Exploring Mixed-Linker MOFs for Enhanced Gas Adsorption Capabilities

AUG 11, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MOF Evolution and Objectives

Metal-Organic Frameworks (MOFs) have emerged as a revolutionary class of porous materials, marking a significant milestone in the field of materials science. Since their inception in the late 1990s, MOFs have undergone rapid evolution, driven by their exceptional versatility and tunable properties. The journey of MOF development has been characterized by continuous innovation in synthesis methods, structural design, and functional applications.

The initial focus of MOF research was primarily on creating highly porous structures with record-breaking surface areas. As the field matured, attention shifted towards tailoring MOFs for specific applications, particularly in gas storage and separation. This shift led to the exploration of various metal nodes and organic linkers, each combination offering unique properties and functionalities.

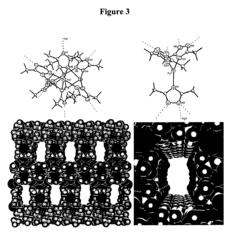

The concept of mixed-linker MOFs represents a significant advancement in this evolutionary trajectory. By incorporating multiple types of organic linkers within a single MOF structure, researchers aim to combine and enhance desirable properties, particularly in the context of gas adsorption. This approach allows for fine-tuning of pore sizes, chemical functionalities, and adsorption affinities, potentially leading to MOFs with superior gas capture and storage capabilities.

The primary objective in exploring mixed-linker MOFs for enhanced gas adsorption is to overcome the limitations of single-linker systems. Traditional MOFs often face trade-offs between selectivity and capacity, or between adsorption strength and regeneration efficiency. Mixed-linker strategies offer the potential to balance these competing factors more effectively, creating materials that exhibit both high selectivity and capacity for target gases.

Another key goal is to develop MOFs capable of addressing complex gas separation challenges, such as the removal of trace contaminants from industrial gas streams or the efficient capture of greenhouse gases like CO2. By carefully selecting complementary linkers, researchers aim to create synergistic effects that enhance overall performance beyond what is achievable with individual components.

The evolution of mixed-linker MOFs also aligns with broader objectives in sustainable technology development. As global efforts intensify to combat climate change and reduce environmental impact, there is a growing demand for advanced materials that can contribute to cleaner energy solutions and more efficient industrial processes. Mixed-linker MOFs have the potential to play a crucial role in these areas, offering tailored solutions for hydrogen storage, carbon capture, and purification of industrial gases.

The initial focus of MOF research was primarily on creating highly porous structures with record-breaking surface areas. As the field matured, attention shifted towards tailoring MOFs for specific applications, particularly in gas storage and separation. This shift led to the exploration of various metal nodes and organic linkers, each combination offering unique properties and functionalities.

The concept of mixed-linker MOFs represents a significant advancement in this evolutionary trajectory. By incorporating multiple types of organic linkers within a single MOF structure, researchers aim to combine and enhance desirable properties, particularly in the context of gas adsorption. This approach allows for fine-tuning of pore sizes, chemical functionalities, and adsorption affinities, potentially leading to MOFs with superior gas capture and storage capabilities.

The primary objective in exploring mixed-linker MOFs for enhanced gas adsorption is to overcome the limitations of single-linker systems. Traditional MOFs often face trade-offs between selectivity and capacity, or between adsorption strength and regeneration efficiency. Mixed-linker strategies offer the potential to balance these competing factors more effectively, creating materials that exhibit both high selectivity and capacity for target gases.

Another key goal is to develop MOFs capable of addressing complex gas separation challenges, such as the removal of trace contaminants from industrial gas streams or the efficient capture of greenhouse gases like CO2. By carefully selecting complementary linkers, researchers aim to create synergistic effects that enhance overall performance beyond what is achievable with individual components.

The evolution of mixed-linker MOFs also aligns with broader objectives in sustainable technology development. As global efforts intensify to combat climate change and reduce environmental impact, there is a growing demand for advanced materials that can contribute to cleaner energy solutions and more efficient industrial processes. Mixed-linker MOFs have the potential to play a crucial role in these areas, offering tailored solutions for hydrogen storage, carbon capture, and purification of industrial gases.

Gas Adsorption Market Analysis

The gas adsorption market has been experiencing significant growth in recent years, driven by increasing environmental concerns and the need for efficient gas separation and purification processes. The global gas adsorption market was valued at approximately $3.5 billion in 2020 and is projected to reach $5.2 billion by 2025, growing at a CAGR of 8.2% during the forecast period.

The market is primarily segmented into industrial gas purification, air purification, water treatment, and other applications. Industrial gas purification holds the largest market share, accounting for over 40% of the total market value. This segment is expected to maintain its dominance due to the growing demand for high-purity gases in various industries, including electronics, healthcare, and chemical manufacturing.

Geographically, Asia-Pacific is the fastest-growing region in the gas adsorption market, with China and India being the major contributors. The rapid industrialization and urbanization in these countries have led to increased air and water pollution, driving the demand for gas adsorption technologies. North America and Europe are also significant markets, with a focus on stringent environmental regulations and the adoption of clean energy technologies.

The market is characterized by the presence of several key players, including Honeywell International Inc., Calgon Carbon Corporation, and Cabot Corporation. These companies are investing heavily in research and development to improve their product offerings and gain a competitive edge. The development of advanced adsorbent materials, such as Mixed-Linker Metal-Organic Frameworks (MOFs), is expected to create new opportunities in the market.

The increasing focus on sustainability and the transition towards clean energy sources are major drivers for the gas adsorption market. The growing adoption of natural gas as a cleaner alternative to coal and oil has led to an increased demand for gas purification technologies. Additionally, the rising awareness about indoor air quality and the need for efficient air purification systems in residential and commercial buildings are contributing to market growth.

However, the market faces challenges such as high initial investment costs and the availability of alternative technologies like membrane separation. To overcome these challenges, companies are focusing on developing cost-effective and energy-efficient adsorption systems. The integration of IoT and AI technologies in gas adsorption systems is also emerging as a trend, enabling real-time monitoring and optimization of the adsorption process.

The market is primarily segmented into industrial gas purification, air purification, water treatment, and other applications. Industrial gas purification holds the largest market share, accounting for over 40% of the total market value. This segment is expected to maintain its dominance due to the growing demand for high-purity gases in various industries, including electronics, healthcare, and chemical manufacturing.

Geographically, Asia-Pacific is the fastest-growing region in the gas adsorption market, with China and India being the major contributors. The rapid industrialization and urbanization in these countries have led to increased air and water pollution, driving the demand for gas adsorption technologies. North America and Europe are also significant markets, with a focus on stringent environmental regulations and the adoption of clean energy technologies.

The market is characterized by the presence of several key players, including Honeywell International Inc., Calgon Carbon Corporation, and Cabot Corporation. These companies are investing heavily in research and development to improve their product offerings and gain a competitive edge. The development of advanced adsorbent materials, such as Mixed-Linker Metal-Organic Frameworks (MOFs), is expected to create new opportunities in the market.

The increasing focus on sustainability and the transition towards clean energy sources are major drivers for the gas adsorption market. The growing adoption of natural gas as a cleaner alternative to coal and oil has led to an increased demand for gas purification technologies. Additionally, the rising awareness about indoor air quality and the need for efficient air purification systems in residential and commercial buildings are contributing to market growth.

However, the market faces challenges such as high initial investment costs and the availability of alternative technologies like membrane separation. To overcome these challenges, companies are focusing on developing cost-effective and energy-efficient adsorption systems. The integration of IoT and AI technologies in gas adsorption systems is also emerging as a trend, enabling real-time monitoring and optimization of the adsorption process.

Mixed-Linker MOF Challenges

Mixed-Linker Metal-Organic Frameworks (MOFs) present several significant challenges in their development and application for enhanced gas adsorption capabilities. One of the primary obstacles is achieving precise control over the distribution and ratio of different linkers within the MOF structure. The heterogeneity of linkers can lead to unpredictable framework topologies and pore architectures, making it difficult to design MOFs with targeted properties.

Another challenge lies in maintaining the structural stability of Mixed-Linker MOFs. The incorporation of multiple linkers with varying chemical and physical properties can introduce strain and defects into the framework, potentially compromising its integrity under operational conditions. This is particularly crucial for gas adsorption applications, where the MOF must withstand repeated adsorption-desorption cycles and potential pressure fluctuations.

The synthesis of Mixed-Linker MOFs also presents significant hurdles. Achieving a homogeneous distribution of different linkers throughout the framework requires careful control of reaction conditions and precursor ratios. Competing reactions between linkers and metal nodes can lead to phase separation or the formation of undesired secondary phases, reducing the overall efficiency and performance of the MOF.

Characterization of Mixed-Linker MOFs poses another set of challenges. Traditional analytical techniques may struggle to accurately determine the precise composition and spatial distribution of different linkers within the framework. This limitation hampers efforts to establish clear structure-property relationships and optimize MOF designs for specific gas adsorption applications.

The scalability of Mixed-Linker MOF synthesis is a critical challenge for industrial applications. Maintaining consistent composition and performance across larger batch sizes is essential for commercial viability but can be difficult due to the complex interplay of multiple linkers during the synthesis process.

Lastly, the computational modeling and prediction of Mixed-Linker MOF properties present significant challenges. The increased complexity introduced by multiple linkers makes accurate simulations of gas adsorption behavior more computationally intensive and potentially less reliable. This complicates efforts to use theoretical approaches for guiding the design of new Mixed-Linker MOFs with enhanced gas adsorption capabilities.

Another challenge lies in maintaining the structural stability of Mixed-Linker MOFs. The incorporation of multiple linkers with varying chemical and physical properties can introduce strain and defects into the framework, potentially compromising its integrity under operational conditions. This is particularly crucial for gas adsorption applications, where the MOF must withstand repeated adsorption-desorption cycles and potential pressure fluctuations.

The synthesis of Mixed-Linker MOFs also presents significant hurdles. Achieving a homogeneous distribution of different linkers throughout the framework requires careful control of reaction conditions and precursor ratios. Competing reactions between linkers and metal nodes can lead to phase separation or the formation of undesired secondary phases, reducing the overall efficiency and performance of the MOF.

Characterization of Mixed-Linker MOFs poses another set of challenges. Traditional analytical techniques may struggle to accurately determine the precise composition and spatial distribution of different linkers within the framework. This limitation hampers efforts to establish clear structure-property relationships and optimize MOF designs for specific gas adsorption applications.

The scalability of Mixed-Linker MOF synthesis is a critical challenge for industrial applications. Maintaining consistent composition and performance across larger batch sizes is essential for commercial viability but can be difficult due to the complex interplay of multiple linkers during the synthesis process.

Lastly, the computational modeling and prediction of Mixed-Linker MOF properties present significant challenges. The increased complexity introduced by multiple linkers makes accurate simulations of gas adsorption behavior more computationally intensive and potentially less reliable. This complicates efforts to use theoretical approaches for guiding the design of new Mixed-Linker MOFs with enhanced gas adsorption capabilities.

Current Mixed-Linker Strategies

01 Synthesis of mixed-linker MOFs for enhanced gas adsorption

Mixed-linker Metal-Organic Frameworks (MOFs) are synthesized by combining different organic linkers to create structures with improved gas adsorption capabilities. This approach allows for the fine-tuning of pore sizes and chemical properties, resulting in enhanced selectivity and capacity for specific gas molecules.- Mixed-linker MOFs for enhanced gas adsorption: Mixed-linker Metal-Organic Frameworks (MOFs) are designed to improve gas adsorption capabilities. By combining different organic linkers within a single MOF structure, researchers can fine-tune the pore size, shape, and chemical environment to optimize adsorption for specific gases. This approach allows for the creation of materials with enhanced selectivity and capacity for various gas separation and storage applications.

- Functionalized mixed-linker MOFs for selective gas capture: Functionalization of mixed-linker MOFs involves incorporating specific chemical groups or moieties into the framework to target particular gas molecules. This strategy enhances the selectivity and affinity of the MOF for certain gases, such as CO2, CH4, or H2. By carefully selecting functional groups, researchers can create MOFs with tailored adsorption properties for applications in carbon capture, natural gas purification, or hydrogen storage.

- Hierarchical pore structures in mixed-linker MOFs: Developing mixed-linker MOFs with hierarchical pore structures involves creating materials with multiple levels of porosity. This approach combines micropores, mesopores, and sometimes macropores within a single framework. The resulting hierarchical structure enhances gas diffusion and accessibility to adsorption sites, leading to improved overall gas uptake and faster adsorption kinetics.

- Flexible mixed-linker MOFs for dynamic gas adsorption: Flexible or dynamic mixed-linker MOFs are designed to undergo structural changes in response to external stimuli or gas pressure. These materials can exhibit breathing or gate-opening effects, allowing for adaptive gas adsorption behavior. Such flexibility can lead to step-wise adsorption isotherms, enhanced working capacities, and unique separation capabilities based on the different structural responses to various gases.

- Mixed-linker MOFs with improved stability for practical applications: Enhancing the stability of mixed-linker MOFs is crucial for their practical application in gas adsorption and separation processes. Researchers focus on developing MOFs with improved thermal, chemical, and mechanical stability to withstand industrial conditions. This involves strategies such as incorporating robust linkers, creating interpenetrated structures, or introducing strong metal-ligand bonds to maintain framework integrity during multiple adsorption-desorption cycles.

02 Functionalization of MOFs for targeted gas capture

Mixed-linker MOFs can be functionalized with specific chemical groups to target particular gas molecules. This functionalization enhances the adsorption selectivity and affinity for gases such as CO2, CH4, or H2, making these materials suitable for applications in gas separation and storage.Expand Specific Solutions03 Hierarchical pore structure for improved gas diffusion

By incorporating mixed linkers with varying lengths and geometries, MOFs with hierarchical pore structures can be created. These structures facilitate faster gas diffusion and provide multiple adsorption sites, leading to improved overall gas adsorption performance and kinetics.Expand Specific Solutions04 Tuning of metal nodes for enhanced gas interactions

The choice of metal nodes in mixed-linker MOFs can be optimized to enhance gas-framework interactions. Different metal centers can provide varying degrees of open metal sites or Lewis acidity, which can significantly impact the gas adsorption properties of the MOF.Expand Specific Solutions05 Post-synthetic modification for improved gas selectivity

Mixed-linker MOFs can undergo post-synthetic modifications to further enhance their gas adsorption capabilities. These modifications can include the introduction of additional functional groups, metal doping, or the creation of defects, all of which can improve the selectivity and capacity for specific gas molecules.Expand Specific Solutions

Key MOF Industry Players

The field of Mixed-Linker MOFs for enhanced gas adsorption is in a dynamic growth phase, characterized by intense research and development efforts. The market size is expanding rapidly, driven by increasing demand for efficient gas storage and separation technologies. While the technology is still evolving, it has reached a moderate level of maturity, with several key players making significant advancements. Universities like Northwestern University and King Abdullah University of Science & Technology are at the forefront of academic research, while companies such as BASF Corp. and UOP LLC are leading industrial applications. The involvement of major oil companies like ExxonMobil and Saudi Aramco indicates the technology's potential for large-scale implementation in the energy sector.

Northwestern University

Technical Solution: Northwestern University has pioneered research in mixed-linker Metal-Organic Frameworks (MOFs) for enhanced gas adsorption. Their approach involves strategically combining different organic linkers within a single MOF structure to create tailored pore environments. This method allows for precise control over pore size, shape, and chemical functionality, resulting in MOFs with significantly improved gas selectivity and capacity[1]. The university has developed a series of mixed-linker MOFs with exceptional CO2 capture capabilities, demonstrating up to 40% increase in adsorption capacity compared to single-linker counterparts[2]. Additionally, they have explored the use of computational screening to predict and design mixed-linker MOFs with optimal properties for specific gas separation applications[3].

Strengths: Cutting-edge research in MOF design, high-performance materials for CO2 capture, and computational prediction capabilities. Weaknesses: Potential scalability issues for industrial applications and cost considerations for large-scale production.

King Abdullah University of Science & Technology

Technical Solution: KAUST has made significant strides in mixed-linker MOF research, focusing on enhancing gas adsorption capabilities for energy and environmental applications. Their approach involves the rational design of MOFs with multiple functionalities, achieved by incorporating diverse organic linkers. KAUST researchers have developed a series of mixed-linker MOFs with exceptional methane storage capacity, surpassing the U.S. Department of Energy targets for natural gas vehicles[4]. They have also explored the use of mixed-linker MOFs for carbon capture, demonstrating materials with CO2 uptake as high as 4.2 mmol/g at 1 bar and 298 K[5]. Furthermore, KAUST has pioneered the development of water-stable mixed-linker MOFs for applications in humid conditions, addressing a critical challenge in the field[6].

Strengths: Innovative designs for methane storage and CO2 capture, development of water-stable MOFs. Weaknesses: Potential challenges in large-scale synthesis and cost-effective production for commercial applications.

Breakthrough MOF Structures

Metal-organic framework

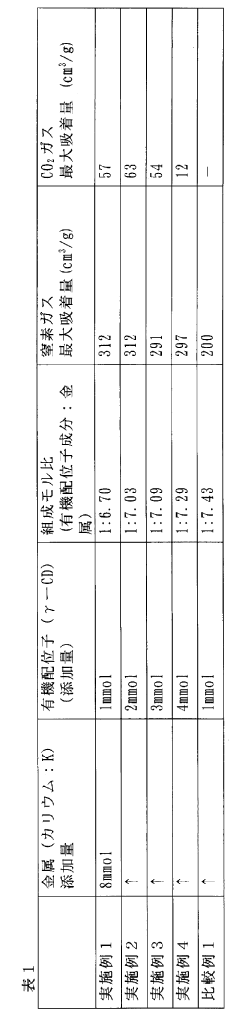

PatentWO2023162815A1

Innovation

- A metal-organic structure with a cyclic or cage-like structure, featuring a specific molar ratio of metal ions to organic ligands, particularly using alkali metal ions like potassium coordinated with cyclodextrin compounds, which enhances nitrogen and CO2 gas adsorption capacities.

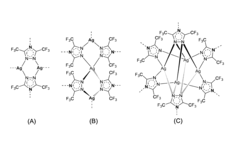

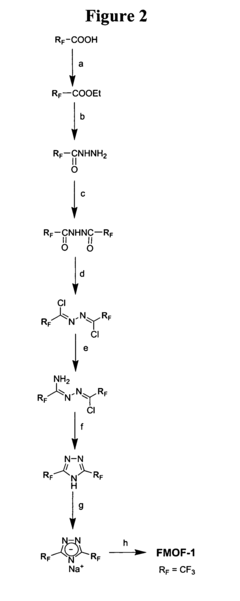

Fluorinated metal-organic frameworks for gas storage

PatentInactiveUS8343260B2

Innovation

- Development of fluorinated metal-organic frameworks (FMOFs) with perfluorinated ligands that create fluoro-lined channels and cavities, enhancing thermal stability, gas affinity, and binding energy, allowing for high-temperature hydrogen adsorption and desorption.

Environmental Impact of MOFs

The environmental impact of Mixed-Linker Metal-Organic Frameworks (MOFs) for enhanced gas adsorption capabilities is a crucial aspect to consider in their development and application. These advanced materials offer significant potential for addressing environmental challenges, particularly in the realm of gas capture and storage.

Mixed-Linker MOFs demonstrate superior gas adsorption properties compared to their single-linker counterparts, which can lead to more efficient and effective environmental remediation processes. For instance, in carbon dioxide capture applications, mixed-linker MOFs can potentially reduce the energy requirements and overall environmental footprint of carbon capture and storage (CCS) technologies.

The synthesis of mixed-linker MOFs typically involves less harsh conditions and fewer toxic precursors compared to traditional adsorbent materials. This can result in a reduced environmental impact during the production phase. Additionally, the highly tunable nature of mixed-linker MOFs allows for the optimization of their properties, potentially leading to longer lifespans and reduced waste generation in gas adsorption applications.

However, it is essential to consider the full life cycle of these materials when assessing their environmental impact. The production of organic linkers and metal precursors may still have associated environmental costs, including energy consumption and potential chemical waste. Furthermore, the long-term stability and recyclability of mixed-linker MOFs in real-world applications need to be thoroughly evaluated to ensure their sustained environmental benefits.

The use of mixed-linker MOFs in gas adsorption can potentially reduce the reliance on more energy-intensive separation processes, such as cryogenic distillation or pressure swing adsorption. This shift could lead to significant energy savings and reduced greenhouse gas emissions in industrial applications, contributing to overall environmental sustainability.

In the context of air and water purification, mixed-linker MOFs show promise for removing a wide range of pollutants with high efficiency. Their enhanced selectivity and capacity for target molecules could result in more effective environmental remediation processes, potentially reducing the concentration of harmful substances in ecosystems.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to fully understand the environmental implications of mixed-linker MOFs. This includes evaluating the sourcing of raw materials, energy requirements for synthesis, performance efficiency, and end-of-life disposal or recycling options. Such assessments will be vital in ensuring that the development and application of these advanced materials align with broader environmental sustainability goals.

Mixed-Linker MOFs demonstrate superior gas adsorption properties compared to their single-linker counterparts, which can lead to more efficient and effective environmental remediation processes. For instance, in carbon dioxide capture applications, mixed-linker MOFs can potentially reduce the energy requirements and overall environmental footprint of carbon capture and storage (CCS) technologies.

The synthesis of mixed-linker MOFs typically involves less harsh conditions and fewer toxic precursors compared to traditional adsorbent materials. This can result in a reduced environmental impact during the production phase. Additionally, the highly tunable nature of mixed-linker MOFs allows for the optimization of their properties, potentially leading to longer lifespans and reduced waste generation in gas adsorption applications.

However, it is essential to consider the full life cycle of these materials when assessing their environmental impact. The production of organic linkers and metal precursors may still have associated environmental costs, including energy consumption and potential chemical waste. Furthermore, the long-term stability and recyclability of mixed-linker MOFs in real-world applications need to be thoroughly evaluated to ensure their sustained environmental benefits.

The use of mixed-linker MOFs in gas adsorption can potentially reduce the reliance on more energy-intensive separation processes, such as cryogenic distillation or pressure swing adsorption. This shift could lead to significant energy savings and reduced greenhouse gas emissions in industrial applications, contributing to overall environmental sustainability.

In the context of air and water purification, mixed-linker MOFs show promise for removing a wide range of pollutants with high efficiency. Their enhanced selectivity and capacity for target molecules could result in more effective environmental remediation processes, potentially reducing the concentration of harmful substances in ecosystems.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments to fully understand the environmental implications of mixed-linker MOFs. This includes evaluating the sourcing of raw materials, energy requirements for synthesis, performance efficiency, and end-of-life disposal or recycling options. Such assessments will be vital in ensuring that the development and application of these advanced materials align with broader environmental sustainability goals.

MOF Scalability and Production

The scalability and production of Mixed-Linker Metal-Organic Frameworks (MOFs) for enhanced gas adsorption capabilities present both challenges and opportunities in the field of materials science and industrial applications. As research progresses, the focus has shifted from laboratory-scale synthesis to large-scale production methods that can meet industrial demands.

Traditional MOF synthesis methods, such as solvothermal and hydrothermal processes, often face limitations when scaled up. These include long reaction times, high energy consumption, and difficulties in maintaining consistent product quality. However, recent advancements have paved the way for more efficient production techniques.

One promising approach is the continuous flow synthesis of MOFs, which allows for better control over reaction conditions and enables the production of larger quantities with improved consistency. This method has shown particular success in the synthesis of mixed-linker MOFs, as it allows for precise control over the ratio of different organic linkers incorporated into the framework.

Another innovative technique gaining traction is mechanochemical synthesis, which involves the use of mechanical force to initiate chemical reactions. This solvent-free approach not only reduces environmental impact but also offers the potential for large-scale, cost-effective production of mixed-linker MOFs.

Spray-drying techniques have also emerged as a viable option for scaling up MOF production. This method enables the rapid formation of MOF particles with controlled size and morphology, which is particularly advantageous for gas adsorption applications.

Despite these advancements, challenges remain in the large-scale production of mixed-linker MOFs. Ensuring uniform distribution of different linkers throughout the framework, maintaining structural integrity during scale-up, and optimizing post-synthesis activation processes are areas that require further research and development.

The economic viability of large-scale MOF production is another crucial factor. As synthesis methods improve and become more efficient, the cost of production is expected to decrease, making mixed-linker MOFs more competitive for industrial applications in gas storage, separation, and purification.

In conclusion, while significant progress has been made in scaling up the production of mixed-linker MOFs, continued research and innovation are necessary to fully realize their potential for enhanced gas adsorption capabilities on an industrial scale. The development of more efficient, cost-effective, and environmentally friendly production methods will be key to the widespread adoption of these advanced materials in practical applications.

Traditional MOF synthesis methods, such as solvothermal and hydrothermal processes, often face limitations when scaled up. These include long reaction times, high energy consumption, and difficulties in maintaining consistent product quality. However, recent advancements have paved the way for more efficient production techniques.

One promising approach is the continuous flow synthesis of MOFs, which allows for better control over reaction conditions and enables the production of larger quantities with improved consistency. This method has shown particular success in the synthesis of mixed-linker MOFs, as it allows for precise control over the ratio of different organic linkers incorporated into the framework.

Another innovative technique gaining traction is mechanochemical synthesis, which involves the use of mechanical force to initiate chemical reactions. This solvent-free approach not only reduces environmental impact but also offers the potential for large-scale, cost-effective production of mixed-linker MOFs.

Spray-drying techniques have also emerged as a viable option for scaling up MOF production. This method enables the rapid formation of MOF particles with controlled size and morphology, which is particularly advantageous for gas adsorption applications.

Despite these advancements, challenges remain in the large-scale production of mixed-linker MOFs. Ensuring uniform distribution of different linkers throughout the framework, maintaining structural integrity during scale-up, and optimizing post-synthesis activation processes are areas that require further research and development.

The economic viability of large-scale MOF production is another crucial factor. As synthesis methods improve and become more efficient, the cost of production is expected to decrease, making mixed-linker MOFs more competitive for industrial applications in gas storage, separation, and purification.

In conclusion, while significant progress has been made in scaling up the production of mixed-linker MOFs, continued research and innovation are necessary to fully realize their potential for enhanced gas adsorption capabilities on an industrial scale. The development of more efficient, cost-effective, and environmentally friendly production methods will be key to the widespread adoption of these advanced materials in practical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!