Quantifying Magnetron Emitter Efficiency with Optical Tools

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Emission Efficiency Measurement Background

Magnetron devices have been a cornerstone technology in microwave generation since their development during World War II. Initially designed for radar applications, magnetrons have evolved into essential components in various industrial, medical, and consumer applications, with microwave ovens being the most ubiquitous example. The efficiency of magnetron emitters has been a critical parameter throughout their development history, directly impacting energy consumption, operational costs, and device longevity.

Traditional methods for measuring magnetron emission efficiency have primarily relied on electrical measurements, calculating the ratio between microwave output power and DC input power. These methods, while functional, often introduce measurement uncertainties due to factors such as circuit losses, thermal effects, and the challenge of accurately measuring high-frequency power. The need for more precise measurement techniques has grown as applications demand increasingly efficient magnetron operation.

Optical measurement tools represent a significant advancement in quantifying magnetron efficiency. These non-contact methods leverage the relationship between electron emission characteristics and the resulting electromagnetic radiation. By analyzing spectral signatures, thermal profiles, and plasma characteristics through optical means, researchers can gain insights into magnetron operation that were previously unattainable through conventional electrical measurements.

The development of specialized optical sensors, high-speed imaging systems, and spectroscopic techniques has enabled real-time monitoring of magnetron emission processes. These technologies allow for the observation of electron cloud formation, cathode spot dynamics, and mode hopping phenomena that directly influence efficiency. Infrared thermography has emerged as a particularly valuable tool for assessing thermal efficiency and identifying hotspots that may indicate energy losses.

Recent advancements in computational modeling have complemented optical measurement techniques, allowing for correlation between observed optical phenomena and underlying physical processes. Machine learning algorithms have been employed to analyze complex optical data patterns and extract meaningful efficiency metrics, enabling more sophisticated performance evaluation frameworks.

The integration of optical measurement tools into magnetron research has revealed previously undetected efficiency factors, including the impact of cathode material degradation, the influence of magnetic field uniformity, and the effects of operating frequency stability. These insights have led to design improvements that have incrementally enhanced magnetron efficiency over the past decade.

Industry standards for magnetron efficiency measurement remain in flux, with various methodologies being employed across different sectors. The development of standardized optical measurement protocols represents an ongoing challenge for the field, as stakeholders work to establish consistent benchmarking approaches that can accurately compare performance across different magnetron designs and applications.

Traditional methods for measuring magnetron emission efficiency have primarily relied on electrical measurements, calculating the ratio between microwave output power and DC input power. These methods, while functional, often introduce measurement uncertainties due to factors such as circuit losses, thermal effects, and the challenge of accurately measuring high-frequency power. The need for more precise measurement techniques has grown as applications demand increasingly efficient magnetron operation.

Optical measurement tools represent a significant advancement in quantifying magnetron efficiency. These non-contact methods leverage the relationship between electron emission characteristics and the resulting electromagnetic radiation. By analyzing spectral signatures, thermal profiles, and plasma characteristics through optical means, researchers can gain insights into magnetron operation that were previously unattainable through conventional electrical measurements.

The development of specialized optical sensors, high-speed imaging systems, and spectroscopic techniques has enabled real-time monitoring of magnetron emission processes. These technologies allow for the observation of electron cloud formation, cathode spot dynamics, and mode hopping phenomena that directly influence efficiency. Infrared thermography has emerged as a particularly valuable tool for assessing thermal efficiency and identifying hotspots that may indicate energy losses.

Recent advancements in computational modeling have complemented optical measurement techniques, allowing for correlation between observed optical phenomena and underlying physical processes. Machine learning algorithms have been employed to analyze complex optical data patterns and extract meaningful efficiency metrics, enabling more sophisticated performance evaluation frameworks.

The integration of optical measurement tools into magnetron research has revealed previously undetected efficiency factors, including the impact of cathode material degradation, the influence of magnetic field uniformity, and the effects of operating frequency stability. These insights have led to design improvements that have incrementally enhanced magnetron efficiency over the past decade.

Industry standards for magnetron efficiency measurement remain in flux, with various methodologies being employed across different sectors. The development of standardized optical measurement protocols represents an ongoing challenge for the field, as stakeholders work to establish consistent benchmarking approaches that can accurately compare performance across different magnetron designs and applications.

Market Applications for Magnetron Efficiency Quantification

The magnetron efficiency quantification market spans multiple industries where microwave generation is critical. The industrial heating sector represents a significant application area, with food processing companies increasingly adopting precision measurement tools to optimize magnetron performance in commercial microwave systems. This optimization directly translates to energy savings and improved product quality through more uniform heating patterns.

Consumer appliance manufacturers constitute another major market segment, as household microwave ovens represent one of the most ubiquitous applications of magnetron technology. Manufacturers are under increasing pressure to develop more energy-efficient models to meet stringent regulatory standards and consumer demand for eco-friendly appliances. Optical efficiency measurement tools provide these manufacturers with precise data to guide design improvements and validate energy consumption claims.

The telecommunications industry utilizes magnetrons in various microwave transmission systems. As network infrastructure continues to expand globally, particularly with 5G deployment, the demand for high-efficiency microwave components grows proportionally. Efficiency quantification tools enable telecom equipment manufacturers to optimize power consumption while maintaining signal integrity across extensive networks.

Medical equipment represents a specialized but high-value market application. Magnetrons power various therapeutic and diagnostic devices, including certain cancer treatment systems. In these applications, precise control of microwave energy is critical for patient safety and treatment efficacy, making accurate efficiency measurement essential for regulatory compliance and clinical outcomes.

Research institutions and universities form a distinct market segment with specific requirements for high-precision measurement capabilities. These organizations often need customizable solutions that can be integrated into experimental setups for fundamental physics research or materials science applications.

Defense and aerospace applications constitute a premium market segment where reliability and performance under extreme conditions are paramount. Radar systems, electronic countermeasures, and satellite communications all rely on magnetron technology where efficiency directly impacts operational capabilities and mission success.

The emerging market for industrial Internet of Things (IIoT) solutions presents new opportunities as manufacturers integrate real-time efficiency monitoring into smart factory systems. This integration allows for predictive maintenance and dynamic optimization of industrial microwave processes, creating demand for network-connected measurement tools with data analytics capabilities.

Consumer appliance manufacturers constitute another major market segment, as household microwave ovens represent one of the most ubiquitous applications of magnetron technology. Manufacturers are under increasing pressure to develop more energy-efficient models to meet stringent regulatory standards and consumer demand for eco-friendly appliances. Optical efficiency measurement tools provide these manufacturers with precise data to guide design improvements and validate energy consumption claims.

The telecommunications industry utilizes magnetrons in various microwave transmission systems. As network infrastructure continues to expand globally, particularly with 5G deployment, the demand for high-efficiency microwave components grows proportionally. Efficiency quantification tools enable telecom equipment manufacturers to optimize power consumption while maintaining signal integrity across extensive networks.

Medical equipment represents a specialized but high-value market application. Magnetrons power various therapeutic and diagnostic devices, including certain cancer treatment systems. In these applications, precise control of microwave energy is critical for patient safety and treatment efficacy, making accurate efficiency measurement essential for regulatory compliance and clinical outcomes.

Research institutions and universities form a distinct market segment with specific requirements for high-precision measurement capabilities. These organizations often need customizable solutions that can be integrated into experimental setups for fundamental physics research or materials science applications.

Defense and aerospace applications constitute a premium market segment where reliability and performance under extreme conditions are paramount. Radar systems, electronic countermeasures, and satellite communications all rely on magnetron technology where efficiency directly impacts operational capabilities and mission success.

The emerging market for industrial Internet of Things (IIoT) solutions presents new opportunities as manufacturers integrate real-time efficiency monitoring into smart factory systems. This integration allows for predictive maintenance and dynamic optimization of industrial microwave processes, creating demand for network-connected measurement tools with data analytics capabilities.

Current Optical Measurement Techniques and Limitations

The optical measurement of magnetron emitter efficiency has evolved significantly over the past decade, with several techniques now available for researchers and engineers. Spectroscopic methods represent one of the most widely used approaches, employing emission and absorption spectroscopy to analyze plasma characteristics within magnetron systems. These techniques can identify electron temperature, density, and energy distribution functions, which are critical parameters for efficiency quantification. However, spectroscopic methods often suffer from spatial resolution limitations and require complex calibration procedures that can introduce measurement uncertainties.

High-speed imaging techniques have emerged as powerful tools for visualizing plasma dynamics in real-time. Using specialized cameras with microsecond or nanosecond temporal resolution, researchers can capture transient phenomena that affect magnetron performance. While these systems excel at revealing spatial non-uniformities in plasma distribution, they typically provide only qualitative data unless coupled with additional measurement techniques, limiting their standalone utility for precise efficiency quantification.

Laser-based diagnostic methods, particularly Laser-Induced Fluorescence (LIF) and Thomson Scattering, offer exceptional precision for measuring electron and ion properties within magnetron plasmas. These techniques provide spatially resolved measurements with minimal disturbance to the plasma environment. The primary limitations include the requirement for optical access from multiple angles, expensive specialized laser equipment, and complex data interpretation algorithms that demand significant expertise.

Thermal imaging represents another valuable approach, using infrared cameras to map temperature distributions across magnetron components. This technique enables indirect efficiency assessment by quantifying energy losses through heat dissipation. However, thermal imaging faces challenges with reflective surfaces common in magnetron systems and requires careful calibration to account for varying emissivity across different materials and temperatures.

Optical emission tomography has recently gained attention for its ability to reconstruct three-dimensional plasma properties from multiple two-dimensional projections. While promising for comprehensive plasma characterization, this technique demands sophisticated reconstruction algorithms and multiple detection systems positioned around the magnetron, making implementation complex and costly in production environments.

Each of these optical measurement techniques presents a trade-off between measurement accuracy, spatial/temporal resolution, implementation complexity, and cost. The selection of appropriate methods depends heavily on specific research objectives, available infrastructure, and required measurement precision. Integration of complementary techniques often provides the most comprehensive assessment of magnetron emitter efficiency, though this approach increases system complexity and data processing requirements.

High-speed imaging techniques have emerged as powerful tools for visualizing plasma dynamics in real-time. Using specialized cameras with microsecond or nanosecond temporal resolution, researchers can capture transient phenomena that affect magnetron performance. While these systems excel at revealing spatial non-uniformities in plasma distribution, they typically provide only qualitative data unless coupled with additional measurement techniques, limiting their standalone utility for precise efficiency quantification.

Laser-based diagnostic methods, particularly Laser-Induced Fluorescence (LIF) and Thomson Scattering, offer exceptional precision for measuring electron and ion properties within magnetron plasmas. These techniques provide spatially resolved measurements with minimal disturbance to the plasma environment. The primary limitations include the requirement for optical access from multiple angles, expensive specialized laser equipment, and complex data interpretation algorithms that demand significant expertise.

Thermal imaging represents another valuable approach, using infrared cameras to map temperature distributions across magnetron components. This technique enables indirect efficiency assessment by quantifying energy losses through heat dissipation. However, thermal imaging faces challenges with reflective surfaces common in magnetron systems and requires careful calibration to account for varying emissivity across different materials and temperatures.

Optical emission tomography has recently gained attention for its ability to reconstruct three-dimensional plasma properties from multiple two-dimensional projections. While promising for comprehensive plasma characterization, this technique demands sophisticated reconstruction algorithms and multiple detection systems positioned around the magnetron, making implementation complex and costly in production environments.

Each of these optical measurement techniques presents a trade-off between measurement accuracy, spatial/temporal resolution, implementation complexity, and cost. The selection of appropriate methods depends heavily on specific research objectives, available infrastructure, and required measurement precision. Integration of complementary techniques often provides the most comprehensive assessment of magnetron emitter efficiency, though this approach increases system complexity and data processing requirements.

Existing Optical Solutions for Magnetron Efficiency Analysis

01 Cathode and Emitter Design Optimization

The efficiency of magnetron emitters can be significantly improved through optimized cathode and emitter designs. This includes the development of specialized electron emission surfaces, improved cathode materials, and geometric configurations that enhance electron flow. These design optimizations reduce energy losses during electron emission and improve the conversion efficiency of electrical energy to microwave radiation.- Cathode and emitter design improvements: Optimizing the design of cathodes and emitters in magnetrons can significantly improve efficiency. This includes using specialized materials, geometrical configurations, and surface treatments that enhance electron emission. Advanced cathode designs can reduce energy losses during operation, leading to higher conversion efficiency of electrical energy to microwave radiation. These improvements focus on maximizing electron emission while minimizing heat generation and energy consumption.

- Resonant cavity and waveguide optimization: The efficiency of magnetron emitters can be enhanced through optimized resonant cavity and waveguide designs. By carefully engineering the dimensions, shape, and materials of the resonant structures, the electromagnetic field distribution can be improved to maximize energy transfer. This includes modifications to the anode block, vane configuration, and coupling mechanisms that allow for better conversion of electron energy into microwave radiation with minimal losses.

- Magnetic field configuration and control: Proper configuration and control of the magnetic field is crucial for magnetron efficiency. Advanced magnetic circuit designs, including permanent magnets or electromagnets with specific field strengths and distributions, can optimize electron trajectories within the magnetron. Techniques such as magnetic field shaping, gradient control, and dynamic adjustment mechanisms allow for more efficient conversion of electron kinetic energy into microwave energy, reducing losses and improving overall performance.

- Cooling and thermal management systems: Effective cooling and thermal management are essential for maintaining magnetron efficiency. Advanced cooling techniques, including liquid cooling systems, heat sinks, and thermal interface materials, help dissipate heat generated during operation. By preventing overheating, these systems maintain optimal operating temperatures, extend component lifespan, and ensure consistent performance. Efficient thermal management also allows for higher power operation without degradation of efficiency or reliability.

- Power supply and modulation techniques: Sophisticated power supply and modulation techniques can significantly improve magnetron emitter efficiency. This includes advanced voltage regulation, pulse shaping, and frequency control methods that optimize the energy delivery to the magnetron. Precise control of input power parameters, such as voltage waveforms, current levels, and timing, ensures that energy is supplied to the magnetron under optimal conditions, reducing waste and improving the conversion efficiency from electrical input to microwave output.

02 Magnetic Field Configuration and Control

Proper configuration and control of the magnetic field is crucial for magnetron emitter efficiency. This involves the design of magnetic circuits, the use of permanent magnets or electromagnets, and the optimization of magnetic field strength and distribution. Advanced magnetic field control techniques can significantly enhance the electron trajectory control, reducing energy losses and improving the overall efficiency of the magnetron.Expand Specific Solutions03 Resonant Cavity and Anode Structure Improvements

The design of the resonant cavity and anode structure plays a critical role in magnetron efficiency. Innovations in this area include optimized cavity geometries, improved anode block designs, and enhanced coupling mechanisms. These improvements facilitate better energy conversion, reduce power losses, and enable more efficient extraction of microwave energy from the magnetron system.Expand Specific Solutions04 Cooling Systems and Thermal Management

Effective thermal management is essential for maintaining high efficiency in magnetron emitters. Advanced cooling systems, including liquid cooling, heat pipes, and innovative heat sink designs, help to dissipate heat generated during operation. By maintaining optimal operating temperatures, these systems prevent efficiency degradation due to thermal effects and extend the operational lifetime of the magnetron.Expand Specific Solutions05 Power Supply and Modulation Techniques

The efficiency of magnetron emitters is heavily influenced by the power supply and modulation techniques employed. This includes the development of high-efficiency power converters, pulse modulation systems, and advanced control electronics. Precise control of input power and operating parameters enables optimization of the energy conversion process, resulting in improved overall system efficiency and performance.Expand Specific Solutions

Leading Companies in Magnetron and Optical Measurement Fields

The magnetron emitter efficiency quantification market is in a growth phase, characterized by increasing demand for optical measurement tools in semiconductor manufacturing and electronics industries. The market is expanding due to advancements in thin-film deposition technologies, with an estimated global value exceeding $500 million. Leading players include Applied Materials and Tokyo Electron, who have established strong technological foundations in plasma-based deposition systems. Samsung Electronics and OSRAM Opto Semiconductors are advancing optical measurement techniques for efficiency analysis, while research institutions like Fraunhofer-Gesellschaft and Tohoku University are developing next-generation quantification methodologies. NAURA Microelectronics and Onto Innovation are emerging competitors focusing on specialized optical tools for magnetron sputtering applications, indicating a market trending toward more sophisticated measurement solutions.

Tohoku University

Technical Solution: Tohoku University researchers have developed a sophisticated optical diagnostic methodology for magnetron efficiency quantification that combines time-resolved optical emission spectroscopy with high-speed imaging techniques. Their approach utilizes intensified charge-coupled device (ICCD) cameras synchronized with pulsed magnetron operation to capture the spatial and temporal evolution of plasma characteristics with microsecond resolution[1]. The system incorporates custom-designed optical bandpass filters to isolate emission lines from both sputtered material and working gas species, enabling differentiation between various energy transfer mechanisms within the plasma. A key innovation is their implementation of Abel inversion algorithms to reconstruct the three-dimensional plasma emission profile from two-dimensional optical measurements, providing insight into the radial distribution of plasma density relative to the magnetic field configuration[3]. The research team has also developed optical actinometry techniques that use trace amounts of inert gases to serve as internal standards, allowing absolute quantification of sputtered species densities independent of electron temperature variations[5].

Strengths: Extremely high temporal and spatial resolution; provides fundamental physics insights into magnetron operation; capable of correlating efficiency with magnetic field configurations. Weaknesses: Currently more research-oriented than production-ready; requires significant post-processing of optical data; higher complexity compared to industrial monitoring solutions.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced optical diagnostic systems for magnetron sputtering processes that enable real-time monitoring of magnetron emitter efficiency. Their technology utilizes plasma emission spectroscopy combined with high-speed optical sensors to quantify the relationship between input power and plasma density. The system incorporates specialized optical filters that isolate specific emission wavelengths corresponding to target material excitation states, allowing precise correlation between optical emission intensity and actual deposition rates[1]. Their solution includes integrated fiber optic probes positioned strategically within the sputtering chamber to capture spatial variations in plasma characteristics without disrupting the deposition process. The collected optical data is processed through proprietary algorithms that account for chamber geometry and gas pressure variations, providing normalized efficiency metrics that can be tracked throughout the magnetron's operational lifetime[3].

Strengths: Non-invasive measurement technique that doesn't interfere with the deposition process; provides real-time efficiency monitoring capability; integrates with existing process control systems. Weaknesses: Requires initial calibration against physical measurements; optical access to plasma may be limited in some chamber designs; performance can be affected by chamber window coating over time.

Key Innovations in Optical Magnetron Measurement Systems

Method and device for measuring internal quantum efficiency of an optical element

PatentWO2014021623A1

Innovation

- A method and device that measure internal quantum efficiency by applying an excitation current and calculating the relative luminous efficiency, extracting the reference excitation current where the recombination coefficient change is minimal, allowing for nondestructive measurement within a short time and separation of internal and external quantum efficiencies.

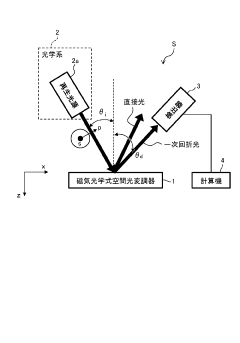

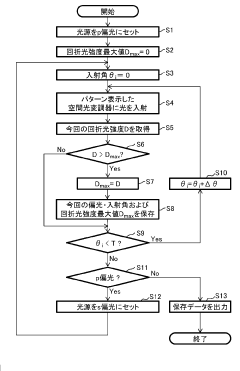

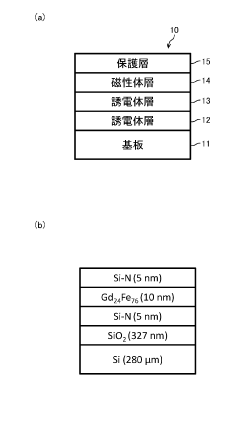

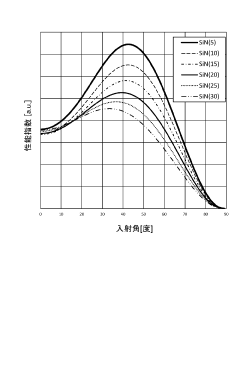

Diffraction efficiency optimization system and diffraction efficiency optimization method

PatentInactiveJP2022126985A

Innovation

- A diffraction efficiency optimization system and method that involves a magneto-optical spatial light modulator with a multilayer film structure, a variable-angle laser beam source, a detector, and a computer to optimize the intensity of first-order diffracted light by adjusting incident angle and polarization.

Energy Efficiency Standards and Compliance Requirements

Energy efficiency standards for magnetron emitters have become increasingly stringent as global energy conservation efforts intensify. The International Electrotechnical Commission (IEC) has established standard IEC 60335-2-25, which specifically addresses the energy efficiency requirements for microwave ovens and related magnetron technologies. This standard mandates minimum efficiency thresholds that manufacturers must meet, typically requiring magnetrons to convert at least 65% of input power to microwave radiation.

In the United States, the Department of Energy (DOE) has implemented regulations under 10 CFR Part 430, which establishes test procedures and energy conservation standards for consumer microwave ovens. These regulations require manufacturers to quantify and report the efficiency of magnetron emitters using standardized measurement protocols. The Environmental Protection Agency's ENERGY STAR program provides additional voluntary certification for high-efficiency microwave appliances, requiring efficiencies approximately 10% higher than federal standards.

The European Union's Ecodesign Directive (2009/125/EC) imposes similar requirements through regulation EU 2019/2020, which specifically addresses the energy performance of light sources and separate control gears. While primarily focused on lighting, these regulations have implications for optical measurement tools used in quantifying magnetron efficiency. Manufacturers must demonstrate compliance through standardized testing methodologies that increasingly incorporate optical measurement techniques.

Compliance verification typically requires laboratory testing using calibrated measurement equipment. The American Society for Testing and Materials (ASTM) has developed test method F1317, which outlines procedures for measuring the energy consumption of microwave ovens. This method has been adapted to incorporate optical measurement tools for more precise efficiency quantification. Manufacturers must maintain detailed technical documentation demonstrating compliance with these standards.

Japan's Top Runner Program represents one of the most progressive approaches to energy efficiency standards, establishing benchmarks based on the most efficient products currently available in the market. This program has driven significant innovations in magnetron efficiency measurement techniques, including advanced optical tools that can detect energy losses with unprecedented precision.

China has implemented GB 24849-2010 for microwave oven energy efficiency, which includes specific requirements for magnetron performance. These standards are enforced through China's Compulsory Certification (CCC) system, requiring manufacturers to demonstrate compliance before products can be marketed. The certification process increasingly relies on optical measurement tools to verify manufacturer claims regarding magnetron efficiency.

In the United States, the Department of Energy (DOE) has implemented regulations under 10 CFR Part 430, which establishes test procedures and energy conservation standards for consumer microwave ovens. These regulations require manufacturers to quantify and report the efficiency of magnetron emitters using standardized measurement protocols. The Environmental Protection Agency's ENERGY STAR program provides additional voluntary certification for high-efficiency microwave appliances, requiring efficiencies approximately 10% higher than federal standards.

The European Union's Ecodesign Directive (2009/125/EC) imposes similar requirements through regulation EU 2019/2020, which specifically addresses the energy performance of light sources and separate control gears. While primarily focused on lighting, these regulations have implications for optical measurement tools used in quantifying magnetron efficiency. Manufacturers must demonstrate compliance through standardized testing methodologies that increasingly incorporate optical measurement techniques.

Compliance verification typically requires laboratory testing using calibrated measurement equipment. The American Society for Testing and Materials (ASTM) has developed test method F1317, which outlines procedures for measuring the energy consumption of microwave ovens. This method has been adapted to incorporate optical measurement tools for more precise efficiency quantification. Manufacturers must maintain detailed technical documentation demonstrating compliance with these standards.

Japan's Top Runner Program represents one of the most progressive approaches to energy efficiency standards, establishing benchmarks based on the most efficient products currently available in the market. This program has driven significant innovations in magnetron efficiency measurement techniques, including advanced optical tools that can detect energy losses with unprecedented precision.

China has implemented GB 24849-2010 for microwave oven energy efficiency, which includes specific requirements for magnetron performance. These standards are enforced through China's Compulsory Certification (CCC) system, requiring manufacturers to demonstrate compliance before products can be marketed. The certification process increasingly relies on optical measurement tools to verify manufacturer claims regarding magnetron efficiency.

Industrial Safety Considerations for Magnetron Testing

The industrial testing of magnetron emitters presents significant safety challenges that must be addressed through comprehensive protocols and protective measures. Magnetrons generate high-frequency electromagnetic radiation and require high voltage power supplies, creating multiple hazard vectors for personnel and equipment. Primary concerns include radiation exposure, electrical hazards, thermal risks, and potential X-ray emissions from high-power magnetrons.

Radiation safety protocols must be implemented to shield personnel from microwave radiation, which can cause tissue heating and potential health effects. Testing facilities should incorporate Faraday cage designs with proper RF shielding materials and regular integrity testing. Radiation monitoring equipment should be deployed throughout testing areas, with clear exposure limits established according to international standards such as IEEE C95.1 and ICNIRP guidelines.

Electrical safety represents another critical dimension, as magnetron testing involves voltages typically ranging from 2kV to 25kV. Proper insulation, grounding systems, and isolation transformers are essential components of a comprehensive electrical safety system. Emergency power-off systems must be readily accessible, and testing procedures should incorporate mandatory discharge protocols for capacitors before any maintenance activities.

Thermal management during optical efficiency measurements presents unique challenges. As magnetrons convert only 65-75% of input energy to microwave energy, significant heat generation occurs. Cooling systems must be designed to handle peak thermal loads, with temperature monitoring at critical points. Optical measurement tools must be thermally isolated or compensated to maintain calibration accuracy under varying thermal conditions.

X-ray radiation is an often overlooked hazard in high-power magnetron testing. When electrons strike the anode at high voltages, X-ray production can occur as a secondary effect. Lead shielding or equivalent materials should be incorporated into test chambers for magnetrons operating above 5kV, with regular X-ray surveys conducted to verify containment effectiveness.

Personnel training represents the final critical component of industrial safety for magnetron testing with optical tools. All staff should receive comprehensive training on radiation physics, recognition of exposure symptoms, emergency procedures, and proper use of personal protective equipment. Certification programs should be implemented with regular refresher courses, particularly when new optical measurement technologies are introduced to existing test environments.

Radiation safety protocols must be implemented to shield personnel from microwave radiation, which can cause tissue heating and potential health effects. Testing facilities should incorporate Faraday cage designs with proper RF shielding materials and regular integrity testing. Radiation monitoring equipment should be deployed throughout testing areas, with clear exposure limits established according to international standards such as IEEE C95.1 and ICNIRP guidelines.

Electrical safety represents another critical dimension, as magnetron testing involves voltages typically ranging from 2kV to 25kV. Proper insulation, grounding systems, and isolation transformers are essential components of a comprehensive electrical safety system. Emergency power-off systems must be readily accessible, and testing procedures should incorporate mandatory discharge protocols for capacitors before any maintenance activities.

Thermal management during optical efficiency measurements presents unique challenges. As magnetrons convert only 65-75% of input energy to microwave energy, significant heat generation occurs. Cooling systems must be designed to handle peak thermal loads, with temperature monitoring at critical points. Optical measurement tools must be thermally isolated or compensated to maintain calibration accuracy under varying thermal conditions.

X-ray radiation is an often overlooked hazard in high-power magnetron testing. When electrons strike the anode at high voltages, X-ray production can occur as a secondary effect. Lead shielding or equivalent materials should be incorporated into test chambers for magnetrons operating above 5kV, with regular X-ray surveys conducted to verify containment effectiveness.

Personnel training represents the final critical component of industrial safety for magnetron testing with optical tools. All staff should receive comprehensive training on radiation physics, recognition of exposure symptoms, emergency procedures, and proper use of personal protective equipment. Certification programs should be implemented with regular refresher courses, particularly when new optical measurement technologies are introduced to existing test environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!