How to Innovate Magnetron Test Circuits for Performance

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Testing Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 20th century, becoming a cornerstone of microwave generation systems across multiple industries. The development trajectory of magnetron testing methodologies has historically lagged behind the advancement of the devices themselves, creating a technological gap that presents both challenges and opportunities for innovation. Current magnetron testing circuits often rely on conventional approaches established decades ago, which increasingly fail to meet the precision and efficiency demands of modern applications.

The evolution of magnetron technology has been driven by applications in radar systems, industrial heating, and consumer microwave ovens, each requiring specific performance parameters and testing protocols. Traditional testing methodologies have focused primarily on power output, frequency stability, and efficiency measurements using analog circuits and basic load testing. However, these approaches provide limited insights into the complex operational characteristics that determine real-world performance and longevity.

Recent technological trends indicate a shift toward more sophisticated testing paradigms that incorporate digital signal processing, real-time monitoring capabilities, and predictive analytics. This evolution is necessitated by the increasing complexity of magnetron applications in medical equipment, advanced radar systems, and precision industrial processes where performance margins are increasingly narrow and reliability requirements more stringent.

The primary objective of innovating magnetron test circuits is to develop comprehensive testing methodologies that can accurately characterize device performance across multiple parameters simultaneously, while providing actionable insights for design optimization and quality control. This includes the ability to detect subtle performance variations that may indicate potential failure modes before they manifest in operational settings.

Secondary objectives include reducing testing time and costs through automation and standardization, enabling more accurate prediction of operational lifespan through accelerated stress testing, and developing non-invasive testing methods that preserve the integrity of the device under test. These advancements would significantly enhance manufacturing efficiency and product reliability across the magnetron industry.

The technological goal is to create a new generation of test circuits that integrate advanced sensing technologies, real-time data analysis capabilities, and machine learning algorithms to provide comprehensive performance profiles. These systems would ideally operate across multiple frequency bands, power levels, and environmental conditions to simulate real-world operational scenarios with unprecedented fidelity.

Achieving these objectives requires a multidisciplinary approach that combines expertise in microwave engineering, electronic circuit design, signal processing, and data analytics. The resulting innovations in magnetron test circuits would not only enhance current manufacturing and quality control processes but also enable the development of next-generation magnetron devices with superior performance characteristics and reliability profiles.

The evolution of magnetron technology has been driven by applications in radar systems, industrial heating, and consumer microwave ovens, each requiring specific performance parameters and testing protocols. Traditional testing methodologies have focused primarily on power output, frequency stability, and efficiency measurements using analog circuits and basic load testing. However, these approaches provide limited insights into the complex operational characteristics that determine real-world performance and longevity.

Recent technological trends indicate a shift toward more sophisticated testing paradigms that incorporate digital signal processing, real-time monitoring capabilities, and predictive analytics. This evolution is necessitated by the increasing complexity of magnetron applications in medical equipment, advanced radar systems, and precision industrial processes where performance margins are increasingly narrow and reliability requirements more stringent.

The primary objective of innovating magnetron test circuits is to develop comprehensive testing methodologies that can accurately characterize device performance across multiple parameters simultaneously, while providing actionable insights for design optimization and quality control. This includes the ability to detect subtle performance variations that may indicate potential failure modes before they manifest in operational settings.

Secondary objectives include reducing testing time and costs through automation and standardization, enabling more accurate prediction of operational lifespan through accelerated stress testing, and developing non-invasive testing methods that preserve the integrity of the device under test. These advancements would significantly enhance manufacturing efficiency and product reliability across the magnetron industry.

The technological goal is to create a new generation of test circuits that integrate advanced sensing technologies, real-time data analysis capabilities, and machine learning algorithms to provide comprehensive performance profiles. These systems would ideally operate across multiple frequency bands, power levels, and environmental conditions to simulate real-world operational scenarios with unprecedented fidelity.

Achieving these objectives requires a multidisciplinary approach that combines expertise in microwave engineering, electronic circuit design, signal processing, and data analytics. The resulting innovations in magnetron test circuits would not only enhance current manufacturing and quality control processes but also enable the development of next-generation magnetron devices with superior performance characteristics and reliability profiles.

Market Demand Analysis for Advanced Magnetron Test Solutions

The global magnetron test equipment market is experiencing significant growth, driven by the expanding applications of magnetrons across multiple industries. Current market analysis indicates a robust demand trajectory, particularly in sectors such as defense, telecommunications, medical equipment manufacturing, and industrial microwave systems. The increasing complexity of magnetron-based devices necessitates more sophisticated testing solutions to ensure optimal performance and reliability.

In the defense sector, advanced radar systems require precise magnetron performance testing to maintain operational readiness and accuracy. Military contractors are increasingly demanding test circuits capable of evaluating magnetrons under simulated battlefield conditions, creating a specialized high-value market segment. Similarly, the telecommunications industry's ongoing expansion of satellite communication networks has created substantial demand for magnetron testing equipment that can verify performance across multiple frequency bands and power levels.

The medical equipment manufacturing sector represents another significant market driver, particularly for testing magnetrons used in radiation therapy and medical imaging devices. These applications demand exceptionally precise performance parameters and reliability testing, as equipment failure could have serious consequences for patient safety. Market research indicates healthcare facilities are increasingly implementing regular magnetron testing protocols, creating a steady demand for both initial and replacement test equipment.

Industrial microwave processing applications, including food processing, material drying, and chemical processing, constitute a rapidly growing market segment. As these industries adopt more sophisticated microwave technologies, the need for advanced magnetron test circuits has increased proportionally. Manufacturers require testing solutions that can accurately measure performance under various load conditions and operational environments.

Market analysis reveals a clear trend toward integrated testing systems that combine multiple measurement capabilities into single platforms. End-users increasingly prefer comprehensive solutions that can evaluate not only basic parameters like frequency stability and power output but also more complex characteristics such as phase noise, harmonic content, and thermal performance under various operational conditions.

Geographically, North America and Europe currently represent the largest markets for advanced magnetron test equipment, primarily due to their established defense and medical technology sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing investment in telecommunications infrastructure. China, in particular, has emerged as a significant market as it expands its domestic microwave technology capabilities.

Price sensitivity varies considerably across market segments, with defense and medical applications typically accepting premium pricing for high-precision equipment, while industrial applications tend to be more cost-conscious. This market stratification presents opportunities for tiered product offerings that address different performance and price requirements across various industry segments.

In the defense sector, advanced radar systems require precise magnetron performance testing to maintain operational readiness and accuracy. Military contractors are increasingly demanding test circuits capable of evaluating magnetrons under simulated battlefield conditions, creating a specialized high-value market segment. Similarly, the telecommunications industry's ongoing expansion of satellite communication networks has created substantial demand for magnetron testing equipment that can verify performance across multiple frequency bands and power levels.

The medical equipment manufacturing sector represents another significant market driver, particularly for testing magnetrons used in radiation therapy and medical imaging devices. These applications demand exceptionally precise performance parameters and reliability testing, as equipment failure could have serious consequences for patient safety. Market research indicates healthcare facilities are increasingly implementing regular magnetron testing protocols, creating a steady demand for both initial and replacement test equipment.

Industrial microwave processing applications, including food processing, material drying, and chemical processing, constitute a rapidly growing market segment. As these industries adopt more sophisticated microwave technologies, the need for advanced magnetron test circuits has increased proportionally. Manufacturers require testing solutions that can accurately measure performance under various load conditions and operational environments.

Market analysis reveals a clear trend toward integrated testing systems that combine multiple measurement capabilities into single platforms. End-users increasingly prefer comprehensive solutions that can evaluate not only basic parameters like frequency stability and power output but also more complex characteristics such as phase noise, harmonic content, and thermal performance under various operational conditions.

Geographically, North America and Europe currently represent the largest markets for advanced magnetron test equipment, primarily due to their established defense and medical technology sectors. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization and increasing investment in telecommunications infrastructure. China, in particular, has emerged as a significant market as it expands its domestic microwave technology capabilities.

Price sensitivity varies considerably across market segments, with defense and medical applications typically accepting premium pricing for high-precision equipment, while industrial applications tend to be more cost-conscious. This market stratification presents opportunities for tiered product offerings that address different performance and price requirements across various industry segments.

Current Challenges in Magnetron Test Circuit Technology

Despite significant advancements in magnetron technology, current test circuit methodologies face several critical challenges that impede accurate performance evaluation and optimization. Traditional test circuits often struggle with precise measurement of high-frequency parameters, particularly in the microwave spectrum where magnetrons typically operate. The inherent non-linear behavior of magnetrons creates substantial difficulties in developing standardized testing protocols that can reliably predict real-world performance across varying operational conditions.

Power measurement accuracy remains a persistent challenge, with many existing test circuits exhibiting significant measurement errors when dealing with high-power magnetrons. These errors stem from impedance mismatches, thermal effects, and electromagnetic interference that become increasingly problematic at higher power levels. Additionally, current test setups frequently lack adequate thermal management capabilities, leading to measurement drift during extended testing periods and compromising result reliability.

Frequency stability assessment presents another major hurdle. Modern applications demand increasingly stable frequency outputs, yet conventional test circuits often fail to characterize frequency pushing and pulling effects with sufficient precision. This limitation becomes particularly problematic when evaluating magnetrons intended for sensitive applications such as medical devices or precision industrial equipment where frequency stability is paramount.

The integration of digital control systems with traditional analog test circuits creates compatibility issues that complicate automated testing procedures. Many legacy test systems lack the necessary interfaces for modern data acquisition systems, resulting in inefficient testing workflows and potential data translation errors. Furthermore, the absence of standardized digital protocols specifically designed for magnetron testing contributes to inconsistencies in measurement methodologies across different testing facilities.

Noise characterization represents an increasingly important yet underaddressed aspect of magnetron testing. Current circuits typically provide inadequate resolution for measuring phase noise, spurious emissions, and harmonic content—all critical parameters for modern applications with strict electromagnetic compatibility requirements. The industry lacks consensus on standardized metrics for quantifying these noise characteristics, further complicating comparative performance analysis.

Lifecycle testing capabilities present significant limitations in current test circuit designs. Accelerated aging tests, which are essential for reliability engineering, often fail to accurately simulate real-world operational stresses. This gap between laboratory testing and actual deployment conditions leads to discrepancies between predicted and actual service lifespans, creating challenges for manufacturers in providing accurate reliability specifications.

Power measurement accuracy remains a persistent challenge, with many existing test circuits exhibiting significant measurement errors when dealing with high-power magnetrons. These errors stem from impedance mismatches, thermal effects, and electromagnetic interference that become increasingly problematic at higher power levels. Additionally, current test setups frequently lack adequate thermal management capabilities, leading to measurement drift during extended testing periods and compromising result reliability.

Frequency stability assessment presents another major hurdle. Modern applications demand increasingly stable frequency outputs, yet conventional test circuits often fail to characterize frequency pushing and pulling effects with sufficient precision. This limitation becomes particularly problematic when evaluating magnetrons intended for sensitive applications such as medical devices or precision industrial equipment where frequency stability is paramount.

The integration of digital control systems with traditional analog test circuits creates compatibility issues that complicate automated testing procedures. Many legacy test systems lack the necessary interfaces for modern data acquisition systems, resulting in inefficient testing workflows and potential data translation errors. Furthermore, the absence of standardized digital protocols specifically designed for magnetron testing contributes to inconsistencies in measurement methodologies across different testing facilities.

Noise characterization represents an increasingly important yet underaddressed aspect of magnetron testing. Current circuits typically provide inadequate resolution for measuring phase noise, spurious emissions, and harmonic content—all critical parameters for modern applications with strict electromagnetic compatibility requirements. The industry lacks consensus on standardized metrics for quantifying these noise characteristics, further complicating comparative performance analysis.

Lifecycle testing capabilities present significant limitations in current test circuit designs. Accelerated aging tests, which are essential for reliability engineering, often fail to accurately simulate real-world operational stresses. This gap between laboratory testing and actual deployment conditions leads to discrepancies between predicted and actual service lifespans, creating challenges for manufacturers in providing accurate reliability specifications.

Current Test Circuit Architectures and Implementations

01 Magnetron testing and measurement systems

Various systems and methods for testing magnetron performance, including specialized measurement equipment and techniques for evaluating operational parameters. These systems enable accurate assessment of magnetron characteristics such as power output, frequency stability, and efficiency under different operating conditions. The testing systems typically include signal generators, analyzers, and specialized circuits designed to evaluate magnetron performance metrics.- Magnetron testing and measurement systems: Various systems and methods for testing magnetron performance, including specialized measurement circuits that evaluate key parameters such as power output, frequency stability, and efficiency. These systems typically incorporate sensors, analyzers, and data acquisition components to provide comprehensive performance evaluation under different operating conditions.

- Magnetron circuit performance optimization: Techniques for optimizing magnetron circuit performance through improved circuit designs, component selection, and configuration adjustments. These approaches focus on enhancing power efficiency, reducing noise, and improving overall operational stability of magnetron circuits through careful impedance matching, filtering, and power supply regulation.

- Magnetron reliability and durability testing: Methods and circuits designed specifically for evaluating the reliability and durability of magnetrons under various stress conditions. These test circuits simulate real-world operating environments, including temperature variations, voltage fluctuations, and extended operation periods to predict service life and identify potential failure modes.

- Automated magnetron testing platforms: Integrated systems that provide automated testing of magnetron performance parameters. These platforms typically include computer-controlled test sequences, data logging capabilities, and analysis software to streamline the testing process and ensure consistent, repeatable results across multiple test cycles or production batches.

- Specialized magnetron test fixtures and interfaces: Custom-designed fixtures, jigs, and interface circuits specifically developed for connecting magnetrons to test equipment. These specialized components ensure proper electrical and thermal connections, accurate signal routing, and appropriate load simulation to obtain reliable test measurements while protecting both the magnetron and test equipment.

02 Magnetron circuit design and optimization

Innovative circuit designs for improving magnetron performance and reliability. These designs focus on optimizing the electrical parameters of magnetron circuits to enhance efficiency, stability, and output power. Circuit optimization techniques include impedance matching, filtering, and specialized component arrangements that minimize losses and maximize energy transfer. Advanced circuit designs also address issues such as thermal management and electromagnetic interference.Expand Specific Solutions03 Magnetron performance monitoring and diagnostics

Systems and methods for real-time monitoring and diagnostics of magnetron performance during operation. These solutions include sensors, monitoring circuits, and diagnostic tools that can detect abnormalities, predict failures, and assess the health of magnetron components. Performance monitoring systems help maintain optimal operation by providing data on critical parameters such as anode current, cathode temperature, and RF output characteristics.Expand Specific Solutions04 Magnetron protection and safety circuits

Specialized protection circuits designed to safeguard magnetrons from damage due to abnormal operating conditions. These circuits monitor critical parameters and implement protective measures such as automatic shutdown, power limiting, or load adjustment when dangerous conditions are detected. Safety features include overvoltage protection, thermal protection, and reflected power monitoring to prevent damage to the magnetron and associated components.Expand Specific Solutions05 Magnetron calibration and reference circuits

Calibration systems and reference circuits for ensuring accurate and consistent magnetron performance measurements. These systems establish standardized testing conditions and provide reference signals for comparison with magnetron outputs. Calibration circuits help maintain measurement accuracy across different test environments and equipment setups, enabling reliable performance evaluation and quality control in magnetron manufacturing and maintenance.Expand Specific Solutions

Key Industry Players in Magnetron Testing Equipment

The magnetron test circuit innovation landscape is currently in a growth phase, with increasing market demand driven by advancements in microwave technology applications. The market is expanding as key players like Midea Group, LG Electronics, and Galanz Enterprises focus on improving magnetron performance for consumer appliances, while semiconductor leaders including Texas Instruments, NXP, and Renesas Electronics develop specialized testing solutions. Research institutions such as MIT and University of Electronic Science & Technology of China are advancing fundamental technologies. The competitive landscape shows varying maturity levels, with established electronics giants like Samsung, Siemens, and Bosch possessing mature testing capabilities, while specialized testing equipment manufacturers like Advantest and Guildline Instruments offer precision measurement solutions for performance optimization.

Midea Group Co. Ltd.

Technical Solution: Midea has developed an integrated magnetron test solution that combines production efficiency with comprehensive performance characterization. Their approach utilizes specialized test fixtures with precise impedance matching networks that simulate actual application conditions while maintaining measurement accuracy. The system incorporates advanced thermal management techniques that can characterize magnetron performance across operating temperature ranges, critical for understanding real-world behavior. Midea's test circuits feature specialized pulse modulation capabilities that can evaluate magnetron response to various power control schemes used in modern appliances. Their solution includes proprietary algorithms for analyzing frequency stability and spectral characteristics under dynamic load conditions, providing insights into magnetron behavior during actual usage scenarios. The platform integrates automated visual inspection systems with electrical performance testing, enabling comprehensive quality assessment in a single test station.

Strengths: Excellent integration of multiple test parameters in a single platform; good balance between production efficiency and measurement depth; comprehensive correlation with end-product performance. Weaknesses: Less specialized for cutting-edge research applications; limited flexibility for non-standard test requirements; primarily optimized for consumer appliance applications rather than industrial or scientific magnetrons.

Guangdong Galanz Enterprises Co., Ltd.

Technical Solution: Galanz has developed an innovative magnetron test platform specifically optimized for consumer microwave applications. Their approach integrates high-volume production testing with precision performance characterization through specialized test fixtures that simulate actual microwave cavity conditions. The system employs proprietary load simulation circuits that can reproduce the varying impedance conditions encountered in consumer microwave ovens, enabling more realistic performance evaluation. Galanz's test solution incorporates specialized measurement techniques for analyzing magnetron efficiency, power stability, and harmonic content across different power levels and duty cycles. Their test circuits feature automated calibration systems that maintain measurement accuracy in high-throughput production environments while minimizing operator intervention. The platform includes specialized analysis tools for evaluating magnetron noise characteristics and electromagnetic interference profiles, critical for consumer product compliance.

Strengths: Optimized for high-volume production environments; excellent correlation between test results and real-world performance; comprehensive integration with manufacturing execution systems. Weaknesses: Less suitable for research and development applications; limited flexibility for testing non-standard magnetron designs; focused primarily on consumer rather than industrial or medical applications.

Critical Patents and Technical Literature in Magnetron Testing

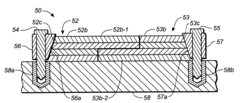

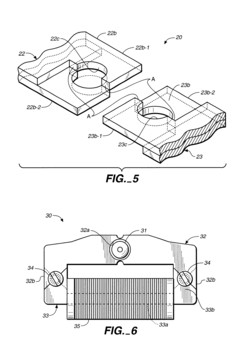

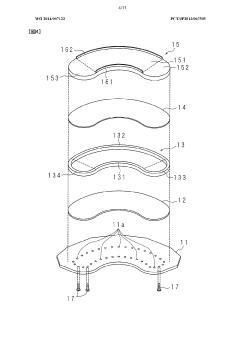

Magnetic circuit structure, and power-generating device and electronic device using the same

PatentInactiveUS6800983B1

Innovation

- A magnetic circuit structure featuring laminated members with opposing concave structures that are mated in a staggered manner to increase the joint area, allowing magnetic flux to pass without stepping or gaps, thereby reducing magnetic resistance and enhancing effective magnetic flux, while also stabilizing the joint and facilitating assembly.

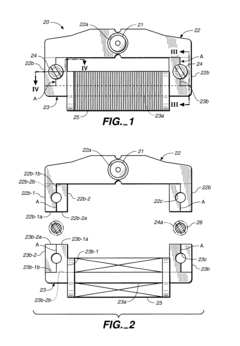

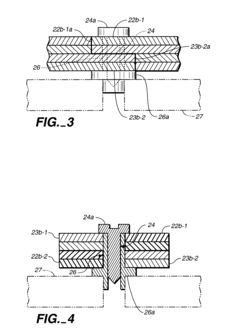

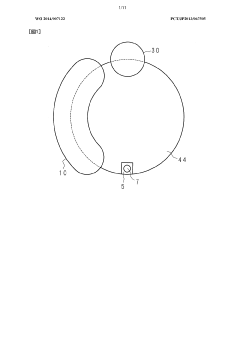

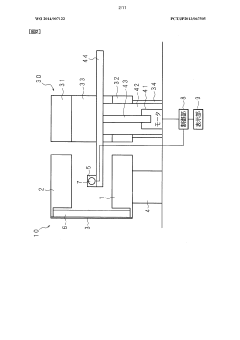

Magnetic circuit

PatentWO2014007122A1

Innovation

- A magnetic circuit design featuring two arc-shaped magnets with arcuate yokes and protruding pieces, along with a plate-shaped auxiliary yoke and adjustable screw holes, creates a wider uniform magnetic field space, allowing for extended magnetic field application and improved field uniformity, enhancing the sensitivity of ESR measurements while minimizing the impact of adjacent magnetic fields.

Safety Standards and Compliance Requirements

Magnetron testing involves significant safety considerations due to high voltage, microwave radiation, and thermal hazards. Compliance with international safety standards is non-negotiable for manufacturers and testing facilities. The IEC 60335-2-25 standard specifically addresses safety requirements for microwave appliances, including magnetrons, while IEEE C95.1 establishes exposure limits for electromagnetic fields. These standards mandate specific shielding requirements to prevent radiation leakage, with maximum permissible exposure limits typically set at 5mW/cm² at 5cm from the device.

Testing facilities must implement comprehensive safety protocols including proper grounding systems, interlocked enclosures, and radiation monitoring equipment. The EN 61010-1 standard for laboratory equipment safety requires test circuits to incorporate emergency shutdown mechanisms and clear hazard indicators. Additionally, the OSHA 29 CFR 1910.97 regulations in the United States establish workplace safety requirements for non-ionizing radiation exposure, necessitating regular monitoring and documentation.

Environmental considerations are increasingly important in magnetron testing. The RoHS Directive restricts hazardous substances in electronic equipment, while WEEE regulations govern the disposal of electronic waste. Modern test circuits must be designed with these environmental compliance requirements in mind, particularly regarding the use of lead-free components and proper disposal protocols for beryllium oxide ceramics often found in magnetron assemblies.

Quality management systems such as ISO 9001 certification are essential for ensuring consistent compliance with safety standards. Documentation requirements include detailed test procedures, calibration records, and traceability of all measurement equipment. Regular third-party audits are typically required to maintain certification and verify ongoing compliance with evolving standards.

Emerging standards are addressing new concerns in magnetron testing. IEC 62311 focuses on the assessment of electronic equipment related to human exposure restrictions for electromagnetic fields, while updated EMC (Electromagnetic Compatibility) standards like IEC 61000 series address potential interference issues with other electronic systems. Test circuit innovations must anticipate these evolving requirements, incorporating features that allow for compliance with both current and anticipated future standards.

For international markets, test circuits must be designed to meet regional variations in safety standards. The UL 923 standard in North America, the GB 4706.21 standard in China, and the AS/NZS 60335.2.25 standard in Australia/New Zealand all contain specific requirements that may differ from IEC standards. Manufacturers developing innovative test circuits must consider these regional variations to ensure global market access.

Testing facilities must implement comprehensive safety protocols including proper grounding systems, interlocked enclosures, and radiation monitoring equipment. The EN 61010-1 standard for laboratory equipment safety requires test circuits to incorporate emergency shutdown mechanisms and clear hazard indicators. Additionally, the OSHA 29 CFR 1910.97 regulations in the United States establish workplace safety requirements for non-ionizing radiation exposure, necessitating regular monitoring and documentation.

Environmental considerations are increasingly important in magnetron testing. The RoHS Directive restricts hazardous substances in electronic equipment, while WEEE regulations govern the disposal of electronic waste. Modern test circuits must be designed with these environmental compliance requirements in mind, particularly regarding the use of lead-free components and proper disposal protocols for beryllium oxide ceramics often found in magnetron assemblies.

Quality management systems such as ISO 9001 certification are essential for ensuring consistent compliance with safety standards. Documentation requirements include detailed test procedures, calibration records, and traceability of all measurement equipment. Regular third-party audits are typically required to maintain certification and verify ongoing compliance with evolving standards.

Emerging standards are addressing new concerns in magnetron testing. IEC 62311 focuses on the assessment of electronic equipment related to human exposure restrictions for electromagnetic fields, while updated EMC (Electromagnetic Compatibility) standards like IEC 61000 series address potential interference issues with other electronic systems. Test circuit innovations must anticipate these evolving requirements, incorporating features that allow for compliance with both current and anticipated future standards.

For international markets, test circuits must be designed to meet regional variations in safety standards. The UL 923 standard in North America, the GB 4706.21 standard in China, and the AS/NZS 60335.2.25 standard in Australia/New Zealand all contain specific requirements that may differ from IEC standards. Manufacturers developing innovative test circuits must consider these regional variations to ensure global market access.

Cost-Performance Optimization Strategies

Optimizing the cost-performance ratio in magnetron test circuits represents a critical challenge for manufacturers and research institutions. The implementation of strategic cost-reduction measures without compromising performance integrity requires a multifaceted approach. Material selection stands as a primary consideration, where substituting expensive noble metals with more cost-effective alternatives can yield significant savings. For instance, replacing gold-plated connectors with tin-plated or silver-plated alternatives in non-critical circuit sections can reduce costs by 30-40% while maintaining acceptable performance parameters.

Modular design principles offer another avenue for cost optimization. By developing standardized, interchangeable components, organizations can benefit from economies of scale in production while simultaneously reducing maintenance expenses. This approach enables targeted upgrades to specific circuit elements rather than complete system replacements, extending the operational lifespan of test equipment and distributing investment costs over longer periods.

Advanced simulation tools present opportunities for substantial cost reduction in the development phase. Virtual prototyping using electromagnetic simulation software can identify potential design flaws before physical manufacturing begins, reducing iteration cycles and associated expenses. Companies implementing comprehensive simulation protocols report development cost reductions of 15-25% and significantly accelerated time-to-market for new test circuit designs.

Manufacturing process optimization represents another key strategy. Techniques such as Design for Manufacturing (DFM) and Design for Assembly (DFA) can streamline production workflows, reducing labor costs and minimizing material waste. Automated testing procedures further enhance efficiency by reducing human error and increasing throughput, particularly beneficial for high-volume production environments.

Calibration methodology refinement offers dual benefits in cost reduction and performance enhancement. Implementing statistical process control techniques and automated calibration systems reduces the time required for setup and calibration while improving measurement accuracy. Organizations have reported operational efficiency improvements of up to 20% through the implementation of advanced calibration protocols.

Energy efficiency considerations, though often overlooked, contribute significantly to long-term operational costs. Designing test circuits with power management features, such as automatic standby modes and optimized power supply units, reduces electricity consumption during extended testing procedures. The integration of regenerative load testing, where energy is recycled rather than dissipated as heat, can reduce energy costs by 30-50% in high-power testing applications.

Modular design principles offer another avenue for cost optimization. By developing standardized, interchangeable components, organizations can benefit from economies of scale in production while simultaneously reducing maintenance expenses. This approach enables targeted upgrades to specific circuit elements rather than complete system replacements, extending the operational lifespan of test equipment and distributing investment costs over longer periods.

Advanced simulation tools present opportunities for substantial cost reduction in the development phase. Virtual prototyping using electromagnetic simulation software can identify potential design flaws before physical manufacturing begins, reducing iteration cycles and associated expenses. Companies implementing comprehensive simulation protocols report development cost reductions of 15-25% and significantly accelerated time-to-market for new test circuit designs.

Manufacturing process optimization represents another key strategy. Techniques such as Design for Manufacturing (DFM) and Design for Assembly (DFA) can streamline production workflows, reducing labor costs and minimizing material waste. Automated testing procedures further enhance efficiency by reducing human error and increasing throughput, particularly beneficial for high-volume production environments.

Calibration methodology refinement offers dual benefits in cost reduction and performance enhancement. Implementing statistical process control techniques and automated calibration systems reduces the time required for setup and calibration while improving measurement accuracy. Organizations have reported operational efficiency improvements of up to 20% through the implementation of advanced calibration protocols.

Energy efficiency considerations, though often overlooked, contribute significantly to long-term operational costs. Designing test circuits with power management features, such as automatic standby modes and optimized power supply units, reduces electricity consumption during extended testing procedures. The integration of regenerative load testing, where energy is recycled rather than dissipated as heat, can reduce energy costs by 30-50% in high-power testing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!