How to Monitor Magnetron Vibration Sensitivity in Systems

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Vibration Monitoring Background and Objectives

Magnetron technology has evolved significantly since its invention during World War II, transitioning from purely military applications to becoming an essential component in various commercial and industrial systems. Initially developed for radar systems, magnetrons now serve as critical components in microwave ovens, industrial heating applications, medical equipment, and advanced radar systems. The evolution of magnetron technology has been characterized by continuous improvements in power efficiency, frequency stability, and operational reliability.

The sensitivity of magnetrons to vibration represents a significant challenge in maintaining system performance and reliability. Vibrations can cause frequency shifts, power fluctuations, and reduced operational lifespan of magnetron devices. These effects are particularly problematic in mobile applications, industrial environments, and precision systems where stability is paramount. Recent industry data indicates that vibration-induced failures account for approximately 15-20% of magnetron replacements in industrial settings.

The primary objective of magnetron vibration monitoring is to develop comprehensive methodologies and technologies that can accurately detect, measure, and analyze vibration effects on magnetron performance in real-time. This includes establishing correlations between specific vibration patterns and their impact on frequency stability, output power, and overall system reliability. By understanding these relationships, engineers can implement preventive measures and design improvements to mitigate vibration-related issues.

Current technological trends in this field are moving toward integrated monitoring systems that combine advanced sensors, real-time data processing, and predictive analytics. The integration of IoT capabilities and machine learning algorithms represents a promising direction for enhancing vibration monitoring capabilities, enabling predictive maintenance and adaptive control strategies.

The global market for precision electronic components, including magnetrons, is projected to reach $35.4 billion by 2026, with reliability and performance stability being key differentiators in competitive positioning. Industries such as aerospace, defense, medical equipment, and industrial manufacturing are particularly invested in advancing vibration monitoring technologies to ensure system integrity and operational continuity.

From a technical perspective, the evolution path for magnetron vibration monitoring is expected to focus on miniaturization of sensing technologies, increased measurement precision, and the development of non-invasive monitoring methods that do not interfere with system operation. The convergence of vibration monitoring with broader system diagnostics represents an important trend toward holistic performance management in complex electronic systems.

The sensitivity of magnetrons to vibration represents a significant challenge in maintaining system performance and reliability. Vibrations can cause frequency shifts, power fluctuations, and reduced operational lifespan of magnetron devices. These effects are particularly problematic in mobile applications, industrial environments, and precision systems where stability is paramount. Recent industry data indicates that vibration-induced failures account for approximately 15-20% of magnetron replacements in industrial settings.

The primary objective of magnetron vibration monitoring is to develop comprehensive methodologies and technologies that can accurately detect, measure, and analyze vibration effects on magnetron performance in real-time. This includes establishing correlations between specific vibration patterns and their impact on frequency stability, output power, and overall system reliability. By understanding these relationships, engineers can implement preventive measures and design improvements to mitigate vibration-related issues.

Current technological trends in this field are moving toward integrated monitoring systems that combine advanced sensors, real-time data processing, and predictive analytics. The integration of IoT capabilities and machine learning algorithms represents a promising direction for enhancing vibration monitoring capabilities, enabling predictive maintenance and adaptive control strategies.

The global market for precision electronic components, including magnetrons, is projected to reach $35.4 billion by 2026, with reliability and performance stability being key differentiators in competitive positioning. Industries such as aerospace, defense, medical equipment, and industrial manufacturing are particularly invested in advancing vibration monitoring technologies to ensure system integrity and operational continuity.

From a technical perspective, the evolution path for magnetron vibration monitoring is expected to focus on miniaturization of sensing technologies, increased measurement precision, and the development of non-invasive monitoring methods that do not interfere with system operation. The convergence of vibration monitoring with broader system diagnostics represents an important trend toward holistic performance management in complex electronic systems.

Market Demand Analysis for Vibration-Resistant Magnetron Systems

The global market for vibration-resistant magnetron systems has been experiencing significant growth, driven primarily by the expanding applications in radar systems, satellite communications, medical equipment, and industrial heating processes. The demand for magnetrons with enhanced vibration sensitivity monitoring capabilities has increased substantially as these devices are increasingly deployed in harsh operational environments where mechanical stability is critical.

In the defense sector, radar systems utilizing magnetrons must maintain precise frequency stability despite exposure to severe vibration conditions during deployment on aircraft, ships, and ground vehicles. Market research indicates that military and aerospace applications account for approximately 40% of the current demand for vibration-resistant magnetron systems, with annual growth rates exceeding the industry average.

The telecommunications industry represents another major market segment, particularly with the ongoing expansion of satellite communication networks. As more countries invest in space-based communication infrastructure, the need for magnetrons that can withstand launch vibrations and maintain performance in orbit has created a specialized high-value market niche.

Medical equipment manufacturers have also emerged as significant consumers of vibration-resistant magnetron technology. Modern medical imaging and therapy systems, particularly those used in mobile or portable applications, require magnetrons that maintain consistent performance despite transportation and handling. This sector has shown consistent demand growth over the past five years, with particular emphasis on compact systems for field deployment.

Industrial applications, including food processing, material drying, and chemical processing, constitute a growing market segment. These applications often involve environments with inherent vibration challenges from nearby machinery, creating demand for magnetrons with integrated vibration monitoring and compensation capabilities.

Market analysis reveals a clear price premium for magnetron systems with advanced vibration sensitivity monitoring features, with customers willing to pay 15-25% more for systems that offer real-time vibration analysis and performance adjustment capabilities. This premium pricing has attracted new entrants to the market, intensifying competition among established manufacturers.

Regional market distribution shows North America and Europe leading in terms of technology adoption, while Asia-Pacific represents the fastest-growing market due to expanding manufacturing capabilities and increasing defense spending in countries like China, India, and South Korea.

Future market projections indicate continued growth, with particular emphasis on miniaturized systems for portable applications and integrated solutions that combine vibration monitoring with automated performance adjustment mechanisms. The market is expected to benefit from technological convergence with IoT and AI capabilities, enabling predictive maintenance and remote monitoring features that add significant value for end users.

In the defense sector, radar systems utilizing magnetrons must maintain precise frequency stability despite exposure to severe vibration conditions during deployment on aircraft, ships, and ground vehicles. Market research indicates that military and aerospace applications account for approximately 40% of the current demand for vibration-resistant magnetron systems, with annual growth rates exceeding the industry average.

The telecommunications industry represents another major market segment, particularly with the ongoing expansion of satellite communication networks. As more countries invest in space-based communication infrastructure, the need for magnetrons that can withstand launch vibrations and maintain performance in orbit has created a specialized high-value market niche.

Medical equipment manufacturers have also emerged as significant consumers of vibration-resistant magnetron technology. Modern medical imaging and therapy systems, particularly those used in mobile or portable applications, require magnetrons that maintain consistent performance despite transportation and handling. This sector has shown consistent demand growth over the past five years, with particular emphasis on compact systems for field deployment.

Industrial applications, including food processing, material drying, and chemical processing, constitute a growing market segment. These applications often involve environments with inherent vibration challenges from nearby machinery, creating demand for magnetrons with integrated vibration monitoring and compensation capabilities.

Market analysis reveals a clear price premium for magnetron systems with advanced vibration sensitivity monitoring features, with customers willing to pay 15-25% more for systems that offer real-time vibration analysis and performance adjustment capabilities. This premium pricing has attracted new entrants to the market, intensifying competition among established manufacturers.

Regional market distribution shows North America and Europe leading in terms of technology adoption, while Asia-Pacific represents the fastest-growing market due to expanding manufacturing capabilities and increasing defense spending in countries like China, India, and South Korea.

Future market projections indicate continued growth, with particular emphasis on miniaturized systems for portable applications and integrated solutions that combine vibration monitoring with automated performance adjustment mechanisms. The market is expected to benefit from technological convergence with IoT and AI capabilities, enabling predictive maintenance and remote monitoring features that add significant value for end users.

Current Challenges in Magnetron Vibration Sensitivity Detection

Despite significant advancements in magnetron technology, the detection and monitoring of vibration sensitivity in these devices present several persistent challenges. Current detection methodologies often struggle with the complex electromagnetic environment in which magnetrons operate, creating substantial signal-to-noise ratio problems. The high-power RF emissions from magnetrons themselves interfere with conventional vibration sensors, making accurate measurements difficult to obtain without sophisticated filtering techniques.

Traditional accelerometers and vibration sensors require direct physical attachment to the magnetron, which can alter the very vibration characteristics they aim to measure. This observer effect introduces measurement uncertainties that are difficult to quantify and compensate for, particularly in precision applications such as medical linear accelerators or advanced radar systems where even minor vibration anomalies can significantly impact performance.

Real-time monitoring presents another significant challenge, as current systems often exhibit substantial latency between vibration events and their detection. This delay limits the effectiveness of preventive maintenance protocols and reduces the ability to implement adaptive control systems that could compensate for vibration-induced performance variations. The trade-off between sampling frequency and data processing capabilities remains a bottleneck in achieving truly responsive monitoring systems.

Temperature variations in operational environments further complicate vibration sensitivity detection. Thermal expansion and contraction of magnetron components can mimic vibration signatures or mask actual vibration events, leading to false positives or missed detection of critical vibration patterns. Current thermal compensation algorithms lack the sophistication needed to fully distinguish between thermal effects and mechanical vibrations.

Miniaturization of detection systems represents another frontier challenge. As magnetrons are integrated into increasingly compact systems, the corresponding vibration monitoring equipment must similarly decrease in size without sacrificing sensitivity or accuracy. Current miniaturized sensors often exhibit reduced performance compared to their larger counterparts, creating a technological gap in applications where space constraints are significant.

Cost-effectiveness remains a persistent obstacle, particularly for widespread implementation in commercial applications. High-precision vibration monitoring systems typically require expensive components and complex calibration procedures, limiting their adoption in cost-sensitive markets. The absence of standardized testing protocols further complicates comparative evaluation of different detection methodologies, hindering the establishment of industry benchmarks for vibration sensitivity monitoring.

Traditional accelerometers and vibration sensors require direct physical attachment to the magnetron, which can alter the very vibration characteristics they aim to measure. This observer effect introduces measurement uncertainties that are difficult to quantify and compensate for, particularly in precision applications such as medical linear accelerators or advanced radar systems where even minor vibration anomalies can significantly impact performance.

Real-time monitoring presents another significant challenge, as current systems often exhibit substantial latency between vibration events and their detection. This delay limits the effectiveness of preventive maintenance protocols and reduces the ability to implement adaptive control systems that could compensate for vibration-induced performance variations. The trade-off between sampling frequency and data processing capabilities remains a bottleneck in achieving truly responsive monitoring systems.

Temperature variations in operational environments further complicate vibration sensitivity detection. Thermal expansion and contraction of magnetron components can mimic vibration signatures or mask actual vibration events, leading to false positives or missed detection of critical vibration patterns. Current thermal compensation algorithms lack the sophistication needed to fully distinguish between thermal effects and mechanical vibrations.

Miniaturization of detection systems represents another frontier challenge. As magnetrons are integrated into increasingly compact systems, the corresponding vibration monitoring equipment must similarly decrease in size without sacrificing sensitivity or accuracy. Current miniaturized sensors often exhibit reduced performance compared to their larger counterparts, creating a technological gap in applications where space constraints are significant.

Cost-effectiveness remains a persistent obstacle, particularly for widespread implementation in commercial applications. High-precision vibration monitoring systems typically require expensive components and complex calibration procedures, limiting their adoption in cost-sensitive markets. The absence of standardized testing protocols further complicates comparative evaluation of different detection methodologies, hindering the establishment of industry benchmarks for vibration sensitivity monitoring.

Existing Magnetron Vibration Sensitivity Measurement Solutions

01 Magnetron vibration reduction mechanisms

Various mechanisms have been developed to reduce vibration sensitivity in magnetrons. These include specialized mounting structures, damping systems, and isolation techniques that minimize the transmission of external vibrations to the magnetron components. Such mechanisms help maintain stable operation and prevent frequency shifts or performance degradation caused by environmental vibrations, which is particularly important in high-precision applications.- Magnetron mounting structures to reduce vibration sensitivity: Various mounting structures are designed to isolate magnetrons from external vibrations. These include shock-absorbing mounts, vibration dampening systems, and specialized brackets that minimize the transmission of mechanical vibrations to the magnetron. Such mounting structures help maintain stable operation of the magnetron in environments prone to vibration, ensuring consistent performance and extending the device's operational life.

- Vibration detection and monitoring systems for magnetrons: Systems designed to detect and monitor vibrations in magnetrons allow for real-time assessment of operational conditions. These systems typically include sensors that measure vibration amplitude and frequency, coupled with analysis software to interpret the data. By monitoring vibration patterns, operators can identify potential issues before they lead to performance degradation or component failure, enabling preventive maintenance and ensuring optimal magnetron operation.

- Structural improvements to reduce magnetron vibration: Innovative structural designs aim to inherently reduce a magnetron's sensitivity to vibration. These include modifications to the cathode support structure, reinforced anode blocks, and improved internal component arrangements that minimize resonance effects. By enhancing the structural integrity of key components, these improvements help maintain frequency stability and output power consistency even when the magnetron is subjected to external mechanical disturbances.

- Vibration compensation techniques in magnetron sputtering systems: In magnetron sputtering applications, vibration can significantly impact deposition quality. Compensation techniques include active vibration cancellation systems, adaptive power control algorithms that respond to detected vibrations, and specialized chamber designs that isolate the process from environmental vibrations. These approaches help maintain uniform film deposition and consistent sputtering rates despite vibration challenges in industrial environments.

- Electronic stabilization methods for vibration-affected magnetrons: Electronic approaches to mitigate vibration effects include frequency stabilization circuits, phase-locked loops that maintain consistent output despite mechanical disturbances, and adaptive power control systems. These electronic solutions can detect changes in magnetron performance caused by vibration and make real-time adjustments to maintain stable operation. Such methods are particularly valuable in applications requiring precise frequency control and consistent power output under variable environmental conditions.

02 Vibration monitoring and detection systems for magnetrons

Advanced monitoring systems have been developed to detect and measure vibrations affecting magnetron performance. These systems employ sensors and analytical tools to identify vibration patterns, allowing for real-time adjustments or preventive maintenance. By continuously monitoring vibration levels, these systems help maintain optimal magnetron operation and prevent damage from excessive vibration exposure.Expand Specific Solutions03 Magnetron design optimization for vibration resistance

Specialized design approaches focus on making magnetrons inherently less sensitive to vibrations. These include structural reinforcements, optimized component geometries, and material selections that enhance vibration resistance. Such design optimizations improve the robustness of magnetrons in vibration-prone environments without requiring additional external damping systems.Expand Specific Solutions04 Vibration impact on magnetron sputtering processes

Research has examined how vibrations affect magnetron sputtering processes used in thin film deposition. Vibrations can influence film uniformity, deposition rates, and overall quality of coatings. Understanding these effects has led to improved process controls and equipment designs that maintain consistent sputtering performance even when environmental vibrations are present.Expand Specific Solutions05 Testing methodologies for magnetron vibration sensitivity

Specialized testing protocols have been developed to evaluate magnetron vibration sensitivity under controlled conditions. These methodologies include vibration simulation equipment, measurement techniques, and performance analysis tools that quantify how different vibration frequencies and amplitudes affect magnetron operation. Such testing enables manufacturers to certify vibration tolerance specifications and users to select appropriate magnetrons for specific operating environments.Expand Specific Solutions

Leading Companies in Magnetron Vibration Sensing Technology

Magnetron vibration sensitivity monitoring technology is currently in a growth phase, with increasing adoption across aerospace, defense, and industrial sectors. The market size is expanding due to rising demand for precision equipment monitoring, estimated at approximately $2-3 billion globally. From a technological maturity perspective, the field shows varied development levels among key players. Toshiba, IBM, and Lockheed Martin lead with advanced vibration analysis systems, while SKF Magnetic Mechatronics and SpinDrive offer specialized magnetic bearing solutions. Siemens and Bosch are developing integrated monitoring platforms, and emerging players like VIE Technologies and MultiDimension Technology are introducing innovative sensor technologies. The competitive landscape reflects a mix of established industrial giants and specialized technology providers focusing on different aspects of magnetron vibration monitoring.

Toshiba Corp.

Technical Solution: Toshiba has developed an advanced magnetron vibration monitoring system that combines fiber optic sensing technology with sophisticated digital signal processing. Their solution employs distributed acoustic sensing (DAS) technology that converts standard optical fibers into highly sensitive vibration sensors capable of detecting minute changes in magnetron operational characteristics. The system features a non-intrusive installation approach where sensing fibers can be retrofitted to existing magnetron installations without requiring significant modifications or downtime. Toshiba's proprietary algorithms perform real-time frequency analysis to identify specific vibration signatures associated with different magnetron failure modes, including cathode degradation, vacuum integrity issues, and structural fatigue. The monitoring platform incorporates adaptive baseline comparison that accounts for normal variations in operating conditions while still detecting subtle changes that may indicate developing problems. Their system includes a comprehensive data visualization interface that presents vibration data in intuitive formats, allowing technicians to quickly identify trends and anomalies without specialized training in vibration analysis.

Strengths: Non-intrusive fiber optic sensing eliminates electromagnetic interference concerns, scalable architecture suitable for both single units and large installations, and excellent sensitivity even in electromagnetically noisy environments. Weaknesses: Higher initial implementation cost, requires specialized expertise for system calibration, and limited historical performance data compared to more established technologies.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has engineered a specialized magnetron vibration sensitivity monitoring system primarily for defense and aerospace applications. Their solution employs high-precision piezoelectric sensors with exceptional sensitivity to detect micro-vibrations in magnetron assemblies operating in extreme environments. The system features a distributed sensor network that monitors not only the magnetron itself but also surrounding components to create a comprehensive vibration profile. Lockheed's proprietary signal processing algorithms can distinguish between normal operational vibrations and anomalous patterns that might indicate potential failures or performance issues. The monitoring system incorporates military-grade encryption and secure data transmission protocols to protect sensitive operational data. A key innovation is their adaptive threshold technology that automatically adjusts sensitivity parameters based on operational conditions, allowing for reliable monitoring across varying mission profiles and environmental conditions. The system integrates with Lockheed's broader condition-based maintenance framework to enable predictive maintenance scheduling.

Strengths: Exceptional sensitivity for early detection of potential failures, ruggedized design for extreme environments, and military-grade security features. Weaknesses: Significantly higher cost than commercial alternatives, requires specialized training for operation, and limited compatibility with non-defense systems.

Key Patents and Research in Magnetron Vibration Analysis

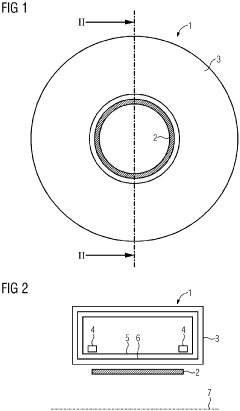

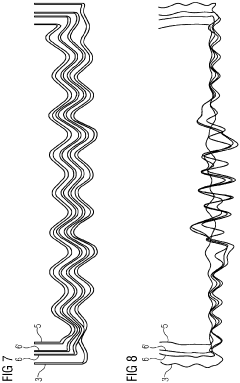

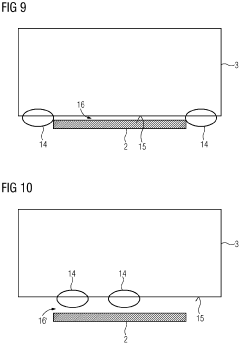

Monitoring an mr magnet based on vibrations

PatentActiveEP3650879A1

Innovation

- A method involving vibration amplitude measurement of the outer and intermediate housings, using a transmission ratio to indirectly determine operating parameters such as energy input into the magnet device, allowing for real-time monitoring and potential system shutdown before critical conditions are reached.

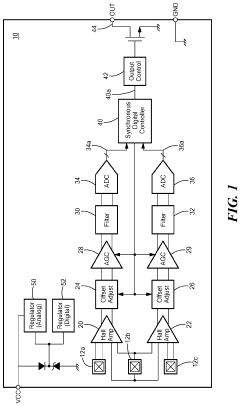

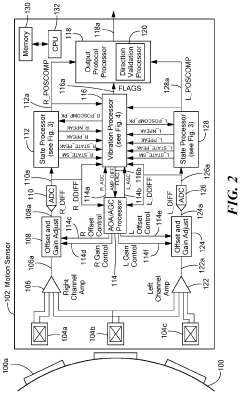

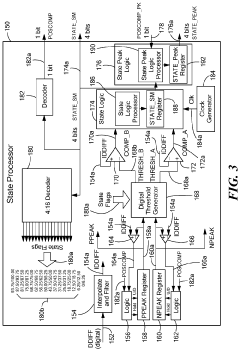

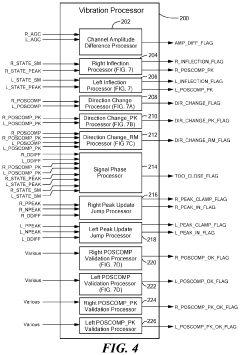

System and method for vibration detection with no loss of position information using a magnetic field sensor

PatentActiveUS20200355522A1

Innovation

- A method for a magnetic field sensor that generates detector output signals with state transitions, determines a vibration flag, enters a vibration mode to hold peak values, and returns to a running mode after a predetermined number of state transitions without further vibration flags, allowing for direction information provision during vibrations.

Reliability Standards for Magnetron-Based Equipment

Reliability standards for magnetron-based equipment must address vibration sensitivity as a critical factor affecting system performance and longevity. Industry standards such as MIL-STD-810 and IEC 60068 provide comprehensive frameworks for vibration testing, with specific provisions applicable to magnetron systems. These standards typically require equipment to maintain operational stability under various vibration conditions, including sinusoidal, random, and shock vibrations across multiple frequency ranges.

For magnetron-based systems, reliability standards commonly mandate vibration tolerance thresholds between 5-2000 Hz, with acceleration levels ranging from 0.5g to 10g depending on the application environment. Medical equipment standards (IEC 60601) impose stricter vibration sensitivity requirements compared to industrial applications, reflecting the critical nature of medical diagnostics and treatment systems.

The IEEE Standard 1613 provides specific guidelines for electronic measurement equipment in high-vibration environments, with particular relevance to magnetron monitoring systems. These standards typically require continuous operation without performance degradation during and after exposure to specified vibration profiles.

Compliance verification protocols generally involve three-axis vibration testing using electrodynamic shakers or mechanical vibration tables. Test procedures must document frequency response, resonance points, and performance metrics before, during, and after vibration exposure. For magnetron systems, frequency drift, power output stability, and waveform distortion are key parameters monitored during these tests.

Reliability standards also address long-term vibration effects through accelerated life testing protocols. These tests simulate years of operational vibration in compressed timeframes, allowing manufacturers to predict mean time between failures (MTBF) and establish appropriate maintenance schedules. For critical applications, standards may require redundant vibration monitoring systems with automated shutdown capabilities when vibration exceeds predetermined thresholds.

Recent updates to international standards have incorporated specific provisions for advanced magnetron technologies, including solid-state variants and hybrid systems. These updated standards recognize the unique vibration sensitivity profiles of modern magnetron designs and provide more nuanced testing methodologies. Additionally, emerging standards are beginning to address the integration of real-time vibration monitoring as a mandatory reliability feature rather than an optional diagnostic tool.

For magnetron-based systems, reliability standards commonly mandate vibration tolerance thresholds between 5-2000 Hz, with acceleration levels ranging from 0.5g to 10g depending on the application environment. Medical equipment standards (IEC 60601) impose stricter vibration sensitivity requirements compared to industrial applications, reflecting the critical nature of medical diagnostics and treatment systems.

The IEEE Standard 1613 provides specific guidelines for electronic measurement equipment in high-vibration environments, with particular relevance to magnetron monitoring systems. These standards typically require continuous operation without performance degradation during and after exposure to specified vibration profiles.

Compliance verification protocols generally involve three-axis vibration testing using electrodynamic shakers or mechanical vibration tables. Test procedures must document frequency response, resonance points, and performance metrics before, during, and after vibration exposure. For magnetron systems, frequency drift, power output stability, and waveform distortion are key parameters monitored during these tests.

Reliability standards also address long-term vibration effects through accelerated life testing protocols. These tests simulate years of operational vibration in compressed timeframes, allowing manufacturers to predict mean time between failures (MTBF) and establish appropriate maintenance schedules. For critical applications, standards may require redundant vibration monitoring systems with automated shutdown capabilities when vibration exceeds predetermined thresholds.

Recent updates to international standards have incorporated specific provisions for advanced magnetron technologies, including solid-state variants and hybrid systems. These updated standards recognize the unique vibration sensitivity profiles of modern magnetron designs and provide more nuanced testing methodologies. Additionally, emerging standards are beginning to address the integration of real-time vibration monitoring as a mandatory reliability feature rather than an optional diagnostic tool.

Environmental Factors Affecting Magnetron Vibration Performance

Environmental factors play a crucial role in determining magnetron vibration sensitivity and overall performance in various systems. Temperature variations represent one of the most significant environmental influences, as they can cause thermal expansion or contraction of magnetron components, altering resonant frequencies and operational characteristics. In extreme temperature conditions, both excessive heat and cold can lead to material stress, potentially causing permanent deformation or misalignment of critical magnetron elements.

Humidity levels similarly impact magnetron vibration performance through multiple mechanisms. High humidity environments may introduce moisture into the system, affecting electrical properties and potentially causing corrosion at connection points. This corrosion can alter the mechanical coupling between components, changing vibration transmission characteristics and introducing unpredictable resonance behaviors.

Atmospheric pressure fluctuations, though often overlooked, significantly influence magnetron operation, particularly in aerospace or high-altitude applications. Pressure changes affect cooling efficiency and can modify the electrical breakdown characteristics within the magnetron cavity, indirectly influencing vibration sensitivity through thermal management pathways.

Electromagnetic interference (EMI) from surrounding equipment or environmental sources constitutes another critical factor. External electromagnetic fields can interact with the magnetron's own magnetic field, potentially inducing unwanted vibrations or altering the electron path within the device. This interference may manifest as performance instability that correlates with specific environmental electromagnetic conditions.

Mechanical shock and continuous vibration from the operating environment represent direct challenges to magnetron stability. These external forces can cause immediate performance degradation or contribute to cumulative fatigue damage over time. The frequency spectrum of environmental vibrations is particularly important, as resonance effects occur when external vibration frequencies align with the natural frequencies of magnetron components.

Dust and particulate contamination can physically interfere with moving parts or cooling systems, leading to localized heating and thermal expansion that alters vibration characteristics. In severe cases, particulate buildup may cause mechanical obstruction or electrical arcing, creating additional vibration sources within the system.

Radiation exposure in specialized environments can degrade material properties over time, particularly affecting semiconductor components and insulating materials. This degradation may progressively alter the mechanical properties of magnetron components, changing their vibration response characteristics and potentially shortening operational lifespan.

Humidity levels similarly impact magnetron vibration performance through multiple mechanisms. High humidity environments may introduce moisture into the system, affecting electrical properties and potentially causing corrosion at connection points. This corrosion can alter the mechanical coupling between components, changing vibration transmission characteristics and introducing unpredictable resonance behaviors.

Atmospheric pressure fluctuations, though often overlooked, significantly influence magnetron operation, particularly in aerospace or high-altitude applications. Pressure changes affect cooling efficiency and can modify the electrical breakdown characteristics within the magnetron cavity, indirectly influencing vibration sensitivity through thermal management pathways.

Electromagnetic interference (EMI) from surrounding equipment or environmental sources constitutes another critical factor. External electromagnetic fields can interact with the magnetron's own magnetic field, potentially inducing unwanted vibrations or altering the electron path within the device. This interference may manifest as performance instability that correlates with specific environmental electromagnetic conditions.

Mechanical shock and continuous vibration from the operating environment represent direct challenges to magnetron stability. These external forces can cause immediate performance degradation or contribute to cumulative fatigue damage over time. The frequency spectrum of environmental vibrations is particularly important, as resonance effects occur when external vibration frequencies align with the natural frequencies of magnetron components.

Dust and particulate contamination can physically interfere with moving parts or cooling systems, leading to localized heating and thermal expansion that alters vibration characteristics. In severe cases, particulate buildup may cause mechanical obstruction or electrical arcing, creating additional vibration sources within the system.

Radiation exposure in specialized environments can degrade material properties over time, particularly affecting semiconductor components and insulating materials. This degradation may progressively alter the mechanical properties of magnetron components, changing their vibration response characteristics and potentially shortening operational lifespan.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!