How to Ensure Magnetron Performance Under Varying Loads

AUG 28, 20256 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Performance Objectives

Magnetron technology has evolved significantly since its invention in the 1920s, with major advancements occurring during World War II when it became crucial for radar systems. Initially designed for fixed-load applications, modern magnetrons now face the challenge of maintaining consistent performance across varying load conditions in diverse applications ranging from industrial heating to medical equipment and telecommunications.

The fundamental operating principle of a magnetron involves electrons moving in a crossed electric and magnetic field, generating microwave radiation. This process is highly sensitive to load impedance variations, which can cause frequency pulling, mode jumping, and efficiency losses. The historical development trajectory shows a clear trend toward more stable and adaptable magnetron designs, with recent innovations focusing on frequency-locking techniques and adaptive matching networks.

Current technological objectives in magnetron development center on achieving stable performance metrics regardless of load variations. Key performance indicators include frequency stability (typically aiming for drift less than ±5 MHz), power output consistency (maintaining output within ±10% of nominal value under varying loads), and operational efficiency (targeting 65-75% across the load range). Additional objectives include extended operational lifespan under fluctuating conditions and reduced sensitivity to reflected power.

The evolution of magnetron technology has been driven by increasing demands from applications requiring precise energy delivery. Industrial heating processes, for example, require consistent power delivery even as material properties change during processing. Medical applications demand extremely stable frequency output for targeted therapy, while commercial microwave systems must maintain performance despite varying food loads and compositions.

Recent technological trends indicate a shift toward hybrid solutions that combine traditional magnetron technology with solid-state components for improved control. Digital feedback systems that can detect load variations and make real-time adjustments are becoming increasingly important. Additionally, computational modeling approaches are enabling more sophisticated prediction of magnetron behavior under varying load conditions.

The technical challenges that must be addressed include thermal management during load fluctuations, prevention of mode hopping when impedance changes occur, and development of more sophisticated matching networks that can rapidly adapt to changing load conditions. These challenges are compounded by market pressures for more compact, energy-efficient, and cost-effective solutions.

Looking forward, the technological roadmap for magnetrons includes development of smart adaptive systems with integrated sensing and control mechanisms, advanced materials for cathode and anode structures that provide greater stability, and novel circuit topologies that inherently compensate for load variations without requiring complex external matching networks.

The fundamental operating principle of a magnetron involves electrons moving in a crossed electric and magnetic field, generating microwave radiation. This process is highly sensitive to load impedance variations, which can cause frequency pulling, mode jumping, and efficiency losses. The historical development trajectory shows a clear trend toward more stable and adaptable magnetron designs, with recent innovations focusing on frequency-locking techniques and adaptive matching networks.

Current technological objectives in magnetron development center on achieving stable performance metrics regardless of load variations. Key performance indicators include frequency stability (typically aiming for drift less than ±5 MHz), power output consistency (maintaining output within ±10% of nominal value under varying loads), and operational efficiency (targeting 65-75% across the load range). Additional objectives include extended operational lifespan under fluctuating conditions and reduced sensitivity to reflected power.

The evolution of magnetron technology has been driven by increasing demands from applications requiring precise energy delivery. Industrial heating processes, for example, require consistent power delivery even as material properties change during processing. Medical applications demand extremely stable frequency output for targeted therapy, while commercial microwave systems must maintain performance despite varying food loads and compositions.

Recent technological trends indicate a shift toward hybrid solutions that combine traditional magnetron technology with solid-state components for improved control. Digital feedback systems that can detect load variations and make real-time adjustments are becoming increasingly important. Additionally, computational modeling approaches are enabling more sophisticated prediction of magnetron behavior under varying load conditions.

The technical challenges that must be addressed include thermal management during load fluctuations, prevention of mode hopping when impedance changes occur, and development of more sophisticated matching networks that can rapidly adapt to changing load conditions. These challenges are compounded by market pressures for more compact, energy-efficient, and cost-effective solutions.

Looking forward, the technological roadmap for magnetrons includes development of smart adaptive systems with integrated sensing and control mechanisms, advanced materials for cathode and anode structures that provide greater stability, and novel circuit topologies that inherently compensate for load variations without requiring complex external matching networks.

Market Analysis for Load-Adaptive Magnetron Applications

The magnetron market is experiencing significant growth driven by diverse applications across multiple industries. The global magnetron market was valued at approximately 6.8 billion USD in 2022 and is projected to reach 9.5 billion USD by 2028, representing a compound annual growth rate of 5.7%. This growth is primarily fueled by expanding applications in industrial heating, medical equipment, and consumer appliances.

The consumer microwave oven segment continues to dominate market share, accounting for nearly 45% of total magnetron demand. However, industrial applications are showing the fastest growth rate at 7.2% annually, particularly in food processing, material drying, and chemical processing industries where load-adaptive capabilities are increasingly critical.

Regional analysis reveals Asia-Pacific as the largest market, controlling 38% of global magnetron production and consumption, followed by North America (27%) and Europe (22%). China remains the manufacturing hub, while Japan and South Korea lead in technological innovation, particularly in load-adaptive magnetron systems.

The demand for load-adaptive magnetrons is being driven by several key factors. Energy efficiency requirements are becoming more stringent globally, with the EU's EcoDesign Directive and similar regulations in North America mandating improved efficiency in microwave systems. This regulatory pressure is compelling manufacturers to develop magnetrons that can maintain optimal performance across varying load conditions.

Industrial users are increasingly demanding precision heating solutions that can automatically adjust power output based on material properties and load variations. The food processing industry, in particular, requires systems that can adapt to different food compositions and quantities while maintaining consistent cooking results.

Market research indicates that end-users are willing to pay a 15-20% premium for magnetron systems with advanced load-adaptive capabilities, provided they deliver demonstrable improvements in energy efficiency and process consistency. This price sensitivity varies by application, with medical and scientific users showing higher willingness to pay for precision performance.

The aftermarket and replacement segment presents significant opportunities, as existing installations seek upgrades to improve efficiency without complete system replacement. This segment is growing at 6.3% annually and represents a lower barrier entry point for innovative load-adaptive technologies.

Customer feedback analysis reveals that reliability under varying load conditions ranks as the top concern among industrial users, followed by energy efficiency and maintenance requirements. This prioritization underscores the market's readiness for advanced load-adaptive magnetron solutions that can address these specific pain points.

The consumer microwave oven segment continues to dominate market share, accounting for nearly 45% of total magnetron demand. However, industrial applications are showing the fastest growth rate at 7.2% annually, particularly in food processing, material drying, and chemical processing industries where load-adaptive capabilities are increasingly critical.

Regional analysis reveals Asia-Pacific as the largest market, controlling 38% of global magnetron production and consumption, followed by North America (27%) and Europe (22%). China remains the manufacturing hub, while Japan and South Korea lead in technological innovation, particularly in load-adaptive magnetron systems.

The demand for load-adaptive magnetrons is being driven by several key factors. Energy efficiency requirements are becoming more stringent globally, with the EU's EcoDesign Directive and similar regulations in North America mandating improved efficiency in microwave systems. This regulatory pressure is compelling manufacturers to develop magnetrons that can maintain optimal performance across varying load conditions.

Industrial users are increasingly demanding precision heating solutions that can automatically adjust power output based on material properties and load variations. The food processing industry, in particular, requires systems that can adapt to different food compositions and quantities while maintaining consistent cooking results.

Market research indicates that end-users are willing to pay a 15-20% premium for magnetron systems with advanced load-adaptive capabilities, provided they deliver demonstrable improvements in energy efficiency and process consistency. This price sensitivity varies by application, with medical and scientific users showing higher willingness to pay for precision performance.

The aftermarket and replacement segment presents significant opportunities, as existing installations seek upgrades to improve efficiency without complete system replacement. This segment is growing at 6.3% annually and represents a lower barrier entry point for innovative load-adaptive technologies.

Customer feedback analysis reveals that reliability under varying load conditions ranks as the top concern among industrial users, followed by energy efficiency and maintenance requirements. This prioritization underscores the market's readiness for advanced load-adaptive magnetron solutions that can address these specific pain points.

Current Challenges in Magnetron Load Variation Management

Magnetron performance under varying load conditions presents significant challenges for both manufacturers and end-users. The primary issue stems from the inherent sensitivity of magnetrons to load impedance variations, which can cause frequency pulling, mode jumping, and overall efficiency degradation. When load conditions deviate from optimal parameters, magnetrons may experience thermal stress, reduced output power, and shortened operational lifespan.

One critical challenge is the impedance matching problem. Magnetrons are designed to operate with specific load impedance values, typically 50 ohms in industrial applications. However, real-world applications rarely maintain constant impedance, especially in processes involving materials with changing dielectric properties. This mismatch creates standing waves in the waveguide system, leading to power reflection back to the magnetron, which can cause overheating and potential damage to the device.

Thermal management represents another significant hurdle. Load variations induce inconsistent power absorption patterns, creating hotspots within the magnetron structure. These thermal gradients accelerate component degradation, particularly affecting the cathode emission properties and the integrity of vacuum seals. Current cooling systems often struggle to adapt dynamically to these changing thermal profiles, resulting in suboptimal heat dissipation during load fluctuations.

Frequency stability issues compound these challenges. As loads vary, magnetrons tend to exhibit frequency drift, which can be particularly problematic in applications requiring precise frequency control, such as industrial heating processes or scientific research. The current frequency-locking mechanisms have limited effectiveness when confronted with rapid load changes, creating process inconsistencies and reduced energy transfer efficiency.

Control system limitations further exacerbate these problems. Most existing magnetron power supplies employ relatively simple control algorithms that cannot adequately compensate for dynamic load variations. The feedback mechanisms typically operate with significant latency, preventing real-time adjustments to maintain optimal operating conditions. This control gap results in performance fluctuations that compromise process reliability and product quality.

Material degradation accelerates under varying load conditions. The cathode, anode, and other critical components experience inconsistent electrical and thermal stresses, leading to uneven wear patterns. This degradation manifests as reduced emission efficiency, altered resonant characteristics, and ultimately premature failure. Current material solutions lack the resilience to withstand these fluctuating operational demands without significant performance deterioration over time.

Diagnostic capabilities present another challenge area. Existing monitoring systems provide limited real-time insight into magnetron performance under dynamic load conditions. This diagnostic gap makes it difficult to implement predictive maintenance strategies or to optimize operational parameters during actual use, resulting in preventable failures and suboptimal performance.

One critical challenge is the impedance matching problem. Magnetrons are designed to operate with specific load impedance values, typically 50 ohms in industrial applications. However, real-world applications rarely maintain constant impedance, especially in processes involving materials with changing dielectric properties. This mismatch creates standing waves in the waveguide system, leading to power reflection back to the magnetron, which can cause overheating and potential damage to the device.

Thermal management represents another significant hurdle. Load variations induce inconsistent power absorption patterns, creating hotspots within the magnetron structure. These thermal gradients accelerate component degradation, particularly affecting the cathode emission properties and the integrity of vacuum seals. Current cooling systems often struggle to adapt dynamically to these changing thermal profiles, resulting in suboptimal heat dissipation during load fluctuations.

Frequency stability issues compound these challenges. As loads vary, magnetrons tend to exhibit frequency drift, which can be particularly problematic in applications requiring precise frequency control, such as industrial heating processes or scientific research. The current frequency-locking mechanisms have limited effectiveness when confronted with rapid load changes, creating process inconsistencies and reduced energy transfer efficiency.

Control system limitations further exacerbate these problems. Most existing magnetron power supplies employ relatively simple control algorithms that cannot adequately compensate for dynamic load variations. The feedback mechanisms typically operate with significant latency, preventing real-time adjustments to maintain optimal operating conditions. This control gap results in performance fluctuations that compromise process reliability and product quality.

Material degradation accelerates under varying load conditions. The cathode, anode, and other critical components experience inconsistent electrical and thermal stresses, leading to uneven wear patterns. This degradation manifests as reduced emission efficiency, altered resonant characteristics, and ultimately premature failure. Current material solutions lack the resilience to withstand these fluctuating operational demands without significant performance deterioration over time.

Diagnostic capabilities present another challenge area. Existing monitoring systems provide limited real-time insight into magnetron performance under dynamic load conditions. This diagnostic gap makes it difficult to implement predictive maintenance strategies or to optimize operational parameters during actual use, resulting in preventable failures and suboptimal performance.

Existing Solutions for Magnetron Performance Stabilization

01 Magnetron design optimization for improved performance

Optimizing the design of magnetrons can significantly enhance their performance. This includes modifications to the cathode structure, anode configuration, and magnetic field arrangement. These design improvements can lead to increased power output, better efficiency, and extended operational lifetime. Advanced materials and precision engineering techniques are employed to achieve optimal magnetron performance across various applications.- Magnetron design optimization for improved performance: Optimizing the design of magnetrons can significantly enhance their performance. This includes modifications to the cathode structure, anode configuration, and magnetic field arrangement. Improved designs can lead to higher efficiency, better power output stability, and extended operational lifetime. Design optimizations may also focus on reducing size while maintaining performance characteristics for specific applications.

- Sputtering magnetron performance enhancements: Specific modifications to sputtering magnetrons can improve their deposition performance. These include optimized target utilization, enhanced plasma confinement, and improved cooling systems. Advanced sputtering magnetrons may incorporate rotating magnets or specialized magnetic field configurations to achieve more uniform film deposition and higher deposition rates while maintaining target integrity over extended operational periods.

- Magnetron power supply and control systems: The performance of magnetrons is significantly affected by their power supply and control systems. Advanced power supplies with precise voltage and current regulation can enhance stability and efficiency. Control systems that monitor and adjust operational parameters in real-time can prevent overheating, arcing, and other performance issues. Integration of feedback mechanisms allows for dynamic adjustment of magnetron operation based on changing conditions.

- Thermal management for magnetron performance: Effective thermal management is crucial for maintaining optimal magnetron performance. Advanced cooling techniques, including liquid cooling systems and heat dissipation structures, help prevent overheating that can degrade performance and shorten operational life. Thermal management solutions may include specialized materials with high thermal conductivity, optimized heat sink designs, and strategic placement of cooling components to address hotspots during operation.

- Magnetron performance monitoring and diagnostics: Systems for monitoring and diagnosing magnetron performance help maintain optimal operation and extend service life. These include sensors for measuring temperature, power output, reflected power, and other critical parameters. Advanced diagnostic tools can detect early signs of performance degradation or potential failure, allowing for preventive maintenance. Real-time monitoring systems may incorporate machine learning algorithms to predict maintenance needs based on operational patterns.

02 Sputtering magnetron performance enhancement

Sputtering magnetrons used in thin film deposition can be enhanced through various techniques. These include optimizing target materials, adjusting power supply parameters, and implementing specialized cooling systems. Improved sputtering magnetron performance results in better film quality, increased deposition rates, and more uniform coating distribution. Advanced control systems can also be implemented to monitor and adjust operating parameters in real-time for optimal performance.Expand Specific Solutions03 Magnetron power supply and control systems

The performance of magnetrons is heavily influenced by their power supply and control systems. Advanced power supply designs can provide stable voltage and current, reducing fluctuations that affect magnetron operation. Sophisticated control systems can monitor operating parameters and make real-time adjustments to maintain optimal performance. These systems can also implement protection mechanisms to prevent damage during abnormal operating conditions, thereby extending the magnetron's service life.Expand Specific Solutions04 Thermal management for magnetron performance

Effective thermal management is crucial for maintaining optimal magnetron performance. Heat dissipation techniques, including advanced cooling systems and thermally conductive materials, help prevent overheating that can degrade magnetron efficiency and lifespan. Temperature monitoring and control mechanisms ensure that magnetrons operate within their optimal temperature range. Proper thermal management also contributes to the stability of the magnetron's output frequency and power level.Expand Specific Solutions05 Magnetron performance testing and measurement

Accurate testing and measurement techniques are essential for evaluating and optimizing magnetron performance. These include methods for measuring output power, frequency stability, efficiency, and operational lifetime. Advanced diagnostic tools can identify performance issues and guide improvements. Standardized testing protocols ensure consistent performance evaluation across different magnetron designs and applications. Real-time monitoring systems can track performance parameters during operation, allowing for immediate adjustments when necessary.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Magnetron Technology

The magnetron performance under varying loads market is in a growth phase, with an estimated global market size exceeding $2 billion. The technology maturity varies across applications, with consumer electronics being more established than industrial applications. Key players demonstrate different technological approaches: Midea Group, LG Electronics, Galanz, and Samsung focus on consumer-grade magnetron optimization, while Panasonic and Teledyne lead in advanced load-matching technologies. Research institutions like University of Electronic Science & Technology of China and Sichuan University contribute fundamental innovations, particularly in impedance matching and power stability. Specialized companies like Varex Imaging and Teledyne ETM are developing niche solutions for medical and military applications, indicating the technology's expanding application scope beyond traditional microwave ovens.

Midea Group Co., Ltd.

Technical Solution: Midea has pioneered a comprehensive Adaptive Magnetron Control System (AMCS) that ensures consistent performance under varying loads. Their technology incorporates advanced impedance matching circuits that dynamically adjust the magnetron's operating parameters based on real-time load conditions. The system features a multi-sensor array that continuously monitors cavity conditions, including temperature, humidity, and load characteristics. This data feeds into Midea's proprietary algorithm that optimizes power delivery by modulating the magnetron's output frequency and power levels. Their solution also includes innovative thermal management techniques that prevent overheating during challenging load scenarios, such as metal-adjacent materials or low moisture content. Midea's magnetrons incorporate specially designed cathode structures that maintain emission efficiency across varying power levels, ensuring consistent performance throughout the magnetron's operational lifetime.

Strengths: Exceptional stability across extreme load variations; reduced energy consumption by up to 30% compared to conventional systems; significantly extended magnetron lifespan through stress reduction; precise power delivery for improved cooking results. Weaknesses: Higher component costs; increased complexity requiring sophisticated manufacturing processes; potential reliability issues with the additional sensor systems if not properly maintained.

LG Electronics, Inc.

Technical Solution: LG has developed a Precision Magnetron Control System (PMCS) that maintains optimal performance under varying load conditions. Their technology features an advanced digital power supply with microsecond response times that can precisely adjust magnetron operating parameters based on real-time load characteristics. The system incorporates a sophisticated impedance matching network with electronically variable components that continuously optimize energy transfer efficiency. LG's solution includes a comprehensive sensing system that monitors multiple parameters including reflected power, cavity temperature, and load moisture content. This data drives their adaptive control algorithms that dynamically adjust magnetron frequency, power levels, and pulse characteristics to maintain stable performance regardless of load variations. Their magnetrons feature specialized cathode designs with enhanced emission stability across varying power levels and innovative cooling systems that prevent thermal-related performance degradation under challenging load conditions. LG has also implemented protection circuits that prevent magnetron damage during extreme mismatch conditions.

Strengths: Exceptional stability across diverse load types; precise power control with minimal variation; energy efficiency improvements of up to 28% compared to conventional systems; significantly extended component lifespan through stress reduction. Weaknesses: Higher manufacturing complexity requiring specialized production equipment; increased cost compared to conventional magnetrons; requires more complex control circuitry that may increase failure points.

Key Technical Innovations in Adaptive Magnetron Control Systems

Device for detecting the abnormal operation of a load such as a magnetron

PatentInactiveEP0593660A1

Innovation

- A device is mounted on the power source to measure, store, and analyze voltage peak values across the secondary winding of a high-voltage transformer, detecting overshoot signals and calculating the frequency of voltage fluctuations to prevent frequent malfunctions, thereby controlling the operation of the magnetron and reducing overheating.

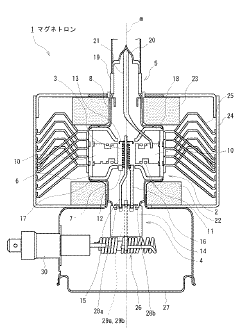

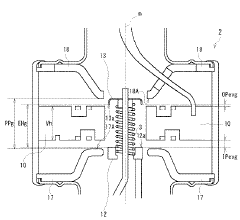

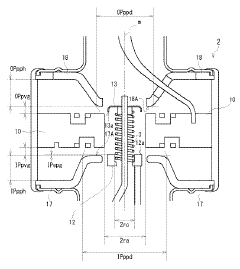

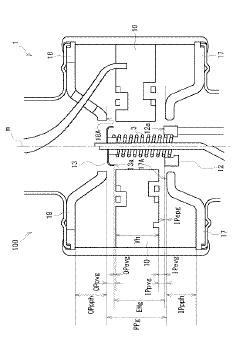

magnetron

PatentActiveJP2016110761A

Innovation

- The magnetron design includes specific ratios and spacings between components such as the vane height, end hat-vane distances, and pole piece-vane intervals, ensuring 1.12≦EHg/Vh≦1.26, IPpvg>OPpvg, and IPevg>OPpvg, which maintain high efficiency and improve load stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!