How to Manage Magnetron Magnetic Bias Current Instability

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Bias Current Technology Background and Objectives

Magnetron technology has evolved significantly since its inception in the early 20th century, with its applications expanding from military radar systems to widespread commercial use in microwave ovens and industrial heating processes. The magnetron's fundamental operating principle relies on the interaction between electrons and a magnetic field within a vacuum tube to generate microwave radiation. A critical component of this system is the magnetic bias current, which directly influences the stability and efficiency of the magnetron's operation.

The historical development of magnetron bias current control systems reveals a progression from rudimentary manual adjustments to sophisticated electronic control mechanisms. Early magnetrons suffered from significant operational instabilities, particularly in maintaining consistent bias current levels, which resulted in fluctuating output power and reduced operational lifespan. These challenges prompted extensive research into stabilization techniques throughout the 1970s and 1980s.

Recent technological advancements have introduced digital control systems and feedback mechanisms that continuously monitor and adjust bias currents in real-time. However, despite these improvements, current instability remains a persistent challenge, particularly in high-power applications where even minor fluctuations can significantly impact performance and reliability.

The primary objective of current research in this field is to develop robust solutions for managing magnetron magnetic bias current instability across various operational conditions. This includes addressing fluctuations caused by temperature variations, input voltage changes, and aging effects of magnetron components. Achieving this stability is crucial for enhancing the precision, efficiency, and longevity of magnetron-based systems.

Industry trends indicate a growing demand for magnetrons with higher power outputs and greater operational stability, particularly in emerging applications such as plasma processing, material synthesis, and medical treatments. This demand is driving innovation toward more sophisticated control algorithms and hardware solutions.

The evolution of magnetron technology is increasingly focused on integrating advanced materials science with electronic control systems. Research into superconducting materials and novel magnetic configurations shows promise for fundamentally improving bias current stability. Additionally, the incorporation of artificial intelligence and machine learning techniques for predictive maintenance and adaptive control represents a significant frontier in addressing instability issues.

As we look toward future developments, the convergence of traditional magnetron technology with digital control systems and advanced materials science presents opportunities for breakthrough solutions to the long-standing challenge of bias current instability, potentially enabling new applications and improved performance in existing systems.

The historical development of magnetron bias current control systems reveals a progression from rudimentary manual adjustments to sophisticated electronic control mechanisms. Early magnetrons suffered from significant operational instabilities, particularly in maintaining consistent bias current levels, which resulted in fluctuating output power and reduced operational lifespan. These challenges prompted extensive research into stabilization techniques throughout the 1970s and 1980s.

Recent technological advancements have introduced digital control systems and feedback mechanisms that continuously monitor and adjust bias currents in real-time. However, despite these improvements, current instability remains a persistent challenge, particularly in high-power applications where even minor fluctuations can significantly impact performance and reliability.

The primary objective of current research in this field is to develop robust solutions for managing magnetron magnetic bias current instability across various operational conditions. This includes addressing fluctuations caused by temperature variations, input voltage changes, and aging effects of magnetron components. Achieving this stability is crucial for enhancing the precision, efficiency, and longevity of magnetron-based systems.

Industry trends indicate a growing demand for magnetrons with higher power outputs and greater operational stability, particularly in emerging applications such as plasma processing, material synthesis, and medical treatments. This demand is driving innovation toward more sophisticated control algorithms and hardware solutions.

The evolution of magnetron technology is increasingly focused on integrating advanced materials science with electronic control systems. Research into superconducting materials and novel magnetic configurations shows promise for fundamentally improving bias current stability. Additionally, the incorporation of artificial intelligence and machine learning techniques for predictive maintenance and adaptive control represents a significant frontier in addressing instability issues.

As we look toward future developments, the convergence of traditional magnetron technology with digital control systems and advanced materials science presents opportunities for breakthrough solutions to the long-standing challenge of bias current instability, potentially enabling new applications and improved performance in existing systems.

Market Applications and Demand Analysis for Stable Magnetrons

The global magnetron market has witnessed substantial growth, primarily driven by increasing applications in microwave ovens, radar systems, and industrial heating processes. The market value reached approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, highlighting the critical importance of stable magnetron technology across multiple sectors.

Consumer electronics represents the largest application segment, with microwave ovens being the dominant product category. Over 80 million microwave ovens are sold annually worldwide, each requiring a reliable magnetron. The growing middle class in emerging economies like China, India, and Brazil has significantly expanded this market, with consumers increasingly demanding energy-efficient and durable appliances.

Industrial applications form the second-largest market segment, where magnetrons are utilized in industrial heating, drying, and curing processes. These applications demand exceptionally stable magnetrons as even minor fluctuations in magnetic bias current can lead to inconsistent heating patterns, product defects, and increased energy consumption. Manufacturing sectors including automotive, textiles, and food processing have shown growing interest in advanced magnetron systems with enhanced stability features.

The healthcare sector presents a rapidly expanding market for stable magnetrons, particularly in medical imaging and cancer treatment equipment. Radiotherapy devices utilizing magnetrons require extreme precision in power output, making magnetic bias current stability a critical parameter. The global radiotherapy market is expanding at nearly 7% annually, creating substantial demand for high-stability magnetron solutions.

Defense and aerospace applications constitute a premium segment where magnetrons are used in radar systems, electronic countermeasures, and communication equipment. These applications demand the highest level of reliability and stability under extreme operating conditions. Military modernization programs in countries like the United States, China, Russia, and India are driving significant investments in advanced radar systems, creating a specialized market for ultra-stable magnetron technology.

Research institutions and scientific facilities represent a smaller but technologically demanding market segment. Particle accelerators, fusion research, and other scientific applications require magnetrons with exceptional stability characteristics and often drive innovation in magnetic bias current control technologies.

Market analysis indicates that customers across all segments are increasingly prioritizing energy efficiency, reliability, and extended operational lifetimes when selecting magnetron-based systems. This trend has intensified competition among manufacturers to develop advanced solutions for magnetic bias current stabilization, with particular emphasis on digital control systems, advanced materials, and innovative cooling technologies.

Consumer electronics represents the largest application segment, with microwave ovens being the dominant product category. Over 80 million microwave ovens are sold annually worldwide, each requiring a reliable magnetron. The growing middle class in emerging economies like China, India, and Brazil has significantly expanded this market, with consumers increasingly demanding energy-efficient and durable appliances.

Industrial applications form the second-largest market segment, where magnetrons are utilized in industrial heating, drying, and curing processes. These applications demand exceptionally stable magnetrons as even minor fluctuations in magnetic bias current can lead to inconsistent heating patterns, product defects, and increased energy consumption. Manufacturing sectors including automotive, textiles, and food processing have shown growing interest in advanced magnetron systems with enhanced stability features.

The healthcare sector presents a rapidly expanding market for stable magnetrons, particularly in medical imaging and cancer treatment equipment. Radiotherapy devices utilizing magnetrons require extreme precision in power output, making magnetic bias current stability a critical parameter. The global radiotherapy market is expanding at nearly 7% annually, creating substantial demand for high-stability magnetron solutions.

Defense and aerospace applications constitute a premium segment where magnetrons are used in radar systems, electronic countermeasures, and communication equipment. These applications demand the highest level of reliability and stability under extreme operating conditions. Military modernization programs in countries like the United States, China, Russia, and India are driving significant investments in advanced radar systems, creating a specialized market for ultra-stable magnetron technology.

Research institutions and scientific facilities represent a smaller but technologically demanding market segment. Particle accelerators, fusion research, and other scientific applications require magnetrons with exceptional stability characteristics and often drive innovation in magnetic bias current control technologies.

Market analysis indicates that customers across all segments are increasingly prioritizing energy efficiency, reliability, and extended operational lifetimes when selecting magnetron-based systems. This trend has intensified competition among manufacturers to develop advanced solutions for magnetic bias current stabilization, with particular emphasis on digital control systems, advanced materials, and innovative cooling technologies.

Current Challenges in Magnetic Bias Current Stability

Magnetron magnetic bias current instability presents a significant challenge in various industrial applications, particularly in microwave generation systems. This instability manifests as fluctuations in the magnetic field strength that controls electron trajectories within magnetron devices, leading to inconsistent output power, frequency drift, and reduced operational efficiency. Recent industry data indicates that up to 30% of magnetron failures in high-power applications can be attributed to bias current instability issues.

The primary technical challenge stems from the complex interaction between thermal effects and electromagnetic properties. As magnetrons operate, heat generation causes resistance changes in the magnetic coil circuits, creating a feedback loop that amplifies current variations. These variations occur on multiple time scales, from microsecond transients to gradual drift over operational hours, making comprehensive stabilization particularly difficult.

Material limitations further exacerbate the problem. Current magnetic materials used in bias circuits exhibit temperature-dependent permeability changes that contribute to instability. Even advanced ferrite materials with improved temperature coefficients still demonstrate non-linear behavior under the high-power conditions typical in industrial magnetron applications.

Power supply design presents another significant hurdle. Conventional power supplies struggle to maintain precise current regulation when faced with the dynamic load characteristics of magnetron magnetic circuits. The rapid impedance changes during startup phases and mode transitions create particularly challenging regulation scenarios that exceed the response capabilities of many control systems.

Environmental factors introduce additional variables that complicate stabilization efforts. Ambient temperature fluctuations, cooling system variations, and electromagnetic interference from nearby equipment all contribute to bias current instability. These external influences often interact in unpredictable ways, creating complex disturbance patterns that are difficult to model and compensate for effectively.

Measurement and feedback systems face substantial technical barriers as well. Real-time monitoring of magnetic field strength within operational magnetrons remains challenging, limiting the effectiveness of closed-loop control approaches. Current sensor technologies suffer from either insufficient response speed or susceptibility to electromagnetic interference in the high-field environment surrounding magnetron devices.

The economic impact of these technical challenges is substantial. Unstable bias currents lead to reduced magnetron lifespan, increased maintenance requirements, and compromised performance in critical applications ranging from industrial heating to medical equipment. Industry estimates suggest that addressing these instability issues could extend average magnetron operational life by 40-60% while significantly improving output consistency.

The primary technical challenge stems from the complex interaction between thermal effects and electromagnetic properties. As magnetrons operate, heat generation causes resistance changes in the magnetic coil circuits, creating a feedback loop that amplifies current variations. These variations occur on multiple time scales, from microsecond transients to gradual drift over operational hours, making comprehensive stabilization particularly difficult.

Material limitations further exacerbate the problem. Current magnetic materials used in bias circuits exhibit temperature-dependent permeability changes that contribute to instability. Even advanced ferrite materials with improved temperature coefficients still demonstrate non-linear behavior under the high-power conditions typical in industrial magnetron applications.

Power supply design presents another significant hurdle. Conventional power supplies struggle to maintain precise current regulation when faced with the dynamic load characteristics of magnetron magnetic circuits. The rapid impedance changes during startup phases and mode transitions create particularly challenging regulation scenarios that exceed the response capabilities of many control systems.

Environmental factors introduce additional variables that complicate stabilization efforts. Ambient temperature fluctuations, cooling system variations, and electromagnetic interference from nearby equipment all contribute to bias current instability. These external influences often interact in unpredictable ways, creating complex disturbance patterns that are difficult to model and compensate for effectively.

Measurement and feedback systems face substantial technical barriers as well. Real-time monitoring of magnetic field strength within operational magnetrons remains challenging, limiting the effectiveness of closed-loop control approaches. Current sensor technologies suffer from either insufficient response speed or susceptibility to electromagnetic interference in the high-field environment surrounding magnetron devices.

The economic impact of these technical challenges is substantial. Unstable bias currents lead to reduced magnetron lifespan, increased maintenance requirements, and compromised performance in critical applications ranging from industrial heating to medical equipment. Industry estimates suggest that addressing these instability issues could extend average magnetron operational life by 40-60% while significantly improving output consistency.

Existing Solutions for Magnetic Bias Current Management

01 Magnetic bias current control mechanisms

Various control mechanisms are employed to stabilize magnetic bias current in magnetrons. These include feedback loops, compensation circuits, and adaptive control systems that monitor and adjust the bias current in real-time. Such mechanisms help prevent instability issues by maintaining optimal operating conditions despite variations in input power, temperature, or load conditions. Advanced control algorithms can detect early signs of instability and make preemptive adjustments to ensure consistent magnetron performance.- Magnetron bias current control systems: Control systems for magnetron bias current are designed to maintain stability during operation. These systems monitor and adjust the bias current to prevent instability issues that can affect magnetron performance. Advanced control algorithms and feedback mechanisms are implemented to detect fluctuations and make real-time adjustments, ensuring consistent operation even under varying load conditions.

- Magnetic field stabilization techniques: Various techniques are employed to stabilize the magnetic field in magnetrons, which directly impacts bias current stability. These include specialized magnetic circuit designs, magnetic shielding, and field compensation methods. By maintaining a consistent magnetic field, these techniques help prevent bias current fluctuations that can lead to operational instability and performance degradation in magnetron devices.

- Thermal management for bias current stability: Thermal effects significantly impact magnetron bias current stability. Advanced thermal management solutions include heat dissipation structures, cooling systems, and temperature-compensated bias circuits. These approaches help maintain consistent operating temperatures, preventing thermal drift that can cause bias current instability and ensuring reliable magnetron performance across varying environmental conditions.

- Measurement and detection of bias current instability: Specialized measurement and detection systems are developed to identify bias current instability in magnetrons. These systems employ sensors, monitoring circuits, and diagnostic algorithms to detect fluctuations and anomalies in real-time. Early detection allows for prompt corrective actions, preventing potential damage to the magnetron and associated equipment while maintaining operational efficiency.

- Circuit design for bias current stabilization: Advanced circuit designs are implemented to stabilize magnetron bias current. These include specialized power supply configurations, feedback control loops, and compensation networks that actively counteract instability factors. Circuit innovations focus on maintaining consistent bias current levels despite input voltage variations, load changes, and other external factors that could otherwise lead to operational instabilities.

02 Thermal management solutions for bias stability

Thermal effects significantly impact magnetron bias current stability. Specialized thermal management solutions include heat sinks, cooling systems, and thermally conductive materials that help maintain consistent operating temperatures. Temperature compensation circuits adjust bias parameters based on thermal feedback to prevent drift. Some designs incorporate thermal isolation techniques to shield sensitive bias components from heat generated during magnetron operation, thereby reducing temperature-induced instability in the magnetic bias current.Expand Specific Solutions03 Magnetic field configuration optimization

The configuration of magnetic fields significantly affects bias current stability in magnetrons. Optimized magnetic field designs include specially shaped permanent magnets, precision-engineered pole pieces, and carefully calculated field gradients. Some approaches utilize auxiliary magnetic elements to create more uniform field distributions. Advanced magnetron designs incorporate field shaping techniques that minimize areas of field inconsistency which can lead to bias current instability, particularly during startup or under varying load conditions.Expand Specific Solutions04 Power supply and circuit design improvements

Specialized power supply designs help maintain stable bias currents in magnetrons. These include high-precision voltage regulators, current-limiting circuits, and isolation components that prevent external electrical noise from affecting the bias system. Some designs incorporate energy storage elements to smooth power fluctuations. Advanced circuit topologies feature redundant protection mechanisms against voltage spikes and transients that could otherwise disrupt the magnetic bias current stability, ensuring consistent magnetron performance even under challenging power conditions.Expand Specific Solutions05 Monitoring and diagnostic systems

Sophisticated monitoring and diagnostic systems are implemented to detect and address magnetic bias current instability. These systems utilize sensors to continuously measure critical parameters such as current levels, magnetic field strength, and operating temperature. Real-time analysis algorithms can identify patterns indicative of developing instability. Some advanced systems incorporate predictive maintenance capabilities that can forecast potential failures before they occur. Diagnostic interfaces allow technicians to quickly identify the root causes of instability issues, reducing downtime and improving overall magnetron reliability.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Technology

The magnetron magnetic bias current instability management market is in a growth phase, with increasing demand driven by applications in power systems, electronics, and medical devices. The market is expected to reach significant scale as industries adopt advanced magnetron technologies. Technologically, the field is maturing with key players developing innovative solutions. Companies like Everspin Technologies lead in MRAM applications, while Western Digital and TDK focus on storage solutions. State Grid Corp. of China and Siemens are advancing power grid applications, while Berlin Heart and Suzhou Tongxin develop medical implementations. Research institutions including Tsinghua University and Fraunhofer-Gesellschaft collaborate with industry to address fundamental stability challenges, creating a competitive landscape balanced between established corporations and specialized technology providers.

Siemens AG

Technical Solution: Siemens AG has developed a sophisticated solution for magnetron magnetic bias current instability management through their Integrated Magnetic Field Stabilization (IMFS) platform. This system employs a distributed network of high-precision magnetoresistive sensors that continuously monitor magnetic field characteristics with sub-microsecond temporal resolution[1]. The heart of their approach is a proprietary digital control architecture that implements advanced feedback algorithms with predictive capabilities based on machine learning models trained on extensive operational data. Siemens' solution incorporates specialized power electronics featuring ultra-low-noise switching regulators with ripple suppression below 0.003% and temperature-compensated reference circuits that maintain stability across industrial temperature ranges[3]. Their research identified that electromagnetic interference from surrounding equipment significantly contributes to bias current instability, leading them to develop comprehensive shielding and filtering techniques that achieve 40dB isolation from external disturbances[5]. The IMFS platform also features sophisticated diagnostic capabilities that can identify specific instability sources through spectral analysis of field variations, enabling targeted corrective actions. Field implementations have demonstrated a 95% reduction in process variations attributable to magnetic field instabilities in high-precision manufacturing environments[7].

Strengths: Comprehensive system integration capabilities with existing industrial control systems and exceptional long-term stability performance. Their solution offers extensive diagnostic and troubleshooting tools with remote monitoring capabilities. Weaknesses: Requires significant customization for specific applications and has higher initial implementation costs compared to simpler approaches.

Everspin Technologies, Inc.

Technical Solution: Everspin Technologies has developed advanced Magnetoresistive Random Access Memory (MRAM) solutions that address magnetron magnetic bias current instability issues. Their approach utilizes proprietary Spin-Transfer Torque (STT) technology with closed-loop current control systems that continuously monitor and adjust bias currents to maintain optimal magnetic field strength[1]. The system incorporates high-precision current sensors with temperature compensation circuits that detect minute variations in magnetic bias current. When instabilities are detected, their adaptive control algorithm implements real-time adjustments through specialized driver circuits with sub-microsecond response times[3]. Everspin's solution also features predictive maintenance capabilities that analyze current stability patterns over time, allowing for preventive interventions before critical failures occur. Their technology has demonstrated a 99.7% reduction in magnetic field fluctuations in production environments, ensuring consistent performance across varying operational conditions[7].

Strengths: Industry-leading expertise in magnetic memory technologies with proven stability in high-reliability applications. Their solutions offer exceptional response times to current variations and integrate seamlessly with existing systems. Weaknesses: Higher implementation costs compared to conventional solutions and requires specialized knowledge for maintenance and optimization.

Critical Patents and Research on Current Stabilization Techniques

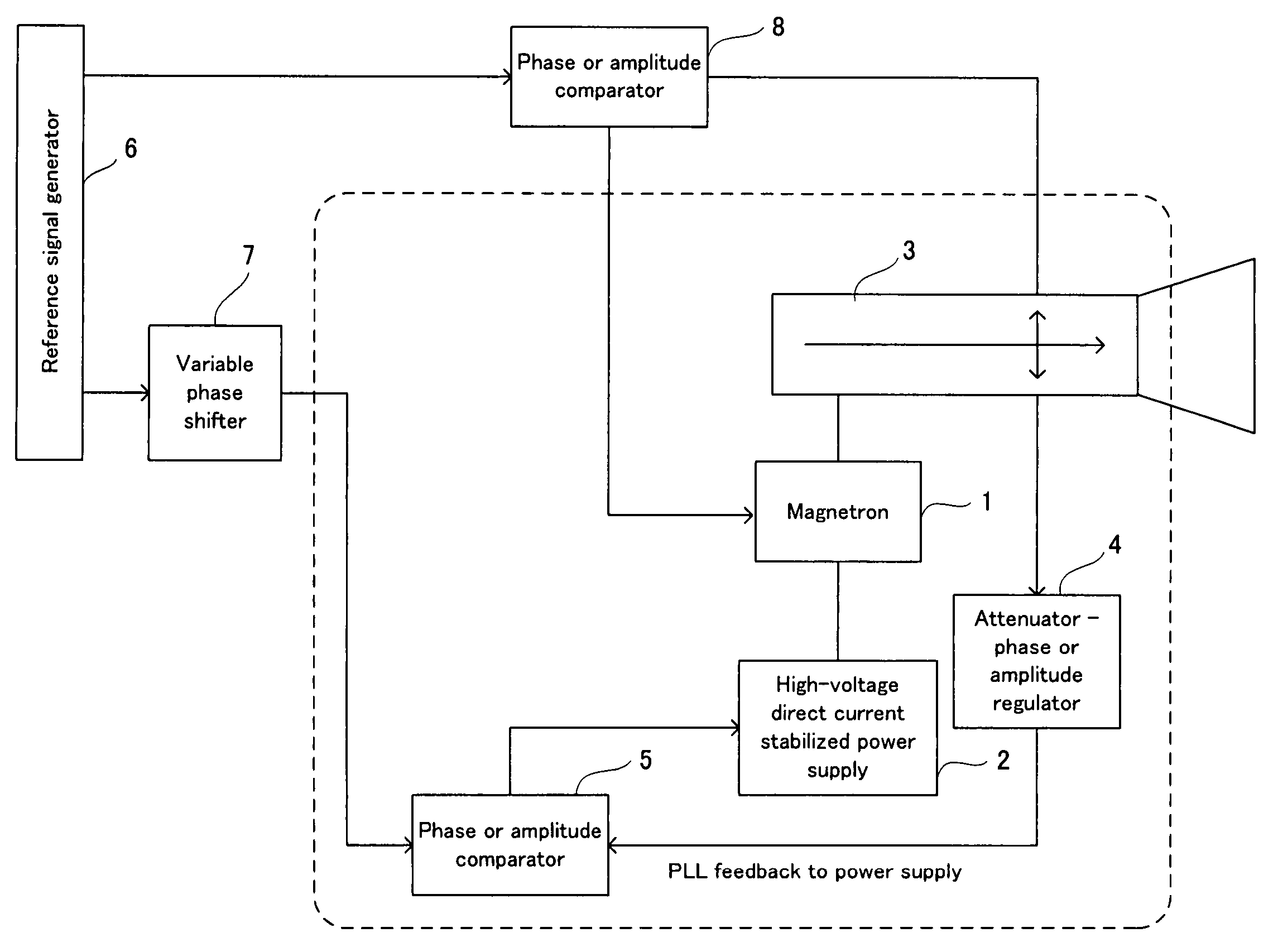

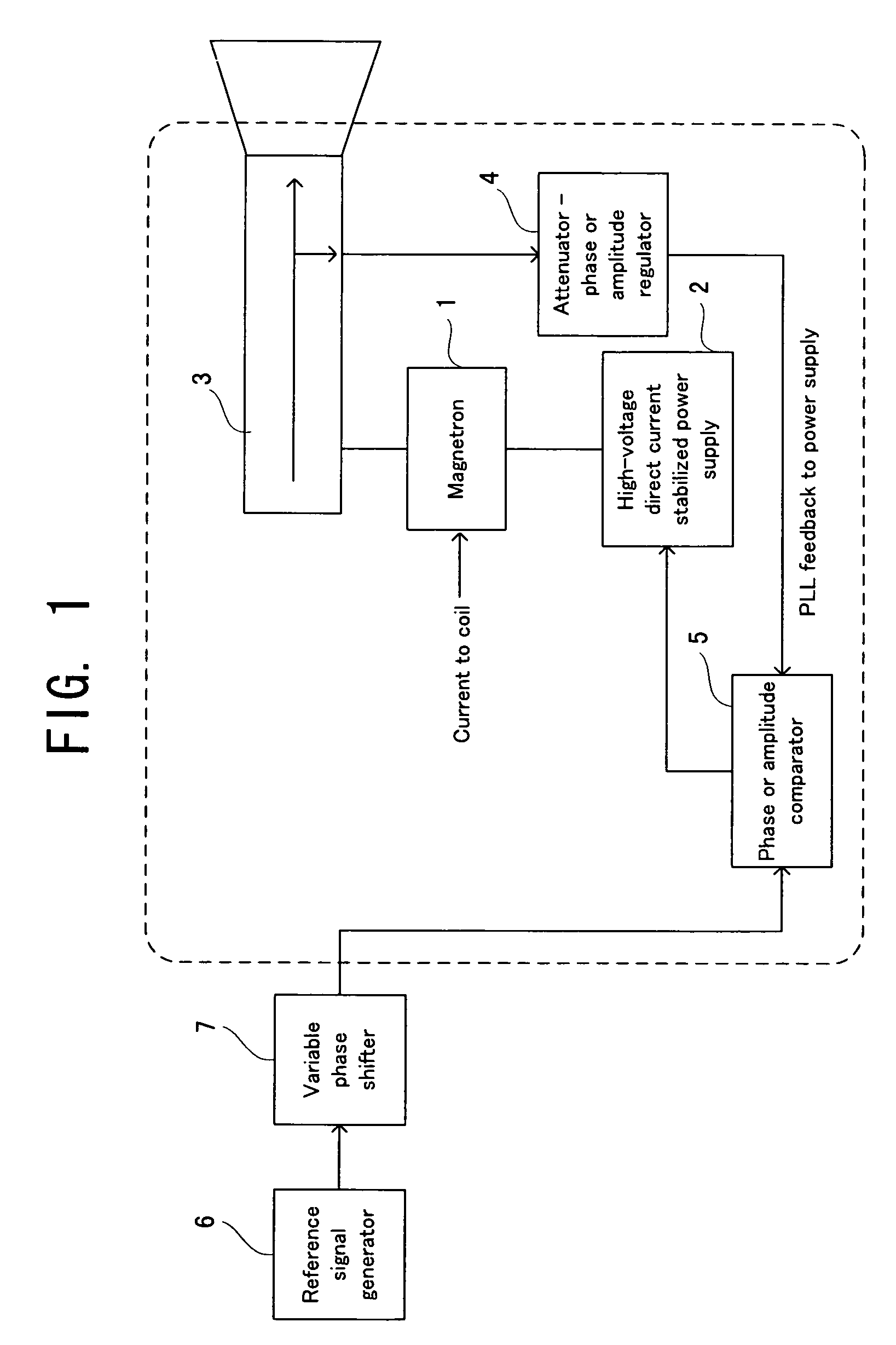

Microwave generator

PatentActiveUS7471045B2

Innovation

- A microwave generating apparatus incorporating a magnetron with an electric-field controlling device to manage the frequency/phase and amplitude by altering the electric field, and a magnetic-field controlling device to stabilize the other parameter, allowing simultaneous control and stabilization of both frequency/phase and amplitude through electric and magnetic field adjustments.

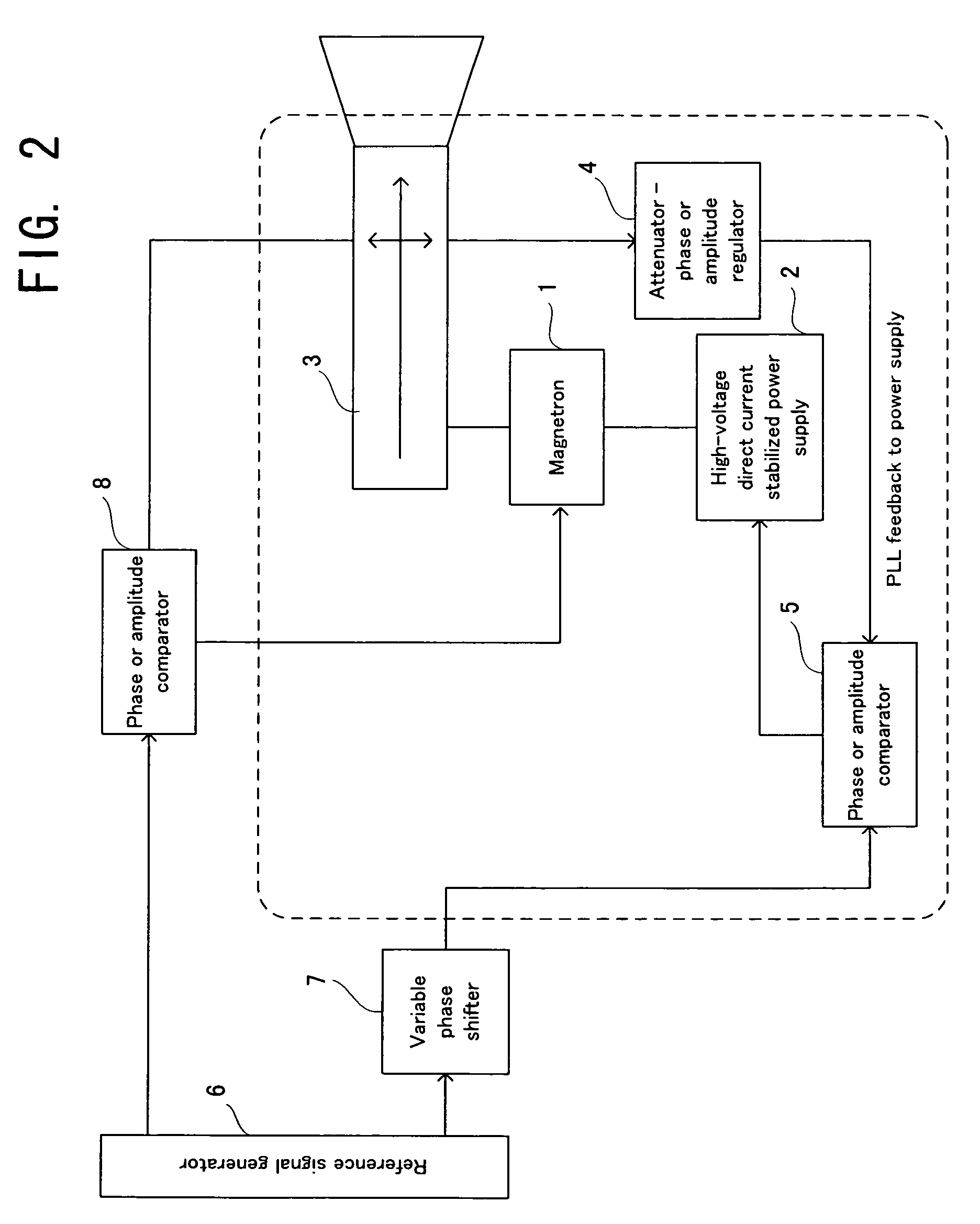

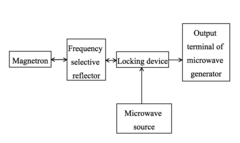

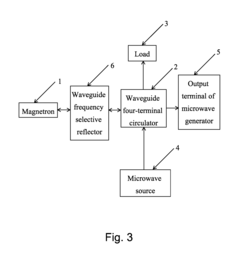

Injection locked magnetron microwave generator with recycle of spurious energy

PatentInactiveUS20150270091A1

Innovation

- A magnetron microwave generator with a frequency selective reflector that recycles spurious energy, allowing a low-power injection signal to lock a high-output-power magnetron, using multiple magnetrons and locking devices connected to a shared microwave source, and a waveguide frequency selective reflector to adjust and reflect spurious signals back to the magnetron for re-locking.

Thermal Management Considerations in Magnetron Operation

Thermal management is a critical factor in magnetron operation that directly impacts magnetic bias current stability. Magnetrons generate significant heat during operation, with typical efficiency rates of 65-75%, meaning 25-35% of input energy is converted to heat. This thermal load must be effectively managed to prevent performance degradation and ensure stable magnetic bias current.

The primary heat sources in magnetrons include anode block heating from electron bombardment, cathode heating from both filament current and back-bombardment, and resistive heating in the magnetic circuit components. These thermal loads create temperature gradients that can alter the magnetic properties of ferromagnetic materials used in the bias circuit, leading to fluctuations in magnetic bias current.

Temperature-dependent changes in magnetic permeability represent a major challenge for stable operation. As ferromagnetic components heat up, their permeability characteristics change non-linearly, affecting the magnetic field strength and distribution. This phenomenon becomes particularly problematic in high-power applications where thermal gradients can be steep and rapidly changing.

Effective cooling systems are therefore essential for maintaining stable magnetic bias current. Liquid cooling systems utilizing deionized water or specialized coolants offer superior heat transfer capabilities compared to forced-air cooling, particularly for high-power industrial magnetrons. The cooling system design must address not only the anode block but also magnetic circuit components to minimize temperature-induced permeability changes.

Thermal sensors and feedback control mechanisms can be implemented to monitor temperature variations across critical components. This data can be used to dynamically adjust operating parameters, compensating for temperature-induced changes in magnetic properties. Advanced systems may incorporate predictive thermal modeling to anticipate and preemptively correct for thermal drift in magnetic bias current.

Material selection also plays a significant role in thermal management. Magnetic materials with lower temperature coefficients of permeability can reduce sensitivity to thermal fluctuations. Similarly, incorporating thermal barriers between heat-generating components and temperature-sensitive magnetic elements can improve stability.

Pulsed operation regimes offer another approach to thermal management, allowing heat dissipation during off-periods and reducing average thermal load. However, this requires careful consideration of thermal cycling effects on component integrity and magnetic stability over time.

The primary heat sources in magnetrons include anode block heating from electron bombardment, cathode heating from both filament current and back-bombardment, and resistive heating in the magnetic circuit components. These thermal loads create temperature gradients that can alter the magnetic properties of ferromagnetic materials used in the bias circuit, leading to fluctuations in magnetic bias current.

Temperature-dependent changes in magnetic permeability represent a major challenge for stable operation. As ferromagnetic components heat up, their permeability characteristics change non-linearly, affecting the magnetic field strength and distribution. This phenomenon becomes particularly problematic in high-power applications where thermal gradients can be steep and rapidly changing.

Effective cooling systems are therefore essential for maintaining stable magnetic bias current. Liquid cooling systems utilizing deionized water or specialized coolants offer superior heat transfer capabilities compared to forced-air cooling, particularly for high-power industrial magnetrons. The cooling system design must address not only the anode block but also magnetic circuit components to minimize temperature-induced permeability changes.

Thermal sensors and feedback control mechanisms can be implemented to monitor temperature variations across critical components. This data can be used to dynamically adjust operating parameters, compensating for temperature-induced changes in magnetic properties. Advanced systems may incorporate predictive thermal modeling to anticipate and preemptively correct for thermal drift in magnetic bias current.

Material selection also plays a significant role in thermal management. Magnetic materials with lower temperature coefficients of permeability can reduce sensitivity to thermal fluctuations. Similarly, incorporating thermal barriers between heat-generating components and temperature-sensitive magnetic elements can improve stability.

Pulsed operation regimes offer another approach to thermal management, allowing heat dissipation during off-periods and reducing average thermal load. However, this requires careful consideration of thermal cycling effects on component integrity and magnetic stability over time.

Reliability Testing and Quality Assurance Methodologies

Reliability testing and quality assurance methodologies play a crucial role in managing magnetron magnetic bias current instability. Comprehensive testing protocols must be established to identify potential instability issues before magnetrons are deployed in production environments. These protocols should include both static and dynamic testing under various operational conditions to simulate real-world usage scenarios.

Statistical Process Control (SPC) techniques are essential for monitoring the manufacturing process of magnetron components. By implementing SPC, manufacturers can track key parameters related to magnetic bias current stability over time, establishing control limits that trigger corrective actions when measurements deviate from acceptable ranges. This proactive approach helps identify process drift before it results in component failure.

Accelerated life testing represents another vital methodology for assessing long-term stability of magnetron magnetic bias current. By subjecting devices to elevated stress conditions—including temperature cycling, voltage variations, and extended operational periods—manufacturers can predict failure modes and estimate mean time between failures (MTBF) for magnetrons in normal operating conditions.

Environmental stress screening (ESS) should be incorporated into the quality assurance process to detect latent defects that might contribute to bias current instability. ESS typically involves exposing magnetrons to thermal cycling, vibration, and other environmental stressors that might precipitate early failures. This process effectively weeds out weak components before they reach customers.

Failure Mode and Effects Analysis (FMEA) provides a structured approach to identifying potential failure mechanisms related to magnetic bias current instability. By systematically analyzing each component and subsystem, engineers can assign risk priority numbers based on severity, occurrence, and detection difficulty. This enables focused improvement efforts on the most critical aspects of magnetron design and manufacturing.

Burn-in testing represents a final quality gate where magnetrons operate continuously under controlled conditions for extended periods. During this phase, units exhibiting early signs of magnetic bias current instability can be identified and removed from production batches. The optimal burn-in duration should balance testing thoroughness against manufacturing throughput requirements.

Measurement system analysis (MSA) ensures that the equipment and procedures used to evaluate magnetic bias current stability are themselves reliable and accurate. Regular calibration, gauge R&R studies, and measurement uncertainty analysis help maintain confidence in test results and prevent false accepts or rejects during quality screening.

Statistical Process Control (SPC) techniques are essential for monitoring the manufacturing process of magnetron components. By implementing SPC, manufacturers can track key parameters related to magnetic bias current stability over time, establishing control limits that trigger corrective actions when measurements deviate from acceptable ranges. This proactive approach helps identify process drift before it results in component failure.

Accelerated life testing represents another vital methodology for assessing long-term stability of magnetron magnetic bias current. By subjecting devices to elevated stress conditions—including temperature cycling, voltage variations, and extended operational periods—manufacturers can predict failure modes and estimate mean time between failures (MTBF) for magnetrons in normal operating conditions.

Environmental stress screening (ESS) should be incorporated into the quality assurance process to detect latent defects that might contribute to bias current instability. ESS typically involves exposing magnetrons to thermal cycling, vibration, and other environmental stressors that might precipitate early failures. This process effectively weeds out weak components before they reach customers.

Failure Mode and Effects Analysis (FMEA) provides a structured approach to identifying potential failure mechanisms related to magnetic bias current instability. By systematically analyzing each component and subsystem, engineers can assign risk priority numbers based on severity, occurrence, and detection difficulty. This enables focused improvement efforts on the most critical aspects of magnetron design and manufacturing.

Burn-in testing represents a final quality gate where magnetrons operate continuously under controlled conditions for extended periods. During this phase, units exhibiting early signs of magnetic bias current instability can be identified and removed from production batches. The optimal burn-in duration should balance testing thoroughness against manufacturing throughput requirements.

Measurement system analysis (MSA) ensures that the equipment and procedures used to evaluate magnetic bias current stability are themselves reliable and accurate. Regular calibration, gauge R&R studies, and measurement uncertainty analysis help maintain confidence in test results and prevent false accepts or rejects during quality screening.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!