How to Alleviate Magnetron Environmental Stress Under Operation

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Environmental Stress Background and Objectives

Magnetron devices have been a cornerstone technology in microwave applications since their development during World War II. Initially designed for radar systems, magnetrons have evolved to become essential components in various industrial, medical, and consumer applications, with microwave ovens being the most ubiquitous example. Despite their widespread use, magnetrons face significant environmental stress challenges during operation that affect their performance, reliability, and lifespan.

The primary environmental stressors affecting magnetrons include thermal stress, electromagnetic interference, mechanical vibration, and atmospheric conditions. Thermal stress arises from the high operating temperatures (often exceeding 200°C) generated during the conversion of electrical energy to microwave radiation. This thermal loading creates expansion and contraction cycles that can lead to material fatigue and eventual failure of critical components.

Electromagnetic stress manifests as both internal and external factors. Internally, the high-frequency oscillations and intense electromagnetic fields can cause electron emission instabilities and cathode degradation. Externally, surrounding equipment or systems may introduce electromagnetic interference that disrupts the magnetron's delicate operating parameters.

Mechanical stress sources include vibration from cooling fans, mounting systems, or external equipment. These vibrations can cause misalignment of critical components, leading to arcing, frequency drift, or catastrophic failure. Additionally, shock events during transportation or installation can create microfractures that develop into failure points during operation.

Atmospheric conditions represent another significant stressor. Humidity, air pressure variations, and contaminants can affect the vacuum integrity of the magnetron tube and accelerate corrosion processes. In industrial settings, exposure to corrosive gases or particulates further compounds these challenges.

The technical objectives of this research are multifaceted. First, we aim to develop comprehensive models that accurately predict the combined effects of multiple environmental stressors on magnetron performance and lifespan. Second, we seek to identify novel materials and structural designs that enhance resilience against identified stressors without compromising performance or increasing manufacturing costs.

Additionally, we intend to explore adaptive control systems that can dynamically adjust operating parameters in response to changing environmental conditions, thereby maintaining optimal performance while minimizing stress-induced degradation. Finally, we aim to establish standardized testing protocols that can reliably evaluate the effectiveness of stress mitigation strategies across different magnetron designs and applications.

By addressing these objectives, we anticipate significant advancements in magnetron technology that will extend operational lifespans, improve reliability in harsh environments, and potentially enable new applications where current magnetron technology is limited by environmental constraints.

The primary environmental stressors affecting magnetrons include thermal stress, electromagnetic interference, mechanical vibration, and atmospheric conditions. Thermal stress arises from the high operating temperatures (often exceeding 200°C) generated during the conversion of electrical energy to microwave radiation. This thermal loading creates expansion and contraction cycles that can lead to material fatigue and eventual failure of critical components.

Electromagnetic stress manifests as both internal and external factors. Internally, the high-frequency oscillations and intense electromagnetic fields can cause electron emission instabilities and cathode degradation. Externally, surrounding equipment or systems may introduce electromagnetic interference that disrupts the magnetron's delicate operating parameters.

Mechanical stress sources include vibration from cooling fans, mounting systems, or external equipment. These vibrations can cause misalignment of critical components, leading to arcing, frequency drift, or catastrophic failure. Additionally, shock events during transportation or installation can create microfractures that develop into failure points during operation.

Atmospheric conditions represent another significant stressor. Humidity, air pressure variations, and contaminants can affect the vacuum integrity of the magnetron tube and accelerate corrosion processes. In industrial settings, exposure to corrosive gases or particulates further compounds these challenges.

The technical objectives of this research are multifaceted. First, we aim to develop comprehensive models that accurately predict the combined effects of multiple environmental stressors on magnetron performance and lifespan. Second, we seek to identify novel materials and structural designs that enhance resilience against identified stressors without compromising performance or increasing manufacturing costs.

Additionally, we intend to explore adaptive control systems that can dynamically adjust operating parameters in response to changing environmental conditions, thereby maintaining optimal performance while minimizing stress-induced degradation. Finally, we aim to establish standardized testing protocols that can reliably evaluate the effectiveness of stress mitigation strategies across different magnetron designs and applications.

By addressing these objectives, we anticipate significant advancements in magnetron technology that will extend operational lifespans, improve reliability in harsh environments, and potentially enable new applications where current magnetron technology is limited by environmental constraints.

Market Demand Analysis for Robust Magnetron Solutions

The global magnetron market is experiencing robust growth, driven primarily by increasing applications in microwave ovens, radar systems, and industrial heating processes. Current market projections indicate the magnetron market will reach approximately $2.3 billion by 2027, with a compound annual growth rate of 5.8% from 2022. This growth trajectory underscores the critical need for magnetrons capable of withstanding harsh environmental conditions during operation.

Consumer electronics represents the largest market segment, with microwave ovens accounting for over 60% of magnetron demand. However, industrial applications are showing the fastest growth rate at 7.2% annually, particularly in semiconductor manufacturing, material processing, and medical equipment. These industrial applications typically subject magnetrons to more severe environmental stresses than consumer applications, creating significant market pull for enhanced durability solutions.

Market research reveals that premature magnetron failure due to environmental stress factors costs end-users an estimated $340 million annually in replacement parts and downtime. Surveys of industrial users indicate that 78% would pay a premium of 15-20% for magnetrons with demonstrably improved environmental stress resistance, particularly against thermal cycling, humidity, and vibration.

The defense and aerospace sectors present particularly stringent requirements, with military radar systems demanding magnetrons that can operate reliably in extreme temperature ranges (-40°C to +85°C), high humidity environments, and under significant mechanical shock and vibration. This segment, though smaller in volume, offers higher profit margins and drives technological advancement in stress-resistant designs.

Regional analysis shows Asia-Pacific dominating magnetron production with 62% market share, while North America leads in high-performance magnetron consumption for specialized applications. European markets show particular interest in environmentally sustainable magnetron solutions with reduced energy consumption and longer operational lifespans.

Key customer pain points identified through market surveys include thermal management challenges (cited by 83% of industrial users), frequency drift under environmental stress (problematic for 76% of precision applications), and shortened operational lifespan in humid environments (affecting 65% of installations in coastal and tropical regions). These pain points represent significant opportunities for manufacturers who can develop robust solutions.

The market increasingly demands magnetrons with comprehensive environmental stress protection as systems are deployed in more diverse and challenging environments. This trend is further accelerated by the growing adoption of magnetron technology in emerging applications such as plasma lighting, medical sterilization equipment, and advanced material processing, where operational reliability under variable environmental conditions is paramount.

Consumer electronics represents the largest market segment, with microwave ovens accounting for over 60% of magnetron demand. However, industrial applications are showing the fastest growth rate at 7.2% annually, particularly in semiconductor manufacturing, material processing, and medical equipment. These industrial applications typically subject magnetrons to more severe environmental stresses than consumer applications, creating significant market pull for enhanced durability solutions.

Market research reveals that premature magnetron failure due to environmental stress factors costs end-users an estimated $340 million annually in replacement parts and downtime. Surveys of industrial users indicate that 78% would pay a premium of 15-20% for magnetrons with demonstrably improved environmental stress resistance, particularly against thermal cycling, humidity, and vibration.

The defense and aerospace sectors present particularly stringent requirements, with military radar systems demanding magnetrons that can operate reliably in extreme temperature ranges (-40°C to +85°C), high humidity environments, and under significant mechanical shock and vibration. This segment, though smaller in volume, offers higher profit margins and drives technological advancement in stress-resistant designs.

Regional analysis shows Asia-Pacific dominating magnetron production with 62% market share, while North America leads in high-performance magnetron consumption for specialized applications. European markets show particular interest in environmentally sustainable magnetron solutions with reduced energy consumption and longer operational lifespans.

Key customer pain points identified through market surveys include thermal management challenges (cited by 83% of industrial users), frequency drift under environmental stress (problematic for 76% of precision applications), and shortened operational lifespan in humid environments (affecting 65% of installations in coastal and tropical regions). These pain points represent significant opportunities for manufacturers who can develop robust solutions.

The market increasingly demands magnetrons with comprehensive environmental stress protection as systems are deployed in more diverse and challenging environments. This trend is further accelerated by the growing adoption of magnetron technology in emerging applications such as plasma lighting, medical sterilization equipment, and advanced material processing, where operational reliability under variable environmental conditions is paramount.

Current Challenges in Magnetron Operational Environment

Magnetrons operate in diverse and often harsh environments that pose significant challenges to their performance, reliability, and longevity. The operational environment of magnetrons encompasses a complex interplay of thermal, electrical, mechanical, and electromagnetic factors that collectively contribute to environmental stress.

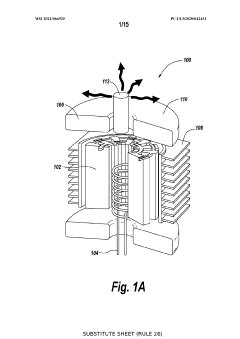

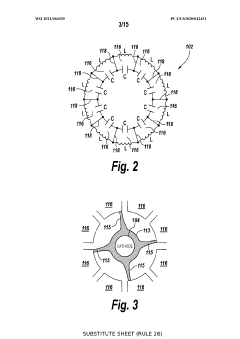

Thermal stress represents one of the most critical challenges, as magnetrons generate substantial heat during operation. The anode block can reach temperatures exceeding 200°C, while the cathode operates at even higher temperatures. This thermal gradient creates expansion and contraction cycles that accelerate material fatigue and can lead to structural deformation over time. Additionally, inadequate cooling systems or cooling failures can result in catastrophic thermal runaway scenarios.

Electromagnetic interference (EMI) presents another significant environmental challenge. Magnetrons produce strong electromagnetic fields that can interfere with nearby electronic components and systems. This interference can manifest as noise in communication systems, disruption of control circuits, or even damage to sensitive electronic equipment. The management of EMI requires careful shielding and grounding strategies that add complexity to system design.

Vacuum integrity maintenance poses a persistent challenge in magnetron operation. The vacuum environment within the magnetron tube is essential for proper electron movement between cathode and anode. Environmental factors such as temperature fluctuations, mechanical vibration, and material outgassing can compromise vacuum integrity over time. Even microscopic leaks can lead to performance degradation and eventually complete failure of the device.

Mechanical vibration and shock represent significant environmental stressors, particularly in mobile or industrial applications. These mechanical forces can misalign critical components, damage delicate structures, or initiate microcracks that propagate over time. The resonant frequencies of various magnetron components can amplify these effects, leading to accelerated wear and potential catastrophic failure.

Power supply variations and electrical transients constitute another environmental challenge. Voltage spikes, frequency fluctuations, and power interruptions can create abnormal operating conditions that stress magnetron components beyond their design parameters. These electrical environmental factors can cause arcing, cathode damage, or control circuit malfunction.

Atmospheric contaminants pose challenges to magnetron cooling systems and external components. Dust, humidity, corrosive gases, and particulates can accumulate on cooling fins, reducing thermal efficiency. In industrial environments, conductive dust can create electrical short circuits or partial discharges that damage insulation materials.

Radiation effects, both from the magnetron itself and from external sources in certain applications, can degrade materials and electronic components over time. This is particularly relevant in aerospace, defense, and certain scientific applications where background radiation levels may be elevated.

Thermal stress represents one of the most critical challenges, as magnetrons generate substantial heat during operation. The anode block can reach temperatures exceeding 200°C, while the cathode operates at even higher temperatures. This thermal gradient creates expansion and contraction cycles that accelerate material fatigue and can lead to structural deformation over time. Additionally, inadequate cooling systems or cooling failures can result in catastrophic thermal runaway scenarios.

Electromagnetic interference (EMI) presents another significant environmental challenge. Magnetrons produce strong electromagnetic fields that can interfere with nearby electronic components and systems. This interference can manifest as noise in communication systems, disruption of control circuits, or even damage to sensitive electronic equipment. The management of EMI requires careful shielding and grounding strategies that add complexity to system design.

Vacuum integrity maintenance poses a persistent challenge in magnetron operation. The vacuum environment within the magnetron tube is essential for proper electron movement between cathode and anode. Environmental factors such as temperature fluctuations, mechanical vibration, and material outgassing can compromise vacuum integrity over time. Even microscopic leaks can lead to performance degradation and eventually complete failure of the device.

Mechanical vibration and shock represent significant environmental stressors, particularly in mobile or industrial applications. These mechanical forces can misalign critical components, damage delicate structures, or initiate microcracks that propagate over time. The resonant frequencies of various magnetron components can amplify these effects, leading to accelerated wear and potential catastrophic failure.

Power supply variations and electrical transients constitute another environmental challenge. Voltage spikes, frequency fluctuations, and power interruptions can create abnormal operating conditions that stress magnetron components beyond their design parameters. These electrical environmental factors can cause arcing, cathode damage, or control circuit malfunction.

Atmospheric contaminants pose challenges to magnetron cooling systems and external components. Dust, humidity, corrosive gases, and particulates can accumulate on cooling fins, reducing thermal efficiency. In industrial environments, conductive dust can create electrical short circuits or partial discharges that damage insulation materials.

Radiation effects, both from the magnetron itself and from external sources in certain applications, can degrade materials and electronic components over time. This is particularly relevant in aerospace, defense, and certain scientific applications where background radiation levels may be elevated.

Existing Stress Alleviation Techniques and Methodologies

01 Thermal stress management in magnetrons

Magnetrons are subject to thermal stress during operation, which can affect their performance and lifespan. Various methods have been developed to manage thermal stress, including improved cooling systems, heat-resistant materials, and thermal insulation techniques. These approaches help to maintain optimal operating temperatures and prevent damage from thermal cycling, ensuring reliable magnetron performance in demanding environments.- Thermal stress management in magnetrons: Magnetrons are subject to thermal stress during operation, which can affect their performance and lifespan. Various cooling systems and thermal management techniques have been developed to mitigate these effects. These include specialized heat sinks, cooling channels, and materials with high thermal conductivity to dissipate heat efficiently. Proper thermal management helps maintain operational stability and extends the service life of magnetron devices in high-power applications.

- Radiation resistance and shielding for magnetrons: Magnetrons operate in environments with significant electromagnetic radiation, which can cause stress to both the device and surrounding components. Effective shielding techniques and radiation-resistant materials are essential for protecting magnetrons from environmental radiation and preventing electromagnetic interference. These solutions include specialized coatings, structural designs that minimize radiation leakage, and materials that can withstand prolonged exposure to electromagnetic fields.

- Vibration and mechanical stress resistance in magnetrons: Magnetrons can be subjected to mechanical stresses including vibration, shock, and pressure variations in their operating environments. Engineering solutions to address these stresses include robust mounting systems, vibration dampening materials, and structural reinforcements. These improvements help maintain the alignment of critical components within the magnetron and prevent performance degradation or failure under mechanical stress conditions.

- Chemical and corrosion resistance for magnetron components: Magnetrons operating in harsh environments may be exposed to corrosive substances or chemical agents that can degrade their components. Protective coatings, corrosion-resistant materials, and sealed designs have been developed to enhance the chemical resistance of magnetrons. These solutions help prevent deterioration of critical components and maintain performance integrity even when exposed to potentially damaging chemical environments.

- Environmental testing and stress simulation for magnetrons: To ensure magnetrons can withstand various environmental stresses, specialized testing methods and stress simulation techniques have been developed. These include accelerated aging tests, environmental chambers that replicate extreme conditions, and computational models that predict stress responses. Such testing protocols help identify potential failure modes and validate design improvements before magnetrons are deployed in real-world applications where they may face multiple environmental stressors simultaneously.

02 Vibration and mechanical stress resistance

Magnetrons used in various applications must withstand mechanical stresses including vibration, shock, and physical impact. Engineering solutions include reinforced mounting structures, vibration dampening systems, and stress-resistant component designs. These improvements help magnetrons maintain operational stability and extend service life when exposed to mechanical environmental stressors in industrial, military, or transportation applications.Expand Specific Solutions03 Humidity and corrosion protection

Environmental moisture and corrosive agents can significantly impact magnetron performance and durability. Protective measures include specialized coatings, hermetic sealing techniques, and corrosion-resistant materials. These solutions prevent oxidation of critical components and electrical degradation, allowing magnetrons to function reliably in humid, marine, or chemically aggressive environments where moisture-related stress would otherwise cause premature failure.Expand Specific Solutions04 Radiation and electromagnetic interference management

Magnetrons generate significant electromagnetic radiation that can cause interference with nearby electronic systems and potentially create environmental stress. Shielding technologies, radiation-absorbing materials, and specialized circuit designs have been developed to contain and manage these emissions. These approaches minimize electromagnetic interference while maintaining operational efficiency, ensuring magnetrons can be safely integrated into sensitive electronic environments.Expand Specific Solutions05 Testing and monitoring systems for environmental stress

Advanced testing methodologies and monitoring systems have been developed to evaluate magnetron performance under various environmental stressors. These include accelerated aging tests, environmental simulation chambers, and real-time monitoring solutions. Such systems help identify potential failure modes, validate design improvements, and ensure magnetrons meet reliability standards when subjected to combined environmental stresses in actual operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The magnetron environmental stress alleviation market is currently in a growth phase, with increasing demand driven by the expanding microwave technology applications across consumer electronics and industrial sectors. The global market size is estimated to exceed $2 billion, growing at 5-7% annually as manufacturers seek longer-lasting, more efficient magnetrons. Leading players include Applied Materials and Tokyo Electron dominating the semiconductor equipment sector, while Panasonic Holdings, LG Electronics, and Midea Group lead consumer applications. NAURA Microelectronics and ULVAC are emerging with innovative stress-reduction technologies. Technical maturity varies significantly, with established companies focusing on thermal management solutions and newer entrants developing advanced materials and coating technologies to address environmental stressors during magnetron operation.

Beijing NAURA Microelectronics Equipment Co., Ltd.

Technical Solution: NAURA has developed a comprehensive magnetron environmental stress management system called "MagShield" specifically designed for high-power density applications. Their approach focuses on thermal management through a combination of active and passive cooling technologies. The system incorporates microfluidic cooling channels directly integrated into the magnetron assembly, providing targeted cooling to critical components. NAURA's solution also features specialized ceramic-metal composite materials at thermal interfaces that maintain structural integrity under thermal cycling while providing excellent thermal conductivity. Their magnetrons employ optimized magnet configurations that distribute plasma more uniformly across the target surface, reducing localized heating. Additionally, NAURA has implemented advanced power control algorithms that dynamically adjust power delivery based on real-time temperature monitoring, preventing thermal runaway conditions.

Strengths: Excellent thermal management in high-power applications, robust design suitable for demanding manufacturing environments, cost-effective implementation. Weaknesses: Less sophisticated in predictive maintenance capabilities compared to competitors, limited flexibility for specialized applications.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced thermal management systems for magnetrons that incorporate liquid cooling channels directly integrated into the magnetron body. Their solution uses a combination of direct water cooling and specialized thermal interface materials to efficiently dissipate heat from critical components. The company has implemented advanced thermal simulation techniques to identify hotspots and optimize cooling channel geometry. Their magnetrons feature specialized coatings on critical components that reduce thermal expansion stress and improve thermal conductivity. Additionally, Applied Materials has developed proprietary magnetic field configurations that distribute plasma more evenly, reducing localized heating and extending magnetron lifespan in high-power sputtering applications.

Strengths: Industry-leading thermal management expertise, comprehensive simulation capabilities, and integrated cooling solutions. Weaknesses: Higher implementation costs compared to standard solutions, and requires specialized maintenance procedures.

Critical Patents and Research on Magnetron Durability

Magnetron

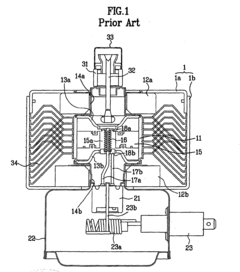

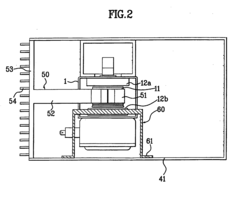

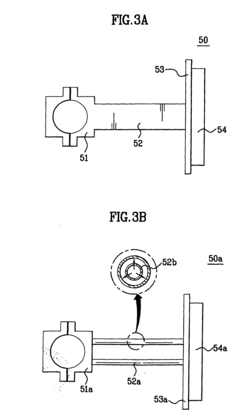

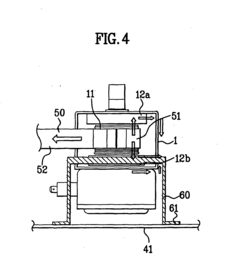

PatentInactiveEP1355340B1

Innovation

- The implementation of a magnetron design that includes a main cooling device for the anode and supplementary cooling devices for the magnets and yoke, utilizing heat conductors and insulating members to enhance heat transfer and prevent heat transfer to sensitive components, such as copper-based heat conductors and heat pipes for efficient heat dissipation.

Microwave magnetron with constant anodic impedance and systems using the same

PatentWO2021066925A1

Innovation

- A microwave magnetron with a controller that maintains constant anodic impedance by adjusting anodic current and magnetic field intensity, ensuring stable electron flow and output power, while monitoring and controlling filament and electromagnet currents to prevent interruptions.

Thermal Management Strategies for Magnetron Longevity

Effective thermal management is critical for ensuring magnetron longevity and reliable operation in various applications. Magnetrons, as high-power microwave generators, experience significant thermal stress during operation that can lead to premature failure if not properly addressed. The primary thermal management strategies focus on heat dissipation, temperature monitoring, and structural design optimization.

Heat sink technologies represent the first line of defense against thermal stress. Advanced copper-based heat sinks with optimized fin designs can increase surface area for heat dissipation while maintaining structural integrity. Recent developments include composite materials that combine copper's thermal conductivity with aluminum's lightweight properties, offering up to 30% improvement in heat transfer efficiency compared to traditional solutions.

Active cooling systems provide dynamic thermal management capabilities essential for high-power applications. Liquid cooling circuits using deionized water or specialized coolants can remove heat more efficiently than air-based systems, with some modern designs achieving heat removal rates of 500-1000 W/cm². Closed-loop systems with temperature-controlled flow rates offer adaptive cooling that responds to varying operational demands.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between the magnetron and cooling systems. Next-generation graphene-enhanced thermal pads and metal-based liquid compounds demonstrate thermal conductivities exceeding 20 W/m·K, significantly reducing thermal bottlenecks at critical junctions.

Structural design considerations also contribute substantially to thermal management. Optimized cathode and anode geometries that promote uniform heat distribution can prevent localized hotspots that accelerate component degradation. Computational fluid dynamics (CFD) modeling has enabled the development of internal cooling channels that reduce thermal gradients by up to 40% in high-stress regions.

Temperature monitoring and feedback systems represent the intelligence layer of thermal management strategies. Distributed temperature sensors with sub-millisecond response times allow for real-time thermal mapping and predictive intervention before critical thresholds are reached. Integration with operational control systems enables dynamic power adjustment to maintain optimal thermal conditions throughout the magnetron's operational cycle.

Emerging technologies such as phase-change materials and microfluidic cooling channels show promise for next-generation magnetrons. These innovations can absorb thermal energy during peak operation and release it during idle periods, effectively smoothing thermal cycles that contribute to mechanical stress and eventual failure.

Heat sink technologies represent the first line of defense against thermal stress. Advanced copper-based heat sinks with optimized fin designs can increase surface area for heat dissipation while maintaining structural integrity. Recent developments include composite materials that combine copper's thermal conductivity with aluminum's lightweight properties, offering up to 30% improvement in heat transfer efficiency compared to traditional solutions.

Active cooling systems provide dynamic thermal management capabilities essential for high-power applications. Liquid cooling circuits using deionized water or specialized coolants can remove heat more efficiently than air-based systems, with some modern designs achieving heat removal rates of 500-1000 W/cm². Closed-loop systems with temperature-controlled flow rates offer adaptive cooling that responds to varying operational demands.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between the magnetron and cooling systems. Next-generation graphene-enhanced thermal pads and metal-based liquid compounds demonstrate thermal conductivities exceeding 20 W/m·K, significantly reducing thermal bottlenecks at critical junctions.

Structural design considerations also contribute substantially to thermal management. Optimized cathode and anode geometries that promote uniform heat distribution can prevent localized hotspots that accelerate component degradation. Computational fluid dynamics (CFD) modeling has enabled the development of internal cooling channels that reduce thermal gradients by up to 40% in high-stress regions.

Temperature monitoring and feedback systems represent the intelligence layer of thermal management strategies. Distributed temperature sensors with sub-millisecond response times allow for real-time thermal mapping and predictive intervention before critical thresholds are reached. Integration with operational control systems enables dynamic power adjustment to maintain optimal thermal conditions throughout the magnetron's operational cycle.

Emerging technologies such as phase-change materials and microfluidic cooling channels show promise for next-generation magnetrons. These innovations can absorb thermal energy during peak operation and release it during idle periods, effectively smoothing thermal cycles that contribute to mechanical stress and eventual failure.

Regulatory Standards for Magnetron Safety and Reliability

Regulatory standards for magnetron safety and reliability have evolved significantly over the past decades, establishing comprehensive frameworks to ensure both operational safety and environmental protection. These standards are primarily governed by international bodies such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and regional authorities including the European Union's CE marking requirements and the U.S. Federal Communications Commission (FCC).

The IEC 60335 series specifically addresses safety requirements for household microwave ovens, with detailed provisions for magnetron operation under various environmental conditions. These standards mandate specific testing protocols for thermal cycling, humidity resistance, and vibration tolerance—all critical factors in environmental stress mitigation for magnetrons during operation.

Environmental stress testing requirements have become increasingly stringent, with standards now specifying operational parameters across temperature ranges from -20°C to +85°C for industrial applications, and humidity levels up to 95% non-condensing. These parameters ensure magnetrons can withstand the environmental variations encountered in diverse deployment scenarios without performance degradation or safety risks.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, establish limits for electromagnetic emissions and immunity requirements. These are particularly relevant for magnetron operation, as they must function reliably without causing interference to other electronic equipment while simultaneously withstanding external electromagnetic influences.

Military and aerospace applications follow even more rigorous standards, such as MIL-STD-810, which outlines environmental engineering considerations and laboratory tests for extreme conditions. These standards address specific environmental stressors including altitude, shock, salt fog, and sand/dust exposure—all potential factors affecting magnetron reliability in specialized applications.

Radiation safety standards, governed by bodies like the International Commission on Non-Ionizing Radiation Protection (ICNIRP), establish exposure limits for microwave radiation. Manufacturers must demonstrate compliance through leakage testing and safety interlocks, ensuring magnetrons operate within safe radiation emission parameters even under environmental stress conditions.

Recent regulatory developments have increasingly focused on energy efficiency and environmental sustainability. The EU's Ecodesign Directive and similar regulations worldwide now impose minimum efficiency requirements and standby power limitations, indirectly influencing magnetron design to optimize performance while minimizing environmental impact throughout the product lifecycle.

The IEC 60335 series specifically addresses safety requirements for household microwave ovens, with detailed provisions for magnetron operation under various environmental conditions. These standards mandate specific testing protocols for thermal cycling, humidity resistance, and vibration tolerance—all critical factors in environmental stress mitigation for magnetrons during operation.

Environmental stress testing requirements have become increasingly stringent, with standards now specifying operational parameters across temperature ranges from -20°C to +85°C for industrial applications, and humidity levels up to 95% non-condensing. These parameters ensure magnetrons can withstand the environmental variations encountered in diverse deployment scenarios without performance degradation or safety risks.

Electromagnetic compatibility (EMC) standards, including IEC 61000 series, establish limits for electromagnetic emissions and immunity requirements. These are particularly relevant for magnetron operation, as they must function reliably without causing interference to other electronic equipment while simultaneously withstanding external electromagnetic influences.

Military and aerospace applications follow even more rigorous standards, such as MIL-STD-810, which outlines environmental engineering considerations and laboratory tests for extreme conditions. These standards address specific environmental stressors including altitude, shock, salt fog, and sand/dust exposure—all potential factors affecting magnetron reliability in specialized applications.

Radiation safety standards, governed by bodies like the International Commission on Non-Ionizing Radiation Protection (ICNIRP), establish exposure limits for microwave radiation. Manufacturers must demonstrate compliance through leakage testing and safety interlocks, ensuring magnetrons operate within safe radiation emission parameters even under environmental stress conditions.

Recent regulatory developments have increasingly focused on energy efficiency and environmental sustainability. The EU's Ecodesign Directive and similar regulations worldwide now impose minimum efficiency requirements and standby power limitations, indirectly influencing magnetron design to optimize performance while minimizing environmental impact throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!