma-enhanced chemical vapor deposition (PECVD), these coatings demonstrate remarkable adhesion properties and resistance to thermal shock, addressing a critical failure mode in continuous duty applications.

The integration of self-healing material systems presents perhaps the most revolutionary advancement. These materials incorporate microencapsulated healing agents that are released when microcracks form, effectively repairing damage during operation. Preliminary studies suggest potential lifespan extensions of 200-300% in continuous duty applications, though commercial implementation remains in early stages due to manufacturing complexity and cost considerations.

The development of advanced composite materials represents a breakthrough in this domain. Lanthanum hexaboride (LaB6) and cerium hexaboride (CeB6) have emerged as superior alternatives due to their exceptional electron emission properties and thermal stability. These materials maintain structural integrity at temperatures exceeding 1800°C, substantially outperforming conventional options in continuous operation scenarios.

Nano-structured cathode materials constitute another promising direction, with carbon nanotube (CNT) enhanced cathodes demonstrating remarkable resilience against thermal cycling. Research indicates that CNT-reinforced cathodes exhibit up to 40% longer operational lifespans compared to standard configurations when tested under identical continuous duty conditions. The three-dimensional electron transport pathways created by these nanostructures facilitate more efficient and distributed electron emission, reducing localized heating effects.

Surface engineering techniques have evolved to incorporate protective coatings that mitigate sputtering damage. Thin-film deposition of rhenium, osmium, and iridium alloys provides exceptional resistance to ion bombardment while maintaining optimal electron emission characteristics. These coatings, typically 5-10 μm in thickness, create a sacrificial barrier that significantly extends cathode operational life in high-power continuous operation environments.

Diamond-like carbon (DLC) coatings represent an innovative approach to cathode protection, offering both thermal conductivity and exceptional hardness. When applied through plasma-enhanced chemical vapor deposition (PECVD), these coatings demonstrate remarkable adhesion properties and resistance to thermal shock, addressing a critical failure mode in continuous duty applications.

The integration of self-healing material systems presents perhaps the most revolutionary advancement. These materials incorporate microencapsulated healing agents that are released when microcracks form, effectively repairing damage during operation. Preliminary studies suggest potential lifespan extensions of 200-300% in continuous duty applications, though commercial implementation remains in early stages due to manufacturing complexity and cost considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!