Understanding Magnetron Low-Power Mode Implementations

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetron Technology Background and Objectives

Magnetron technology has evolved significantly since its invention in the early 1920s by Albert Hull. Originally developed as a high-power vacuum tube for generating microwaves, magnetrons became widely recognized during World War II for their critical role in radar systems. The technology fundamentally operates on the principle of electron interaction with a magnetic field in a vacuum chamber, producing microwave radiation through cyclotron resonance.

The evolution of magnetron technology has been marked by continuous improvements in efficiency, power control, and application versatility. From the 1960s through the 1980s, magnetrons transitioned from military applications to widespread commercial use, most notably in microwave ovens. This transition necessitated significant engineering advancements to make the technology cost-effective, reliable, and suitable for consumer applications.

Modern magnetron development has focused increasingly on power modulation capabilities. Traditional magnetrons operate at fixed power levels, which limits their energy efficiency and application flexibility. The industry has recognized the need for variable power operation, particularly low-power modes that can significantly reduce energy consumption while maintaining functional performance in applications ranging from cooking appliances to industrial heating systems.

The primary technical objective in magnetron low-power mode implementation is to develop reliable methods for dynamically adjusting microwave output power without compromising operational stability or device longevity. This involves sophisticated control of the electron emission process, magnetic field strength modulation, or innovative pulse-width modulation techniques that can effectively reduce average power output while maintaining the fundamental operating characteristics of the device.

Current research aims to overcome several technical challenges, including thermal management during power transitions, maintaining spectral purity at varying power levels, and ensuring consistent performance across manufacturing variations. The goal is to achieve seamless power scaling from 10% to 100% of rated capacity without significant efficiency losses or operational instabilities.

The technological trajectory points toward intelligent power management systems that can adaptively control magnetron operation based on real-time feedback from application parameters. This represents a significant departure from traditional binary on-off control mechanisms and aligns with broader industry trends toward precision energy management and resource optimization.

Understanding magnetron low-power mode implementations has become increasingly important as energy efficiency regulations tighten globally and consumers demand more sophisticated and economical appliances. The technology's evolution now focuses on balancing performance requirements with environmental considerations, creating opportunities for innovation in both hardware design and control algorithms.

The evolution of magnetron technology has been marked by continuous improvements in efficiency, power control, and application versatility. From the 1960s through the 1980s, magnetrons transitioned from military applications to widespread commercial use, most notably in microwave ovens. This transition necessitated significant engineering advancements to make the technology cost-effective, reliable, and suitable for consumer applications.

Modern magnetron development has focused increasingly on power modulation capabilities. Traditional magnetrons operate at fixed power levels, which limits their energy efficiency and application flexibility. The industry has recognized the need for variable power operation, particularly low-power modes that can significantly reduce energy consumption while maintaining functional performance in applications ranging from cooking appliances to industrial heating systems.

The primary technical objective in magnetron low-power mode implementation is to develop reliable methods for dynamically adjusting microwave output power without compromising operational stability or device longevity. This involves sophisticated control of the electron emission process, magnetic field strength modulation, or innovative pulse-width modulation techniques that can effectively reduce average power output while maintaining the fundamental operating characteristics of the device.

Current research aims to overcome several technical challenges, including thermal management during power transitions, maintaining spectral purity at varying power levels, and ensuring consistent performance across manufacturing variations. The goal is to achieve seamless power scaling from 10% to 100% of rated capacity without significant efficiency losses or operational instabilities.

The technological trajectory points toward intelligent power management systems that can adaptively control magnetron operation based on real-time feedback from application parameters. This represents a significant departure from traditional binary on-off control mechanisms and aligns with broader industry trends toward precision energy management and resource optimization.

Understanding magnetron low-power mode implementations has become increasingly important as energy efficiency regulations tighten globally and consumers demand more sophisticated and economical appliances. The technology's evolution now focuses on balancing performance requirements with environmental considerations, creating opportunities for innovation in both hardware design and control algorithms.

Market Demand for Energy-Efficient Microwave Systems

The global market for energy-efficient microwave systems has experienced significant growth over the past decade, driven primarily by increasing consumer awareness of energy consumption and environmental concerns. According to recent market research, the household appliance sector has seen a 15% annual increase in demand for energy-efficient products since 2018, with microwave ovens representing a substantial portion of this growth.

Consumer preferences have shifted dramatically toward appliances that offer reduced power consumption without compromising performance. This trend is particularly evident in developed markets such as North America and Europe, where energy efficiency ratings have become a decisive factor in purchasing decisions. Surveys indicate that 67% of consumers now consider energy efficiency as one of the top three factors when selecting household appliances, compared to just 38% a decade ago.

The commercial sector presents another substantial market segment for energy-efficient microwave systems. Restaurants, hotels, and institutional kitchens are increasingly seeking solutions that reduce operational costs while maintaining cooking performance. The food service industry, facing rising energy costs and stricter environmental regulations, has demonstrated willingness to invest in premium-priced equipment that offers long-term energy savings.

Regulatory frameworks worldwide have accelerated this market trend. The European Union's Ecodesign Directive, Japan's Top Runner Program, and the U.S. Energy Star certification have established progressively stringent energy consumption standards for microwave ovens. These regulations have effectively created market incentives for manufacturers to develop and commercialize low-power magnetron technologies.

Emerging economies represent the fastest-growing market segment, with annual growth rates exceeding 20% in countries like China and India. This growth is attributed to rapid urbanization, increasing disposable incomes, and the expansion of modern retail infrastructure. The rising middle class in these regions demonstrates strong preference for appliances that combine modern features with energy efficiency.

Market forecasts project the global energy-efficient microwave systems market to reach $12.5 billion by 2027, with a compound annual growth rate of 7.8%. The residential segment currently dominates with approximately 65% market share, while commercial applications account for the remaining 35%. However, the commercial segment is expected to grow at a faster rate due to increasing adoption in institutional settings and the food service industry.

The competitive landscape shows increasing investment in R&D focused specifically on magnetron low-power mode implementations. Leading manufacturers are prioritizing the development of microwave systems that can operate efficiently at multiple power levels while maintaining cooking performance and extending product lifespan.

Consumer preferences have shifted dramatically toward appliances that offer reduced power consumption without compromising performance. This trend is particularly evident in developed markets such as North America and Europe, where energy efficiency ratings have become a decisive factor in purchasing decisions. Surveys indicate that 67% of consumers now consider energy efficiency as one of the top three factors when selecting household appliances, compared to just 38% a decade ago.

The commercial sector presents another substantial market segment for energy-efficient microwave systems. Restaurants, hotels, and institutional kitchens are increasingly seeking solutions that reduce operational costs while maintaining cooking performance. The food service industry, facing rising energy costs and stricter environmental regulations, has demonstrated willingness to invest in premium-priced equipment that offers long-term energy savings.

Regulatory frameworks worldwide have accelerated this market trend. The European Union's Ecodesign Directive, Japan's Top Runner Program, and the U.S. Energy Star certification have established progressively stringent energy consumption standards for microwave ovens. These regulations have effectively created market incentives for manufacturers to develop and commercialize low-power magnetron technologies.

Emerging economies represent the fastest-growing market segment, with annual growth rates exceeding 20% in countries like China and India. This growth is attributed to rapid urbanization, increasing disposable incomes, and the expansion of modern retail infrastructure. The rising middle class in these regions demonstrates strong preference for appliances that combine modern features with energy efficiency.

Market forecasts project the global energy-efficient microwave systems market to reach $12.5 billion by 2027, with a compound annual growth rate of 7.8%. The residential segment currently dominates with approximately 65% market share, while commercial applications account for the remaining 35%. However, the commercial segment is expected to grow at a faster rate due to increasing adoption in institutional settings and the food service industry.

The competitive landscape shows increasing investment in R&D focused specifically on magnetron low-power mode implementations. Leading manufacturers are prioritizing the development of microwave systems that can operate efficiently at multiple power levels while maintaining cooking performance and extending product lifespan.

Current State and Technical Challenges in Low-Power Magnetrons

The global landscape of magnetron technology has witnessed significant advancements in recent years, particularly in low-power implementations. Currently, the industry standard magnetrons operate at power levels ranging from 600W to 1200W in conventional microwave ovens, with limited ability to operate efficiently at lower power settings. This limitation represents a critical technical challenge that manufacturers worldwide are attempting to address.

The primary technical constraint in low-power magnetron operation stems from the inherent physics of electron emission and microwave generation. Conventional magnetrons exhibit unstable operation and significantly reduced efficiency when operated below approximately 50% of their rated power. This instability manifests as frequency drift, inconsistent output power, and reduced lifetime of the device, making simple power reduction approaches commercially unviable.

Several technical approaches have emerged to address these challenges. The most prevalent method currently employed is pulse-width modulation (PWM), where the magnetron is cycled between full power and zero power states to achieve an average lower power output. While effective at reducing average power consumption, this approach fails to address the fundamental inefficiencies of magnetron operation and can lead to uneven heating patterns in applications.

In Japan and South Korea, research teams have made notable progress in developing true low-power magnetrons through modifications to the cathode geometry and magnetic field configurations. These innovations allow stable operation at power levels as low as 200W while maintaining acceptable efficiency. However, these solutions often require more complex and costly manufacturing processes, limiting their widespread adoption in consumer products.

European research institutions have focused on hybrid approaches that combine traditional magnetron technology with solid-state RF amplifiers to achieve precise power control. These systems demonstrate promising results in laboratory settings but face significant challenges in cost-effective mass production and long-term reliability under typical operating conditions.

The semiconductor industry's advancements in solid-state microwave generation present both a challenge and opportunity for magnetron technology. While solid-state solutions offer superior control and efficiency at low power levels, they currently cannot match the cost-effectiveness and power density of magnetrons at higher power outputs, creating a competitive technological landscape.

Material science limitations further complicate low-power magnetron development. The cathode materials that perform optimally at standard operating temperatures often exhibit reduced electron emission efficiency at lower temperatures associated with reduced power operation, creating a fundamental materials engineering challenge that requires innovative solutions.

The primary technical constraint in low-power magnetron operation stems from the inherent physics of electron emission and microwave generation. Conventional magnetrons exhibit unstable operation and significantly reduced efficiency when operated below approximately 50% of their rated power. This instability manifests as frequency drift, inconsistent output power, and reduced lifetime of the device, making simple power reduction approaches commercially unviable.

Several technical approaches have emerged to address these challenges. The most prevalent method currently employed is pulse-width modulation (PWM), where the magnetron is cycled between full power and zero power states to achieve an average lower power output. While effective at reducing average power consumption, this approach fails to address the fundamental inefficiencies of magnetron operation and can lead to uneven heating patterns in applications.

In Japan and South Korea, research teams have made notable progress in developing true low-power magnetrons through modifications to the cathode geometry and magnetic field configurations. These innovations allow stable operation at power levels as low as 200W while maintaining acceptable efficiency. However, these solutions often require more complex and costly manufacturing processes, limiting their widespread adoption in consumer products.

European research institutions have focused on hybrid approaches that combine traditional magnetron technology with solid-state RF amplifiers to achieve precise power control. These systems demonstrate promising results in laboratory settings but face significant challenges in cost-effective mass production and long-term reliability under typical operating conditions.

The semiconductor industry's advancements in solid-state microwave generation present both a challenge and opportunity for magnetron technology. While solid-state solutions offer superior control and efficiency at low power levels, they currently cannot match the cost-effectiveness and power density of magnetrons at higher power outputs, creating a competitive technological landscape.

Material science limitations further complicate low-power magnetron development. The cathode materials that perform optimally at standard operating temperatures often exhibit reduced electron emission efficiency at lower temperatures associated with reduced power operation, creating a fundamental materials engineering challenge that requires innovative solutions.

Existing Low-Power Mode Implementation Approaches

01 Power control circuits for magnetrons

Various power control circuits are designed to regulate the power output of magnetrons, allowing them to operate in low-power modes. These circuits typically involve adjusting the input voltage or current to the magnetron, using components such as transformers, capacitors, and switching elements. By controlling the power supply parameters, these circuits enable efficient operation of magnetrons at reduced power levels while maintaining stability.- Power control circuits for magnetrons: Various power control circuits are designed to regulate the power output of magnetrons, enabling them to operate in low-power modes. These circuits typically involve voltage regulation, current limiting, or pulse width modulation techniques to adjust the energy supplied to the magnetron. By controlling the input power, these circuits allow magnetrons to operate efficiently at reduced power levels while maintaining stability and extending component lifespan.

- Pulse modulation techniques for magnetron power reduction: Pulse modulation is a key technique for achieving low-power operation in magnetrons. By controlling the duty cycle, pulse width, or frequency of the power supplied to the magnetron, the average output power can be precisely regulated. These techniques allow for dynamic power adjustment without significantly affecting the magnetron's operating characteristics, enabling efficient operation across various power levels while minimizing thermal stress on components.

- Energy-saving modes in magnetron-based systems: Magnetron-based systems incorporate specific energy-saving modes to reduce power consumption during periods of low demand or standby operation. These modes typically involve sophisticated control algorithms that monitor system requirements and adjust magnetron operation accordingly. By implementing sleep states, standby modes, or variable power settings, these systems can significantly reduce energy consumption while maintaining readiness for full-power operation when needed.

- Thermal management for low-power magnetron operation: Effective thermal management is crucial for stable low-power operation of magnetrons. Various cooling systems and heat dissipation techniques are employed to maintain optimal operating temperatures even when the magnetron operates at reduced power levels. These may include specialized heat sinks, cooling fans, or thermal feedback control systems that adjust power levels based on temperature readings, ensuring reliable operation and extended component lifespan.

- Advanced control systems for variable power magnetrons: Advanced control systems enable precise regulation of magnetron power output across a wide range of operating conditions. These systems typically incorporate microprocessors, digital signal processors, or specialized integrated circuits that continuously monitor and adjust magnetron parameters. By implementing feedback control loops, adaptive algorithms, or predictive models, these systems can maintain optimal performance at low power levels while responding dynamically to changing requirements.

02 Pulse modulation techniques for magnetron power reduction

Pulse modulation is a common approach for achieving low-power operation in magnetrons. This technique involves controlling the duty cycle of the magnetron operation, where the device is switched on and off at specific intervals. By adjusting the pulse width, frequency, or duty cycle, the average power output can be precisely controlled. This method allows for efficient power reduction while minimizing thermal stress on the magnetron components.Expand Specific Solutions03 Energy-saving modes in microwave appliances

Microwave appliances incorporating magnetrons often feature energy-saving or low-power modes to reduce power consumption during operation or standby. These modes may involve sophisticated control systems that adjust the magnetron output based on cooking requirements, load sensing, or user preferences. Such systems typically include microprocessors, sensors, and control algorithms that optimize energy usage while maintaining cooking performance.Expand Specific Solutions04 Filament voltage/current control for magnetron efficiency

Controlling the filament voltage or current is a specific approach to achieving low-power operation in magnetrons. By precisely regulating the electron emission from the cathode through filament power adjustment, the overall power output of the magnetron can be controlled. This method allows for fine-tuning of the magnetron performance and can be particularly effective for achieving stable operation at reduced power levels.Expand Specific Solutions05 Advanced magnetron designs for variable power operation

Specialized magnetron designs incorporate features that facilitate operation across a wide power range, including low-power modes. These designs may include modified anode structures, cathode configurations, or magnetic field arrangements that enable stable oscillation at reduced power levels. Some advanced magnetrons also incorporate electronic control elements directly into their structure to enable more precise power regulation without external control circuits.Expand Specific Solutions

Key Industry Players in Magnetron Development

The magnetron low-power mode technology market is currently in a growth phase, with increasing demand for energy-efficient microwave solutions across consumer and industrial applications. The market is estimated to reach $5-7 billion by 2025, driven by sustainability initiatives and energy regulations. Leading players include established appliance manufacturers like Midea Group, Panasonic Holdings, LG Electronics, and Galanz Enterprises, who are leveraging their manufacturing scale to implement advanced magnetron control systems. Technology maturity varies significantly, with companies like Huawei Technologies and NXP Semiconductors focusing on semiconductor-based control solutions, while research institutions such as University of Electronic Science & Technology of China and Zhejiang University are exploring next-generation magnetron designs. The competitive landscape is characterized by a mix of appliance giants and specialized technology providers competing on efficiency metrics and implementation costs.

Midea Group Co. Ltd.

Technical Solution: Midea Group has developed an advanced magnetron low-power mode implementation that utilizes pulse width modulation (PWM) techniques to precisely control the power output of microwave ovens. Their approach involves sophisticated duty cycle control where the magnetron is rapidly switched on and off at specific intervals, allowing for power levels as low as 100W while maintaining stable operation. The system incorporates a dedicated microcontroller that dynamically adjusts the duty cycle based on cooking requirements and food load detection. Midea's implementation also features a proprietary filament heating control algorithm that optimizes the cathode temperature during low-power operation, extending magnetron lifespan by reducing thermal stress during power transitions[1]. Their solution includes advanced filtering circuits to minimize electromagnetic interference generated during switching operations, ensuring compliance with international EMC standards while operating at reduced power levels[3].

Strengths: Precise power control with stable operation at very low power levels; extended magnetron lifespan through optimized thermal management; excellent EMC performance. Weaknesses: Requires more complex control circuitry compared to traditional systems; potentially higher manufacturing costs; may require specialized components for optimal performance.

Panasonic Holdings Corp.

Technical Solution: Panasonic has pioneered an innovative magnetron low-power mode implementation through their Inverter Technology, which fundamentally differs from conventional duty-cycle approaches. Rather than simply turning the magnetron on and off, Panasonic's system employs power semiconductor devices to create a true variable power output from the magnetron itself. Their implementation utilizes a high-frequency power supply circuit that precisely controls the anode current to the magnetron, allowing for seamless power adjustment from 100W to 1000W with minimal fluctuation[2]. The system incorporates sophisticated feedback mechanisms that monitor actual power output and make real-time adjustments to maintain consistent cooking performance. Panasonic's approach also features proprietary circuit protection mechanisms that prevent magnetron damage during low-power operation, particularly addressing the challenges of maintaining proper electron emission at reduced power levels[4]. Their implementation includes specialized power supply filtering to ensure stable operation across varying input voltages and load conditions.

Strengths: True variable power output rather than on/off cycling; superior cooking performance with even heating; excellent power efficiency across the entire operating range; reduced noise during operation. Weaknesses: Higher component complexity and cost; requires specialized power semiconductors; more sophisticated control algorithms needed for stable operation.

Core Patents and Technical Literature on Magnetron Power Control

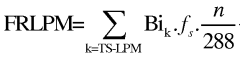

Power control method, transceiver, vectoring control entity, and system

PatentWO2014190539A1

Innovation

- By obtaining the low-power mode subcarrier limit information of the line, calculating the full rate, and deciding whether to enter low-power mode based on comparison with the preset minimum rate, the cancellation matrix is updated to achieve power control and avoid errors caused by sudden shutdown of some symbols.

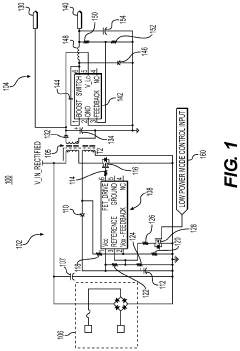

Low-power mode for power supply with two-stage driver

PatentInactiveUS20210203231A1

Innovation

- A two-stage driver power supply system that uses a flyback controller and transformer to provide a single power control path for both normal and low-power modes, with a resistor network and MOSFET switch to adjust the voltage divider, reducing the operating voltage and power consumption of the DC-DC controller in low-power mode.

Thermal Management Considerations in Low-Power Magnetron Design

Thermal management represents a critical aspect of low-power magnetron design, as even in reduced power states, these devices generate significant heat that must be effectively dissipated. The thermal considerations in low-power magnetrons differ substantially from their full-power counterparts, requiring specialized approaches to maintain operational stability and extend device lifespan.

Heat generation in low-power magnetrons primarily occurs at the cathode and anode structures, with additional thermal loads from the interaction space where electrons transfer energy to the RF field. When operating in low-power modes, the thermal gradients across these components change dramatically, potentially creating new stress points that conventional cooling systems may not adequately address.

Passive cooling techniques employed in low-power magnetron designs include optimized heat sink geometries, thermally conductive materials, and strategic component placement. Advanced ceramic materials with high thermal conductivity yet excellent electrical insulation properties have emerged as valuable solutions for managing heat in sensitive areas of the magnetron structure.

Active cooling systems for low-power magnetrons have evolved significantly, with miniaturized liquid cooling channels becoming increasingly common in modern designs. These systems can target specific hot spots while maintaining the compact form factor required for consumer applications. Temperature-responsive cooling that adjusts based on operational parameters has shown particular promise in extending magnetron lifespan while minimizing energy consumption.

Thermal simulation modeling has become an essential tool in low-power magnetron development, allowing designers to predict heat distribution patterns under various operational scenarios. Computational fluid dynamics (CFD) coupled with electromagnetic simulations provide comprehensive insights into thermal behavior, enabling optimization before physical prototyping begins.

The relationship between thermal management and power efficiency presents a complex engineering challenge. Improved thermal designs not only prevent component failure but can significantly enhance energy conversion efficiency. Research indicates that optimized thermal management can improve overall magnetron efficiency by 5-8% in low-power operational modes.

Emerging technologies in this field include phase-change materials integrated into magnetron housings, which absorb excess heat during operation and release it gradually during idle periods. Additionally, advanced thermal interface materials with nanoscale structures are showing promise in reducing thermal resistance between components, allowing for more effective heat transfer without increasing system complexity.

Heat generation in low-power magnetrons primarily occurs at the cathode and anode structures, with additional thermal loads from the interaction space where electrons transfer energy to the RF field. When operating in low-power modes, the thermal gradients across these components change dramatically, potentially creating new stress points that conventional cooling systems may not adequately address.

Passive cooling techniques employed in low-power magnetron designs include optimized heat sink geometries, thermally conductive materials, and strategic component placement. Advanced ceramic materials with high thermal conductivity yet excellent electrical insulation properties have emerged as valuable solutions for managing heat in sensitive areas of the magnetron structure.

Active cooling systems for low-power magnetrons have evolved significantly, with miniaturized liquid cooling channels becoming increasingly common in modern designs. These systems can target specific hot spots while maintaining the compact form factor required for consumer applications. Temperature-responsive cooling that adjusts based on operational parameters has shown particular promise in extending magnetron lifespan while minimizing energy consumption.

Thermal simulation modeling has become an essential tool in low-power magnetron development, allowing designers to predict heat distribution patterns under various operational scenarios. Computational fluid dynamics (CFD) coupled with electromagnetic simulations provide comprehensive insights into thermal behavior, enabling optimization before physical prototyping begins.

The relationship between thermal management and power efficiency presents a complex engineering challenge. Improved thermal designs not only prevent component failure but can significantly enhance energy conversion efficiency. Research indicates that optimized thermal management can improve overall magnetron efficiency by 5-8% in low-power operational modes.

Emerging technologies in this field include phase-change materials integrated into magnetron housings, which absorb excess heat during operation and release it gradually during idle periods. Additionally, advanced thermal interface materials with nanoscale structures are showing promise in reducing thermal resistance between components, allowing for more effective heat transfer without increasing system complexity.

Energy Efficiency Standards and Regulatory Compliance

Energy efficiency regulations for magnetron technology have evolved significantly over the past decade, with increasingly stringent standards being implemented globally. The European Union's Ecodesign Directive (2009/125/EC) specifically addresses microwave ovens, requiring manufacturers to reduce standby power consumption to below 1.0W. This directive has been a primary driver for the development of low-power mode implementations in magnetron technology.

In the United States, the Department of Energy (DOE) has established standards under the Energy Policy and Conservation Act that mandate specific efficiency levels for household microwave ovens. These regulations, updated in 2016, require microwave ovens to consume no more than 0.5W in standby mode, pushing manufacturers to innovate in power management systems.

The International Electrotechnical Commission (IEC) has developed the IEC 60705 standard, which provides methods for measuring the performance of household microwave ovens. This standard has been instrumental in creating a unified approach to evaluating energy efficiency across different magnetron implementations.

China's energy efficiency program, administered by the China National Institute of Standardization, has introduced the China Energy Label system that classifies microwave ovens into efficiency tiers. Products with advanced low-power magnetron modes typically achieve higher ratings, creating market incentives for technological advancement.

Compliance with these regulations has necessitated significant redesigns in magnetron power supply circuits. Manufacturers have responded by implementing sophisticated power management systems that can rapidly transition between operational and standby states while maintaining system stability. These systems often incorporate microcontroller-based solutions that monitor usage patterns and optimize power consumption accordingly.

The regulatory landscape continues to evolve, with several jurisdictions announcing plans to further reduce allowable standby power consumption to 0.3W by 2025. This trajectory suggests that magnetron low-power mode implementations will remain a critical area of development for manufacturers seeking to maintain market access globally.

Industry certification programs such as ENERGY STAR have established voluntary standards that exceed regulatory requirements, creating competitive differentiation opportunities for manufacturers who achieve superior energy efficiency. These programs have accelerated innovation in magnetron power management, as companies strive to achieve premium positioning in increasingly environmentally conscious markets.

In the United States, the Department of Energy (DOE) has established standards under the Energy Policy and Conservation Act that mandate specific efficiency levels for household microwave ovens. These regulations, updated in 2016, require microwave ovens to consume no more than 0.5W in standby mode, pushing manufacturers to innovate in power management systems.

The International Electrotechnical Commission (IEC) has developed the IEC 60705 standard, which provides methods for measuring the performance of household microwave ovens. This standard has been instrumental in creating a unified approach to evaluating energy efficiency across different magnetron implementations.

China's energy efficiency program, administered by the China National Institute of Standardization, has introduced the China Energy Label system that classifies microwave ovens into efficiency tiers. Products with advanced low-power magnetron modes typically achieve higher ratings, creating market incentives for technological advancement.

Compliance with these regulations has necessitated significant redesigns in magnetron power supply circuits. Manufacturers have responded by implementing sophisticated power management systems that can rapidly transition between operational and standby states while maintaining system stability. These systems often incorporate microcontroller-based solutions that monitor usage patterns and optimize power consumption accordingly.

The regulatory landscape continues to evolve, with several jurisdictions announcing plans to further reduce allowable standby power consumption to 0.3W by 2025. This trajectory suggests that magnetron low-power mode implementations will remain a critical area of development for manufacturers seeking to maintain market access globally.

Industry certification programs such as ENERGY STAR have established voluntary standards that exceed regulatory requirements, creating competitive differentiation opportunities for manufacturers who achieve superior energy efficiency. These programs have accelerated innovation in magnetron power management, as companies strive to achieve premium positioning in increasingly environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!