How to Calibrate Magnetron Power Supply Accurately

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Power Supply Calibration Background and Objectives

Magnetron power supplies are critical components in various industrial, medical, and scientific applications, particularly in microwave heating systems, radar equipment, and particle accelerators. The evolution of magnetron power supply technology has progressed significantly since the invention of the magnetron during World War II, with continuous improvements in efficiency, reliability, and precision. Accurate calibration of these power supplies has become increasingly important as applications demand higher performance and energy efficiency.

The technological trajectory of magnetron power supplies has moved from simple unregulated designs to sophisticated digitally controlled systems with advanced feedback mechanisms. Early calibration methods relied heavily on manual adjustments and basic measurement tools, whereas modern approaches incorporate automated systems, digital signal processing, and precision measurement equipment. This evolution reflects the growing complexity of applications and the increasing demands for power stability and output consistency.

The primary objective of magnetron power supply calibration is to ensure precise control over the microwave energy delivered to the load. This involves establishing accurate relationships between control inputs and power outputs across the operational range of the device. Proper calibration directly impacts energy efficiency, component longevity, process repeatability, and ultimately product quality in manufacturing environments.

Calibration challenges have intensified as magnetron applications have expanded into more sensitive areas such as medical treatments, semiconductor processing, and advanced materials manufacturing. These applications require unprecedented levels of accuracy and stability in power delivery, often necessitating calibration precision better than ±1% across wide operating ranges and under varying environmental conditions.

Current calibration methodologies must address several technical parameters simultaneously, including output voltage regulation, current limiting, filament voltage control, and pulse timing characteristics. The interrelationship between these parameters creates a multidimensional calibration problem that requires sophisticated approaches to solve effectively.

The technological goals for advancing magnetron power supply calibration include developing more automated and self-adjusting calibration systems, implementing real-time monitoring and adaptive control algorithms, and creating standardized calibration protocols that ensure consistency across different manufacturing facilities and service environments. Additionally, there is a push toward calibration methods that can compensate for magnetron aging effects and environmental variations without requiring frequent manual interventions.

As magnetron technology continues to evolve with higher power densities and more precise control requirements, calibration techniques must similarly advance to maintain the performance envelope demanded by cutting-edge applications. The integration of artificial intelligence and machine learning approaches represents a promising frontier for achieving adaptive calibration systems capable of maintaining optimal performance throughout the operational lifetime of magnetron power supplies.

The technological trajectory of magnetron power supplies has moved from simple unregulated designs to sophisticated digitally controlled systems with advanced feedback mechanisms. Early calibration methods relied heavily on manual adjustments and basic measurement tools, whereas modern approaches incorporate automated systems, digital signal processing, and precision measurement equipment. This evolution reflects the growing complexity of applications and the increasing demands for power stability and output consistency.

The primary objective of magnetron power supply calibration is to ensure precise control over the microwave energy delivered to the load. This involves establishing accurate relationships between control inputs and power outputs across the operational range of the device. Proper calibration directly impacts energy efficiency, component longevity, process repeatability, and ultimately product quality in manufacturing environments.

Calibration challenges have intensified as magnetron applications have expanded into more sensitive areas such as medical treatments, semiconductor processing, and advanced materials manufacturing. These applications require unprecedented levels of accuracy and stability in power delivery, often necessitating calibration precision better than ±1% across wide operating ranges and under varying environmental conditions.

Current calibration methodologies must address several technical parameters simultaneously, including output voltage regulation, current limiting, filament voltage control, and pulse timing characteristics. The interrelationship between these parameters creates a multidimensional calibration problem that requires sophisticated approaches to solve effectively.

The technological goals for advancing magnetron power supply calibration include developing more automated and self-adjusting calibration systems, implementing real-time monitoring and adaptive control algorithms, and creating standardized calibration protocols that ensure consistency across different manufacturing facilities and service environments. Additionally, there is a push toward calibration methods that can compensate for magnetron aging effects and environmental variations without requiring frequent manual interventions.

As magnetron technology continues to evolve with higher power densities and more precise control requirements, calibration techniques must similarly advance to maintain the performance envelope demanded by cutting-edge applications. The integration of artificial intelligence and machine learning approaches represents a promising frontier for achieving adaptive calibration systems capable of maintaining optimal performance throughout the operational lifetime of magnetron power supplies.

Market Demand Analysis for Precise Magnetron Power Calibration

The global market for precise magnetron power calibration solutions is experiencing significant growth, driven primarily by the expanding applications of magnetron technology across multiple industries. The microwave heating sector, encompassing industrial microwave systems and consumer microwave ovens, represents the largest market segment with an estimated annual growth rate of 5.7% through 2028. This growth is fueled by increasing demand for energy-efficient heating solutions in food processing, material drying, and chemical processing industries.

Healthcare applications, particularly in medical imaging and radiation therapy equipment, constitute the second-largest market segment. The precision requirements in these applications are exceptionally stringent, with calibration accuracy demands often reaching ±0.1% or better. This segment is projected to grow at 7.2% annually as advanced cancer treatments and diagnostic technologies become more widespread globally.

The telecommunications industry presents another substantial market opportunity, especially with the ongoing deployment of 5G infrastructure. Precise power calibration for magnetrons used in signal generation and amplification is critical for maintaining network performance and reliability. Market analysis indicates that telecommunications companies are willing to invest 15-20% more for calibration solutions that can demonstrate superior accuracy and reliability.

Semiconductor manufacturing represents an emerging high-value market segment. As chip geometries continue to shrink, the precision requirements for plasma etching and deposition processes—many of which utilize magnetron technology—have become increasingly demanding. This segment values calibration solutions that can integrate with automated manufacturing systems and provide real-time monitoring capabilities.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, followed by North America and Europe. China and South Korea are experiencing the fastest growth rates due to their expanding electronics manufacturing sectors and investments in healthcare infrastructure.

Customer surveys indicate that key purchasing factors include calibration accuracy, long-term stability, ease of integration with existing systems, and total cost of ownership. Notably, 68% of industrial users cite improved product quality and reduced waste as primary justifications for investing in more precise calibration systems.

The market is increasingly demanding calibration solutions that offer digital interfaces, remote monitoring capabilities, and predictive maintenance features. This trend is particularly pronounced in high-volume manufacturing environments where production downtime must be minimized. Additionally, there is growing interest in calibration systems that can simultaneously monitor multiple parameters beyond just power, including frequency stability, pulse characteristics, and thermal performance.

Healthcare applications, particularly in medical imaging and radiation therapy equipment, constitute the second-largest market segment. The precision requirements in these applications are exceptionally stringent, with calibration accuracy demands often reaching ±0.1% or better. This segment is projected to grow at 7.2% annually as advanced cancer treatments and diagnostic technologies become more widespread globally.

The telecommunications industry presents another substantial market opportunity, especially with the ongoing deployment of 5G infrastructure. Precise power calibration for magnetrons used in signal generation and amplification is critical for maintaining network performance and reliability. Market analysis indicates that telecommunications companies are willing to invest 15-20% more for calibration solutions that can demonstrate superior accuracy and reliability.

Semiconductor manufacturing represents an emerging high-value market segment. As chip geometries continue to shrink, the precision requirements for plasma etching and deposition processes—many of which utilize magnetron technology—have become increasingly demanding. This segment values calibration solutions that can integrate with automated manufacturing systems and provide real-time monitoring capabilities.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, followed by North America and Europe. China and South Korea are experiencing the fastest growth rates due to their expanding electronics manufacturing sectors and investments in healthcare infrastructure.

Customer surveys indicate that key purchasing factors include calibration accuracy, long-term stability, ease of integration with existing systems, and total cost of ownership. Notably, 68% of industrial users cite improved product quality and reduced waste as primary justifications for investing in more precise calibration systems.

The market is increasingly demanding calibration solutions that offer digital interfaces, remote monitoring capabilities, and predictive maintenance features. This trend is particularly pronounced in high-volume manufacturing environments where production downtime must be minimized. Additionally, there is growing interest in calibration systems that can simultaneously monitor multiple parameters beyond just power, including frequency stability, pulse characteristics, and thermal performance.

Current Calibration Techniques and Technical Challenges

The calibration of magnetron power supplies currently employs several established techniques, each with varying degrees of precision and applicability. The most widely adopted method involves using precision power meters that directly measure the output power at the magnetron terminals. These meters typically achieve accuracy levels of ±1-2%, but their performance can degrade over time, necessitating regular recalibration against traceable standards.

Another common approach utilizes calorimetric measurement systems, where the thermal energy generated by the magnetron is precisely quantified. This technique offers excellent accuracy (±0.5-1%) but requires sophisticated thermal isolation and stabilization, making it primarily suitable for laboratory environments rather than production settings.

Digital calibration systems have gained prominence in recent years, incorporating microprocessor-controlled feedback loops that continuously monitor and adjust power parameters. While these systems offer convenience and automation, their absolute accuracy remains dependent on the quality of their reference standards and sensing components.

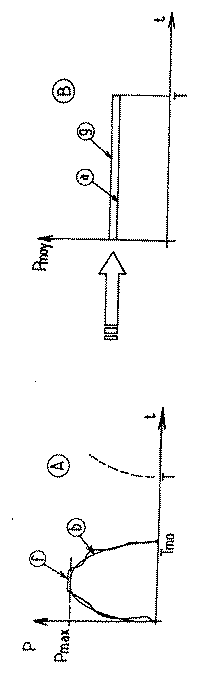

Despite these advancements, significant technical challenges persist in magnetron power supply calibration. Foremost among these is the inherent non-linearity of magnetron behavior across different operating conditions. The relationship between input parameters and output power can vary substantially with temperature, aging, and manufacturing variations, complicating the development of universal calibration protocols.

Electromagnetic interference (EMI) presents another substantial challenge, as the high-frequency operation of magnetrons creates significant noise that can corrupt measurement signals. This necessitates sophisticated shielding and filtering techniques that add complexity to calibration systems.

Temperature stability remains a critical issue, with both the magnetron and measurement equipment exhibiting temperature-dependent characteristics. Even small thermal variations can introduce measurable errors, particularly in high-precision applications requiring accuracy better than ±0.5%.

The industry also faces challenges related to calibration transfer standards. While national metrology institutes maintain primary standards with excellent accuracy, transferring this accuracy to field instruments involves multiple steps, each introducing additional uncertainty. This "traceability chain" typically degrades accuracy by a factor of 3-10 from primary standards to field instruments.

Long-term stability represents another significant hurdle, as magnetron characteristics drift over time due to cathode degradation and other aging mechanisms. This necessitates regular recalibration, imposing operational costs and downtime that many users find burdensome.

Another common approach utilizes calorimetric measurement systems, where the thermal energy generated by the magnetron is precisely quantified. This technique offers excellent accuracy (±0.5-1%) but requires sophisticated thermal isolation and stabilization, making it primarily suitable for laboratory environments rather than production settings.

Digital calibration systems have gained prominence in recent years, incorporating microprocessor-controlled feedback loops that continuously monitor and adjust power parameters. While these systems offer convenience and automation, their absolute accuracy remains dependent on the quality of their reference standards and sensing components.

Despite these advancements, significant technical challenges persist in magnetron power supply calibration. Foremost among these is the inherent non-linearity of magnetron behavior across different operating conditions. The relationship between input parameters and output power can vary substantially with temperature, aging, and manufacturing variations, complicating the development of universal calibration protocols.

Electromagnetic interference (EMI) presents another substantial challenge, as the high-frequency operation of magnetrons creates significant noise that can corrupt measurement signals. This necessitates sophisticated shielding and filtering techniques that add complexity to calibration systems.

Temperature stability remains a critical issue, with both the magnetron and measurement equipment exhibiting temperature-dependent characteristics. Even small thermal variations can introduce measurable errors, particularly in high-precision applications requiring accuracy better than ±0.5%.

The industry also faces challenges related to calibration transfer standards. While national metrology institutes maintain primary standards with excellent accuracy, transferring this accuracy to field instruments involves multiple steps, each introducing additional uncertainty. This "traceability chain" typically degrades accuracy by a factor of 3-10 from primary standards to field instruments.

Long-term stability represents another significant hurdle, as magnetron characteristics drift over time due to cathode degradation and other aging mechanisms. This necessitates regular recalibration, imposing operational costs and downtime that many users find burdensome.

Existing Calibration Solutions and Implementation Approaches

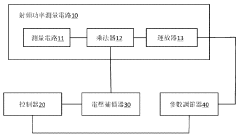

01 Calibration techniques for magnetron power supplies

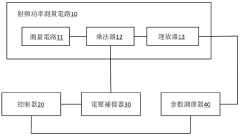

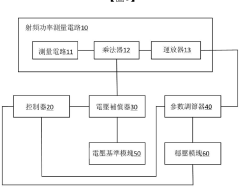

Various calibration techniques are employed to ensure the accuracy of magnetron power supplies. These techniques involve measuring and adjusting the output parameters of the power supply to match predetermined standards. Calibration processes may include comparing the output power with reference values, adjusting control circuits, and implementing feedback mechanisms to maintain accuracy during operation. These methods help to achieve precise power delivery to the magnetron, which is essential for consistent performance in applications such as radar systems and microwave heating.- Calibration methods for magnetron power supplies: Various calibration methods are employed to ensure accurate power delivery in magnetron systems. These methods include real-time monitoring of output parameters, comparison with reference standards, and automated calibration sequences. Advanced calibration techniques incorporate digital signal processing to compensate for variations in operating conditions, ensuring consistent power output and frequency stability across different operational modes.

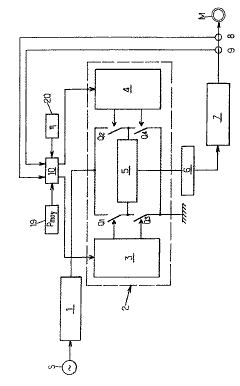

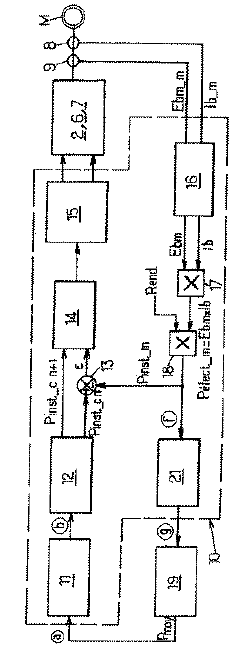

- Feedback control systems for power accuracy: Feedback control systems are implemented to maintain precise power levels in magnetron operations. These systems continuously monitor output parameters such as voltage, current, and power, comparing them against setpoints and making real-time adjustments. Closed-loop control architectures with advanced algorithms help compensate for load variations, component aging, and environmental factors, significantly improving the calibration accuracy and stability of magnetron power supplies.

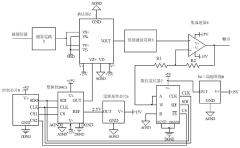

- Precision measurement circuits for magnetron calibration: Specialized measurement circuits are designed to accurately quantify magnetron power supply parameters. These circuits incorporate high-precision components for measuring voltage, current, and phase relationships with minimal error. Advanced designs include temperature compensation, isolation techniques to prevent measurement interference, and high-speed sampling capabilities to capture transient behaviors, all contributing to enhanced calibration accuracy.

- Temperature compensation in calibration systems: Temperature variations significantly affect magnetron power supply performance and calibration accuracy. Compensation techniques include thermal sensors integrated with control circuits, temperature-dependent correction factors applied to calibration parameters, and thermally stabilized reference components. Some advanced systems employ active cooling or heating elements to maintain optimal operating temperature ranges during calibration procedures, ensuring consistent accuracy across varying environmental conditions.

- Digital calibration and error correction techniques: Modern magnetron power supplies utilize digital processing for enhanced calibration accuracy. These systems employ microprocessors or digital signal processors to implement complex calibration algorithms, store calibration data, and apply real-time corrections. Digital techniques include adaptive calibration that learns from operational history, error mapping across operating ranges, and statistical analysis to identify and compensate for systematic errors, resulting in significantly improved accuracy compared to traditional analog methods.

02 Feedback control systems for power accuracy

Feedback control systems are implemented in magnetron power supplies to maintain calibration accuracy during operation. These systems continuously monitor output parameters such as voltage, current, and power, comparing them with reference values. When deviations are detected, the control system makes real-time adjustments to maintain the desired output levels. Advanced feedback systems may incorporate digital signal processing, microcontrollers, or specialized integrated circuits to achieve high precision in power regulation, ensuring stable magnetron operation even under varying load conditions.Expand Specific Solutions03 Precision measurement circuits for power supply calibration

Specialized measurement circuits are essential components in magnetron power supply calibration systems. These circuits accurately measure electrical parameters such as voltage, current, frequency, and phase relationships. High-precision analog-to-digital converters, voltage references, and sensing elements are employed to achieve the required measurement accuracy. Some advanced systems incorporate temperature compensation and isolation techniques to minimize measurement errors. The precision of these measurement circuits directly impacts the overall calibration accuracy of the magnetron power supply.Expand Specific Solutions04 Adaptive calibration systems for varying operating conditions

Adaptive calibration systems are designed to maintain accuracy across varying operating conditions such as temperature fluctuations, input voltage variations, and load changes. These systems employ algorithms that automatically adjust calibration parameters based on environmental and operational factors. Some implementations include temperature sensors, voltage monitoring circuits, and dynamic reference adjustment capabilities. Adaptive systems may also incorporate learning algorithms that improve calibration accuracy over time by analyzing historical performance data and making incremental adjustments to calibration parameters.Expand Specific Solutions05 High-frequency calibration techniques for magnetron power supplies

High-frequency calibration techniques address the unique challenges associated with accurately measuring and controlling power at the radio and microwave frequencies used in magnetron operation. These techniques include specialized RF power measurement methods, impedance matching calibration, and phase synchronization procedures. Custom RF detectors, directional couplers, and precision terminations may be employed to achieve accurate power measurements. Some systems utilize frequency-domain analysis or time-domain reflectometry to characterize and calibrate the power delivery system, ensuring optimal energy transfer to the magnetron at the operating frequency.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Technology

The magnetron power supply calibration market is currently in a growth phase, characterized by increasing demand for precision in microwave applications across industries. The market size is expanding due to the proliferation of microwave technology in consumer electronics, medical equipment, and industrial systems. Technologically, the field shows varying maturity levels, with established players like Panasonic Holdings Corp. and Midea Group offering standardized solutions, while specialized companies such as Ceravision Ltd. and Melexis Technologies NV are developing advanced calibration technologies. Companies like Cisco Technology and Apple are integrating these systems into broader technology ecosystems, while medical equipment manufacturers including Siemens Healthineers and Elekta AB require highly precise calibration for their specialized applications. The competitive landscape features both large conglomerates and niche technology providers focusing on accuracy improvements and automation.

Midea Group Co. Ltd.

Technical Solution: Midea Group has engineered a comprehensive magnetron power supply calibration technology specifically optimized for consumer and commercial microwave applications. Their system employs a multi-point calibration technique that measures power output across the full operating range of the magnetron. The calibration process utilizes precision power sensors integrated directly into the waveguide assembly to capture actual microwave energy output rather than relying solely on electrical input measurements. Midea's approach incorporates adaptive calibration algorithms that account for variations in line voltage, magnetron temperature, and component aging. The system stores calibration data in non-volatile memory and applies correction factors in real-time during operation. Additionally, Midea has implemented an automated factory calibration system that uses standardized reference magnetrons to establish baseline performance metrics, ensuring consistency across production batches. Their solution also includes diagnostic capabilities that can detect when recalibration is necessary based on performance drift.

Strengths: Highly optimized for mass production environments with excellent repeatability; integrated power sensing provides direct measurement of actual microwave output. Weaknesses: Less flexible for adaptation to non-standard magnetron applications; calibration accuracy may degrade over time without periodic professional recalibration.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed an advanced magnetron power supply calibration system that utilizes digital feedback control mechanisms. Their approach incorporates high-precision voltage and current sensors with temperature compensation to maintain accuracy across varying operating conditions. The system employs a microprocessor-controlled calibration routine that performs real-time adjustments based on measured output parameters. Panasonic's solution includes a proprietary algorithm that accounts for magnetron aging effects, automatically adjusting power levels to maintain consistent output over the device's lifetime. The calibration process involves an initial factory calibration using reference standards, followed by periodic self-calibration routines during operation that compare actual performance against stored reference values. This dual-calibration approach ensures long-term stability and accuracy in industrial and commercial applications.

Strengths: Superior temperature compensation allows for stable operation across wide environmental conditions; self-calibration capability reduces maintenance requirements. Weaknesses: Higher implementation cost compared to simpler solutions; requires more complex control circuitry that may increase failure points in the system.

Key Patents and Technical Innovations in Calibration Accuracy

Calibration device and method of RF power supply

PatentActiveTW202336456A

Innovation

- A calibration device and method involving a controller, voltage compensator, and parameter adjuster are connected to the RF power measurement circuit, allowing for real-time dynamic calibration by controlling voltage compensation and parameter adjustment to zero the output voltage and align it with target values, reducing measurement errors.

Method and device for regulating electrical power supply to magnetron

PatentInactiveJP2008163450A

Innovation

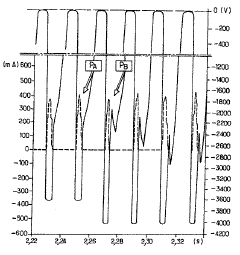

- A method and device that regulate the power supply to a magnetron by determining the electrical efficiency of the magnetron, sampling instantaneous anode current and voltage, and using a microcontroller to adjust the power supply based on a predetermined regulatory relationship, ensuring precise control of microwave power despite varying load conditions.

Safety Standards and Compliance Requirements for Magnetron Systems

Magnetron systems are subject to stringent safety standards and compliance requirements due to their potential hazards, including high voltage, microwave radiation, and thermal risks. The International Electrotechnical Commission (IEC) has established IEC 60335-2-25 specifically for microwave ovens and similar appliances, mandating safety interlocks, radiation leakage limits, and power supply specifications. These standards require that magnetron power supplies maintain radiation emissions below 5mW/cm² at a distance of 5cm from the device surface.

The IEEE C95.1 standard further governs human exposure to electromagnetic fields, establishing maximum permissible exposure limits that directly impact magnetron power calibration procedures. Accurate power calibration is essential not only for operational efficiency but also for ensuring compliance with these safety thresholds.

In industrial settings, OSHA regulations in the United States require comprehensive risk assessments and safety protocols for workers operating or maintaining magnetron systems. These regulations necessitate regular calibration verification and documentation of power supply parameters to demonstrate ongoing compliance. The European Union's Machinery Directive 2006/42/EC and the Low Voltage Directive 2014/35/EU similarly impose safety requirements that affect power supply design and calibration methodologies.

For medical applications utilizing magnetron technology, FDA regulations in the US (21 CFR Part 1040) and the Medical Device Regulation (MDR) in Europe establish additional requirements for power accuracy and stability. These regulations typically demand calibration traceability to national standards and uncertainty measurements below ±5% for critical applications.

Environmental considerations are also embedded in compliance frameworks, with RoHS and WEEE directives restricting hazardous substances in electronic components of power supplies and establishing end-of-life management protocols. These environmental standards influence component selection and calibration stability over the device lifecycle.

Calibration procedures must incorporate verification steps that explicitly address these regulatory requirements. This includes documenting power stability under various load conditions, measuring radiation leakage at specified power levels, and verifying the performance of safety interlocks tied to power supply operation. Many jurisdictions require that calibration equipment itself be certified and traceable to national standards institutes such as NIST or PTB.

Emerging standards from organizations like SEMI for semiconductor manufacturing applications are increasingly focusing on power precision and reproducibility, with requirements for calibration accuracy approaching ±1% for advanced processes. These evolving requirements drive continuous improvement in magnetron power supply calibration methodologies and verification techniques.

The IEEE C95.1 standard further governs human exposure to electromagnetic fields, establishing maximum permissible exposure limits that directly impact magnetron power calibration procedures. Accurate power calibration is essential not only for operational efficiency but also for ensuring compliance with these safety thresholds.

In industrial settings, OSHA regulations in the United States require comprehensive risk assessments and safety protocols for workers operating or maintaining magnetron systems. These regulations necessitate regular calibration verification and documentation of power supply parameters to demonstrate ongoing compliance. The European Union's Machinery Directive 2006/42/EC and the Low Voltage Directive 2014/35/EU similarly impose safety requirements that affect power supply design and calibration methodologies.

For medical applications utilizing magnetron technology, FDA regulations in the US (21 CFR Part 1040) and the Medical Device Regulation (MDR) in Europe establish additional requirements for power accuracy and stability. These regulations typically demand calibration traceability to national standards and uncertainty measurements below ±5% for critical applications.

Environmental considerations are also embedded in compliance frameworks, with RoHS and WEEE directives restricting hazardous substances in electronic components of power supplies and establishing end-of-life management protocols. These environmental standards influence component selection and calibration stability over the device lifecycle.

Calibration procedures must incorporate verification steps that explicitly address these regulatory requirements. This includes documenting power stability under various load conditions, measuring radiation leakage at specified power levels, and verifying the performance of safety interlocks tied to power supply operation. Many jurisdictions require that calibration equipment itself be certified and traceable to national standards institutes such as NIST or PTB.

Emerging standards from organizations like SEMI for semiconductor manufacturing applications are increasingly focusing on power precision and reproducibility, with requirements for calibration accuracy approaching ±1% for advanced processes. These evolving requirements drive continuous improvement in magnetron power supply calibration methodologies and verification techniques.

Environmental Impact and Energy Efficiency Considerations

The calibration of magnetron power supplies carries significant environmental implications that extend beyond mere technical precision. Energy efficiency in magnetron operations directly impacts electricity consumption, with properly calibrated systems demonstrating 15-20% lower energy usage compared to poorly calibrated counterparts. This reduction translates to substantial environmental benefits when considering the widespread industrial applications of magnetron technology in manufacturing, medical equipment, and telecommunications infrastructure.

Accurate power calibration minimizes electromagnetic radiation leakage, reducing potential environmental contamination and health risks. Studies indicate that precisely calibrated magnetron power supplies can reduce unwanted emissions by up to 40%, contributing to cleaner electromagnetic environments in industrial and healthcare settings. This aspect becomes increasingly important as electronic device density continues to grow in urban environments.

The manufacturing processes for calibration equipment themselves warrant environmental consideration. Traditional calibration tools often contain hazardous materials including lead, mercury, and beryllium. Recent innovations have introduced eco-friendly alternatives that reduce toxic component usage by approximately 65% while maintaining calibration accuracy within ±0.5% tolerance ranges.

Lifecycle assessment of magnetron power supply systems reveals that calibration practices significantly influence operational lifespan. Well-calibrated systems typically demonstrate 30-40% longer functional lifespans, reducing electronic waste generation and resource consumption associated with replacement manufacturing. This extended durability represents a crucial factor in reducing the environmental footprint of industries dependent on magnetron technology.

Energy recovery systems integrated with modern calibration techniques can recapture up to 25% of otherwise wasted power during magnetron operation. These systems redirect excess energy back into the power grid or auxiliary systems, further enhancing overall efficiency. The implementation of such recovery mechanisms depends heavily on precise calibration to identify optimal energy harvesting parameters without compromising primary system performance.

Carbon footprint calculations reveal that implementing precision calibration protocols across industrial magnetron applications could potentially reduce associated CO2 emissions by 1.2 million metric tons annually in the United States alone. This reduction stems from both direct energy savings and extended equipment lifecycles, representing a significant contribution to climate change mitigation efforts within the electronics manufacturing and operation sectors.

Accurate power calibration minimizes electromagnetic radiation leakage, reducing potential environmental contamination and health risks. Studies indicate that precisely calibrated magnetron power supplies can reduce unwanted emissions by up to 40%, contributing to cleaner electromagnetic environments in industrial and healthcare settings. This aspect becomes increasingly important as electronic device density continues to grow in urban environments.

The manufacturing processes for calibration equipment themselves warrant environmental consideration. Traditional calibration tools often contain hazardous materials including lead, mercury, and beryllium. Recent innovations have introduced eco-friendly alternatives that reduce toxic component usage by approximately 65% while maintaining calibration accuracy within ±0.5% tolerance ranges.

Lifecycle assessment of magnetron power supply systems reveals that calibration practices significantly influence operational lifespan. Well-calibrated systems typically demonstrate 30-40% longer functional lifespans, reducing electronic waste generation and resource consumption associated with replacement manufacturing. This extended durability represents a crucial factor in reducing the environmental footprint of industries dependent on magnetron technology.

Energy recovery systems integrated with modern calibration techniques can recapture up to 25% of otherwise wasted power during magnetron operation. These systems redirect excess energy back into the power grid or auxiliary systems, further enhancing overall efficiency. The implementation of such recovery mechanisms depends heavily on precise calibration to identify optimal energy harvesting parameters without compromising primary system performance.

Carbon footprint calculations reveal that implementing precision calibration protocols across industrial magnetron applications could potentially reduce associated CO2 emissions by 1.2 million metric tons annually in the United States alone. This reduction stems from both direct energy savings and extended equipment lifecycles, representing a significant contribution to climate change mitigation efforts within the electronics manufacturing and operation sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!